Bed Insulator, Nozzle Mount replaced with Metal Parts.

Posted by TMD_RS436

|

Bed Insulator, Nozzle Mount replaced with Metal Parts. January 23, 2014 02:02PM |

Registered: 10 years ago Posts: 119 |

Hello All

Well I have been having loads of issues with the "Bed Plane Compensation" where I am having to do it before every print due to any slight movement like even removing the last printed item or even cleaning the bed after the print changes the previous setting.

So I have opted for a 3mm aluminium sheet 500mm x 300mm (so it will need to be cut to size and use the bed-insulator as a template) along with a 19.05mm x 19.05mm square rod to be cut to replace the "nozzle-mount" will also need a few holes drilled then cut and filed to size.

Along with loads of 20mm M3 Socket head cap screws, washers, locking washers and hex nuts.

Hopefully with the above changes (if all goes well) I should have a level aligned bed and a nozzle mount that doesn't melt or soften resulting in sagging after long prints.

The above items etc should arrive over the next couple of days, so if all goes well I will post some pictures of the changed items.

Ian, I will try and return the faulty Duet board some time next week, I will also email you the Tracking code and don't worry about refunding the return costs, shouldn't be that much anyway.

Paul

RS Ormerod No 436

Well I have been having loads of issues with the "Bed Plane Compensation" where I am having to do it before every print due to any slight movement like even removing the last printed item or even cleaning the bed after the print changes the previous setting.

So I have opted for a 3mm aluminium sheet 500mm x 300mm (so it will need to be cut to size and use the bed-insulator as a template) along with a 19.05mm x 19.05mm square rod to be cut to replace the "nozzle-mount" will also need a few holes drilled then cut and filed to size.

Along with loads of 20mm M3 Socket head cap screws, washers, locking washers and hex nuts.

Hopefully with the above changes (if all goes well) I should have a level aligned bed and a nozzle mount that doesn't melt or soften resulting in sagging after long prints.

The above items etc should arrive over the next couple of days, so if all goes well I will post some pictures of the changed items.

Ian, I will try and return the faulty Duet board some time next week, I will also email you the Tracking code and don't worry about refunding the return costs, shouldn't be that much anyway.

Paul

RS Ormerod No 436

|

Re: Bed Insulator, Nozzle Mount replaced with Metal Parts. January 23, 2014 02:14PM |

Registered: 10 years ago Posts: 578 |

I replaced my nozzle mount with delrin (stays stiff up to 175 or so), dieterzar replaced his with ptfe (withstands very high temps but isn't so stiff to start with) - the problem with using metal there is that it will conduct the heat (that would have buckled your original mount) to the carriage (and let that buckle). In normal use, printing ABS (nozzle around 235, bed around 90 and room temp around 22), my heatsink mount (the aluminium that the nozzle mount screws onto) doesn't get past 40°C, dmould has reported similar temps. that mount may well get hotter (victors has for sure) at higher ambients, but not enough to let delrin deform, and probably not high enough to affect an ABS printed version I'd guess (it would have to be nearer 100°C). Remember to keep insulation between the heater and your aluminium plate, or you'll have trouble getting the bed hot enough (and the conducted heat may affect bearings if they're in thermal contact with it).

Ray

Ray

|

Re: Bed Insulator, Nozzle Mount replaced with Metal Parts. January 23, 2014 02:39PM |

Registered: 10 years ago Posts: 119 |

Hello Ray

Well I had seen that a few other people had changed their nozzle mount so I thought I would do the same, I was buying 19mm x 19mm square aluminium rod for something else and thought may as well use 40mm of that rod for this.

I will still be using the MDF insulator between the two metal parts and I am hoping that with an extra bit of heat compound on it will also transfer the heat if any also over to the heat sink.

As for the Heat Bed, yeah I will still be using the cardboard sheet plus there will be a few extra mm gap for the alignment of the bed.

Didn't think about the bearings.

Thanks

Paul

RS Ormerod No 436

Well I had seen that a few other people had changed their nozzle mount so I thought I would do the same, I was buying 19mm x 19mm square aluminium rod for something else and thought may as well use 40mm of that rod for this.

I will still be using the MDF insulator between the two metal parts and I am hoping that with an extra bit of heat compound on it will also transfer the heat if any also over to the heat sink.

As for the Heat Bed, yeah I will still be using the cardboard sheet plus there will be a few extra mm gap for the alignment of the bed.

Didn't think about the bearings.

Thanks

Paul

RS Ormerod No 436

|

Re: Bed Insulator, Nozzle Mount replaced with Metal Parts. January 23, 2014 03:52PM |

Registered: 10 years ago Posts: 132 |

|

Re: Bed Insulator, Nozzle Mount replaced with Metal Parts. January 23, 2014 04:22PM |

Registered: 10 years ago Posts: 859 |

Hi Guys, I'm reading this thread with interest. I'm curious about the Ally Nozzle Hanger as I think the heat from the Extruder will convect up and you might find it compounds the problem and melt the X axis bearing hanger. I fancy the idea of MDF myself, but still keep the seperate MDF insulator, as I think that it might cut down on heat transfer.

What I intend to do with the table:-

As for the table I like the idea of two more ribs, as close to the ends of the carriage longitudinal as poss, with one or two longitudinal stringers to stiffen it all up. Then to make it even better, move the existing bearing to one of the new ribs, and buy another bearing for the other new rib, so by making a raft on 4 bearings. Well that's the way I want to go.

I do wonder if you can print on to ally sheet, and think it would be ideal for the IR Probe.

(Ian if your reading this, I did message you about some parts I wanted to buy on Wednesday when I pass by to go home.

I think you might have lost the msg as I haven't heard anything).

Kim

What I intend to do with the table:-

As for the table I like the idea of two more ribs, as close to the ends of the carriage longitudinal as poss, with one or two longitudinal stringers to stiffen it all up. Then to make it even better, move the existing bearing to one of the new ribs, and buy another bearing for the other new rib, so by making a raft on 4 bearings. Well that's the way I want to go.

I do wonder if you can print on to ally sheet, and think it would be ideal for the IR Probe.

(Ian if your reading this, I did message you about some parts I wanted to buy on Wednesday when I pass by to go home.

I think you might have lost the msg as I haven't heard anything).

Kim

|

Re: Bed Insulator, Nozzle Mount replaced with Metal Parts. January 23, 2014 04:38PM |

Registered: 10 years ago Posts: 578 |

John, I get my plastics from this place [www.edplastics.co.uk] they have a trade counter/shop and cut to order (generally "no size too small") - they carry a huge range of plastics in various shapes and sizes at competitive prices, and I'm lucky enough to live and work within easy driving distance. I'm not sure what sort of service they offer via post, but you can sound them out.

I used an offcut of some 45mm plate I bought from them recently, I'm not sure that you can get delrin (acetal homopolymer) or acetal copolymer (aka POM ) in anything other than round rod, sheet and plate easily. I said Delrin, but actually I used acetal copolymer - not much difference between the two in this context though. of course if you have a mill, you can square up round rod pretty quickly (it's lovely stuff to machine, just don't do it too fast to keep the fumes down).

If you can't find anything at a reasonable price, I can send you a chunk big enough for the bracket if you like, pm me with your details,

Cheers

Ray

I used an offcut of some 45mm plate I bought from them recently, I'm not sure that you can get delrin (acetal homopolymer) or acetal copolymer (aka POM ) in anything other than round rod, sheet and plate easily. I said Delrin, but actually I used acetal copolymer - not much difference between the two in this context though. of course if you have a mill, you can square up round rod pretty quickly (it's lovely stuff to machine, just don't do it too fast to keep the fumes down).

If you can't find anything at a reasonable price, I can send you a chunk big enough for the bracket if you like, pm me with your details,

Cheers

Ray

|

Re: Bed Insulator, Nozzle Mount replaced with Metal Parts. January 23, 2014 04:55PM |

Registered: 10 years ago Posts: 578 |

@Kim - you'll need to watch that you don't "overconstrain" the motion - ideally the two back bearings prevent X and Z motion of the table, allowing Y, and the other bearings would be best "floating" in at least X. If all four bearings don't allow any motion in X or Z, then if they're not exactly parallel, they'll bind and cause the motor to skip steps and stall - it might be why the rib at present pretty much floats on the front bearing - doubling up the bearings and ribs on the front would be easier if you keep this "floating" aspect I think.

Cheers

Ray

Cheers

Ray

|

Re: Bed Insulator, Nozzle Mount replaced with Metal Parts. January 23, 2014 05:11PM |

Registered: 10 years ago Posts: 859 |

Yep I agree Ray... With that said I have fastened my front bearing to the rib with cable ties, as the table seemed to flap about abit.

On a ship here, and it does get allot of movement some times. LoL I was extruding yesterday when it was quite choppy out there.

I don't think I could have left it printing without the cable ties.

Kim..

On a ship here, and it does get allot of movement some times. LoL I was extruding yesterday when it was quite choppy out there.

I don't think I could have left it printing without the cable ties.

Kim..

|

Re: Bed Insulator, Nozzle Mount replaced with Metal Parts. January 23, 2014 05:24PM |

Registered: 10 years ago Posts: 14,672 |

I think it is better to leave a single bearing at the front and support the bed at just 3 points. The real problem is that the back bearings are some distance from the back corner bed support points, and the MDF isn't stiff and stable enough, so it tends to sag in the back corners. So you can manually level the bed, or use the automatic mechanism to compensate for it not being level, but either way the bed doesn't remain level. I kept the plywood ribs but replaced the MDF by a triangular bed support made from 3mm aluminium.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Bed Insulator, Nozzle Mount replaced with Metal Parts. January 23, 2014 05:30PM |

Registered: 10 years ago Posts: 119 |

RS sells the following:

Acetal Homopolymer Black Rod Diameter - 20mm 197-4277

Acetal Homopolymer White Rod Diameter - 20mm 770-305

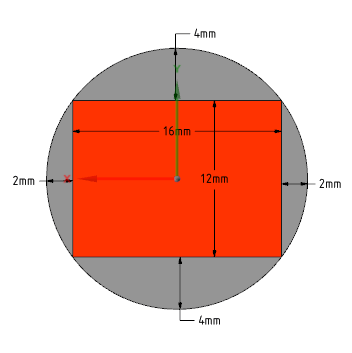

You can get rod of exactly 16mm x 12mm but you need to be exact when slicing the 4 sides off.

Paul

Edited 2 time(s). Last edit at 01/23/2014 05:50PM by TMD_RS436.

RS Ormerod No 436

Acetal Homopolymer Black Rod Diameter - 20mm 197-4277

Acetal Homopolymer White Rod Diameter - 20mm 770-305

You can get rod of exactly 16mm x 12mm but you need to be exact when slicing the 4 sides off.

Paul

Edited 2 time(s). Last edit at 01/23/2014 05:50PM by TMD_RS436.

RS Ormerod No 436

|

Re: Bed Insulator, Nozzle Mount replaced with Metal Parts. January 24, 2014 06:11AM |

Registered: 10 years ago Posts: 1,230 |

Quote

dc42

.....The real problem is that the back bearings are some distance from the back corner bed support points, and the MDF isn't stiff and stable enough, so it tends to sag in the back corners.....

It don't have to be that way, turn the bearings mounts 180 degrees and put the rip on the other side - and the activator for the micro switch, print it as a part of the bearing mount, it so logic that I wonder why it was not made that way in the first place

Edit: but then again, I also wonder why the made the bed of fluffy stuff like MDF

Erik

Edited 1 time(s). Last edit at 01/24/2014 06:13AM by ormerod168.

Sorry, only registered users may post in this forum.