support structures - need help

Posted by #442

|

support structures - need help January 26, 2014 04:55AM |

Registered: 10 years ago Posts: 14 |

Have a very simple object (see stl-file). I used Slic3r, KISSlicer and Cura for testing different support structures. They only provide patterns like honeycomp, rectilinear ...

Which slicing software can generate tree- or more advanced support structures?

Is there an ormerod engine for netfabb?

Which slicing software can generate tree- or more advanced support structures?

Is there an ormerod engine for netfabb?

|

Re: support structures - need help January 26, 2014 05:57AM |

Registered: 10 years ago Posts: 578 |

hi 442 - do you mean support starting with a trunk then branching out as it goes higher? If so I don't think so (skeinforge also seems to do prismatic support btw, though I haven't used it much and I may be missing something).

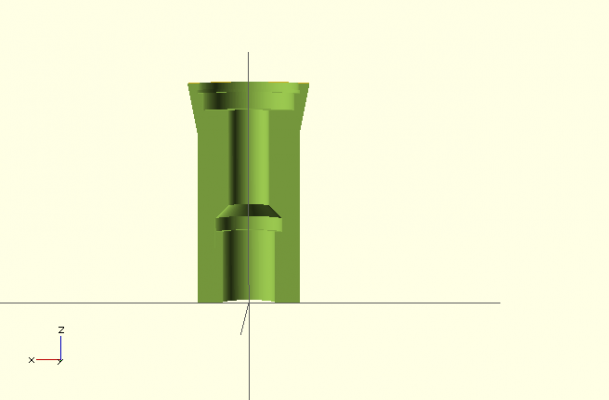

I try to avoid support if I can (since it slows things down and can leave a "witness" on the print, or can be very hard to remove from internal structures) - angling lower surfaces can help in bridging (and small short sufaces say 5mm across should bridge OK anyhow). I've attached a section of one of my models that is a tube with an internal bayonet fitting, originally I made both the top and bottom of the bayonet groove horizontal, but it got filled with support (as did the central bore) and was very difficult to fettle after printing - I made the top surface conical and now it prints with no support - maybe you could use a similar strategy on yours...

Ray

I try to avoid support if I can (since it slows things down and can leave a "witness" on the print, or can be very hard to remove from internal structures) - angling lower surfaces can help in bridging (and small short sufaces say 5mm across should bridge OK anyhow). I've attached a section of one of my models that is a tube with an internal bayonet fitting, originally I made both the top and bottom of the bayonet groove horizontal, but it got filled with support (as did the central bore) and was very difficult to fettle after printing - I made the top surface conical and now it prints with no support - maybe you could use a similar strategy on yours...

Ray

|

Re: support structures - need help January 26, 2014 06:54AM |

Registered: 10 years ago Posts: 14 |

|

Re: support structures - need help January 26, 2014 07:05AM |

Registered: 10 years ago Posts: 103 |

Quote

#442

Have a very simple object (see stl-file). I used Slic3r, KISSlicer and Cura for testing different support structures. They only provide patterns like honeycomp, rectilinear ...

Which slicing software can generate tree- or more advanced support structures?

Is there an ormerod engine for netfabb?

Hi #442, I have printed parts with support, very large support in fact (support alone added 7hrs to print - I have kept it and will post a pic later). I am disappointed with how slic3r generates the support, but then it is a free SW... For example after doing a test I found that i could print up to 56deg without support so I setup slic3r with a 50deg limit. Slic3r however still print the entire support although only "connect" it to the part above 50deg. I takes just a long to print but admittedly makes less of a mess as I only have to remove interface support on a smaller surface.

I generally find it very difficult to remove the support from the part and need to look into it more. It would also help to be able to print the support with a different color as the boundary is not always clear. I am beginning to think that I should draw my support in CAD and disable the option in slic3r. It may be what you have to do as I would imagine the clever commercial slicing SW are unlikely to be free or affordable.

Hopefully someone may have a better idea?

|

Re: support structures - need help January 26, 2014 07:04PM |

Registered: 10 years ago Posts: 46 |

My best practice so far is exactly the combination of what is suggested here

I apply them in the following order (higher number has better quality outcome);

I still wish there where a good (cant get the existing of the part nicely) automatic solution for stuff like big domes printed horizontally (i now print them vertically with moddeld support on one edge)

I apply them in the following order (higher number has better quality outcome);

- Not relying in sliz3r

- Turn the part for best printing angle

- Model support in CAD software

- Design the part (evt. with support) from scratch for the manufacturing process

I still wish there where a good (cant get the existing of the part nicely) automatic solution for stuff like big domes printed horizontally (i now print them vertically with moddeld support on one edge)

|

Re: support structures - need help January 27, 2014 03:01PM |

Registered: 10 years ago Posts: 2,472 |

Sorry, only registered users may post in this forum.