Test prints

Posted by PaulHam

|

Test prints February 02, 2014 05:38PM |

Registered: 10 years ago Posts: 147 |

I've just seen ormerod168's post about the Single Wall Alignment Test

Now I'm wondering what tests do you guys like to do to check your machine?

Also, I saw a comb on thingiverse and the description said each tooth was a different setting, is it possible to get slicer to used different settings in one print or have I got the wrong end of the stick?

Now I'm wondering what tests do you guys like to do to check your machine?

Also, I saw a comb on thingiverse and the description said each tooth was a different setting, is it possible to get slicer to used different settings in one print or have I got the wrong end of the stick?

|

Re: Test prints February 02, 2014 06:46PM |

Registered: 10 years ago Posts: 14,672 |

I print this [www.thingiverse.com] at half size as a general check. It's no good for calibration, but it's quite a good test of bed adhesion (because the contact area is quite small) and the quality of overhangs and bridging.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Test prints February 03, 2014 08:10AM |

Registered: 10 years ago Posts: 145 |

|

Re: Test prints February 03, 2014 08:24AM |

Registered: 10 years ago Posts: 14,672 |

You can scale it to half size in slic3r. The settings I use in slic3r are similar to the Ormerod 0.5 ones from RRP except that I set 4mm retraction, first layer 195C, other layers 190C, skirt separation 15mm, skirt loops 2.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Test prints February 04, 2014 01:18PM |

Registered: 10 years ago Posts: 145 |

Very pleased with my Dodecahedron.

A few wisps when trying to start the top pentagon.

Flushed with success, I graduated to the thin wall test.

Worked perfectly - except it is not watertight.

Pictures tomorrow.

Now to the problem:

It was quite happily running Matt's web interface, and dc's firmware before yesterday's trauma - all caused by me trying to fit my newly printed Zrunner.

Snapped Xrib nut holder, Y axis belt cable tie pulled through the plywood slot (when the axis jammed). Kim's elastic band keeping the ribbon cable taught going all wrong and bunching up underneath. The machine was regulalry upside down, bits disconnected, and verbally abused over several hours.

A bit of calm this morning got everything back together - and printing very successfully via Pronterface.

I can no longer run the web interface successfully,

The web page loads, but the Connect button is not enabled. The Send Gcode button is enabled, but nothing happens when I send, say, G1 X50

'get help here' takes me as usual to the forum page

Any ideas?

Greg

Ormerod #17

A few wisps when trying to start the top pentagon.

Flushed with success, I graduated to the thin wall test.

Worked perfectly - except it is not watertight.

Pictures tomorrow.

Now to the problem:

It was quite happily running Matt's web interface, and dc's firmware before yesterday's trauma - all caused by me trying to fit my newly printed Zrunner.

Snapped Xrib nut holder, Y axis belt cable tie pulled through the plywood slot (when the axis jammed). Kim's elastic band keeping the ribbon cable taught going all wrong and bunching up underneath. The machine was regulalry upside down, bits disconnected, and verbally abused over several hours.

A bit of calm this morning got everything back together - and printing very successfully via Pronterface.

I can no longer run the web interface successfully,

The web page loads, but the Connect button is not enabled. The Send Gcode button is enabled, but nothing happens when I send, say, G1 X50

'get help here' takes me as usual to the forum page

Any ideas?

Greg

Ormerod #17

|

Re: Test prints February 04, 2014 02:47PM |

Registered: 10 years ago Posts: 14,672 |

Matt updated the web interface yesterday, so if you are using the remote version, the new .js files you are picking up are no longer compatible with your old reprap.htm file.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Test prints February 04, 2014 02:57PM |

Registered: 10 years ago Posts: 145 |

|

Re: Test prints February 04, 2014 04:17PM |

Registered: 10 years ago Posts: 265 |

Hi Greg,

The latest reprap.htm can be found on my github (link in my signature), if your not hosting the .js files on a web server local to you, use the reprap.remote.min.htm (renamed to reprap.htm).

feel free to ask if you need further help.

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

The latest reprap.htm can be found on my github (link in my signature), if your not hosting the .js files on a web server local to you, use the reprap.remote.min.htm (renamed to reprap.htm).

feel free to ask if you need further help.

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

|

Re: Test prints February 04, 2014 04:22PM |

Registered: 10 years ago Posts: 14,672 |

Quote

iamburny

if your not hosting the .js files on a web server local to you, use the reprap.remote.min.htm (renamed to reprap.htm).

A word of warning: file reprap.remote.min.htm cannot be uploaded to the SD card via Pronterface. File reprap.remote.htm can be, if you rename it to reprap.htm first.

Edited 3 time(s). Last edit at 02/05/2014 05:58AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Test prints February 05, 2014 05:56AM |

Registered: 10 years ago Posts: 66 |

Try printing a lego block, there are quite a few on www.tinkercad.com, easy to use. I printed one over the weekend. Lego needs to be perfect to fit on a genuine lego block. My daughter was impressed. My first layer and rest were at 0.24 and my prints are still not perfect as I have a "flare" at the base which can be seen when fitting the printed block to other blocks. I have high standards, it must be perfect... What followed next was... Dad can you print this and that.... you are warned!

Dieter

#257

Dieter

#257

|

Re: Test prints February 05, 2014 06:23AM |

Registered: 10 years ago Posts: 145 |

Well, two grandchildren went off yesterday playing with their dodecahedrons.

When they come back after school today, I expect they will each have a list of 'things to print'

As I am also expecting another two of the grandchildren to turn up today, I am already on my second dodecahedron of the day!!!

Help please: some time ago, someone posted a bearing with herringbone gears instead of rollers; I have searched for it - unsuccessfully. Does anyone have a link?

Greg

Ormerod #17

When they come back after school today, I expect they will each have a list of 'things to print'

As I am also expecting another two of the grandchildren to turn up today, I am already on my second dodecahedron of the day!!!

Help please: some time ago, someone posted a bearing with herringbone gears instead of rollers; I have searched for it - unsuccessfully. Does anyone have a link?

Greg

Ormerod #17

|

Re: Test prints February 05, 2014 06:47AM |

Registered: 10 years ago Posts: 37 |

Quote

GregL

Well, two grandchildren went off yesterday playing with their dodecahedrons.

When they come back after school today, I expect they will each have a list of 'things to print'

As I am also expecting another two of the grandchildren to turn up today, I am already on my second dodecahedron of the day!!!

Help please: some time ago, someone posted a bearing with herringbone gears instead of rollers; I have searched for it - unsuccessfully. Does anyone have a link?

Greg

Gear Bearing

Check out the rest of his stuff. He is a true artiest.

Emmet

Dan.

Edited 1 time(s). Last edit at 02/05/2014 06:48AM by FalseIdle.

|

Re: Test prints February 05, 2014 08:23AM |

Registered: 10 years ago Posts: 2,472 |

A bit of flaring at the base of a print is caused by zeroing the Z axis slightly too low before you start the print. IME it helps the print to stick, so is often necessary - a few strokes of a needle file or sanding block will fix it afterwards. Maybe print the grandkids some nautilus gears out of fluorescent or glow-in-the-dark filament. Or maybe a whistle - umm - on second thoughts, scrub that last suggestion!

Dave

(#106)

Dave

(#106)

|

Re: Test prints February 05, 2014 09:50AM |

Registered: 10 years ago Posts: 145 |

Thanks Dan,

I have downloaded the bearing - and bookmarked Emmet's web page.

Seeing his model of a sleeve valve engine has reminded me that I can now make a model of my T5 engine design: variable compression ratio, variable expansion ratio, variable capacity - all while the engine is running - and it has fewer components than a standard four stroke!

Meanwhile my fourth dodecahefron has not gone well. I noticed the extruder beginning to stutter fairly early on in the print. It eventually got worse and the print degenerated into a birds nest.

It was a repeat of my early extruder problem, with the small cog being forced closer to the extruder body - generating a lot of friction. A generous squirt of Lock Lube has returned the extruder to a much freer movement. Latest dodecahedron on its top pentagon, and looking good ( just in time - soon be off to collect two from school)

@Dave - I think I will give that whisle a miss!

Greg

Ormerod #17

I have downloaded the bearing - and bookmarked Emmet's web page.

Seeing his model of a sleeve valve engine has reminded me that I can now make a model of my T5 engine design: variable compression ratio, variable expansion ratio, variable capacity - all while the engine is running - and it has fewer components than a standard four stroke!

Meanwhile my fourth dodecahefron has not gone well. I noticed the extruder beginning to stutter fairly early on in the print. It eventually got worse and the print degenerated into a birds nest.

It was a repeat of my early extruder problem, with the small cog being forced closer to the extruder body - generating a lot of friction. A generous squirt of Lock Lube has returned the extruder to a much freer movement. Latest dodecahedron on its top pentagon, and looking good ( just in time - soon be off to collect two from school)

@Dave - I think I will give that whisle a miss!

Greg

Ormerod #17

|

Re: Test prints February 11, 2014 05:11AM |

Registered: 10 years ago Posts: 49 |

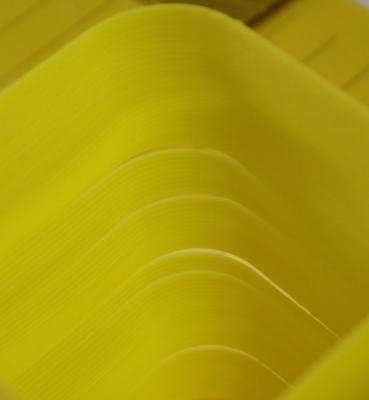

Hi I have been running the thin wall test to determine the difference between different filaments I have here, the problem I am getting is that the wall thickness varies from 0.55 on the curved sections then down to almost 0.3 mm where the walls join is this a printer firmware issue or a slicr3 error?

thanks

Mike

thanks

Mike

|

Re: Test prints February 11, 2014 05:45AM |

Registered: 10 years ago Posts: 191 |

Hi Mike,

I regularly do some tests with a one perimeter cube to adjust the extrusion multiplier ("filament settings" in slic3r).

I have the same oberservations as you have where from the start point (which annoyingly still has a blob at the point where it starts) the first wall is thinner than the rest, than begins to get thicker. The second wall is too thick, while the third an forth are somehow an average of both.

I did so many test already but still can't avoid either the blobby start (that is what is really a bad thing) nor the irregular thickness of the wall. As I do some prints now which have to be very accurate in size I almost gave up to try it with the Ormerod.

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

I regularly do some tests with a one perimeter cube to adjust the extrusion multiplier ("filament settings" in slic3r).

I have the same oberservations as you have where from the start point (which annoyingly still has a blob at the point where it starts) the first wall is thinner than the rest, than begins to get thicker. The second wall is too thick, while the third an forth are somehow an average of both.

I did so many test already but still can't avoid either the blobby start (that is what is really a bad thing) nor the irregular thickness of the wall. As I do some prints now which have to be very accurate in size I almost gave up to try it with the Ormerod.

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

|

Re: Test prints February 11, 2014 09:28AM |

Registered: 10 years ago Posts: 147 |

|

Re: Test prints February 11, 2014 09:51AM |

Registered: 10 years ago Posts: 49 |

|

Re: Test prints February 11, 2014 10:57AM |

Registered: 10 years ago Posts: 145 |

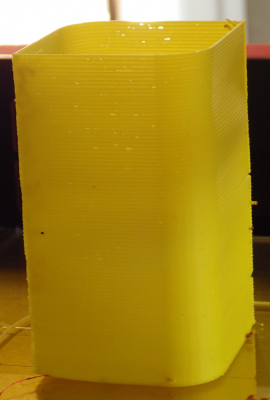

I printed the ThinWall test a few days ago in PLA with standard settings - I was very pleased with it, but it did not hold water

I would also show a picture of a Dodecahedron, but the forum software seems to think the file (at 608Kb) is too big for its stated limit of 614.4 Kb

The bearing Dan suggested turned out brilliantly 52mm dia and 15mm deep - with 5 planet herring-bone gears. It needed a sharp tap on the sun gear to unstick it, then tapping each of the planet gears in turn - now it runs quite smoothly. The current picture at 1.1Mb is too large - I will try and compress it.

Edited 1 time(s). Last edit at 02/11/2014 10:58AM by GregL.

Ormerod #17

I would also show a picture of a Dodecahedron, but the forum software seems to think the file (at 608Kb) is too big for its stated limit of 614.4 Kb

The bearing Dan suggested turned out brilliantly 52mm dia and 15mm deep - with 5 planet herring-bone gears. It needed a sharp tap on the sun gear to unstick it, then tapping each of the planet gears in turn - now it runs quite smoothly. The current picture at 1.1Mb is too large - I will try and compress it.

Edited 1 time(s). Last edit at 02/11/2014 10:58AM by GregL.

Ormerod #17

|

Re: Test prints February 11, 2014 11:01AM |

Registered: 10 years ago Posts: 145 |

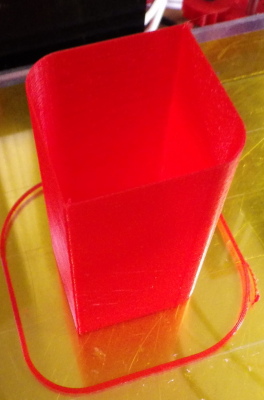

More importantly, and where I need your collective wisdom, I have completed my first ABS print.

First layer temperatures 235, 105

Second and further layers 230, 100

Layer height 0.1

Splitting (noisy) occured during the printing on the curved corner nearest the Duet - and those parts of the wall buckled.

How can I improve things?

Greg

Ormerod #17

First layer temperatures 235, 105

Second and further layers 230, 100

Layer height 0.1

Splitting (noisy) occured during the printing on the curved corner nearest the Duet - and those parts of the wall buckled.

How can I improve things?

Greg

Ormerod #17

|

Re: Test prints February 11, 2014 11:12AM |

Registered: 10 years ago Posts: 145 |

|

Re: Test prints February 11, 2014 12:09PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Mickyblueeyes

Hi I have been running the thin wall test to determine the difference between different filaments I have here, the problem I am getting is that the wall thickness varies from 0.55 on the curved sections then down to almost 0.3 mm where the walls join is this a printer firmware issue or a slicr3 error?

Mike

Hi Mike

Just you have something to compare to - did a measurement on 2 of the same test cubes, 3 measurements each side taking care to measure in the same debt and with the same pressure on the micrometer

Print with ormerod original supplied white filament, C=curve, J=join, numbers x 0.01mm:

J, 60, 56, 56, C, 56, 55, 53, J, 52, 53, 53, C, 61, 60, 59

Print with 3DFilaPrint:

J, 58, 57, 56, C, 57, 58, 57, J, 59, 58, 55, C, 59, 58, 56

This was sliced in Slic3r 1.0.0RC2 and with dc42's ini files

Are you stretching the line?, should you adjust the feed?, have you tried adjusting the extrusion multiplier?

Disclamer: I know absolutely nothing about printing and share it gladly :-)

Erik

|

Re: Test prints February 11, 2014 01:43PM |

Registered: 10 years ago Posts: 14,672 |

I have these measurements, taken using digital calipers:

J 51 53 54 C 64 55 54 55 J 54 53 53 C 56 53 55 54

The numbers immediately after the C are the middle of the corners. It almost holds water - overnight the level decreases by about 2% and a small pool appears around it. I am not getting any blobs, just a very slight roughness down the joins.

I'm trying that bearing now.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

J 51 53 54 C 64 55 54 55 J 54 53 53 C 56 53 55 54

The numbers immediately after the C are the middle of the corners. It almost holds water - overnight the level decreases by about 2% and a small pool appears around it. I am not getting any blobs, just a very slight roughness down the joins.

I'm trying that bearing now.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Test prints February 11, 2014 02:32PM |

Registered: 10 years ago Posts: 2,472 |

Quote

GregL

More importantly, and where I need your collective wisdom, I have completed my first ABS print.

First layer temperatures 235, 105

Second and further layers 230, 100

Layer height 0.1

Splitting (noisy) occured during the printing on the curved corner nearest the Duet - and those parts of the wall buckled.

How can I improve things?

Greg

I was getting warping and splitting with ABS as well. The corner closest to the Duet is indeed the most problematic - probably still something to do with fan wash despite the deflector.

The first thing to do is always try to orient parts on the bed (in Slic3r) so that there is no corner of the part in that orientation. I found that having a cooler bed for all but the first layer was better - I use 105 for the first layer and 90 for the rest. My extruder temperature is usually 250 for all layers. Keep a reasonably high ambient that does not change, and above all keep drafts away from the bed.

Dave

(#106)

|

Re: Test prints February 12, 2014 05:38AM |

Registered: 10 years ago Posts: 49 |

|

Re: Test prints February 12, 2014 08:05AM |

Registered: 10 years ago Posts: 1,230 |

Hi mike

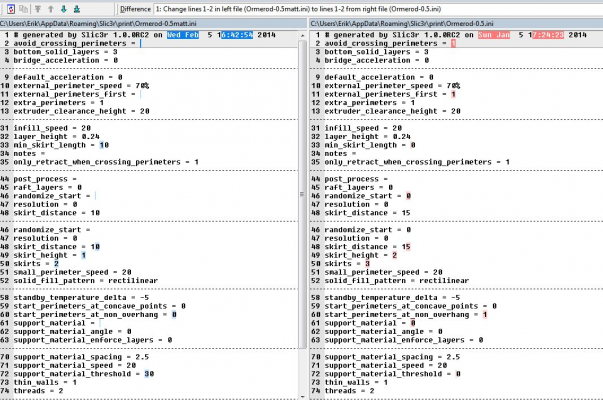

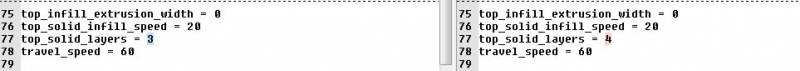

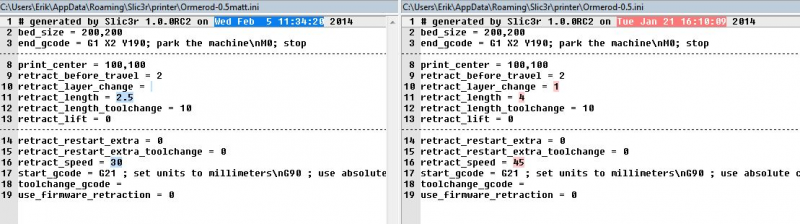

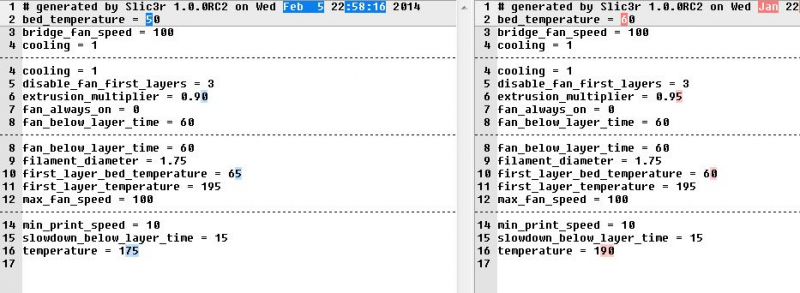

I downloaded Iamburny's setting and made a compare show dif.

Ianburny's at the left, those I use at the right

Print:

Printer:

Filament:

Erik

I downloaded Iamburny's setting and made a compare show dif.

Ianburny's at the left, those I use at the right

Print:

Printer:

Filament:

Erik

|

Re: Test prints February 12, 2014 09:11AM |

Registered: 10 years ago Posts: 49 |

Sorry, only registered users may post in this forum.