Double Helix Z-Gears - iamburny Style

Posted by iamburny

Double Helix Z-Gears - iamburny Style  February 03, 2014 07:59AM |

Registered: 10 years ago Posts: 265 |

A few tiny tweaks to do and i'll post stl's and scad files for these.

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Re: Double Helix Z-Gears - iamburny Style  February 03, 2014 08:13AM |

Registered: 10 years ago Posts: 1,230 |

Re: Double Helix Z-Gears - iamburny Style  February 03, 2014 08:27AM |

Registered: 10 years ago Posts: 37 |

Re: Double Helix Z-Gears - iamburny Style  February 03, 2014 08:42AM |

Registered: 10 years ago Posts: 265 |

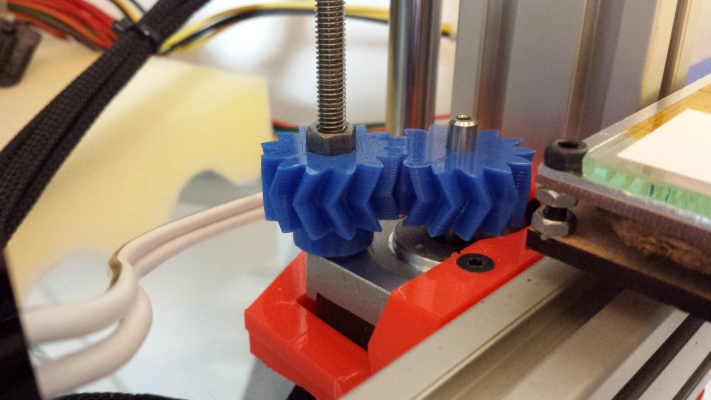

@ormerod168 - I haven't moved the supporting bearing, I designed them to be a direct replacement. Because the teeth are herring bone (double helix) they pretty much level themselves, and its easy to tell if they aren't aligned properly.

@ FalseIdle - There is a "knack" to fitting them as the teeth mesh so closely, I was watching my original gears during printing and noticed a fair bit of slack between them, may have been as they were my own prints from a while back. These new ones are look/feel and sound a whole lot better.

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

@ FalseIdle - There is a "knack" to fitting them as the teeth mesh so closely, I was watching my original gears during printing and noticed a fair bit of slack between them, may have been as they were my own prints from a while back. These new ones are look/feel and sound a whole lot better.

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Re: Double Helix Z-Gears - iamburny Style  February 03, 2014 01:05PM |

Registered: 10 years ago Posts: 265 |

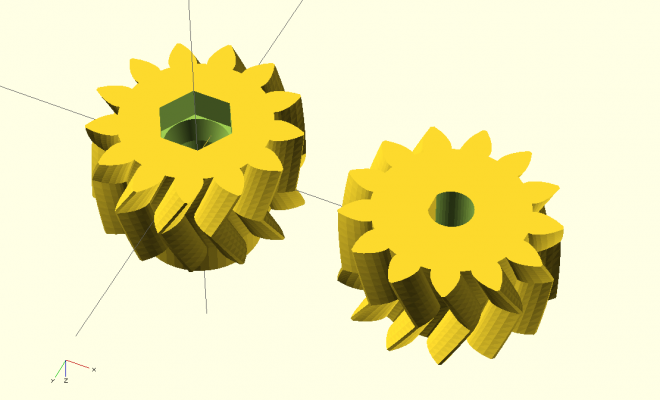

Attached (in the zip file) is the seperate STL's for each gear and the scad for both.

If you want to use the scad you need you have the Involute Gears and Regular Shapes librarys available for scad to import.

The "knack" to fitting them is, put about 3 or 4mm of the stepper gear on motor shaft then put hex nut (on threaded rod) in the nut trap on other gear, check the gears mesh properly as they only fit on way round, once meshed, hold together tightly and slide both down at the same time until the hexnut gear is bedding onto the bearing, run the Z up and down a few times to help that bed together properly.

Matt

Edited 3 time(s). Last edit at 02/03/2014 01:11PM by iamburny.

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

If you want to use the scad you need you have the Involute Gears and Regular Shapes librarys available for scad to import.

The "knack" to fitting them is, put about 3 or 4mm of the stepper gear on motor shaft then put hex nut (on threaded rod) in the nut trap on other gear, check the gears mesh properly as they only fit on way round, once meshed, hold together tightly and slide both down at the same time until the hexnut gear is bedding onto the bearing, run the Z up and down a few times to help that bed together properly.

Matt

Edited 3 time(s). Last edit at 02/03/2014 01:11PM by iamburny.

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Re: Double Helix Z-Gears - iamburny Style  February 04, 2014 01:14PM |

Registered: 10 years ago Posts: 44 |

Re: Double Helix Z-Gears - iamburny Style  February 04, 2014 02:31PM |

Registered: 10 years ago Posts: 2,472 |

Just fitted your Z axis gears - at first test they appear to have less backlash. Before, I went down in 0.1mm increments until the first time I could just feel a sheet of paper being gripped, but then if I went up 0.1mm the paper was still weakly gripped, up another 0.1mm and the paper was loose then back down 0.1mm and still completely loose. With these gears there is no discernable difference whether I go up to the grip point or down to the grip point.

I also printed your extruder gears. They are a bit stiff to the point where the motor misses the occasional step just extruding into air. Putting up the current to 1A stopped that, but I have not yet tried a print with them. Perhaps they need to wear in.

Dave

(#106)

I also printed your extruder gears. They are a bit stiff to the point where the motor misses the occasional step just extruding into air. Putting up the current to 1A stopped that, but I have not yet tried a print with them. Perhaps they need to wear in.

Dave

(#106)

Re: Double Helix Z-Gears - iamburny Style  February 04, 2014 04:07PM |

Registered: 10 years ago Posts: 265 |

Hi Dave,

I was very careful with the distance between centre's and diameters of the gears, and when measured with my vernier caliper the new ones were +/- 0.05mm, I have noticed though with the particular PLA (blue) that i'm using at the moment i do get some shrinkage which maybe why the fit of mine is damn near perfect. Also there maybe other variables involved due to printer differences, slic3r setting etc. i'll happily compare dimensions with the ones you have printed if it will help

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

I was very careful with the distance between centre's and diameters of the gears, and when measured with my vernier caliper the new ones were +/- 0.05mm, I have noticed though with the particular PLA (blue) that i'm using at the moment i do get some shrinkage which maybe why the fit of mine is damn near perfect. Also there maybe other variables involved due to printer differences, slic3r setting etc. i'll happily compare dimensions with the ones you have printed if it will help

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Re: Double Helix Z-Gears - iamburny Style  February 05, 2014 07:21AM |

Registered: 10 years ago Posts: 2,472 |

Quote

iamburny

Hi Dave,

I was very careful with the distance between centre's and diameters of the gears, and when measured with my vernier caliper the new ones were +/- 0.05mm, I have noticed though with the particular PLA (blue) that i'm using at the moment i do get some shrinkage which maybe why the fit of mine is damn near perfect. Also there maybe other variables involved due to printer differences, slic3r setting etc. i'll happily compare dimensions with the ones you have printed if it will help

Matt

No problem Matt, it's common for my gear prints to be a bit stiff at first, but they usually wear in fairly quickly - and these printed so well that I did not feel the need for a touch-up with a needle file, so they really are straight off the bed and onto my Ormerod, so it's probably a slight uneveness in my perimeters rather than anything to do with your excellent design. Couple of pix of your gears on my Ormerod - in black ABS.

Dave

(#106)

Re: Double Helix Z-Gears - iamburny Style  February 05, 2014 08:34AM |

Registered: 10 years ago Posts: 265 |

Very nice Dave =)

hope they are working well for you,

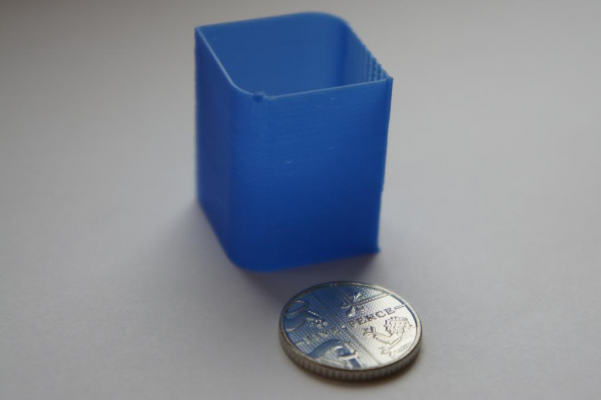

I thought i'd give mine a serious test and printed the Single Wall Alignment Test at 50% scale and 0.12mm layer height, came out pretty good

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

hope they are working well for you,

I thought i'd give mine a serious test and printed the Single Wall Alignment Test at 50% scale and 0.12mm layer height, came out pretty good

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Re: Double Helix Z-Gears - iamburny Style  February 05, 2014 10:12AM |

Registered: 10 years ago Posts: 145 |

It looks as though your Egears might be the answer to my extruder problem, Matt.

Over time the standard small gear is being forced towards the extruder body. Eventually the friction becomes too much, and the extruder starts to stutter - and prints fail.

Your gears should not exert any longitudinal forces (mind you, neither should the current design), so hopefully rubbing won't occur

Greg

Ormerod #17

Over time the standard small gear is being forced towards the extruder body. Eventually the friction becomes too much, and the extruder starts to stutter - and prints fail.

Your gears should not exert any longitudinal forces (mind you, neither should the current design), so hopefully rubbing won't occur

Greg

Ormerod #17

Re: Double Helix Z-Gears - iamburny Style  February 05, 2014 11:18AM |

Registered: 10 years ago Posts: 2,472 |

I discovered that I had left a washer out between the big gear and the bearing after fitting the new gears. That was causing the friction, not your gears, which now work perfectly.

Greg, the gears do exert a longitudinal force - if they are not aligned. So if the small gear starts to wander along the motor shaft, it should be automatically pulled back into alignment by the big gear. Note that you must not fit the small gear onto the shaft first like you do with the original gears, it must be held in mesh with the large gear and both fitted together.

Dave

(#106)

Greg, the gears do exert a longitudinal force - if they are not aligned. So if the small gear starts to wander along the motor shaft, it should be automatically pulled back into alignment by the big gear. Note that you must not fit the small gear onto the shaft first like you do with the original gears, it must be held in mesh with the large gear and both fitted together.

Dave

(#106)

Re: Double Helix Z-Gears - iamburny Style  February 06, 2014 11:51AM |

Registered: 10 years ago Posts: 14 |

Hi Matt

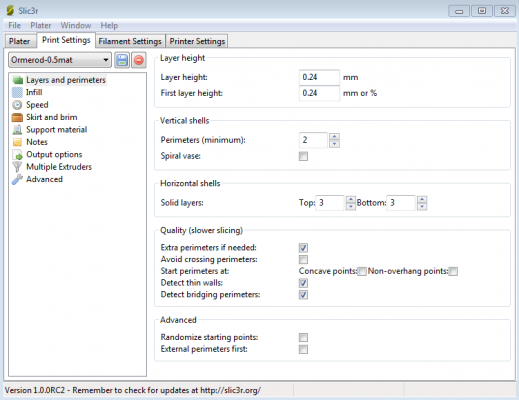

I printed out your two gears but I'm not sure if I've got my Slic3r settings correct as the hex hole for the nut has not worked out very well and the hole down the centre of the other gear doesn't have a flat on it, it has more of a slot. I took a while to use your *.scad file in openscad the attached file shows the error I found. Could you publish the settings used in Slic3r please thanks.

dave

I printed out your two gears but I'm not sure if I've got my Slic3r settings correct as the hex hole for the nut has not worked out very well and the hole down the centre of the other gear doesn't have a flat on it, it has more of a slot. I took a while to use your *.scad file in openscad the attached file shows the error I found. Could you publish the settings used in Slic3r please thanks.

dave

Re: Double Helix Z-Gears - iamburny Style  February 06, 2014 12:17PM |

Registered: 10 years ago Posts: 265 |

Hi Dave,

I had corrected that error on the latest github versions of these gears, also bevelled the corners, thanks for spotting it though.

attached is my (zipped) g-code results from slic3r. might be worth checking the pre-print commands at the start before using them.

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

I had corrected that error on the latest github versions of these gears, also bevelled the corners, thanks for spotting it though.

attached is my (zipped) g-code results from slic3r. might be worth checking the pre-print commands at the start before using them.

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Re: Double Helix Z-Gears - iamburny Style  February 06, 2014 02:00PM |

Registered: 10 years ago Posts: 578 |

Thanks for providing your upgrade parts on github Matt, I'll be printing your E gears tomorrow-I grabbed some from thingiverse last month but they were for a larger extruder, and I've been wondering if I should try to design my own

Cheers

Ray

Edited 1 time(s). Last edit at 02/06/2014 02:01PM by rayhicks.

Cheers

Ray

Edited 1 time(s). Last edit at 02/06/2014 02:01PM by rayhicks.

Re: Double Helix Z-Gears - iamburny Style  February 06, 2014 07:19PM |

Registered: 10 years ago Posts: 105 |

Love 'em, Love 'em, Love 'em

Thank you so much @Iamburny for this beautiful upgrade. Like @dmould I was suffering from too much backlash and could easily get 0.2mm variation when trying to set Z=0, and this straight replacement has completely sorted that...a straight swop for a beautiful looking part that gives an immediate improvement in print quality - couldn't be happier!

I also remain childishly excited about watching my printer print it's own upgrades...

Thank you so much @Iamburny for this beautiful upgrade. Like @dmould I was suffering from too much backlash and could easily get 0.2mm variation when trying to set Z=0, and this straight replacement has completely sorted that...a straight swop for a beautiful looking part that gives an immediate improvement in print quality - couldn't be happier!

I also remain childishly excited about watching my printer print it's own upgrades...

Re: Double Helix Z-Gears - iamburny Style  February 07, 2014 12:24PM |

Registered: 10 years ago Posts: 58 |

Re: Double Helix Z-Gears - iamburny Style  February 08, 2014 06:34AM |

Registered: 10 years ago Posts: 59 |

Matt, really appreciate all your work on this, I've just printed out your zgears from the the gcode you attached earlier and this is the cleanest, neatest, blob free print I've done so far.

Would it be possible to share the slic3r settings you are using?

I'd love to see what settings are different to the ones I'm using. I did notice it seems to print the second inner perimeter first, then the outer. How do you get slic3r to do this?

Tim

RS Ormerod #472

Would it be possible to share the slic3r settings you are using?

I'd love to see what settings are different to the ones I'm using. I did notice it seems to print the second inner perimeter first, then the outer. How do you get slic3r to do this?

Tim

RS Ormerod #472

Re: Double Helix Z-Gears - iamburny Style  February 08, 2014 07:02AM |

Registered: 10 years ago Posts: 265 |

Hi Tim,

It is all about the slic3r settings, they can make or break a printer/print! I've attached my slic3r settings from "%USERPROFILE%\AppData\Roaming\Slic3r" they are a mix of official RRP, Dc42's and some of my own, some caution should be taken though as i print at a relatively cold 175C which although gives great results can put extra strain on the extruder stepper motor.

attached is a screenshot from my Slic3r (v1.0.0RC2), notice at the bottom "External perimeters first" is unchecked which helps improve the outer surface quality a fair bit.

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

It is all about the slic3r settings, they can make or break a printer/print! I've attached my slic3r settings from "%USERPROFILE%\AppData\Roaming\Slic3r" they are a mix of official RRP, Dc42's and some of my own, some caution should be taken though as i print at a relatively cold 175C which although gives great results can put extra strain on the extruder stepper motor.

attached is a screenshot from my Slic3r (v1.0.0RC2), notice at the bottom "External perimeters first" is unchecked which helps improve the outer surface quality a fair bit.

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Re: Double Helix Z-Gears - iamburny Style  February 08, 2014 07:10AM |

Registered: 10 years ago Posts: 59 |

Re: Double Helix Z-Gears - iamburny Style  February 08, 2014 07:13AM |

Registered: 10 years ago Posts: 265 |

bah!, forgot to click attach button! sry

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Re: Double Helix Z-Gears - iamburny Style  February 08, 2014 11:43AM |

Registered: 10 years ago Posts: 59 |

Re: Double Helix Z-Gears - iamburny Style  February 08, 2014 11:51AM |

Registered: 10 years ago Posts: 265 |

your round then Tim Cheers!

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Re: Double Helix Z-Gears - iamburny Style  February 08, 2014 01:01PM |

Registered: 10 years ago Posts: 46 |

Re: Double Helix Z-Gears - iamburny Style  February 09, 2014 11:48AM |

Registered: 10 years ago Posts: 300 |

I just downloaded iamburny's Slic3r settings and it puts up an info box saying that Support material was improved since the last version and it recommends restoring to the default settings although it doesn't mention how to. The version I have is 1.0.0RC2 which looks like an increment since December. The only parameters for support material appear to be Pattern spacing (2.5mm) and Raft layers (0).

RS Components Reprap Ormerod No. 481

RS Components Reprap Ormerod No. 481

Re: Double Helix Z-Gears - iamburny Style  March 07, 2014 06:49AM |

Registered: 10 years ago Posts: 147 |

Re: Double Helix Z-Gears - iamburny Style  March 07, 2014 07:17AM |

Registered: 10 years ago Posts: 135 |

Re: Double Helix Z-Gears - iamburny Style  March 07, 2014 07:21AM |

Registered: 10 years ago Posts: 36 |

Re: Double Helix Z-Gears - iamburny Style  March 07, 2014 07:32AM |

Registered: 10 years ago Posts: 135 |

Re: Double Helix Z-Gears - iamburny Style  September 08, 2016 06:40AM |

Registered: 9 years ago Posts: 82 |

Just so I dig out this subject a little, and to thank Iamburny for this excellent design and excellent Gcode files.

I had trouble printing these models to the correct size (holes ended up too small). I was beginning to think my Ormerod 2 could not achieve such precision. Then I got the gcode files from this thread and it does work, and beautifully.

Printing this showed me that my printer is capable and properly set up, and that I'm actually to blame for my poor results up to now... It was like having a master coming in my flat to show me how things are done.

For all that, thank you

And by the way the new z gears are indeed much better than the previous ones. Incredibly stable and precise.

I had trouble printing these models to the correct size (holes ended up too small). I was beginning to think my Ormerod 2 could not achieve such precision. Then I got the gcode files from this thread and it does work, and beautifully.

Printing this showed me that my printer is capable and properly set up, and that I'm actually to blame for my poor results up to now... It was like having a master coming in my flat to show me how things are done.

For all that, thank you

And by the way the new z gears are indeed much better than the previous ones. Incredibly stable and precise.

Sorry, only registered users may post in this forum.