Stepped test print

Posted by appjaws1

|

Stepped test print February 03, 2014 10:06AM |

Registered: 10 years ago Posts: 780 |

I have now printed 3 copies of the orthogonal axis compensation items and each one has steps on the lower part. I have made various adjustments and re-checks, the bed is level and the Y drive belt is tight with a twang.

If you look at the machine from the front, the piece on the left (Y+ direction) has a 1.5mm high x 0.5mm width step then 5.0mm higher is straight then the last step in 0.5mm and up 1.0mm

The face away from you (X- direction) seems to be reasonably straight with a few very small steps.

The main piece shows the same stepping on the left and more pronounced lines in the rear face. The upright however seems to be correctly printed, it's square, has no steps but you can see each layer.

I've run out of ideas and don't know how to proceed.

Bye-the-way after print 2 I printed the coat hanger and the steps in that were even more pronounce 1st step 5.0mm up 2nd step 2.5mm up and 3rd step 5.0mm.

I've adjusted the Y belt tension again since then and the details of the axis print are now as above.

I've also noticed that the Y belt is rubbing against the idler mount on the face towards the front of the machine and depositing black dust on the table.

I didn't realize that setting up the Ormorod would be so tricky and time consuming -- will I ever print good quality items?

Any suggestions as to what could be wrong?

Thank you

Paul

If you look at the machine from the front, the piece on the left (Y+ direction) has a 1.5mm high x 0.5mm width step then 5.0mm higher is straight then the last step in 0.5mm and up 1.0mm

The face away from you (X- direction) seems to be reasonably straight with a few very small steps.

The main piece shows the same stepping on the left and more pronounced lines in the rear face. The upright however seems to be correctly printed, it's square, has no steps but you can see each layer.

I've run out of ideas and don't know how to proceed.

Bye-the-way after print 2 I printed the coat hanger and the steps in that were even more pronounce 1st step 5.0mm up 2nd step 2.5mm up and 3rd step 5.0mm.

I've adjusted the Y belt tension again since then and the details of the axis print are now as above.

I've also noticed that the Y belt is rubbing against the idler mount on the face towards the front of the machine and depositing black dust on the table.

I didn't realize that setting up the Ormorod would be so tricky and time consuming -- will I ever print good quality items?

Any suggestions as to what could be wrong?

Thank you

Paul

|

Re: Stepped test print February 03, 2014 10:16AM |

Registered: 10 years ago Posts: 14,672 |

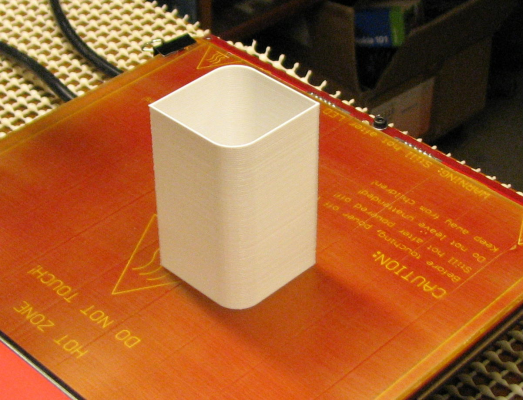

Can you post a photo? That would make it would be easier to understand where the steps are.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Stepped test print February 03, 2014 10:59AM |

Registered: 10 years ago Posts: 578 |

It's likely that interference between the belt and the idler mount is the cause - if it's giving any real resistance to movement, then the motor will be stalling (missing steps) in one direction, this would lead to staggering in Y (much as a slipping belt would - but you say you've got this nice and tight). Is it possible to prevent the rubbing either by turning the belt around (if the teeth are outermost, then remove the twist so they're facing in), or perhaps by filing away the piece of plastic that the belt is interfering with?

Ry

Ry

|

Re: Stepped test print February 03, 2014 11:04AM |

Registered: 10 years ago Posts: 780 |

|

Re: Stepped test print February 03, 2014 11:17AM |

Registered: 10 years ago Posts: 19 |

|

Re: Stepped test print February 03, 2014 11:21AM |

Registered: 10 years ago Posts: 265 |

Hi Trilby,

The stepping in the photo seems to be on the Y axis which is often caused by a loose Y-belt, the Y belt needs to be "Ping!" tight =)

See this Topic [forums.reprap.org]

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

The stepping in the photo seems to be on the Y axis which is often caused by a loose Y-belt, the Y belt needs to be "Ping!" tight =)

See this Topic [forums.reprap.org]

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

|

Re: Stepped test print February 03, 2014 11:21AM |

Registered: 10 years ago Posts: 1,230 |

Quote

rayhicks

It's likely that interference between the belt and the idler mount is the cause - if it's giving any real resistance to movement, then the motor will be stalling (missing steps) in one direction, this would lead to staggering in Y (much as a slipping belt would - but you say you've got this nice and tight). Is it possible to prevent the rubbing either by turning the belt around (if the teeth are outermost, then remove the twist so they're facing in), or perhaps by filing away the piece of plastic that the belt is interfering with?

Ry

Good thinking!, you could be onto something there - the downside to a very tight belt is that it will bend the y-idler-bracket, the belt will no longer self-center on the bearing but try to move sideways and wears against the bracket

My ormerod do this, I see black dust but have no problem printing

A solution could be open the slot and change the bearing for a pulley with a smaller bearing inside

..or make the y-idler-bracket more solid, design a new print, would be easy peacy for those who have the gift

Erik

|

Re: Stepped test print February 03, 2014 11:47AM |

Registered: 10 years ago Posts: 14,672 |

Not only does the y-belt need to be taut, it needs to be not slipping in the groove in the plywood rib. To prevent slipping, the suggestion from RRP is to put a cable tie around the 2 pieces just to the left of the plywood rib, then pull the spare end that comes through the upper slot tight, so as to pull the cable tie against the plywood rib and lock it in place. Alternatively, print a pair of iamburny's y-belt mounts.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Stepped test print February 03, 2014 12:17PM |

Registered: 10 years ago Posts: 780 |

|

Re: Stepped test print February 03, 2014 12:55PM |

Registered: 10 years ago Posts: 578 |

Hi appjaws1 - if you've got a 3d modelling package, you can draw a 3d cube, save it as .stl, then use slicer to make a "shell" by using two bottom layers, one perimeter, and no top layers with 0 percent infill. It's probably the quickest thing to print to get up high quickly - if you haven't got any experience with 3d stuff yet (I certainly didn't when I was at your stage of commissioning), you'll probably want a gcode file of something similar - let me know by PM and I'll post one later.

dc42's comment about belt slippage is also important and easy to check - hold the Y motor pulley firmly by the belt then try moving the bed left and right, if the bed slips either or both ways without the pulley turning, you'll need to clamp the belt to the bed cross-rib somehow (people have used hot glue, bulldog clips, cable ties and custom printed clamps, or screws aroudn which the belt is turned and then clamped to prevent this)

Ray

dc42's comment about belt slippage is also important and easy to check - hold the Y motor pulley firmly by the belt then try moving the bed left and right, if the bed slips either or both ways without the pulley turning, you'll need to clamp the belt to the bed cross-rib somehow (people have used hot glue, bulldog clips, cable ties and custom printed clamps, or screws aroudn which the belt is turned and then clamped to prevent this)

Ray

|

Re: Stepped test print February 03, 2014 02:14PM |

Registered: 10 years ago Posts: 780 |

Ray,

Thank you for your response.

I would like a gcode file please as I have not even thought about slicing etc. yet. That's the next thing once I am happy that the printer is working correctly.

My belt is really tight and produces an audible tone as described in the directions. Is it possible to have the belt too tight?

It will be good to print out a box in the morning

regards

Paul

Thank you for your response.

I would like a gcode file please as I have not even thought about slicing etc. yet. That's the next thing once I am happy that the printer is working correctly.

My belt is really tight and produces an audible tone as described in the directions. Is it possible to have the belt too tight?

It will be good to print out a box in the morning

regards

Paul

|

Re: Stepped test print February 03, 2014 02:47PM |

Registered: 10 years ago Posts: 1,230 |

Paul

Try this one if you like

Single Wall Alignment Test:

[www.thingiverse.com]

printed out just fine for me, and it can hold water :-) (g-code attached)

Erik

Try this one if you like

Single Wall Alignment Test:

[www.thingiverse.com]

printed out just fine for me, and it can hold water :-) (g-code attached)

Erik

|

Re: Stepped test print February 03, 2014 02:57PM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Stepped test print February 03, 2014 04:23PM |

Registered: 10 years ago Posts: 578 |

Sorry I saw this late - I've attached a single wall cube gcode file - the walls should be a 0.5mm thick single perimeter (if you successfully print it and the walls are a different thickness, you can use it adjust your settings in slic3r in the longrun) - there are three bottom layers 50mm by 50mm square, then the shell should rise to 50mm too. There are no homing commands or temperature commands in the file, and it won't wait for temperatures to be reached (set these up front in pronterface to suit PLA - bed around 60, extruder around 200 home manually then wait until your set temperatures are reached before hitting "run").

I printed loads of these when trying to identify the cause of a failure to print thin layers, and for calibrating my extruder and axes (they make handy but weak trinket/desktop organisers! ) Once the base has been laid down, the walls go up pretty quickly since it's a single perimeter (the perimeter speed is set to 50mm/s so ideally it should do a layer every four seconds). I've attached another that will rise even faster (tall tower, which is two layers thick 25mm by 25mm with a brim on the base, then should print to 100mm high as a shell), but I haven't tried printing that - it may topple over

) Once the base has been laid down, the walls go up pretty quickly since it's a single perimeter (the perimeter speed is set to 50mm/s so ideally it should do a layer every four seconds). I've attached another that will rise even faster (tall tower, which is two layers thick 25mm by 25mm with a brim on the base, then should print to 100mm high as a shell), but I haven't tried printing that - it may topple over  The idea of climbing fast is so that you can get to whatever your glitch is asap

The idea of climbing fast is so that you can get to whatever your glitch is asap

If you're going to transfer these to SD card for printing, you'll need to rename in lower case with no spaces to eg "cube.g" and "tower.g" - (".gcode"may not be accepted in the name for transfer to SD)

Cheers

Ray

I printed loads of these when trying to identify the cause of a failure to print thin layers, and for calibrating my extruder and axes (they make handy but weak trinket/desktop organisers!

) Once the base has been laid down, the walls go up pretty quickly since it's a single perimeter (the perimeter speed is set to 50mm/s so ideally it should do a layer every four seconds). I've attached another that will rise even faster (tall tower, which is two layers thick 25mm by 25mm with a brim on the base, then should print to 100mm high as a shell), but I haven't tried printing that - it may topple over

) Once the base has been laid down, the walls go up pretty quickly since it's a single perimeter (the perimeter speed is set to 50mm/s so ideally it should do a layer every four seconds). I've attached another that will rise even faster (tall tower, which is two layers thick 25mm by 25mm with a brim on the base, then should print to 100mm high as a shell), but I haven't tried printing that - it may topple over  The idea of climbing fast is so that you can get to whatever your glitch is asap

The idea of climbing fast is so that you can get to whatever your glitch is asap

If you're going to transfer these to SD card for printing, you'll need to rename in lower case with no spaces to eg "cube.g" and "tower.g" - (".gcode"may not be accepted in the name for transfer to SD)

Cheers

Ray

|

Re: Stepped test print February 04, 2014 07:28AM |

Registered: 10 years ago Posts: 8 |

Hiya guys, I've made a few prints now. Of the two that have been taller than 15mm, I have some layers offset in the Y-axis so I shall be giving my Y Belt some attention a bit later on. (I will also try printing the same model again, but at a lower speed)

I've just flicked the belt and the noise was more 'pong' than 'ping'. But it gave me an idea:

I have a free app called 'G-Strings Guitar Tuner' on my Android phone (alternatives for iOS and WinPho exist). It suggests that my 'pong' is around 95Hz. Has anyone else tried using a guitar tuner to check their belt tightness? What sort of pitch should 'ping' be? (Semi-serious!)

Anyway, good printing everybody. I printed my first functional item yesterday, a bumper case for a phone, downloaded from Thingiverse. I was very impressed by the way the printer bridged small gaps (such as holes for ports) without the use of a support structure.

*offset layers for the first 20mm, then no offset for 30mm, then lots of offsetting for the remaining 30mm. However, the frequency of y offsetting seems to correspond with the complexity of model's cross section in each height range.

[Ormerod, Slic3er, SDcard and Web Interface]

I've just flicked the belt and the noise was more 'pong' than 'ping'. But it gave me an idea:

I have a free app called 'G-Strings Guitar Tuner' on my Android phone (alternatives for iOS and WinPho exist). It suggests that my 'pong' is around 95Hz. Has anyone else tried using a guitar tuner to check their belt tightness? What sort of pitch should 'ping' be? (Semi-serious!)

Anyway, good printing everybody. I printed my first functional item yesterday, a bumper case for a phone, downloaded from Thingiverse. I was very impressed by the way the printer bridged small gaps (such as holes for ports) without the use of a support structure.

*offset layers for the first 20mm, then no offset for 30mm, then lots of offsetting for the remaining 30mm. However, the frequency of y offsetting seems to correspond with the complexity of model's cross section in each height range.

[Ormerod, Slic3er, SDcard and Web Interface]

|

Re: Stepped test print February 04, 2014 12:06PM |

Registered: 10 years ago Posts: 780 |

Thank you to all who responded, I think my issue has been resolved. It may be the belt twisted the other way or the fact that I re-did the belt tightening that solved the step problem.

I have successfully printed the Orthogonal Axis test pieces and they were quite acceptable. I have inputted the readings into my setbed.g file and am now printing Erik's Single Wall Alignment Test which seems to be printing correctly.

The next part for me is to print some spare parts from iamburny OrmerodeUpgrades-master.

Question do I need to do any set up to run the stl files or does Pronterface do it all for me?

Thanks again, a great form

regards

Paul

I have successfully printed the Orthogonal Axis test pieces and they were quite acceptable. I have inputted the readings into my setbed.g file and am now printing Erik's Single Wall Alignment Test which seems to be printing correctly.

The next part for me is to print some spare parts from iamburny OrmerodeUpgrades-master.

Question do I need to do any set up to run the stl files or does Pronterface do it all for me?

Thanks again, a great form

regards

Paul

|

Re: Stepped test print February 04, 2014 01:45PM |

Registered: 10 years ago Posts: 1,230 |

Quote

appjaws1

Question do I need to do any set up to run the stl files or does Pronterface do it all for me?

Thanks again, a great form

regards

Paul

Yes Pronterface will do it all for you as a frontend for Slic3r, but with the standard setup files

The Single Wall Alignment Test is sliced with dc42's changes of settings, 4mm retraction, first layer 195C, then 190C, skirt separation 15mm, loops 2

If my file prints out ok you could use those setting for starters - the easiest would be to copy those ini files of his to the correct folders, I can't find the link to his ini files right now and I would actually rather have him walk you through the install, would hate to mess up a brother in ormerod's system when finally able to print

Edit: ..and btw, those ini files are for the latest version Slic3r 1.0.0RC2, I installed the new version over the old one installed from RepRapPro-Printrun-Slic3r.zip

Erik

Edited 1 time(s). Last edit at 02/04/2014 02:01PM by ormerod168.

|

Re: Stepped test print February 04, 2014 07:14PM |

Registered: 10 years ago Posts: 18 |

I seem to have a similar problem with a stepped print (the standard otho axis compensation model).

However it has exactly one step.

The weird thing is, I printed it again and I get the same step at exacty the same layer (15) (see picture)

The Y belt is rather tight and supported by tie-wrap as suggested. I can't find any slip there. And if it were the Y belt I would expect a more random effect. Twice at the same layer looks like a one in a million chance. So the problem seems to be structural.

Any idea where to look?

Leon

However it has exactly one step.

The weird thing is, I printed it again and I get the same step at exacty the same layer (15) (see picture)

The Y belt is rather tight and supported by tie-wrap as suggested. I can't find any slip there. And if it were the Y belt I would expect a more random effect. Twice at the same layer looks like a one in a million chance. So the problem seems to be structural.

Any idea where to look?

Leon

|

Re: Stepped test print February 05, 2014 07:48AM |

Registered: 10 years ago Posts: 2,472 |

Is it by any chance at about the same thickness as the circular dial piece? If so that may be a clue - If I recall correctly, the last layer or two of the dial piece involves a lot of short fast moves as it prints the radial indents, which is where missed steps typically occur, making it no coincidence that it occurs at the same place on two runs. If the Y belt is too tight it could put more strain on the motor, increasing the chance of a missed step (it is usually the stepper missing a step rather than a slipping belt that causes this). Check that the Y bed moves easily by hand with the power off. Have you increased the motor currents to 1000mA (in the config.g file)? If not, try that. I had to do so to prevent occasional missed steps at higher speeds.

Dave

(#106)

Edited 1 time(s). Last edit at 02/05/2014 07:51AM by dmould.

Dave

(#106)

Edited 1 time(s). Last edit at 02/05/2014 07:51AM by dmould.

|

Re: Stepped test print February 05, 2014 02:59PM |

Registered: 10 years ago Posts: 18 |

Hi Dave,

I can confirm that the "step" is just below the two top layers of the dial, just where the grooves start.

The bed does move reasonably well. Of course you feel the resistance of the motor itself and the belt, but it is rather constant over the entire length.

Of course I'll take your advise to increase the current of at least the Y motor. I'll post the result when I have it.

Kind regards,

Leon

I can confirm that the "step" is just below the two top layers of the dial, just where the grooves start.

The bed does move reasonably well. Of course you feel the resistance of the motor itself and the belt, but it is rather constant over the entire length.

Of course I'll take your advise to increase the current of at least the Y motor. I'll post the result when I have it.

Kind regards,

Leon

Sorry, only registered users may post in this forum.