Double Helix Extruder Gears - iamburny Style

Posted by iamburny

Double Helix Extruder Gears - iamburny Style  February 04, 2014 08:36AM |

Registered: 10 years ago Posts: 265 |

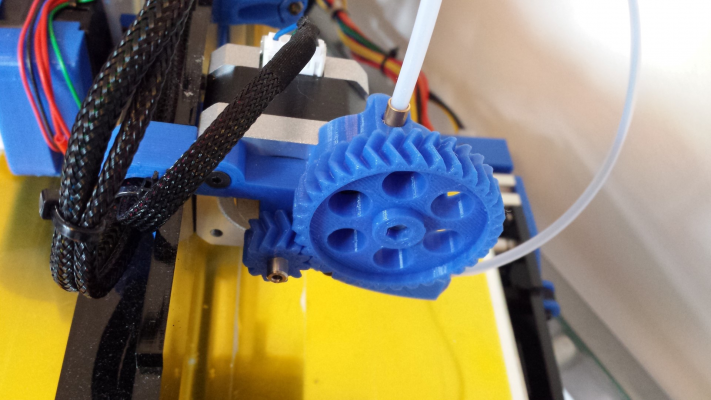

Following on from yesterdays double helix Z Gears [forums.reprap.org], I thought i'd have a bash at some extruder gears too (just so it all matches!!)

I'm pretty pleased with the results, I have also started a new Github repository for the STL's and scad files for my Upgrades, most of the files are now too big to be attached to posts, plus github has a lovely STL viewer =)

Ormerod Upgrade Github

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

I'm pretty pleased with the results, I have also started a new Github repository for the STL's and scad files for my Upgrades, most of the files are now too big to be attached to posts, plus github has a lovely STL viewer =)

Ormerod Upgrade Github

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Re: Double Helix Extruder Gears - iamburny Style  February 04, 2014 08:39AM |

Registered: 10 years ago Posts: 14,672 |

I'm a novice when it comes to gears (and mechanical engineering generally), so can you tell me what is the advantage in this application of double helix gears over single helix gears?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: Double Helix Extruder Gears - iamburny Style  February 04, 2014 08:50AM |

Registered: 10 years ago Posts: 265 |

Apart from looking very pretty, I found there to be significantly less play in the gears, I believe the technical advantages are to do with smoother delivery of power so ideal for the extruder if you have a high retraction setting.

the wikipedia page is sparse but confirms my thoughts [en.wikipedia.org]

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

the wikipedia page is sparse but confirms my thoughts [en.wikipedia.org]

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Re: Double Helix Extruder Gears - iamburny Style  February 04, 2014 09:01AM |

Registered: 10 years ago Posts: 145 |

Single helical gears give smooth drive, but also have axial forces on them. Simple trigonometry on the angle of the helix, will turn the torque into that force.

The double helix is slightly less smooth (the length of the gear tooth is half), but it does cancel out any axial forces.

Greg

Ormerod #17

The double helix is slightly less smooth (the length of the gear tooth is half), but it does cancel out any axial forces.

Greg

Ormerod #17

Re: Double Helix Extruder Gears - iamburny Style  February 04, 2014 09:02AM |

Registered: 10 years ago Posts: 14,672 |

Thanks, Matt.

May I suggest another part for your upgrade library? It would be useful to have a version of the y-motor bracket that has a hole and nut trap in the back to take the 4mm screw from the Duet enclosure. That way, the Duet box could be slid further along, making more room for fan inlet ducts etc.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

May I suggest another part for your upgrade library? It would be useful to have a version of the y-motor bracket that has a hole and nut trap in the back to take the 4mm screw from the Duet enclosure. That way, the Duet box could be slid further along, making more room for fan inlet ducts etc.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: Double Helix Extruder Gears - iamburny Style  February 04, 2014 09:07AM |

Registered: 10 years ago Posts: 147 |

Quote

dc42

Thanks, Matt.

May I suggest another part for your upgrade library? It would be useful to have a version of the y-motor bracket that has a hole and nut trap in the back to take the 4mm screw from the Duet enclosure. That way, the Duet box could be slid further along, making more room for fan inlet ducts etc.

I had a shock when I first tried to zero X axis with my newly printed fan backwash clip on and it hit the Duet enclosure!

I had a shock when I first tried to zero X axis with my newly printed fan backwash clip on and it hit the Duet enclosure!

Re: Double Helix Extruder Gears - iamburny Style  February 04, 2014 09:27AM |

Registered: 10 years ago Posts: 265 |

@dc42 - fixed the support of the Duet enclosure by adding another vertical support inside, it clashes a bit with the backs of the header pins and ive been meaning to add some stand-offs on the internal duet mounts, but it is fine of you dont screw the duet board in tight.

Custom Duet Enclosure

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Custom Duet Enclosure

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Re: Double Helix Extruder Gears - iamburny Style  February 10, 2014 02:43AM |

Registered: 10 years ago Posts: 14 |

Re: Double Helix Extruder Gears - iamburny Style  February 23, 2014 06:49PM |

Registered: 10 years ago Posts: 19 |

Re: Double Helix Extruder Gears - iamburny Style  February 23, 2014 09:39PM |

Registered: 10 years ago Posts: 859 |

I've come to the conclusion that I'm just plain thick, cos I have problems with github to.....

Sometimes I can get the files a treat if there's a big download button, else I'm lost.....

Or going blind..... Oh no that's it...I'm Doomed!!!!..... Not to worry.... I wanted a dog anyway.....

Always look on the bright side of life....

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Sometimes I can get the files a treat if there's a big download button, else I'm lost.....

Or going blind..... Oh no that's it...I'm Doomed!!!!..... Not to worry.... I wanted a dog anyway.....

Always look on the bright side of life....

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Re: Double Helix Extruder Gears - iamburny Style  February 23, 2014 09:51PM |

Registered: 10 years ago Posts: 859 |

PS it was doing those herring bone gears that made me realize my Z axis had slipped out of line....

They don't turn out so nice if it's 5' out... That'll be one of the mods I'll be doing....

And the other reason that herring bone (double helix) gears are used is there is always a section of one of the teeth

engaged in driving the other gear wheel. Which is why they are used in Marine Gearboxes as they

give a very smooth transmission of power (unless your Z axis is out that is.....lol).

[Used to have to blue the teeth and check the mesh of the gears when I was an apprentice...]

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

They don't turn out so nice if it's 5' out... That'll be one of the mods I'll be doing....

And the other reason that herring bone (double helix) gears are used is there is always a section of one of the teeth

engaged in driving the other gear wheel. Which is why they are used in Marine Gearboxes as they

give a very smooth transmission of power (unless your Z axis is out that is.....lol).

[Used to have to blue the teeth and check the mesh of the gears when I was an apprentice...]

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Re: Double Helix Extruder Gears - iamburny Style  April 12, 2014 11:00AM |

Registered: 10 years ago Posts: 64 |

Hi, and thanks for the gears. They work great... now... But printing these made me aware of something I wasn't previously. For example, the large gear has a profile for the hex screw head, but the exact dimensions turn out incorrect, and the head simply doesn't fit. I believe it's about 1 mm to small and I have to file it up. The print appear to be good otherwise. It's like I missed a setting in both Cura and Slic3r. (I tried both) I made measurements in both the STL and in real life; it's not your model, but my print.

Does anyone have an idea if I made a software configuration error?

Does anyone have an idea if I made a software configuration error?

Re: Double Helix Extruder Gears - iamburny Style  April 12, 2014 11:44AM |

Registered: 10 years ago Posts: 73 |

Re: Double Helix Extruder Gears - iamburny Style  April 12, 2014 11:51AM |

Registered: 10 years ago Posts: 314 |

Re: Double Helix Extruder Gears - iamburny Style  April 12, 2014 01:08PM |

Registered: 10 years ago Posts: 327 |

Quote

michaelljunggren

Hi, and thanks for the gears. They work great... now... But printing these made me aware of something I wasn't previously. For example, the large gear has a profile for the hex screw head, but the exact dimensions turn out incorrect, and the head simply doesn't fit. I believe it's about 1 mm to small and I have to file it up. The print appear to be good otherwise. It's like I missed a setting in both Cura and Slic3r. (I tried both) I made measurements in both the STL and in real life; it's not your model, but my print.

Does anyone have an idea if I made a software configuration error?

My first couple came out like yours, I changed the 'Filament settings>Extrusion Multiplier' in to 0.95 in Slic3r and the next one was perfect.

Regards,

Les

Re: Double Helix Extruder Gears - iamburny Style  April 12, 2014 02:15PM |

Registered: 10 years ago Posts: 64 |

Re: Double Helix Extruder Gears - iamburny Style  April 12, 2014 03:52PM |

Registered: 10 years ago Posts: 327 |

I just fitted mine along with Mr Burns extruder block, (the upgraded extruder block has flap to secure the tongue if you need to, and allows you to get the ptfe tube 40mm inside)

On the first test print the motor started stuttering, but after I upped the extruder current to 1amp it's all working beautifully.

Regards,

Les

On the first test print the motor started stuttering, but after I upped the extruder current to 1amp it's all working beautifully.

Regards,

Les

Re: Double Helix Extruder Gears - iamburny Style  April 12, 2014 03:53PM |

Registered: 10 years ago Posts: 314 |

While trying to find a similar post on hole sizes I found this thread that could be of interest.

[forums.reprap.org]

And just because it was interesting someone got improved prints (different printer) with a change to the nozzle cone shape

[forums.reprap.org]

Excuse the randomness of the above, but worth a look!

[Edit] and this one....

[forums.reprap.org]

Edited 1 time(s). Last edit at 04/12/2014 04:00PM by Treth.

Ormerod #007 (shaken but not stirred!)

[forums.reprap.org]

And just because it was interesting someone got improved prints (different printer) with a change to the nozzle cone shape

[forums.reprap.org]

Excuse the randomness of the above, but worth a look!

[Edit] and this one....

[forums.reprap.org]

Edited 1 time(s). Last edit at 04/12/2014 04:00PM by Treth.

Ormerod #007 (shaken but not stirred!)

Re: Double Helix Extruder Gears - iamburny Style  April 12, 2014 04:37PM |

Registered: 10 years ago Posts: 859 |

Quote

Pointy

I just fitted mine along with Mr Burns extruder block, (the upgraded extruder block has flap to secure the tongue if you need to, and allows you to get the ptfe tube 40mm inside)

On the first test print the motor started stuttering, but after I upped the extruder current to 1amp it's all working beautifully.

Regards,

Les

Hi Les, good luck with upping the motor current. I tried it yesterday, and set everything back to 800mA

As for the stuttering, I think you might find your nozzle might have been a fraction low. When it's to low, the table blocks off the nozzle, and then the pressure is to much for the motor, and it stutters.... Have a look at the print you did at the time and see if the first layer was splade out.

It's a trick game getting the height right... With the tall Fan Ducts I use here, I watch the top like a hawk and I can see the top just start to lift as it rests on the the table. As soon as it moves, I go back 0.1mm and set the Z to zero using G92 z0.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Re: Double Helix Extruder Gears - iamburny Style  April 12, 2014 04:48PM |

Registered: 10 years ago Posts: 327 |

I think the head level is fine Kim, I had been printing since 8am without issues, until I changed the parts.

I just had a few more stutters, but think I can see why. I didn't pull the hex nut right into the large gear and it has done it itself while printing. I can see about 2mm of thread before the nyloc nut on the other side. DOH!

I also had some twist in the filament, and since I straightened it, I have had no more stutters, but best I tighten up the nut after this print is finished.

Regards,

Les

I just had a few more stutters, but think I can see why. I didn't pull the hex nut right into the large gear and it has done it itself while printing. I can see about 2mm of thread before the nyloc nut on the other side. DOH!

I also had some twist in the filament, and since I straightened it, I have had no more stutters, but best I tighten up the nut after this print is finished.

Regards,

Les

Re: Double Helix Extruder Gears - iamburny Style  April 12, 2014 05:19PM |

Registered: 10 years ago Posts: 859 |

If they are IamBurny's then they are good gears. But it took me a while to realise my Z-axis was slightly out which messes them up, and you can get tight pots then.

I had my X-carriage bearing fall out from the carriage today.....

I ended up super gluing it back in as I wanted to get a test piece printed in a hurry.

The accident happend halfway throu a long print so I wasn't happy... I was right beside it when it happend, and managed to get the bearing back in on the fly, but it knocked out the X-axis alignment and I had to scrap the piece.... So I tried printing again.... Nope.... No matter what I did it wasn't going to print. I leveled my bed again as it had knocked that out, tried all sorts of temps. Then decided to give up and replace the Nozzle Mount as is was falling apart...

Then I saw the Nozzle wasin't square to the axis... I didn't realise that that could stop it printing till I had put the new mount in place....

It printed first time after that, and the print is nearly finished now.... And it's turning out to be a first class print to....

I must add it to my things to check when it won't print....

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

I had my X-carriage bearing fall out from the carriage today.....

I ended up super gluing it back in as I wanted to get a test piece printed in a hurry.

The accident happend halfway throu a long print so I wasn't happy... I was right beside it when it happend, and managed to get the bearing back in on the fly, but it knocked out the X-axis alignment and I had to scrap the piece.... So I tried printing again.... Nope.... No matter what I did it wasn't going to print. I leveled my bed again as it had knocked that out, tried all sorts of temps. Then decided to give up and replace the Nozzle Mount as is was falling apart...

Then I saw the Nozzle wasin't square to the axis... I didn't realise that that could stop it printing till I had put the new mount in place....

It printed first time after that, and the print is nearly finished now.... And it's turning out to be a first class print to....

I must add it to my things to check when it won't print....

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Re: Double Helix Extruder Gears - iamburny Style  April 13, 2014 05:26AM |

Registered: 10 years ago Posts: 327 |

Well Kim, you will be pleased to know you were correct.

I noticed that the stuttering got less frequent after a few layers, so decided to check everything, I should have just listened to you in the first place!

Something had moved by 0.2mm during all my tinkering, and the head was hitting the glass.

No stuttering so far this morning.

Regards,

Les

I noticed that the stuttering got less frequent after a few layers, so decided to check everything, I should have just listened to you in the first place!

Something had moved by 0.2mm during all my tinkering, and the head was hitting the glass.

No stuttering so far this morning.

Regards,

Les

Re: Double Helix Extruder Gears - iamburny Style  April 17, 2014 12:14PM |

Registered: 10 years ago Posts: 28 |

iamburny

Thank you for sharing the double helix gears for the Omerod Z axis. Very nice work indeed. I printed a set for my Omerod using the default settings and after removing a few 'nibs' they fitted perfectly.

Incidently I think the Omerod is an amazing little printer, I could not be happier.

RayC40

Thank you for sharing the double helix gears for the Omerod Z axis. Very nice work indeed. I printed a set for my Omerod using the default settings and after removing a few 'nibs' they fitted perfectly.

Incidently I think the Omerod is an amazing little printer, I could not be happier.

RayC40

Re: Double Helix Extruder Gears - iamburny Style  April 20, 2014 04:23PM |

Registered: 10 years ago Posts: 265 |

Hi Ray,

Thanks for posting your experiences, I'm very glad they work well for you.

I've been using mine for over 2 months and nearly 6kg of PLA now and they are still virtually unworn and still backlash free =)

have you tried my Z-Axis gears also? [forums.reprap.org]

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Thanks for posting your experiences, I'm very glad they work well for you.

I've been using mine for over 2 months and nearly 6kg of PLA now and they are still virtually unworn and still backlash free =)

have you tried my Z-Axis gears also? [forums.reprap.org]

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Re: Double Helix Extruder Gears - iamburny Style  April 22, 2014 07:28AM |

Registered: 10 years ago Posts: 378 |

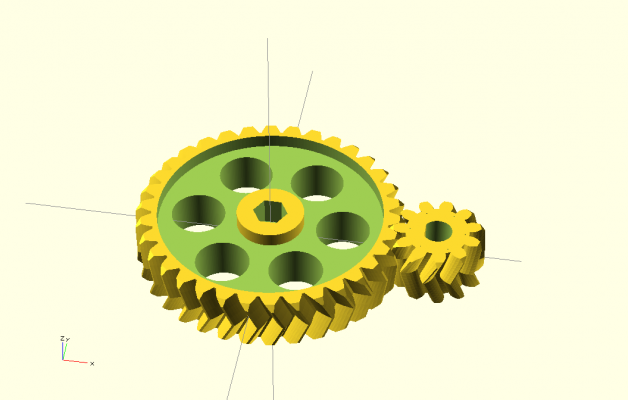

I made some modifications to the "big extruder gear", might as well share it: http://www.thingiverse.com/thing:306252

(STL file too large to attach here)

When I first tried to make this, my machine had some issues getting things done neatly, so I couldn't get a clean print. The "outside rim" of the gear teeth was very thin and would fall off, and the infill would be pretty messy since it was a lot of individual "stops and starts".

I changed iamburny's gear so the rim is a bit thicker (to make it easier to print cleanly and maybe make it a little stronger), while the central parts are a bit thinner. Instead of having holes in it, it's solid so you can just control the amount of material with infill density. Also made the center hole round instead of hexagonal.

The gear teeth themselves are identical to the original, so it should be 100% compatible with the original design

I've printed it but not actually mounted it since the original gears work fine (there was some play in the original Z-axis gears, but none in the extruder gears so I haven't bothered taking the extruder apart).

Edited 1 time(s). Last edit at 04/22/2014 07:29AM by jstck.

(STL file too large to attach here)

When I first tried to make this, my machine had some issues getting things done neatly, so I couldn't get a clean print. The "outside rim" of the gear teeth was very thin and would fall off, and the infill would be pretty messy since it was a lot of individual "stops and starts".

I changed iamburny's gear so the rim is a bit thicker (to make it easier to print cleanly and maybe make it a little stronger), while the central parts are a bit thinner. Instead of having holes in it, it's solid so you can just control the amount of material with infill density. Also made the center hole round instead of hexagonal.

The gear teeth themselves are identical to the original, so it should be 100% compatible with the original design

I've printed it but not actually mounted it since the original gears work fine (there was some play in the original Z-axis gears, but none in the extruder gears so I haven't bothered taking the extruder apart).

Edited 1 time(s). Last edit at 04/22/2014 07:29AM by jstck.

Re: Double Helix Extruder Gears - iamburny Style  December 19, 2015 11:13PM |

Registered: 8 years ago Posts: 200 |

I am looking for a set of these to buy.

I would like the grub nut collar on the small gear.

Any for sale out there?

My replikeo gears were nasty and misprinted. So I am replacing them.

I cant even print a decent set with them to upgrade so I have a unusable printer.

They originals were pla but I would prefer abs if possible. Either kind would be ok if I have to settle.

I would like the grub nut collar on the small gear.

Any for sale out there?

My replikeo gears were nasty and misprinted. So I am replacing them.

I cant even print a decent set with them to upgrade so I have a unusable printer.

They originals were pla but I would prefer abs if possible. Either kind would be ok if I have to settle.

Re: Double Helix Extruder Gears - iamburny Style  December 20, 2015 12:47AM |

Registered: 9 years ago Posts: 1,699 |

Where do you live?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.