Replacement Fan Duct/Heatsink Duct - iamburny

Posted by iamburny

Re: Replacement Fan Duct/Heatsink Duct - iamburny  February 25, 2014 12:17PM |

Registered: 10 years ago Posts: 14,672 |

Ray, yes it is indeed provided for in SamNonDuePin.

Dave, try this firmware [dl.dropboxusercontent.com]. As well as fixing the PWM, I've added an optional P parameter to the M106 command to set the PWM range. The initial default is 1.0 as before. If you send e.g. M106 P255 then subsequent M106 S# commands will interpret # as being out of 255.

PS - there is no internal flyback diode on the fan output. I recommend you add one.

Edited 1 time(s). Last edit at 02/25/2014 12:18PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Dave, try this firmware [dl.dropboxusercontent.com]. As well as fixing the PWM, I've added an optional P parameter to the M106 command to set the PWM range. The initial default is 1.0 as before. If you send e.g. M106 P255 then subsequent M106 S# commands will interpret # as being out of 255.

PS - there is no internal flyback diode on the fan output. I recommend you add one.

Edited 1 time(s). Last edit at 02/25/2014 12:18PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: Replacement Fan Duct/Heatsink Duct - iamburny  February 25, 2014 12:44PM |

Registered: 10 years ago Posts: 578 |

Hi dc42 - that's brilliant - I've run some manual tests and it's working perfectly, I've set it to P255 and about to run a Cura-sliced file (which uses that range). Of course there's one extra snag I forgot to mention... Where to house the damned fan  I'll have a go tonight at editing an stl for the x-carriage to add a bracket near to the rear support bearing for a 40mm fan (angled at around 5 degrees from horizontal it should be a suitable place, though it may affect X homing...) - I'll post a copy of the stl/design files if it works.

I'll have a go tonight at editing an stl for the x-carriage to add a bracket near to the rear support bearing for a 40mm fan (angled at around 5 degrees from horizontal it should be a suitable place, though it may affect X homing...) - I'll post a copy of the stl/design files if it works.

Thanks,

Ray

I'll have a go tonight at editing an stl for the x-carriage to add a bracket near to the rear support bearing for a 40mm fan (angled at around 5 degrees from horizontal it should be a suitable place, though it may affect X homing...) - I'll post a copy of the stl/design files if it works.

I'll have a go tonight at editing an stl for the x-carriage to add a bracket near to the rear support bearing for a 40mm fan (angled at around 5 degrees from horizontal it should be a suitable place, though it may affect X homing...) - I'll post a copy of the stl/design files if it works.Thanks,

Ray

Re: Replacement Fan Duct/Heatsink Duct - iamburny  February 25, 2014 01:06PM |

Registered: 10 years ago Posts: 578 |

dc42 - The Cura slicing test worked a treat - I had to set the minimum fan speed to around 50% on mine (the fan I'm testing with is a random northbridge fan and only whistles/wibbles with pwm set to 75/255), time for me to go home, but I'll have a go at making a fan mount tonight as I said, and also try out Slic3r's heat control tomorrow,

cheers

Ray

cheers

Ray

Re: Replacement Fan Duct/Heatsink Duct - iamburny  February 25, 2014 01:07PM |

Registered: 10 years ago Posts: 578 |

Re: Replacement Fan Duct/Heatsink Duct - iamburny  February 25, 2014 02:06PM |

Registered: 10 years ago Posts: 14,672 |

Quote

rayhicks

PS don't these little fans have controllers in them that cater for flyback?

Ray

I expect they do. The 50V spikes are only a few microseconds long, but I was surprised to see them. The fan current is much less than the heater currents, so I wasn't expecting the wiring inductance to be sufficient to provoke an inductive spike.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: Replacement Fan Duct/Heatsink Duct - iamburny  February 25, 2014 02:45PM |

Registered: 10 years ago Posts: 2,472 |

Quote

rayhicks

Yes Dave - I'm talking about the provision on the board for a print cooling fan, not the extruder cooler which is just connected to 12V - the ouputs are labelled "fan0" on the board, they're just next to the extruder, and it's there as a slicer controlled fan (by inserting M106 Sxxx through out the gcode)

Ray

Oh right! Looks like I completely misunderstood what you're doing, sorry. Looks like it needs a firmware change in that case if you need to control the speed. For just on/off control a clunky fix would be to run the G code through a text editor and do a search & replace on the relevant command lines.

Dave

(#106)

Re: Replacement Fan Duct/Heatsink Duct - iamburny  February 25, 2014 04:55PM |

Registered: 10 years ago Posts: 578 |

Hi Dave - yes I noticed the crossed purpose there The pin that was meant to allow PWM of a print cooling fan wasn't, I looked at the code and was baffled by pin assignments, but dc42 rose to the challenge and fixed it - so now using slic3r or cura we can control a fan whose sole purpose is to help bridging/cool the print on fast layers (actually cura's advanced and expert settings allow very good tuning of cooling and layer speed to help with the latter issue). I brought it up in this thread since dc42 was concerned about bridging when using Matt's new duct, and you were discussing workarounds to slow down layers to allow sufficient cooling - I should have started a new thread that explained the purpose better.

The pin that was meant to allow PWM of a print cooling fan wasn't, I looked at the code and was baffled by pin assignments, but dc42 rose to the challenge and fixed it - so now using slic3r or cura we can control a fan whose sole purpose is to help bridging/cool the print on fast layers (actually cura's advanced and expert settings allow very good tuning of cooling and layer speed to help with the latter issue). I brought it up in this thread since dc42 was concerned about bridging when using Matt's new duct, and you were discussing workarounds to slow down layers to allow sufficient cooling - I should have started a new thread that explained the purpose better.

Cheers

Ray

Edited 1 time(s). Last edit at 02/25/2014 04:56PM by rayhicks.

The pin that was meant to allow PWM of a print cooling fan wasn't, I looked at the code and was baffled by pin assignments, but dc42 rose to the challenge and fixed it - so now using slic3r or cura we can control a fan whose sole purpose is to help bridging/cool the print on fast layers (actually cura's advanced and expert settings allow very good tuning of cooling and layer speed to help with the latter issue). I brought it up in this thread since dc42 was concerned about bridging when using Matt's new duct, and you were discussing workarounds to slow down layers to allow sufficient cooling - I should have started a new thread that explained the purpose better.

The pin that was meant to allow PWM of a print cooling fan wasn't, I looked at the code and was baffled by pin assignments, but dc42 rose to the challenge and fixed it - so now using slic3r or cura we can control a fan whose sole purpose is to help bridging/cool the print on fast layers (actually cura's advanced and expert settings allow very good tuning of cooling and layer speed to help with the latter issue). I brought it up in this thread since dc42 was concerned about bridging when using Matt's new duct, and you were discussing workarounds to slow down layers to allow sufficient cooling - I should have started a new thread that explained the purpose better.Cheers

Ray

Edited 1 time(s). Last edit at 02/25/2014 04:56PM by rayhicks.

Re: Replacement Fan Duct/Heatsink Duct - iamburny  February 26, 2014 07:39AM |

Registered: 10 years ago Posts: 2,472 |

Quote

dc42

Quote

rayhicks

PS don't these little fans have controllers in them that cater for flyback?

Ray

I expect they do. The 50V spikes are only a few microseconds long, but I was surprised to see them. The fan current is much less than the heater currents, so I wasn't expecting the wiring inductance to be sufficient to provoke an inductive spike.

Surely it's the much higher inductance of the fan motor windings rather than the wiring inductance that's the culprit in this case? I've not looked into the design of cooling fans, but I see that many have a 3rd wire which I assume outputs a signal from the fan's internal brushless controller with a frequency proportional to the fan speed. I suppose it would be possible to feed that signal back to the Duet and adjust the PWM output to allow the set value to determine the actual fan speed so that all values in the range can be used and the fan is never in a stalled condition at low settings. Probably extreme over-kill, but maybe a fun bit of programming to give really first-class functionality.

Dave

(#106)

Re: Replacement Fan Duct/Heatsink Duct - iamburny  February 26, 2014 07:58AM |

Registered: 10 years ago Posts: 14,672 |

Quote

dmould

Surely it's the much higher inductance of the fan motor windings rather than the wiring inductance that's the culprit in this case?

You could be right, but I would expect the inductive spikes to last much longer than 5us if this was the cause.

Quote

dmould

I've not looked into the design of cooling fans, but I see that many have a 3rd wire which I assume outputs a signal from the fan's internal brushless controller with a frequency proportional to the fan speed. I suppose it would be possible to feed that signal back to the Duet and adjust the PWM output to allow the set value to determine the actual fan speed so that all values in the range can be used and the fan is never in a stalled condition at low settings. Probably extreme over-kill, but maybe a fun bit of programming to give really first-class functionality.

PWM control of the supply voltage to brushless fans is far from ideal and doesn't provide a good range of speed control. It's much better to use 4-wire PC fans. These have a separate PWM input. The Intel specification for them calls for a minimum speed no greater than 30% of the maximum speed.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: Replacement Fan Duct/Heatsink Duct - iamburny  February 26, 2014 10:17AM |

Registered: 10 years ago Posts: 2,472 |

Quote

dc42

You could be right, but I would expect the inductive spikes to last much longer than 5us if this was the cause.Quote

dmould

Surely it's the much higher inductance of the fan motor windings rather than the wiring inductance that's the culprit in this case?

speed.

Possibly most of the spike is supressed with a diode (or similar) in the controller, but the very start of the spike gets through due to the switching delay of the diode, which is elongated to 5uS by stray capacitance & inductance? You could probably kill something that short better with a low value series resistor and capacitor than a diode, though a diode is always a good safety measure.

On a different but somewhat related issue, I was amused to see that with everything switched off, the fan of the PC PSU would turn if I moved the X or Y carriage by hand at a moderate speed. Then I started wondering whether power generated by the steppers that was sufficient to turn the fan via the 12V rail could cause damage to the Duet, so now I am careful not to manually move any of the motors fast.

--

Cynic

Re: Replacement Fan Duct/Heatsink Duct - iamburny  February 28, 2014 06:54AM |

Registered: 10 years ago Posts: 22 |

Ray,

I'd like to test this feature so I've connected an auxiliary fan to the FAN0 output.

I'm trying now to use Cura but I can not get a proper slicing (i think that extruded filament is much more than it should be).

Can you share your settings for Cura or give me advice ?

Thanks.

Roberto

RS Ormerod #117

I'd like to test this feature so I've connected an auxiliary fan to the FAN0 output.

I'm trying now to use Cura but I can not get a proper slicing (i think that extruded filament is much more than it should be).

Can you share your settings for Cura or give me advice ?

Thanks.

Roberto

RS Ormerod #117

Re: Replacement Fan Duct/Heatsink Duct - iamburny  February 28, 2014 07:18AM |

Registered: 10 years ago Posts: 578 |

Hi Roberto,

I'm using Frank's first plugin for Cura [forums.reprap.org] (which allows relative extrusions), but with my own settings - I've exported the profile and attached it here (this is from the mac version, but it should import OK in to other versions, use File->Open Profile... to use it I think).cura_settings_rh.ini

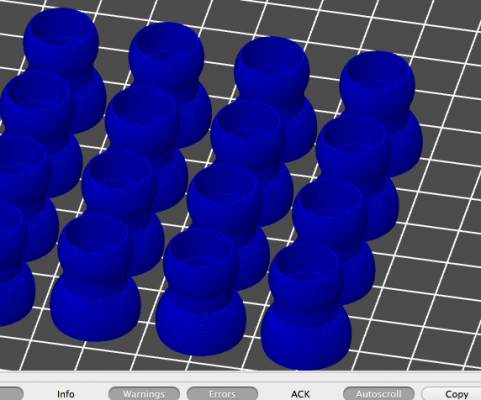

It's not easy to find a place for a fan to sit that doesn't obstruct things - initially I thought one could hang off the X carriage at an angle, but it's hard to find a place where it will not catch the extruder when X moves (or worse catch the print!) - I'm going to try using a hose (I've printed some segments that will interlock, to make a hose, but they may not move freely enough - I should be testing them today) - something like a vacuum cleaner hose might work, but they tend to be quiet stiff and springy, the interlocking parts aren't springy, but may be stiff if not smoothed by sanding, which is tedious They leak a little, but seem to be able to deliver the majority of air blown in at one end to the other end, I need to make a fan adapter and a nozzle for mounting near to the hotend to test it fully... this is what the links look like :

They leak a little, but seem to be able to deliver the majority of air blown in at one end to the other end, I need to make a fan adapter and a nozzle for mounting near to the hotend to test it fully... this is what the links look like :

Cheers

Ray

I'm using Frank's first plugin for Cura [forums.reprap.org] (which allows relative extrusions), but with my own settings - I've exported the profile and attached it here (this is from the mac version, but it should import OK in to other versions, use File->Open Profile... to use it I think).cura_settings_rh.ini

It's not easy to find a place for a fan to sit that doesn't obstruct things - initially I thought one could hang off the X carriage at an angle, but it's hard to find a place where it will not catch the extruder when X moves (or worse catch the print!) - I'm going to try using a hose (I've printed some segments that will interlock, to make a hose, but they may not move freely enough - I should be testing them today) - something like a vacuum cleaner hose might work, but they tend to be quiet stiff and springy, the interlocking parts aren't springy, but may be stiff if not smoothed by sanding, which is tedious

They leak a little, but seem to be able to deliver the majority of air blown in at one end to the other end, I need to make a fan adapter and a nozzle for mounting near to the hotend to test it fully... this is what the links look like :

They leak a little, but seem to be able to deliver the majority of air blown in at one end to the other end, I need to make a fan adapter and a nozzle for mounting near to the hotend to test it fully... this is what the links look like :

Cheers

Ray

Re: Replacement Fan Duct/Heatsink Duct - iamburny  February 28, 2014 07:34AM |

Registered: 10 years ago Posts: 256 |

Quote

rayhicks

Hi Roberto,

I'm using Frank's first plugin for Cura [forums.reprap.org] (which allows relative extrusions), but with my own settings - I've exported the profile and attached it here (this is from the mac version, but it should import OK in to other versions, use File->Open Profile... to use it I think).[attachment 27611 cura_settings_rh.ini]

It's not easy to find a place for a fan to sit that doesn't obstruct things - initially I thought one could hang off the X carriage at an angle, but it's hard to find a place where it will not catch the extruder when X moves (or worse catch the print!) - I'm going to try using a hose (I've printed some segments that will interlock, to make a hose, but they may not move freely enough - I should be testing them today) - something like a vacuum cleaner hose might work, but they tend to be quiet stiff and springy, the interlocking parts aren't springy, but may be stiff if not smoothed by sanding, which is tediousThey leak a little, but seem to be able to deliver the majority of air blown in at one end to the other end, I need to make a fan adapter and a nozzle for mounting near to the hotend to test it fully... this is what the links look like :[attachment 27612 hose.jpg]

Cheers

Ray

And if it doesnt work out you will hve some great looking eggg cups

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

Re: Replacement Fan Duct/Heatsink Duct - iamburny  February 28, 2014 07:58AM |

Registered: 10 years ago Posts: 578 |

@Andy, hehe maybe for very small quail's eggs, or large frogspawn

@Roberto - note that I don't have temperatures set in the ini (so I can use the same gcode for different materials) - you'll need to manually set those yourself, also I'm uploading the cura gcodes to SD card and running them with my usual host (repetier for mac),

Cheers

Ray

@Roberto - note that I don't have temperatures set in the ini (so I can use the same gcode for different materials) - you'll need to manually set those yourself, also I'm uploading the cura gcodes to SD card and running them with my usual host (repetier for mac),

Cheers

Ray

Re: Replacement Fan Duct/Heatsink Duct - iamburny  February 28, 2014 09:16AM |

Registered: 10 years ago Posts: 2,472 |

I certainly need to do something about cooling for bridges. I've just thrown away my 3rd attempt to print a part with a 15mm diameter horizontal hole. When it gets up to the layers where the sides of the hole are rapidly closing and it makes a fill area ready to bridge, the edges begin curling upward and eventually catch the nozzle during a move and make the Y motor miss a step. I am desperately trying to push and file down the raised plastic as it gets to the critical 3 layers, but it is quite a small print and there is not a lot of opportunity to get in with a file while the head is out of the way! If I don't succeed with the current print, I'll rig up a spare fan and use it handheld to see if that provides a temporary fix.

Dave

(#106)

Dave

(#106)

Sorry, only registered users may post in this forum.