Can someone explain how to avoid this happening

Posted by alanbattersby

|

Can someone explain how to avoid this happening February 13, 2014 10:31AM |

Registered: 10 years ago Posts: 55 |

Hi,

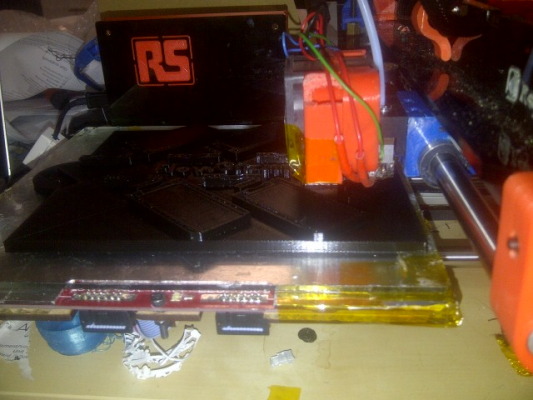

The part shown below is 150 mm long so nearly the length of the bed. As you see from the attached image, part of the base at one corner has distorted. I am just printing it again and the same thing is happening. How can I mitigate/ remove this effect? Usually the (much smaller) bits I have made so far stick quite firmly to the bed. The bed of my machine is mechanically leveled using the lengthened bolts as mentioned on the web site. I am using the standard ormerod settings in slic3r what should I change ? Would leaving the bed temperature high for the first dozen or so layers help in this situation?

Alan

The part shown below is 150 mm long so nearly the length of the bed. As you see from the attached image, part of the base at one corner has distorted. I am just printing it again and the same thing is happening. How can I mitigate/ remove this effect? Usually the (much smaller) bits I have made so far stick quite firmly to the bed. The bed of my machine is mechanically leveled using the lengthened bolts as mentioned on the web site. I am using the standard ormerod settings in slic3r what should I change ? Would leaving the bed temperature high for the first dozen or so layers help in this situation?

Alan

|

Re: Can someone explain how to avoid this happening February 13, 2014 10:42AM |

Registered: 10 years ago Posts: 578 |

Hi Alan - that kind of warping normally happens when the upper layers contract and they pull the bottom layer off the plate - it happens more readily with ABS, but still happens with PLA - the large PLA prints I do are shallower than yours, but a bit longer and I don't get warping - I keep the bed at 60 throughout and print on pipe cement.

Do you have backwash from your fan? markbee noticed this a while back and this thread has a few fixes [forums.reprap.org]

Cheers

Ray

Do you have backwash from your fan? markbee noticed this a while back and this thread has a few fixes [forums.reprap.org]

Cheers

Ray

|

Re: Can someone explain how to avoid this happening February 13, 2014 10:52AM |

Registered: 10 years ago Posts: 55 |

Thanks,

I have not made any fixes to the fan. But part that is lifting is at the rear of the table behind the extruder, nowhere near the fan. Attached image is currently printing as you see the same thing happens. Funnily enough the skirt is firmly attached to the bed. I also do not know the how you would go about using pipe cement. Where do you get it from? Do you just paint it on the bed?

Alan

I have not made any fixes to the fan. But part that is lifting is at the rear of the table behind the extruder, nowhere near the fan. Attached image is currently printing as you see the same thing happens. Funnily enough the skirt is firmly attached to the bed. I also do not know the how you would go about using pipe cement. Where do you get it from? Do you just paint it on the bed?

Alan

|

Re: Can someone explain how to avoid this happening February 13, 2014 11:13AM |

Registered: 10 years ago Posts: 46 |

Try adding a brim in Slic3r -- 5mm helped a lot with this kind of problem on my prints, and generally comes off the finished print nicely.

Also, orienting the object in the other direction might make a difference. I'm thinking that even if this end is away from the fan, the air getting past the nozzle could pass it after a while.

/Allan

Also, orienting the object in the other direction might make a difference. I'm thinking that even if this end is away from the fan, the air getting past the nozzle could pass it after a while.

/Allan

|

Re: Can someone explain how to avoid this happening February 13, 2014 11:27AM |

Registered: 10 years ago Posts: 578 |

I use Marley KS10 Solvent Cement - I use the provided applicator to spread it directly on the glass - after removing the kapton (dc42 and dmould have also adopted this for some purposes), dmould uses a "credit card" to squeegy it on. You should be able to get it anywhere that sells plumbing (B&Q, PlumbCentre etc)

it does look like the wrong side for backwash to be causing it - Is there a draught on the right side of the bed? If you're using PLA I wouldn't expect that it would warp so much or at such a low print height without a draught (you clean the kapton with isopropanol or acetone first, right?). ABS tends to warp at that height though.

I've attached a picture of my current print to show how the PLA is printing on mine with a 60°C bed temp, 195°C nozzle, and no draughts - it's 185 along Y and 160 wide

- it's 185 along Y and 160 wide

cheers

ray

it does look like the wrong side for backwash to be causing it - Is there a draught on the right side of the bed? If you're using PLA I wouldn't expect that it would warp so much or at such a low print height without a draught (you clean the kapton with isopropanol or acetone first, right?). ABS tends to warp at that height though.

I've attached a picture of my current print to show how the PLA is printing on mine with a 60°C bed temp, 195°C nozzle, and no draughts

- it's 185 along Y and 160 wide

- it's 185 along Y and 160 widecheers

ray

|

Re: Can someone explain how to avoid this happening February 13, 2014 11:40AM |

Registered: 10 years ago Posts: 55 |

Thanks,

I do clean the kapton tape with acetone before a print and unfortunately my house is full of draughts. Fortunately the part I am printing only needs to sit flush on the side that is not warped as it is to be bolted onto a piece of 20x80 aluminium section and the warped side overhangs the section. So the part is useable just asking for the future. My son seems to think that an enclosure is the way to go any thoughts on that?

Alan

Edited 1 time(s). Last edit at 02/13/2014 11:46AM by alanbattersby.

I do clean the kapton tape with acetone before a print and unfortunately my house is full of draughts. Fortunately the part I am printing only needs to sit flush on the side that is not warped as it is to be bolted onto a piece of 20x80 aluminium section and the warped side overhangs the section. So the part is useable just asking for the future. My son seems to think that an enclosure is the way to go any thoughts on that?

Alan

Edited 1 time(s). Last edit at 02/13/2014 11:46AM by alanbattersby.

|

Re: Can someone explain how to avoid this happening February 17, 2014 01:00PM |

Registered: 10 years ago Posts: 2,472 |

As others have said, draughts are a major cause of warping. Put something around the machine to keep them out - I've put a bin bag over the whole machine before now, though you need to ensure it doesn't get too hot inside if you do the same and you are still using the original PLA parts. You really should print one of the fan deflectors to stop warps due to fan bachwash. I print ABS, and have blocked off the air outlets at the bottom of the heatsink enclosure (and cut a hole in the top so there is still airflow across the heatsink), which helped tremendously with warping and delamination. I also drop the bed temperature by 10 degrees after the first layer.

If you use solvent cement direct on the glass instead of Kapton tape (highly recommended), my new method is to dilute it a lot with acetone until it is watery, then brush it on with the supplied applicator. That way you don't get many brush strokes and it dries to a very thin coat. It also saves a lot of money! (That glue is expensive). In the UK go to a hardware shop such as B&Q and ask at the counter for "solvent cement". They keep it behind the counter in the UK because of solvent abuse issues. I believe that you can also dissolve bits of ABS filament in acetone to do the same thing, which I may try after I run out of diluted cement, but I expect it will have to be heated to get it to dissolve reasonably quickly. Acetone is highly inflammable. The glue comes off with the print, but you can simply patch up that area - no need to re-coat the entire glass until it becomes very uneven. To strip off all the glue from the glass, just hold it under a running hot tap and give it a rub - it comes off readily.

Dave

(#106)

If you use solvent cement direct on the glass instead of Kapton tape (highly recommended), my new method is to dilute it a lot with acetone until it is watery, then brush it on with the supplied applicator. That way you don't get many brush strokes and it dries to a very thin coat. It also saves a lot of money! (That glue is expensive). In the UK go to a hardware shop such as B&Q and ask at the counter for "solvent cement". They keep it behind the counter in the UK because of solvent abuse issues. I believe that you can also dissolve bits of ABS filament in acetone to do the same thing, which I may try after I run out of diluted cement, but I expect it will have to be heated to get it to dissolve reasonably quickly. Acetone is highly inflammable. The glue comes off with the print, but you can simply patch up that area - no need to re-coat the entire glass until it becomes very uneven. To strip off all the glue from the glass, just hold it under a running hot tap and give it a rub - it comes off readily.

Dave

(#106)

|

Re: Can someone explain how to avoid this happening February 17, 2014 01:51PM |

Registered: 10 years ago Posts: 14,672 |

@dmould, what dilution factor do you use when you dilute the solvent cement with acetone?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Can someone explain how to avoid this happening February 17, 2014 02:26PM |

Registered: 10 years ago Posts: 2,472 |

I didn't measure, but I had about a quarter of a can of glue left and topped it up nearly full with acetone, so probably close to 3:1 (acetone:glue). I don't think it matters much - you don't need a lot of plastic remaining after the acetone has evaporated to make the print stick so you can make it very watery. Shake and stir it well after adding the acetone.Quote

dc42

@dmould, what dilution factor do you use when you dilute the solvent cement with acetone?

Dave

(#106)

|

Re: Can someone explain how to avoid this happening February 17, 2014 05:44PM |

Registered: 10 years ago Posts: 14,672 |

Thanks Dave, I'll try that.

btw someone else said that they use PVA adhesive diluted with water for the same purpose. Have you tried that? I imagine it takes longer to dry, but if the bed is heated to 60C or more before applying it, perhaps it doesn't take too long.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

btw someone else said that they use PVA adhesive diluted with water for the same purpose. Have you tried that? I imagine it takes longer to dry, but if the bed is heated to 60C or more before applying it, perhaps it doesn't take too long.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Can someone explain how to avoid this happening February 17, 2014 05:48PM |

Registered: 10 years ago Posts: 265 |

I use 50/50 PVA and water, works great direct on glass, sometimes a bit too well so i may reduce the mixture to 40/60.

The kids wont be happy when they find out i've raided there modelling supplies!!

Matt

Edited 1 time(s). Last edit at 02/17/2014 05:49PM by iamburny.

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

The kids wont be happy when they find out i've raided there modelling supplies!!

Matt

Edited 1 time(s). Last edit at 02/17/2014 05:49PM by iamburny.

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

|

Re: Can someone explain how to avoid this happening February 17, 2014 06:56PM |

Registered: 10 years ago Posts: 859 |

Hmmmm I like the idea of using PVA... I use it watered down with tap water, and a drop of washing up liquid (a drop, no more than two) to ballast model railway tracks. The washing up liquid stops the surface tension so it should spread better. Never tried it on glass, but will tomorrow if I can get ashore. Having a devil of a job to get the plastic to stick on the first layer at the moment. I think I need to wash the glass again, before the acetone and vinegar... But it's been to rough to print the last couple of days. My printer was printing a treat, then all of a suddenly it start it messing around on the first layer....Grrrrrrrrrrrrrrrrr!

As for the Warping, as a temp fix, I've gaffer taped a piece of flat plastic across about the bottom 1/3 of the fan (the fan not being a positive displacement pump will just speed up, and draw less current...there's enough air to cool what we have still going through), and I plugged the hole in front of the HotEnd with gaffer tape. I also found I'd increased the INFILL in Slic3r to 0.75 and had bad warping on a long print. So have reset the INFILL to 0.4, but not had a chance to try it out due to the rough weather.

(We're bouncing about abit this week.... Oh for an Office job... And why do tankers have to come in the middle of the night...).

If any one has the RS Number for a quiet fan replacement could they PM me please.... Thanks

As for the Warping, as a temp fix, I've gaffer taped a piece of flat plastic across about the bottom 1/3 of the fan (the fan not being a positive displacement pump will just speed up, and draw less current...there's enough air to cool what we have still going through), and I plugged the hole in front of the HotEnd with gaffer tape. I also found I'd increased the INFILL in Slic3r to 0.75 and had bad warping on a long print. So have reset the INFILL to 0.4, but not had a chance to try it out due to the rough weather.

(We're bouncing about abit this week.... Oh for an Office job... And why do tankers have to come in the middle of the night...).

If any one has the RS Number for a quiet fan replacement could they PM me please.... Thanks

|

Re: Can someone explain how to avoid this happening February 17, 2014 07:12PM |

Registered: 10 years ago Posts: 578 |

@Kim It's bad enough being landlocked in the middle of the country for me - must be a nightmare at sea -Fingers crossed for the next print!

I'm pretty sure that your reasoning is right about the fan taping - I've had a bit of tape over the bottom of mine for a month or so now and it works a treat - also you're probably right on the infill, it's the vertical surfaces shrinking that pull the bottom horizontal surface up, and it's worse at corners where there are two sets of walls retracting, the same, I imagine goes for infill ( for my big flat prints I use 20-25% infill and I don't get the corners or sides lifting at all with PLA, and only slightly with ABS),

Cheers

Ray

I'm pretty sure that your reasoning is right about the fan taping - I've had a bit of tape over the bottom of mine for a month or so now and it works a treat - also you're probably right on the infill, it's the vertical surfaces shrinking that pull the bottom horizontal surface up, and it's worse at corners where there are two sets of walls retracting, the same, I imagine goes for infill ( for my big flat prints I use 20-25% infill and I don't get the corners or sides lifting at all with PLA, and only slightly with ABS),

Cheers

Ray

|

Re: Can someone explain how to avoid this happening February 17, 2014 07:22PM |

Registered: 10 years ago Posts: 859 |

As far as bobbing up and down is concerned. We're working flat out at the moment bringing oil tankers in and out.

I'm just glad we only have to go out 3 or 4 miles out, as the Atlantic is pretty 'orrible at the moment.

Just going to try and print a fan cowling if I can remember were I saw one, if I can keep the printer on my desk here that is....

I'm just glad we only have to go out 3 or 4 miles out, as the Atlantic is pretty 'orrible at the moment.

Just going to try and print a fan cowling if I can remember were I saw one, if I can keep the printer on my desk here that is....

|

Re: Can someone explain how to avoid this happening February 18, 2014 10:44AM |

Registered: 10 years ago Posts: 103 |

Hi Alan,

I can count warped parts on one hand, exclusively with black and white filaments. No other colour has ever failed. My print room is cold and draughty. I print on kapton cleaned each time with acetone. I have no time to mess with cement, PVA or else. I have not modified my fan for backwash as I have no need to do so.

You should watch the first layer print and make sure that the nozzle is close enough to the bed, especially if you bed is not perfectly level (0.1mm is not perfectly level if like me you run with no bed compensation). Each time the black and white filaments have warped was because one side of the bed was 0.1mm lower than the other and the nozzle not quite close enough, the extruded first layer does not get "squashed" on plate by nozzle and therefore does not stick very well.

Also, something to remember: having now printed just over 8kg of PLA from 3 different suppliers, I would say that not all PLA is equal and not all colour is equal either. The mistake I made was to buy several colours (9 different colours from 3 different suppliers), almost each colour requires different settings in slic3r, for temperature but also for extrusion width. All print without warping but the surface finish (perimeters and top infill) are very different even if I print the very same g-file with different color of the same supplier.

I can count warped parts on one hand, exclusively with black and white filaments. No other colour has ever failed. My print room is cold and draughty. I print on kapton cleaned each time with acetone. I have no time to mess with cement, PVA or else. I have not modified my fan for backwash as I have no need to do so.

You should watch the first layer print and make sure that the nozzle is close enough to the bed, especially if you bed is not perfectly level (0.1mm is not perfectly level if like me you run with no bed compensation). Each time the black and white filaments have warped was because one side of the bed was 0.1mm lower than the other and the nozzle not quite close enough, the extruded first layer does not get "squashed" on plate by nozzle and therefore does not stick very well.

Also, something to remember: having now printed just over 8kg of PLA from 3 different suppliers, I would say that not all PLA is equal and not all colour is equal either. The mistake I made was to buy several colours (9 different colours from 3 different suppliers), almost each colour requires different settings in slic3r, for temperature but also for extrusion width. All print without warping but the surface finish (perimeters and top infill) are very different even if I print the very same g-file with different color of the same supplier.

|

Re: Can someone explain how to avoid this happening February 18, 2014 11:32AM |

Registered: 10 years ago Posts: 55 |

|

Re: Can someone explain how to avoid this happening February 18, 2014 12:05PM |

Registered: 10 years ago Posts: 103 |

Sorry, only registered users may post in this forum.