My first mod - new Z axis leadscrew

Posted by epninety

|

My first mod - new Z axis leadscrew February 16, 2014 06:50PM |

Registered: 10 years ago Posts: 44 |

I've had my Ormerod up and running for about a month, and despite not making heavy use of it, I was starting to detect ugly warning signs in the Z axis - metal dust, visible wear in the threads, noise etc., so I decided to try fixing it before it broke...

ebay provided a length of 8mm trapezoidal leadscrew and a matching bronze nut for about £30 quid delivered.

I reprinted iamburnys' double helix Z gears, with small mods to accomodate the larger screw size. I sized the centre hole to be the same as the thread root of the leadscrew. Then by gently warming the leadscrew in a gas flame, it was easy to thread the gear straight onto the end of the leadscrew. (Sometimes the low melting point of PLA is an advantage!)

The Z axis nut trap needed serious mods, so after some careful measurements, I drew up a new one from scratch and printed it. Luckily it fitted first time.

The bronze nut has some serious backlash, but that's not too much of a problem for the Z axis where gravity holds the system in tension, as long as everything moves smoothly.

The 'gearing' is now obviously wrong, but the M92 (steps / unit for each axis) command sorts that one out.

I've only tried one print so far - the Single Wall Alignment Test at 50% scale and 0.12mm layer height as iamburny mentioned in his thread and it looks pretty good to me.

It's not finished as yet, only friction stops the cylindrical Z nut from rotating, and I've done nothing about the backlash, but I thought it was a positive start.

Dave

ebay provided a length of 8mm trapezoidal leadscrew and a matching bronze nut for about £30 quid delivered.

I reprinted iamburnys' double helix Z gears, with small mods to accomodate the larger screw size. I sized the centre hole to be the same as the thread root of the leadscrew. Then by gently warming the leadscrew in a gas flame, it was easy to thread the gear straight onto the end of the leadscrew. (Sometimes the low melting point of PLA is an advantage!)

The Z axis nut trap needed serious mods, so after some careful measurements, I drew up a new one from scratch and printed it. Luckily it fitted first time.

The bronze nut has some serious backlash, but that's not too much of a problem for the Z axis where gravity holds the system in tension, as long as everything moves smoothly.

The 'gearing' is now obviously wrong, but the M92 (steps / unit for each axis) command sorts that one out.

I've only tried one print so far - the Single Wall Alignment Test at 50% scale and 0.12mm layer height as iamburny mentioned in his thread and it looks pretty good to me.

It's not finished as yet, only friction stops the cylindrical Z nut from rotating, and I've done nothing about the backlash, but I thought it was a positive start.

Dave

|

Re: My first mod - new Z axis leadscrew February 16, 2014 08:53PM |

Registered: 10 years ago Posts: 176 |

|

Re: My first mod - new Z axis leadscrew February 17, 2014 05:29AM |

Registered: 10 years ago Posts: 578 |

looking good epninety,

if you're worried about the backlash (but I don't think you should be for Z since as you pointed out it's preloaded by the weight of the X axis boom and only the upper surface of the thread is used), you could use (a little more) heat to thermoform a thread in an acetal/delrin nut like this [bbs.homeshopmachinist.net].

To prevent the cylindrical nut from rotating (more of a problem), you could file one or more flats on it, and modify your trap to hold against the flat/s, or you could drill down though the top of the nut trap into the top of the nut to form a dimple, then use a self tapping screw through the plastic and into the dimple to hold it still,

Ray

if you're worried about the backlash (but I don't think you should be for Z since as you pointed out it's preloaded by the weight of the X axis boom and only the upper surface of the thread is used), you could use (a little more) heat to thermoform a thread in an acetal/delrin nut like this [bbs.homeshopmachinist.net].

To prevent the cylindrical nut from rotating (more of a problem), you could file one or more flats on it, and modify your trap to hold against the flat/s, or you could drill down though the top of the nut trap into the top of the nut to form a dimple, then use a self tapping screw through the plastic and into the dimple to hold it still,

Ray

|

Re: My first mod - new Z axis leadscrew February 17, 2014 05:43AM |

Registered: 10 years ago Posts: 132 |

epninety

I have a concern that you have locked the Z nut in top and bottom. The danger is if you drive the Z too low it will force the hot end into the table. With the existing design the nut pops out the bottom and there is no damage done. Apart from that I like it, can you tell me the eBay vendor you bought your rod and nut.

John

I have a concern that you have locked the Z nut in top and bottom. The danger is if you drive the Z too low it will force the hot end into the table. With the existing design the nut pops out the bottom and there is no damage done. Apart from that I like it, can you tell me the eBay vendor you bought your rod and nut.

John

|

Re: My first mod - new Z axis leadscrew February 17, 2014 06:32AM |

Registered: 10 years ago Posts: 44 |

Thanks for the positive comments and ideas

My original plan was to retain the nut with one or more M3 screws tapped into the upper face, running down the Z axis. But when I was measuring and sketching for the new mount I realised I'd prefer the Z nut to be able to move around alittle to ensure the best possible alignment. That could still be done with oversized holes, but I have what I think is a prettier plan... I will move the mounting flanges apart slightly, and groove them to take a couple of O rings to take up the gap. I think that will allow enough freedom to set the alignment and accomodate the inevitable eccentricity, but provide enough resistance that the Z nut won't rotate.

If that doesnt work, then it's time for machined flats or locking screws, or probably just a blob of RTV silicone to persuade it to stay put.

Leadscrew and nut came from these guys

You are right of course, about the danger of crashing the tool into the table - it's a risk I've always lived with in my CNC'd Peatol mill, so I guess I'm more relaxed about it than many. It would be easy to mill flats or a hex into the nut and retain it only at the top, which might solve both problems at once.

EDIT : Forgot to say, only retaining the nut at the top would make assembly much easier too

One thing I think is a glaring omission from probably every 3d printer I've seen is a proper emergency stop button. A reset button inside the box doesn't cut it, nor does a 'pause' button in pronterface that becomes a 'resume' button once clicked

That's probably the next thing I will change. My immediate thought was to mount a button on top of the Z column, but on reflection I want to put the spool holder up there.

Probably not much playtime before next weekend now, but I'll probably have changed the whole plan again by then...

Dave

Edited 1 time(s). Last edit at 02/17/2014 06:36AM by epninety.

My original plan was to retain the nut with one or more M3 screws tapped into the upper face, running down the Z axis. But when I was measuring and sketching for the new mount I realised I'd prefer the Z nut to be able to move around alittle to ensure the best possible alignment. That could still be done with oversized holes, but I have what I think is a prettier plan... I will move the mounting flanges apart slightly, and groove them to take a couple of O rings to take up the gap. I think that will allow enough freedom to set the alignment and accomodate the inevitable eccentricity, but provide enough resistance that the Z nut won't rotate.

If that doesnt work, then it's time for machined flats or locking screws, or probably just a blob of RTV silicone to persuade it to stay put.

Leadscrew and nut came from these guys

You are right of course, about the danger of crashing the tool into the table - it's a risk I've always lived with in my CNC'd Peatol mill, so I guess I'm more relaxed about it than many. It would be easy to mill flats or a hex into the nut and retain it only at the top, which might solve both problems at once.

EDIT : Forgot to say, only retaining the nut at the top would make assembly much easier too

One thing I think is a glaring omission from probably every 3d printer I've seen is a proper emergency stop button. A reset button inside the box doesn't cut it, nor does a 'pause' button in pronterface that becomes a 'resume' button once clicked

That's probably the next thing I will change. My immediate thought was to mount a button on top of the Z column, but on reflection I want to put the spool holder up there.

Probably not much playtime before next weekend now, but I'll probably have changed the whole plan again by then...

Dave

Edited 1 time(s). Last edit at 02/17/2014 06:36AM by epninety.

|

Re: My first mod - new Z axis leadscrew February 17, 2014 12:57PM |

Registered: 10 years ago Posts: 265 |

Very Nice!

Lovely work Dave, and a fantastic resulting print, did you have any trouble centering the threaded rod in the Z-gear?

like the blue too

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Lovely work Dave, and a fantastic resulting print, did you have any trouble centering the threaded rod in the Z-gear?

like the blue too

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

|

Re: My first mod - new Z axis leadscrew February 17, 2014 01:34PM |

Registered: 10 years ago Posts: 44 |

Thanks Matt

No problem centering it - the original M5 nut is 8mm across the flats, so it serves as a handy guide to get the screw initially started.

I modified your gear design to reduce the depth of the hex hole (to get maximum thread engagement), and opened the centre borehole out to 7mm (the root thread size). I'd open it out to 7.5mm next time so the melted plastic has somewhere to go. It pretty much screwed on straight away, then before it cooled too much I backed the Z nut up against it to keep it straight. I think the key is to use the least heat possible to get the job done, so things don't get too floppy.

It has a very slight wobble, but no worse than I had with the original setup, and of course that could be improved with a little gentle attention from a small blowtorch.

The best bit of course, is that if it all goes wrong... just print another one

Dave

No problem centering it - the original M5 nut is 8mm across the flats, so it serves as a handy guide to get the screw initially started.

I modified your gear design to reduce the depth of the hex hole (to get maximum thread engagement), and opened the centre borehole out to 7mm (the root thread size). I'd open it out to 7.5mm next time so the melted plastic has somewhere to go. It pretty much screwed on straight away, then before it cooled too much I backed the Z nut up against it to keep it straight. I think the key is to use the least heat possible to get the job done, so things don't get too floppy.

It has a very slight wobble, but no worse than I had with the original setup, and of course that could be improved with a little gentle attention from a small blowtorch.

The best bit of course, is that if it all goes wrong... just print another one

Dave

|

Re: My first mod - new Z axis leadscrew February 17, 2014 01:54PM |

Registered: 10 years ago Posts: 2,472 |

Quote

epninety

One thing I think is a glaring omission from probably every 3d printer I've seen is a proper emergency stop button. A reset button inside the box doesn't cut it, nor does a 'pause' button in pronterface that becomes a 'resume' button once clicked

That's probably the next thing I will change. My immediate thought was to mount a button on top of the Z column, but on reflection I want to put the spool holder up there.

Dave

The mains switch on the 12V PSU acts as a pretty good emergency stop ... You could feed the PSU via a relay controlled with a traditional red mushroom button.

Dave

(#106)

|

Re: My first mod - new Z axis leadscrew February 17, 2014 02:10PM |

Registered: 10 years ago Posts: 44 |

Thinking along similar lines ... The PS_ON# signal on the PSU loom is pulled low (to ground) to turn the PSU on, and pulled high (to 3.3V) internally in the PSU. There's no particular spec on the response time, or the energy available at switch off, but it should be adequate for an e-stop. Maybe time for an experiment this evening...

Dave

Dave

|

Re: My first mod - new Z axis leadscrew February 19, 2014 08:51AM |

Registered: 10 years ago Posts: 300 |

Rest assured - there's precious little of that!Quote

epninety

...or the energy available at switch off...

Dave

From what I've seen with the Alpine PSU, even with both heaters off, the reservoir caps barely hold up for a missing mains cycle. With the bed heater on, it's down within a millisecond or two.

I've not looked at the PS_ON# response but it's almost certainly equivalent to disconnecting the mains supply.

RS Components Reprap Ormerod No. 481

|

Re: My first mod - new Z axis leadscrew February 19, 2014 09:16AM |

Registered: 10 years ago Posts: 44 |

|

Re: My first mod - new Z axis leadscrew March 09, 2014 08:35PM |

Registered: 10 years ago Posts: 44 |

Another update just to keep the info in one thread...

johneato commented the Z nut was fully captive and that might cause problems if the Z axis crashed the bed. At the same time, I was looking for a better way to retain the Z nut while allowing for misalignment.

So my next design of Z nut bracket centres the Z nut in an O-ring that happily fits the 45degree bevel on the lead nut. It (the O -ring) is retained on the Z bracket with a couple of drops of superglue. Only gravity and friction holds the lead nut, preventing rotation and keeping it centred.

Seems to work nicely, I completed a couple of prints this evening without issue. You can see from the pen mark it hasn't rotated through the print.

It's still not fully safe, the Z nut is too large to pass the stepper motor in the event it makes a bid for freedom, but at least there is a small safety margin if it all goes wrong. With luck it will spin freely with the shaft once the load is off, but I'm not about to try it.

Dave

Edited 1 time(s). Last edit at 03/09/2014 08:36PM by epninety.

johneato commented the Z nut was fully captive and that might cause problems if the Z axis crashed the bed. At the same time, I was looking for a better way to retain the Z nut while allowing for misalignment.

So my next design of Z nut bracket centres the Z nut in an O-ring that happily fits the 45degree bevel on the lead nut. It (the O -ring) is retained on the Z bracket with a couple of drops of superglue. Only gravity and friction holds the lead nut, preventing rotation and keeping it centred.

Seems to work nicely, I completed a couple of prints this evening without issue. You can see from the pen mark it hasn't rotated through the print.

It's still not fully safe, the Z nut is too large to pass the stepper motor in the event it makes a bid for freedom, but at least there is a small safety margin if it all goes wrong. With luck it will spin freely with the shaft once the load is off, but I'm not about to try it.

Dave

Edited 1 time(s). Last edit at 03/09/2014 08:36PM by epninety.

|

Re: My first mod - new Z axis leadscrew March 10, 2014 03:47AM |

Registered: 10 years ago Posts: 132 |

|

Re: My first mod - new Z axis leadscrew March 11, 2014 09:11AM |

Registered: 10 years ago Posts: 47 |

|

Re: My first mod - new Z axis leadscrew March 11, 2014 12:29PM |

Registered: 10 years ago Posts: 44 |

|

Re: My first mod - new Z axis leadscrew March 12, 2014 07:08AM |

Registered: 10 years ago Posts: 47 |

Tank you Dave,

I have ordered the Z nut and the leadscrew I hope to gain in precision and reliably.

The default leadscrew pitch is 1.5mm?

I'll find this site for steps calculation seem's to be usefully...

Can you post your .stl of z-bracket?

I've got some problem with Z-Axis (as soon as I've ordered the new z rod and nut) occasionally the z-axis threaded rod seems to get stuck and i hear "stumph, stumph, stumph" , but it seems to run well when I try to turn it with my fingers, can be a problem of the duet board or of the motor?

, but it seems to run well when I try to turn it with my fingers, can be a problem of the duet board or of the motor?

Edited 1 time(s). Last edit at 03/12/2014 07:10AM by raffybuffy.

I have ordered the Z nut and the leadscrew I hope to gain in precision and reliably.

The default leadscrew pitch is 1.5mm?

I'll find this site for steps calculation seem's to be usefully...

Can you post your .stl of z-bracket?

I've got some problem with Z-Axis (as soon as I've ordered the new z rod and nut) occasionally the z-axis threaded rod seems to get stuck and i hear "stumph, stumph, stumph"

, but it seems to run well when I try to turn it with my fingers, can be a problem of the duet board or of the motor?

, but it seems to run well when I try to turn it with my fingers, can be a problem of the duet board or of the motor?Edited 1 time(s). Last edit at 03/12/2014 07:10AM by raffybuffy.

|

Re: My first mod - new Z axis leadscrew March 12, 2014 05:20PM |

Registered: 10 years ago Posts: 44 |

|

Re: My first mod - new Z axis leadscrew March 12, 2014 06:32PM |

Registered: 12 years ago Posts: 1,611 |

|

Re: My first mod - new Z axis leadscrew March 13, 2014 10:56AM |

Registered: 10 years ago Posts: 47 |

|

Re: My first mod - new Z axis leadscrew March 13, 2014 12:53PM |

Registered: 10 years ago Posts: 2,472 |

Quote

raffybuffy

Thank you Epinety!!!!

Very good job :-D

@droftarts Thank you also for the explanation!!!!

So the actual steps for mm is 4000 e with the new threaded rod will be 2133.33 a little less accurate.... :-D

But I presume the more accurate mechanical structure and longevity are more important.

If you print something that is 200mm high, it will be too short by just over 0.03mm, so the overall inaccuracy is insignificant.

The only thing you may find is that your prints have a bit of vertical banding unless you deliberately choose a layer thickness that is an exact multiple of 1/2133 mm, because otherwise the firmware will have to make some layers 1 step greater or fewer than other layers so as to get the correct average layer thickness.

Dave

(#106)

|

Re: My first mod - new Z axis leadscrew March 13, 2014 01:41PM |

Registered: 10 years ago Posts: 1,230 |

|

Re: My first mod - new Z axis leadscrew March 14, 2014 03:48AM |

Registered: 10 years ago Posts: 42 |

Quote

raffybuffy

So the actual steps for mm is 4000 e with the new threaded rod will be 2133.33 a little less accurate.... :-D

But I presume the more accurate mechanical structure and longevity are more important.

I'm not sure if raffybuffy is meaning resolution rather than accuracy here. Surely the tolerances on any ormerods manufactured parts would mean there accuracy could be out by 0.03mm at 200mm. (thats only 0.00015%, good enough for me) Even if they are built perfectly

|

Re: My first mod - new Z axis leadscrew March 14, 2014 07:00AM |

Registered: 10 years ago Posts: 47 |

Quote

jy_oc_hx

I'm not sure if raffybuffy is meaning resolution rather than accuracy here. Surely the tolerances on any ormerods manufactured parts would mean there accuracy could be out by 0.03mm at 200mm. (thats only 0.00015%, good enough for me) Even if they are built perfectly

I am not so staid,

I just want to say that changing the treated rod, you will not have any disadvantage otherwise the theorical ones!!!!

I have ordered the treated rod and nut because I don't like the original, I think is too poor and I notice that the nut is not stable on the rod, and the rod itself is already worn... and really it look bad!!!!

|

Re: My first mod - new Z axis leadscrew March 17, 2017 01:06PM |

Registered: 9 years ago Posts: 189 |

Quote

epninety

The STL file is attached. The O-ring to fit is BS1806-213, 23.39mm x 3.53mm

leadscrew_znut_v5_rot.stl

Would it be possible to re-design this STL file so that the hole into which the brass nut is 10 mm rather than 8 mm ?

I have linked to this message and to the file from my site [www.3dprintandstuff.co.uk]

As I found this part useful and straight forward to mount a lead screw.

Many Thanks

Chris Hills

Edited 1 time(s). Last edit at 03/17/2017 01:07PM by orictosh.

Supporting 3D Printers with Parts and Build services.

Printer: Ormerod 2 (528.4) Duel extruder set-up with Aluminium X-Rib, RRPro Firmware v1.11-ch (2016-04-08)

|

Re: My first mod - new Z axis leadscrew March 17, 2017 02:12PM |

Registered: 10 years ago Posts: 776 |

Very rare to see an Ormerod 1 with the original acrylic X-Arm on it - can i suggest an aluminium upgrade maybe

Everyone that has fitted one has reported good improvements, see my sig for details below.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Everyone that has fitted one has reported good improvements, see my sig for details below.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: My first mod - new Z axis leadscrew March 17, 2017 07:40PM |

Registered: 10 years ago Posts: 44 |

Quote

Davek0974

Very rare to see an Ormerod 1 with the original acrylic X-Arm on it - can i suggest an aluminium upgrade maybe

Everyone that has fitted one has reported good improvements, see my sig for details below.

You need to check the clock Davek! Those pics were posted more than 3 years ago!

(And I don't believe I reported a good improvement after fitting one of your arms.)

Edited 1 time(s). Last edit at 03/17/2017 07:47PM by epninety.

|

Re: My first mod - new Z axis leadscrew March 17, 2017 08:32PM |

Registered: 10 years ago Posts: 44 |

Quote

orictosh

Would it be possible to re-design this STL file so that the hole into which the brass nut is 10 mm rather than 8 mm ?

Hi Chris

I don't have the original design files anymore, but this is a trivial change to make directly in the stl file.

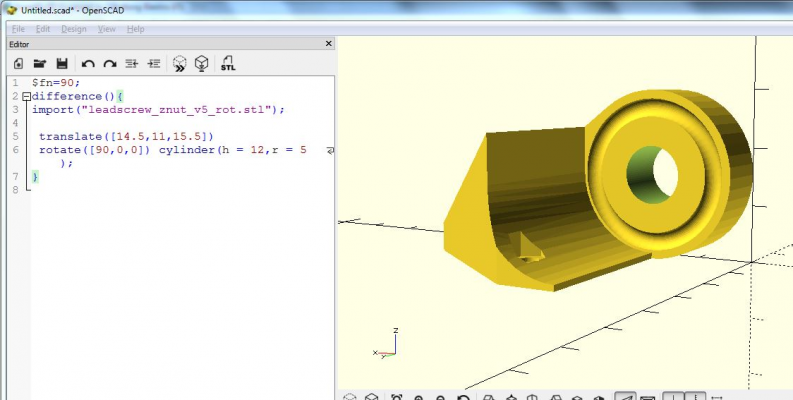

e.g. in OpenSCAD...

- import the .stl file.

- move the part around until the hole in centred on one axis.

- draw a 10mm diameter cylinder at the origin.

- rotate the cylinder until it's in the same plane

- subtract one from the other.

- render the resulting object

- export the object to a new stl file.

It probably took me longer to write this message.

Dave

|

Re: My first mod - new Z axis leadscrew March 18, 2017 04:56AM |

Registered: 10 years ago Posts: 1,230 |

Quote

epninety

I don't have the original design files anymore, but this is a trivial change to make directly in the stl file.

e.g. in OpenSCAD...

- import the .stl file.

- move the part around until the hole in centred on one axis.

- draw a 10mm diameter cylinder at the origin.

- rotate the cylinder until it's in the same plane

- subtract one from the other.

- render the resulting object

- export the object to a new stl file.

It probably took me longer to write this message.

Dave

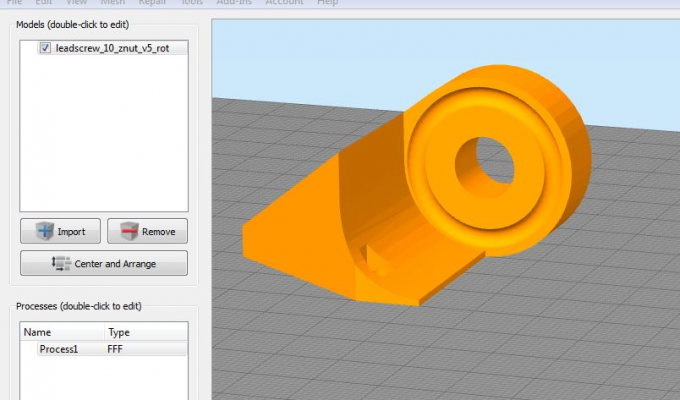

My first try in OpenScad, seems to work, amazing....

leadscrew_10_znut_v5_rot.zip

Erik

Edited 1 time(s). Last edit at 03/18/2017 05:03AM by ormerod168.

|

Re: My first mod - new Z axis leadscrew March 20, 2017 01:03PM |

Registered: 10 years ago Posts: 2,472 |

|

Re: My first mod - new Z axis leadscrew March 21, 2017 06:49AM |

Registered: 10 years ago Posts: 1,230 |

Quote

dmould

Quote

ormerod168

My first try in OpenScad, seems to work, amazing....

Erik

That's done it! You won't want to design with anything other than OpenScad now!

Dave

That's an easy choice, I have no knowledge of 3D modeling programs whatsoever!

...but I like this - I like this a lot!

Erik

Sorry, only registered users may post in this forum.