Extruder wear

Posted by ZeAllan

|

Extruder wear February 17, 2014 04:51PM |

Registered: 10 years ago Posts: 46 |

Hi,

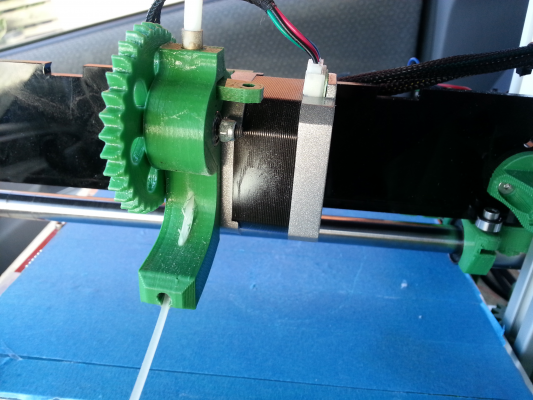

I have had a few spools of filament that made creaking sounds while printing. I happened to change to filament again before thinking too much about it, and the noise went away, so I concluded that it was just the sound that particular colour of filament makes due to moisture, pigmentation or whatnot, and decided that it can safely be ignored, since that colour is'nt used that much -- until today I happened to look at the extruder from the other side:

/Allan

I have had a few spools of filament that made creaking sounds while printing. I happened to change to filament again before thinking too much about it, and the noise went away, so I concluded that it was just the sound that particular colour of filament makes due to moisture, pigmentation or whatnot, and decided that it can safely be ignored, since that colour is'nt used that much -- until today I happened to look at the extruder from the other side:

/Allan

|

Re: Extruder wear February 17, 2014 05:00PM |

Registered: 10 years ago Posts: 147 |

Haha, mines really squeeky and creaky using 'Purple' (more like pink) PLA its a little noisy using a black PLA but i assumed it was the PLA dragging along the bottom of the hole where the filament goes in. i put some PTFE tube in there to cushion it but it keeps popping out on retraction.

Looks like a redesign is required.

Looks like a redesign is required.

|

Re: Extruder wear February 17, 2014 06:17PM |

Registered: 10 years ago Posts: 859 |

Thanks for sharing the picture with us Paul. If it was an animal I'd have it put down looking like that........ I was wondering where the creaking in mine was coming from, but thought maybe one of the bearings was on it's way out. After checking mine I see it's just about to Pop to the surface. I guess I'd best print my self a replacement before I'm stuck, and think about a re-designed feeder at the same time.

Kim

Edited 1 time(s). Last edit at 02/17/2014 06:19PM by KimBrown.

Kim

Edited 1 time(s). Last edit at 02/17/2014 06:19PM by KimBrown.

|

Re: Extruder wear February 17, 2014 06:38PM |

Registered: 10 years ago Posts: 46 |

Actually it seems to perform just fine - perhaps the filament has just discovered a better path..  :-)

:-)

I tried putting vaseline on the gears,since the large one looked like it was touching the side of the extruder body. No difference.

A new extruder body is high up on the todo list now -- I wonder if it one be designed to have room for a PTFE insert...

/Allan

:-)

:-)I tried putting vaseline on the gears,since the large one looked like it was touching the side of the extruder body. No difference.

A new extruder body is high up on the todo list now -- I wonder if it one be designed to have room for a PTFE insert...

/Allan

|

Re: Extruder wear February 17, 2014 06:55PM |

Registered: 10 years ago Posts: 300 |

|

Re: Extruder wear February 17, 2014 07:45PM |

Registered: 10 years ago Posts: 44 |

Just had a good look at mine and I have the same wear pattern just starting to show.

At least I know where that irritating 'fizz' noise is probably coming from now.

Up until yesterday I just finished the first small reel of PLA, the one included in the kit, so that's not really a sustainable wear rate.

More mods on the way I suspect!

At least I know where that irritating 'fizz' noise is probably coming from now.

Up until yesterday I just finished the first small reel of PLA, the one included in the kit, so that's not really a sustainable wear rate.

More mods on the way I suspect!

|

Re: Extruder wear February 17, 2014 08:17PM |

Registered: 10 years ago Posts: 578 |

Can't wait to get back to work tomorrow to check mine out although the only sound I've noticed on my extruder was a gear-related squeak that went away with waxing the gears. Do you guys with wear use the "back-of-the-RS-box" spool holder, or something else (as Radian asked) - is there a lot of tension in the filament? epninety, is yours a green ormerod too? Mine's an orange one and I've printed a couple of kilograms of PLA and ABS since early December and not seen this - not that it hasn't happened of course, my eyes are growing dim

although the only sound I've noticed on my extruder was a gear-related squeak that went away with waxing the gears. Do you guys with wear use the "back-of-the-RS-box" spool holder, or something else (as Radian asked) - is there a lot of tension in the filament? epninety, is yours a green ormerod too? Mine's an orange one and I've printed a couple of kilograms of PLA and ABS since early December and not seen this - not that it hasn't happened of course, my eyes are growing dim - My reels are inline with the extruder about six feet away and rotate pretty freely on a bit of plumbing pipe so don't have much tension.

- My reels are inline with the extruder about six feet away and rotate pretty freely on a bit of plumbing pipe so don't have much tension.

Cheers

Ray

although the only sound I've noticed on my extruder was a gear-related squeak that went away with waxing the gears. Do you guys with wear use the "back-of-the-RS-box" spool holder, or something else (as Radian asked) - is there a lot of tension in the filament? epninety, is yours a green ormerod too? Mine's an orange one and I've printed a couple of kilograms of PLA and ABS since early December and not seen this - not that it hasn't happened of course, my eyes are growing dim

although the only sound I've noticed on my extruder was a gear-related squeak that went away with waxing the gears. Do you guys with wear use the "back-of-the-RS-box" spool holder, or something else (as Radian asked) - is there a lot of tension in the filament? epninety, is yours a green ormerod too? Mine's an orange one and I've printed a couple of kilograms of PLA and ABS since early December and not seen this - not that it hasn't happened of course, my eyes are growing dim - My reels are inline with the extruder about six feet away and rotate pretty freely on a bit of plumbing pipe so don't have much tension.

- My reels are inline with the extruder about six feet away and rotate pretty freely on a bit of plumbing pipe so don't have much tension.Cheers

Ray

|

Re: Extruder wear February 17, 2014 08:52PM |

Registered: 10 years ago Posts: 176 |

|

Re: Extruder wear February 18, 2014 04:27AM |

Registered: 10 years ago Posts: 14,672 |

Looks like we need a new extruder design with either a couple of bearings for the filament to go over in order to do the 90deg turn or a ptfe insert.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Extruder wear February 18, 2014 04:57AM |

Registered: 10 years ago Posts: 46 |

Hi,

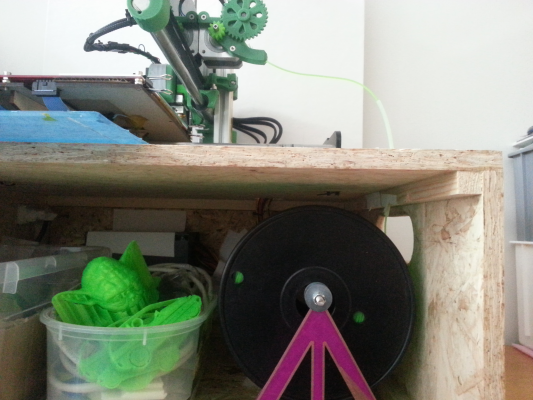

I have the spool running on bearings, standing below the printer on a triangle stand, and the filament running through a PTFE tube up to a height a little above the print bed. The whole thing is designed to be portable, so there isn't room to have the spool beside the printer, and these spools are too big to hang on the Duet enclosure..

/Allan

Quote

Radian

Thanks for the heads-up! I'm wondering how freely your filament comes off the spool though... what kind of reel support do you use?

I have the spool running on bearings, standing below the printer on a triangle stand, and the filament running through a PTFE tube up to a height a little above the print bed. The whole thing is designed to be portable, so there isn't room to have the spool beside the printer, and these spools are too big to hang on the Duet enclosure..

/Allan

|

Re: Extruder wear February 18, 2014 05:28AM |

Registered: 10 years ago Posts: 191 |

It doesn't wear that much if you use the supplied bowden tube to feed the filament.

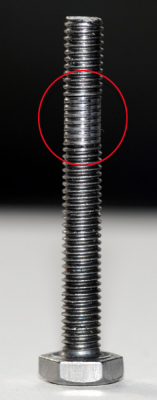

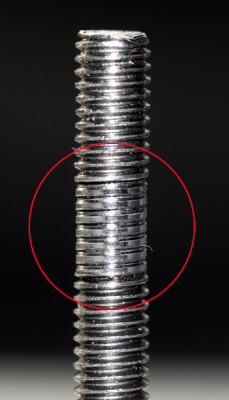

What worries me more is the wear of the screw in the extruder drive itself after only about 3kg filament printed

.

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

What worries me more is the wear of the screw in the extruder drive itself after only about 3kg filament printed

.

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

|

Re: Extruder wear February 18, 2014 06:47AM |

Registered: 10 years ago Posts: 14 |

Hi Guys,

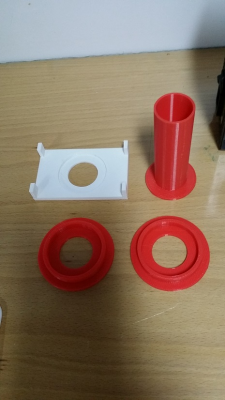

here you are my version of the extruder-drive-block. My drive-block seems to be cutted the next time by the pla-filament, so i will print this modified version a.s.a.p. before it will broke down...

I've modified the filament guide, so now its possible to put in the pfte-tube about 40mm. It will now guide the filament as far as possible. I extruded the block in the area of the gone housing a little bit,too.

Furthermore, i put a flap under the gap, where the retaining tongue has to secure the bowden cable. Now its possible to fix the tongue with a M3 screw and a Hex nut or in a simple way with a cable tie. I also dthe high of the gap for the retaining tongue a little, so the tongue will fit in exactly.

Feel free to print and try or even to optimize!

Edited 1 time(s). Last edit at 02/18/2014 06:48AM by Mr.Burns.

here you are my version of the extruder-drive-block. My drive-block seems to be cutted the next time by the pla-filament, so i will print this modified version a.s.a.p. before it will broke down...

I've modified the filament guide, so now its possible to put in the pfte-tube about 40mm. It will now guide the filament as far as possible. I extruded the block in the area of the gone housing a little bit,too.

Furthermore, i put a flap under the gap, where the retaining tongue has to secure the bowden cable. Now its possible to fix the tongue with a M3 screw and a Hex nut or in a simple way with a cable tie. I also dthe high of the gap for the retaining tongue a little, so the tongue will fit in exactly.

Feel free to print and try or even to optimize!

Edited 1 time(s). Last edit at 02/18/2014 06:48AM by Mr.Burns.

|

Re: Extruder wear February 18, 2014 07:14AM |

Registered: 10 years ago Posts: 859 |

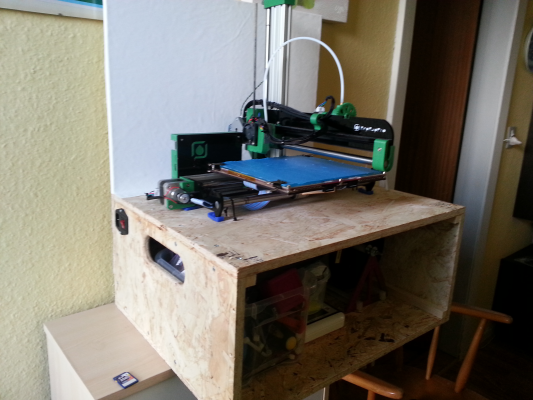

@ZeAllan Hi Allen, where do you have your power supply? I use mine as the base of my spool spindle.......

Picture shows a spool with ID of 32mm..... For my larger 1kg spools (57mm ID) I use the spacer washers...

Doing it this way I can fit everthing on my cabin desk, and use large spools.. Not having bearings it gives just a small amount of drag this keeps the filament tidy...

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Picture shows a spool with ID of 32mm..... For my larger 1kg spools (57mm ID) I use the spacer washers...

Doing it this way I can fit everthing on my cabin desk, and use large spools.. Not having bearings it gives just a small amount of drag this keeps the filament tidy...

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Extruder wear February 18, 2014 12:39PM |

Registered: 10 years ago Posts: 46 |

Hi,

I have the power supply in a square hole in the back of the case, taped flush with the back side, so that it takes air in from behind the box and blows it out through the front (I am considering to let it past the filament spool(s) to help keep it dry, but haven't experimented with that yet).

I find that after I added the bearings, the filament spool is unrolling more evenly than before when it was just hung on a piece of threaded rod. It had more of a tendency to get "wound up" and then unroll more like a spring, whereas now the drag is more even.

I built this box to turn the whole thing into a mobile printer more than as way to carry the printer around, if that description makes sense -- mounted this way I am able to move it between home and office without having to pack/unpack anything:

Next step is to extend the LAN plug to exit beside the power switch, and later an acrylic lid, a little brushed aluminium tape and some kind of air outlet should round the design off (a man can dream, right? :-).

By the way, the blue thingies below the feet of the printer are salvaged from a USB hard drive cabinet -- they literally reduced the noise from the movements to half the level it had before, so it's more of a cozy background hum than a noise. Highly recommended! :-)

/Allan

I have the power supply in a square hole in the back of the case, taped flush with the back side, so that it takes air in from behind the box and blows it out through the front (I am considering to let it past the filament spool(s) to help keep it dry, but haven't experimented with that yet).

I find that after I added the bearings, the filament spool is unrolling more evenly than before when it was just hung on a piece of threaded rod. It had more of a tendency to get "wound up" and then unroll more like a spring, whereas now the drag is more even.

I built this box to turn the whole thing into a mobile printer more than as way to carry the printer around, if that description makes sense -- mounted this way I am able to move it between home and office without having to pack/unpack anything:

Next step is to extend the LAN plug to exit beside the power switch, and later an acrylic lid, a little brushed aluminium tape and some kind of air outlet should round the design off (a man can dream, right? :-).

By the way, the blue thingies below the feet of the printer are salvaged from a USB hard drive cabinet -- they literally reduced the noise from the movements to half the level it had before, so it's more of a cozy background hum than a noise. Highly recommended! :-)

/Allan

|

Re: Extruder wear February 18, 2014 07:00PM |

Registered: 10 years ago Posts: 578 |

I'm happy to report that my extruder plastic is holding up nicely - maybe time to print another one or two though

@markus - I'll look at my screw when I've printed a new set of plastics (I want to put some herringbones on there - iamburny posted some recently) - it's a couple of months since I placed that bolt and I can't remember the construction fully - where is the wear occuring? Is there a bearing there or the hobbed part?

Ray

@markus - I'll look at my screw when I've printed a new set of plastics (I want to put some herringbones on there - iamburny posted some recently) - it's a couple of months since I placed that bolt and I can't remember the construction fully - where is the wear occuring? Is there a bearing there or the hobbed part?

Ray

|

Re: Extruder wear February 18, 2014 11:05PM |

Registered: 10 years ago Posts: 176 |

|

Re: Extruder wear February 19, 2014 01:20AM |

Registered: 10 years ago Posts: 191 |

@Ray

As far as I remember it was near the hobbed part. I changed the screw as I changed the original gears with herringbone ones. I had always some backlash there in certain situations. Since then I had no problems with the extruder drive - but didn't check the screw again. Maybe there was some misalignement?

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

As far as I remember it was near the hobbed part. I changed the screw as I changed the original gears with herringbone ones. I had always some backlash there in certain situations. Since then I had no problems with the extruder drive - but didn't check the screw again. Maybe there was some misalignement?

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

|

Re: Extruder wear February 19, 2014 07:04AM |

Registered: 10 years ago Posts: 44 |

|

Re: Extruder wear February 19, 2014 12:05PM |

Registered: 10 years ago Posts: 2,472 |

Yup, I've just started hearing clicks during the print I'm doing now, and sure enough the filament is breaking through the printed guide. Mine is an ABS extruder mount I printed just a few weeks ago, so reprinting is not going to be a solution, and we cannot lubricate the filament guide. I'll have to have a think about it and keep an eye on solutions posed here. I'm not sure it is going to do any harm when it does completely break through. I see no reason to have any guide on the part - surely the filament could be fed directly from the spool to the hobbed insert? That would also make it easier to clean off plastic dust from the hobbed part, which I once had clogging the grooves and causing slippage.

Dave

(#106)

Dave

(#106)

|

Re: Extruder wear February 20, 2014 08:04PM |

Registered: 10 years ago Posts: 578 |

Quote

dmould

I'm not sure it is going to do any harm when it does completely break through. I see no reason to have any guide on the part - surely the filament could be fed directly from the spool to the hobbed insert?

Let's hope so Dave!

I'm still on my original PLA extruder (I downloaded Matt's gears but haven't printed them yet, when I do I'll strip the whole thing down and assess what damage it's taken) - sticking a bit of PTFE tubing as a feeder might work as long as it doesn't get abraded (it might choke the nozzle if it does). Maybe the abrasion is from air-borne dust rather than just filament-friction? I've seen a couple posts elsewhere where people have added a sponge/piece of cloth upstream of the extruder to wipe the filament before it goes in, and they've shown a lot of crud after a short time, which could well be contributing to wear in some machines (I haven't put a filament wiper on, since my office is so hygenic

)

)I might even have a go at a direct drive feed - I know it'll be heavier and put more inertia on X, but it'll get rid of the hysteresis of the bowden (since I've been printing faster I can see that the feed is going out of phase as the bowden takes time to recover from a retraction and the head has moved on by the time that pressure builds up again, so I get a few centimetres of blobby/spikey printing at the beginning of a layer) - it'll also get rid of the bowden-pressure (a term I just coined) that occurs when the X head moves (if you disconnect the E motor and hold the filament at the inlet of the extruder, you'll probably find that as the X carriage moves, there'll be pulling and pushing in the filament as the bowden bends - which gives rise to pressure variations in the nozzle) - it occurs to me that this may account for the different wall thicknesses when printing single-wall test models people have reported in other threads (depending on where they position their extruder and which wall/corner is furthest away from the extruder)...

Ray

|

Re: Extruder wear February 21, 2014 04:27AM |

Registered: 10 years ago Posts: 265 |

Interesting insight Ray, I had wondered about the pro/cons of a direct drive solution but not enough to research it further.

I wonder if my weeping-nozzle-syndrome (**coined!**) is exacerbated by the bowden approach to extruding?

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

I wonder if my weeping-nozzle-syndrome (**coined!**) is exacerbated by the bowden approach to extruding?

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

|

Re: Extruder wear February 21, 2014 09:19AM |

Registered: 10 years ago Posts: 2,472 |

Yes, I think your observations are very sound, Ray, and a direct drive may well be the way to go if the arm can take the weight - the stepper motor by itself is a lot heavier than the entire hotend assembly, and I fear it might cause too much pressure on the small bearing running on the back of the arm as well as force on the Z runner linear bearings (though I think those should be sturdy enough) so might need quite extensive re-design. Meanwhile it is possible that the Bowden tube could be cut quite a bit shorter (it is long enough to reach from the end mounting positions, and so could be a shorter with only one extruder in the centre so it has to reach half as far), which should reduce the problems, although I'll want to first get hold of a replacement Bowden tube to fit in case it doesn't work out after I cut it!

As a quick test, I see that unclipping the extruder and sitting it on the top of the fan mount with the hotend at the end of the arm does not appear to cause any twisting or other untoward movement of the acrylic X arm and it still moves smoothly, so maybe moving the extruder to the top of the hotend could work. It could probably be done quite simply with some redesigned printed parts. Probably best to extend the L bracket that mounts on the X carriage upwards to take the weight of the extruder, or a new X carriage bearing holder design that incorporates the new L bracket in one piece. The extruder will put the hotend C of G way above the linear X bearing, which will cause twisting forces every time the X axis accelerates or decelerates. Hopefully the bearing can take it.

Dave

(#106)

As a quick test, I see that unclipping the extruder and sitting it on the top of the fan mount with the hotend at the end of the arm does not appear to cause any twisting or other untoward movement of the acrylic X arm and it still moves smoothly, so maybe moving the extruder to the top of the hotend could work. It could probably be done quite simply with some redesigned printed parts. Probably best to extend the L bracket that mounts on the X carriage upwards to take the weight of the extruder, or a new X carriage bearing holder design that incorporates the new L bracket in one piece. The extruder will put the hotend C of G way above the linear X bearing, which will cause twisting forces every time the X axis accelerates or decelerates. Hopefully the bearing can take it.

Dave

(#106)

|

Re: Extruder wear February 21, 2014 09:47AM |

Registered: 10 years ago Posts: 49 |

Hi, putting the extruder on the hot end might be possible for the single extruder version but when we want to use 2 or 3 extruders it's going to get very heavy, I was wondering if some sort of flexible drive could be used between the motors mounted on the arm and the hobbed end mounted on the extruder.

regards

mike

regards

mike

|

Re: Extruder wear February 21, 2014 11:58AM |

Registered: 10 years ago Posts: 2,472 |

I don't see how, given that the distance changes so much with X position. A Bowden rotary drive could be used I suppose (like a car's speedo cable or flexible drill drives), but that will almost certainly have more backlash than the push-pull filament. The only other way I can think of would be an arrangement of arms and pulleys like an old-fashioned dentist's drill, but again there would be lots of backlash in that.Quote

Mickyblueeyes

Hi, putting the extruder on the hot end might be possible for the single extruder version but when we want to use 2 or 3 extruders it's going to get very heavy, I was wondering if some sort of flexible drive could be used between the motors mounted on the arm and the hobbed end mounted on the extruder.

When it comes to using 3 extruders, we'll have to modify the Ormerod to have 3 X-arms, each with their own X carriage and extruder, and extended Y carriage rails so it can pass under all 3 of them!

OK - now to be serious again, it should be possible in firmware to compensate for the filament backlash by making all extruder operations slightly ahead of the associated XY moves. Perhaps putting a fixed delay of a few mS in the XY movement would be sufficient (equal to the "propagation delay" of the filament - make it a settable variable) - does anyone agree it might work? I should think it would be relatively easy to implement, perhaps in the X & Y stepper driver routines (queue every move passed to the driver through a "bucket brigade" buffer), though I've not looked at the code.

To check the delay, move the nozzle over the bed in the X direction at a slow but constant speed, extruding plastic for 5mm and then stop extruding for 5mm etc. to make a dashed line. Then move Y by .5mm and do exactly the same thing at a much faster constant speed, extruding at exactly the same X coordinates as the slow move. Then measure the difference in X axis direction where the dashes of plastic start and stop on the two dashed lines, and it should be possible to calculate the extrusion delay from the known speed difference. Should be easy enough to write some G code by hand that does that. It all depends whether the extrusion delay is a constant time, or varies with the speed / change of speed of the extruder. I think it will be constant ...

(edit) OK scratch that last test - I just tried it and without any retract commands the printer lays down a solid line rather than a dashed line due to the dribble - and including retraction would defeat the purpose of the test.

Dave

(#106)

Edited 1 time(s). Last edit at 02/21/2014 01:04PM by dmould.

|

Re: Extruder wear February 21, 2014 01:42PM |

Registered: 10 years ago Posts: 578 |

As if by fate, my printer stopped extruding today (same reason as Dave's - the teeth on the hobbed nut were filled with powder), so I dismantled it and found the same wear on my drive bolt as Markus (where the thread is pushed against inner part of the rear bearing), as I was putting it together I noticed that a hole has just started to emerge on the back like in Allan's (I swear it wasn't there when I looked on the 19th!). So, Matt's gears are currently printing and it's time to think more about alternatives  (though I'll probably just print a copy of the original extruder body and maybe make my own hobbed bolt to replace the bolt and nut )

(though I'll probably just print a copy of the original extruder body and maybe make my own hobbed bolt to replace the bolt and nut )

Ray

(though I'll probably just print a copy of the original extruder body and maybe make my own hobbed bolt to replace the bolt and nut )

(though I'll probably just print a copy of the original extruder body and maybe make my own hobbed bolt to replace the bolt and nut )Ray

|

Re: Extruder wear February 21, 2014 02:09PM |

Registered: 10 years ago Posts: 2,472 |

There's a design for printing a tool to make hobbed bolts using a Dremmel type drill and the small grinder that such tools usually come with here - [www.thingiverse.com]

Dave

(#106)

Dave

(#106)

|

Re: Extruder wear February 21, 2014 02:25PM |

Registered: 10 years ago Posts: 578 |

Oh, that's quite cute, thanks Dave - I was going to use a tap to hob it like this [www.thingiverse.com], but I'll make something like the one you posted and use my mill instead (I hadn't thought of using the extruder cog and a detente as an indexer - very ingenious).

Cheers

Ray

Cheers

Ray

Sorry, only registered users may post in this forum.