While we wait on a functional auto-probing...

Posted by ormerod168

|

While we wait on a functional auto-probing... February 19, 2014 02:15PM |

Registered: 10 years ago Posts: 1,230 |

...this is what I would do/have done (and have been printing happily ever after), I don't run any setbed.g file at the moment

Make sure the glass is flat, take away the aluminum heat spreader, imho it's not needed, put it to better use on top of - and for support of the corners of the unstable MDF bed

Go for a 3 point adjustment of the bed, this will be stable because of the rather direct line to the 3 bearing foundation it will rest on - make the 2 inner adjustments solid (they carry the momentum of the bed) and the 1 outher springloaded for easy adjustment

Adjust the 2 inner screws so as the bed is perfectly level as seen from the nozzle in the inner position (X30 or such)

Run the nozzle out to the outer corners of the bed, any difference in these corners (while moving the nozzle in the plus minus y-direction) is caused by the outer y-rod, this misalignment if any, is mirrored in the outer bed corners

Use nozzle measurements to adjust the y-axis-end-plates so the rods are at the same hight in both ends

Now go to the inner middle of the bed (X30 Y100 or such), lower and zero the nozzle (G92 Z0)

Raise the nozzle a bit and move out to X180 Y100 or such and lower to nozzle to the zero setpoint

Adjust the bed up to nozzle

That all

The inner corners of my bed is now rock solid stable, I do have to adjust the outer spring loaded screw from print to print, the y-axis-rib under the bed will move a little from time to time when removing the prints

So before any print I heat up the bed, then move the nozzle to inner middle of the bed, X30 Y100, zero the nozzle on paper, move nozzle up a bit to clear the bed and move the nozzle to the outer middle,X180 Y100, zero the nozzle on paper with the spring adjusting screw, then move the nozzle to the middle of the bed aka X100 Y100 (the glass will bulge a bit because of the heat) and make my final zeroing of the nozzle, G92 Z0

Hope that makes any sense, was written in a hurry

Erik

Make sure the glass is flat, take away the aluminum heat spreader, imho it's not needed, put it to better use on top of - and for support of the corners of the unstable MDF bed

Go for a 3 point adjustment of the bed, this will be stable because of the rather direct line to the 3 bearing foundation it will rest on - make the 2 inner adjustments solid (they carry the momentum of the bed) and the 1 outher springloaded for easy adjustment

Adjust the 2 inner screws so as the bed is perfectly level as seen from the nozzle in the inner position (X30 or such)

Run the nozzle out to the outer corners of the bed, any difference in these corners (while moving the nozzle in the plus minus y-direction) is caused by the outer y-rod, this misalignment if any, is mirrored in the outer bed corners

Use nozzle measurements to adjust the y-axis-end-plates so the rods are at the same hight in both ends

Now go to the inner middle of the bed (X30 Y100 or such), lower and zero the nozzle (G92 Z0)

Raise the nozzle a bit and move out to X180 Y100 or such and lower to nozzle to the zero setpoint

Adjust the bed up to nozzle

That all

The inner corners of my bed is now rock solid stable, I do have to adjust the outer spring loaded screw from print to print, the y-axis-rib under the bed will move a little from time to time when removing the prints

So before any print I heat up the bed, then move the nozzle to inner middle of the bed, X30 Y100, zero the nozzle on paper, move nozzle up a bit to clear the bed and move the nozzle to the outer middle,X180 Y100, zero the nozzle on paper with the spring adjusting screw, then move the nozzle to the middle of the bed aka X100 Y100 (the glass will bulge a bit because of the heat) and make my final zeroing of the nozzle, G92 Z0

Hope that makes any sense, was written in a hurry

Erik

|

Re: While we wait on a functional auto-probing... February 19, 2014 02:18PM |

Registered: 10 years ago Posts: 2,472 |

|

Re: While we wait on a functional auto-probing... February 19, 2014 02:21PM |

Registered: 10 years ago Posts: 147 |

Thanks for that Erik,

How do you make the 2 inner adjustments solid?

I will move the alu heat spreader down on top of the MDF bed and cut a hole for the bed temp probe wiring. Then i assume i will need longer M3 screws for the adjustments? with a chunky spring for the outer most middle adjustment?

Cheers

Paul

How do you make the 2 inner adjustments solid?

I will move the alu heat spreader down on top of the MDF bed and cut a hole for the bed temp probe wiring. Then i assume i will need longer M3 screws for the adjustments? with a chunky spring for the outer most middle adjustment?

Cheers

Paul

|

Re: While we wait on a functional auto-probing... February 19, 2014 02:37PM |

Registered: 10 years ago Posts: 265 |

Thanks Erik

Nice easy to follow guide, looks like sound advice to me.

I'm tempted to remove the ally heat spreader as you suggested but rather than lie it on top of the mdf I think I might use it to replace the mdf, so cut out holes to fit directly on the vertical wood supports. I'm trying to think of reasons why this is a bad idea! any thoughts?

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Nice easy to follow guide, looks like sound advice to me.

I'm tempted to remove the ally heat spreader as you suggested but rather than lie it on top of the mdf I think I might use it to replace the mdf, so cut out holes to fit directly on the vertical wood supports. I'm trying to think of reasons why this is a bad idea! any thoughts?

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

|

Re: While we wait on a functional auto-probing... February 19, 2014 02:50PM |

Registered: 10 years ago Posts: 1,230 |

Quote

PaulHam

...How do you make the 2 inner adjustments solid?

Hi Paul,

solid as in screw washer and nut solid was what I meant to say :-)

Quote

I will move the alu heat spreader down on top of the MDF bed and cut a hole for the bed temp probe wiring. Then i assume i will need longer M3 screws for the adjustments? with a chunky spring for the outer most middle adjustment?

the screws, can't remember if that's the original corner one's but the 18mm (heads included ) from the kit did fine for me, just make sure that there is no upwards pressure to the glass/pcb from the cardboard isolation, my isolation hangs under the glass/pcb, locked together by the corner clips, there is not contact to heatspreader/MDF bed underneath

spring, yes you will need a good chunky one, the smaller the diameter the less wire thickness the spring will need to have for the same force, my spring is outer Ø8mm made of wire afair Ø1.1mm

Erik

|

Re: While we wait on a functional auto-probing... February 19, 2014 09:02PM |

Registered: 10 years ago Posts: 859 |

My IR probe is working a treat here... Been using it to zero the HotEnd for the last 3 days.

I'm using 4mm Dark Red Float Glass (cost £12).

First I checked the IR emiter and sensor where pointing in the right direction.

(Mine were bent from new, so I pointed them downwards).

Did some tests with the red glass and got reliable results so altered my

config file entry to:-

G31 Z0.1 P230 ; Set Z probe height and threshold

Now my probe stops every time at either 0.1 or Zero, and it's made printing easy as eating chips...

(I am using it under Florescent light here thou.. WIll have to wait till I go home to test it under anything else)

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

I'm using 4mm Dark Red Float Glass (cost £12).

First I checked the IR emiter and sensor where pointing in the right direction.

(Mine were bent from new, so I pointed them downwards).

Did some tests with the red glass and got reliable results so altered my

config file entry to:-

G31 Z0.1 P230 ; Set Z probe height and threshold

Now my probe stops every time at either 0.1 or Zero, and it's made printing easy as eating chips...

(I am using it under Florescent light here thou.. WIll have to wait till I go home to test it under anything else)

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: While we wait on a functional auto-probing... February 20, 2014 09:41AM |

Registered: 10 years ago Posts: 780 |

Hi Erik,

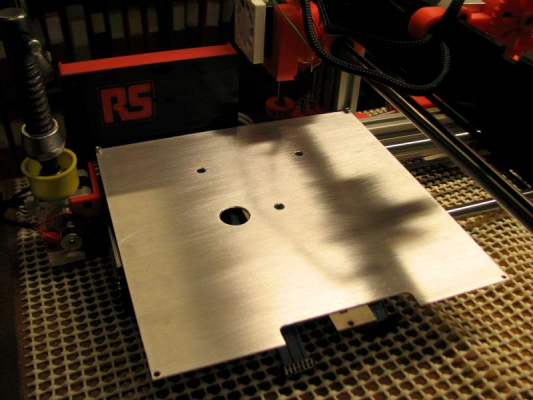

I have done over the last week or so everything you and others have suggested and now use the spreader plate as my base. I am getting P0, P1 and P2 to 0.0 but P3 is -1.39.

I can see why the outer rod could be causing this but I cannot see how to adjust the position of the Y plate.

It seems that either the left hand side needs to be higher by 1.39mm or the right hand side needs to be lower by 1.39.

Any suggestions as to how I could do this?

Thanks for your time

Paul

I have done over the last week or so everything you and others have suggested and now use the spreader plate as my base. I am getting P0, P1 and P2 to 0.0 but P3 is -1.39.

I can see why the outer rod could be causing this but I cannot see how to adjust the position of the Y plate.

It seems that either the left hand side needs to be higher by 1.39mm or the right hand side needs to be lower by 1.39.

Any suggestions as to how I could do this?

Thanks for your time

Paul

|

Re: While we wait on a functional auto-probing... February 20, 2014 10:33AM |

Registered: 10 years ago Posts: 14,672 |

Have you tried loosening the screws (2 at each end) that hold the acrylic to the printed part, and seeing if there is enough slack to enable you to adjust the relative heights?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: While we wait on a functional auto-probing... February 20, 2014 02:34PM |

Registered: 10 years ago Posts: 1,230 |

Hi Paul

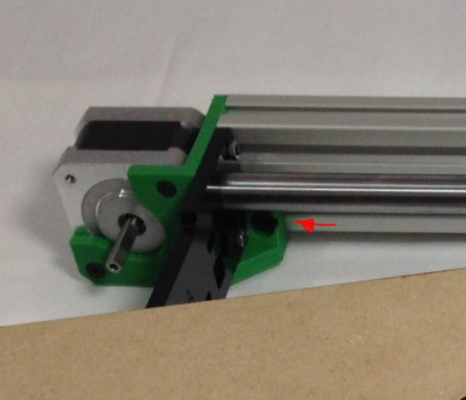

Yes do as dc42 suggest and if that's not enough you can loosen the two M6x16mm countersunk socket head screws in the end of the Aluminium extrusion and force the y-motor-bracket/acrylic part up a bit by placing a spacer under the....ehh..here's a picture from the documentation...where the arrow points to:

..or you could remove some material same place in the other end (the y-idler-end) as to force the end piece down when you tighten the screw

It may take some time to get it just right

Erik

Yes do as dc42 suggest and if that's not enough you can loosen the two M6x16mm countersunk socket head screws in the end of the Aluminium extrusion and force the y-motor-bracket/acrylic part up a bit by placing a spacer under the....ehh..here's a picture from the documentation...where the arrow points to:

..or you could remove some material same place in the other end (the y-idler-end) as to force the end piece down when you tighten the screw

It may take some time to get it just right

Erik

|

Re: While we wait on a functional auto-probing... February 20, 2014 03:28PM |

Registered: 10 years ago Posts: 1,230 |

Quote

iamburny

I'm tempted to remove the ally heat spreader as you suggested but rather than lie it on top of the mdf I think I might use it to replace the mdf, so cut out holes to fit directly on the vertical wood supports. I'm trying to think of reasons why this is a bad idea! any thoughts?

Matt

Thoughts yes, but practical experience came first I'm afraid :-) - I had to try it of cause, I just had to and it was a bad idea..

It made the bed walk all over the place, 0.8mm at the spring adjusted front from room temperature to 60C, wood is way too soft to mount the heat spreader that way, the screws will pull the alu plate down in the center, will cause a preload that makes the alu plate walk with the temperature - compare this amplification of leverage to the Q and D fix where the aluminum rest on the 3 outer end of the x-rib and the x-cross-rib, these ends are quite stable, have a rather direct line down to the bearings, and are the contact points for the heat spreader as it will bulge a bit at the center, carrying the weight of the old mdf and the glass on top

Erik

|

Re: While we wait on a functional auto-probing... February 20, 2014 03:47PM |

Registered: 10 years ago Posts: 859 |

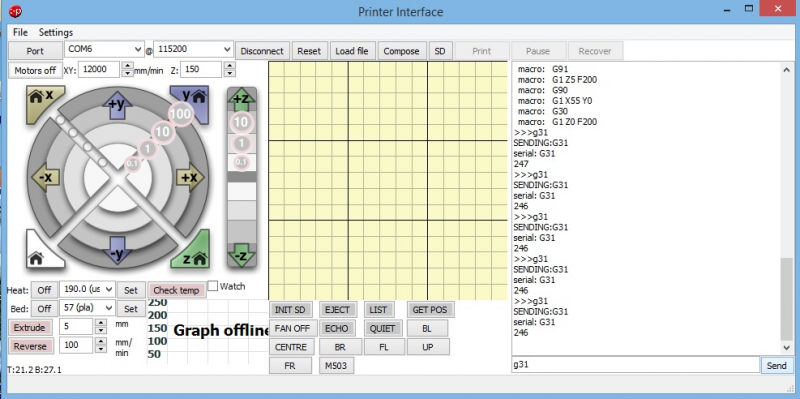

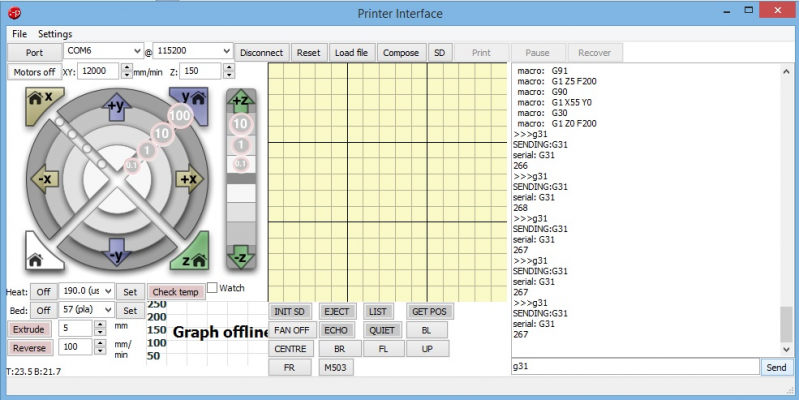

Test 1

Glass washed in Washing up Liquid, not treated with Vinegar... Auto homing and the probe stops at 0.3mm above plate... Every time...

See pic of the G31 readings.... they are repeatable...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Glass washed in Washing up Liquid, not treated with Vinegar... Auto homing and the probe stops at 0.3mm above plate... Every time...

See pic of the G31 readings.... they are repeatable...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: While we wait on a functional auto-probing... February 20, 2014 04:02PM |

Registered: 10 years ago Posts: 859 |

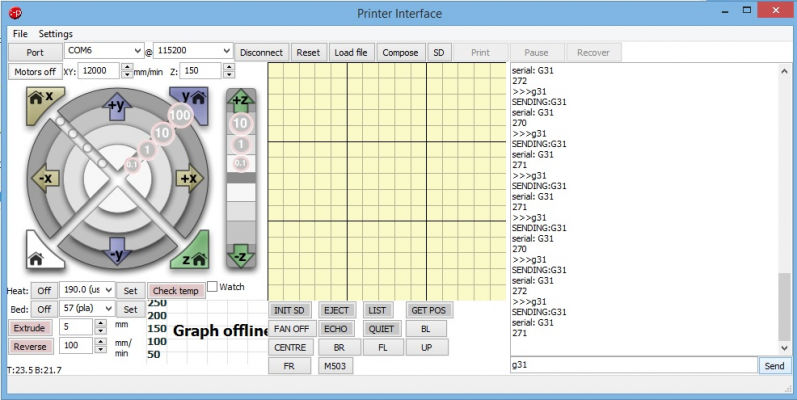

Test 2...

(Alterations:- Config IR Probe setting adjusted, as the New Cover for the circuit board seems to have altered the reading slightly.

New Threshold setting is:-

G31 Z0.1 P250 ; Set Z probe height and threshold)..

Now Head stops at 0.1mm every time..... Readings from probe all similar.... Repeatable... and tested 10 or more times... always stops at 0.1mm

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

(Alterations:- Config IR Probe setting adjusted, as the New Cover for the circuit board seems to have altered the reading slightly.

New Threshold setting is:-

G31 Z0.1 P250 ; Set Z probe height and threshold)..

Now Head stops at 0.1mm every time..... Readings from probe all similar.... Repeatable... and tested 10 or more times... always stops at 0.1mm

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: While we wait on a functional auto-probing... February 20, 2014 04:11PM |

Registered: 10 years ago Posts: 859 |

Test 3

(Alterations:- Glass rotated by 180')

Homed... HotEnd stops again at 0.1mm Repeated 10 times... 0.1mm every time.

So next lets add some incandescent light... On to test 4

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

(Alterations:- Glass rotated by 180')

Homed... HotEnd stops again at 0.1mm Repeated 10 times... 0.1mm every time.

So next lets add some incandescent light... On to test 4

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: While we wait on a functional auto-probing... February 20, 2014 04:51PM |

Registered: 10 years ago Posts: 859 |

Test 4

Alterations:- An incandescent torch was placed approx 2 feet away from the probe (y motor end) angled at about 45' directly

at the position the probe would be viewing... (To be fair, its a bit ex-stream... But....)

When homed the HotEnd stopped repeatedly at 1.3mm. (tolerance 0mm / +0.2mm)

Conclusion:-

For any one situation where the light is not going to vary wildly, the standard probe will give very good repeatable readings using Red Glass.

The probe does pick up incandescent light, but even when it does the readings are repeatable provided the incandescent light

level doesn't change when using the red glass. If the probe had a reference (i.e. a second sensor picking up ambient light to compare with), then it would work perfectly in varying light conditions. Direct sun light however would probably swamp it, but I think that is to be expected.

I will re-run the tests when I get home with different light sources in a weeks time..

In the mean time I will be continuing to use the probe here...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Alterations:- An incandescent torch was placed approx 2 feet away from the probe (y motor end) angled at about 45' directly

at the position the probe would be viewing... (To be fair, its a bit ex-stream... But....)

When homed the HotEnd stopped repeatedly at 1.3mm. (tolerance 0mm / +0.2mm)

Conclusion:-

For any one situation where the light is not going to vary wildly, the standard probe will give very good repeatable readings using Red Glass.

The probe does pick up incandescent light, but even when it does the readings are repeatable provided the incandescent light

level doesn't change when using the red glass. If the probe had a reference (i.e. a second sensor picking up ambient light to compare with), then it would work perfectly in varying light conditions. Direct sun light however would probably swamp it, but I think that is to be expected.

I will re-run the tests when I get home with different light sources in a weeks time..

In the mean time I will be continuing to use the probe here...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: While we wait on a functional auto-probing... February 20, 2014 07:11PM |

Registered: 10 years ago Posts: 859 |

Test 5

Alterations:- I've placed a sheet of plain White paper under the Dark Red Glass. Otherwise its a standard setup....

This has nearly Doubled the IR Probe reading stopping the HotEnd at 1.2mm instead of the o.1mm it would normally stop at.

When lowered to 0.1mm I'm getting constant readings in the order of 424 (+/- 1).

Test 6 (incandescent light test)

Alterations Threshold now set to 410 for the probe in the config file....

Initial test to prove repeatability without incandescent light..... All ok 100%

With a torch at about 2' away directed at the same point that the probe is viewing at angle of about 45'...

Total Failure.... Probe refused to Home....

Oh I wish I had some Black Paper to test under the glass.

This has proved that the probe is seeing through the glass !!!!!!

Edited 1 time(s). Last edit at 02/20/2014 07:13PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Alterations:- I've placed a sheet of plain White paper under the Dark Red Glass. Otherwise its a standard setup....

This has nearly Doubled the IR Probe reading stopping the HotEnd at 1.2mm instead of the o.1mm it would normally stop at.

When lowered to 0.1mm I'm getting constant readings in the order of 424 (+/- 1).

Test 6 (incandescent light test)

Alterations Threshold now set to 410 for the probe in the config file....

Initial test to prove repeatability without incandescent light..... All ok 100%

With a torch at about 2' away directed at the same point that the probe is viewing at angle of about 45'...

Total Failure.... Probe refused to Home....

Oh I wish I had some Black Paper to test under the glass.

This has proved that the probe is seeing through the glass !!!!!!

Edited 1 time(s). Last edit at 02/20/2014 07:13PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: While we wait on a functional auto-probing... February 20, 2014 07:25PM |

Registered: 10 years ago Posts: 578 |

Hi Kim, I thought it might be - glass isn't too reflective straight on (which is why Harry Worth used to line himself up at an oblique angle ) - and I suggested in another thread that it might be the fact that your glass is transmitting more IR than it's reflecting from the surroundings that makes it work better (ie it lets ambient IR light pass through better and reflects less up towards the detector directly) - if so black paper (black for IR that is) may work better ... have you got a marker pen you could draw a black spot with (or just any blue or black pen - both will absorb red light and stop it reflecting - a RED pen would be bad though, since it's likely to be equivalent to white as far as IR is concerned). Hope you don't mind the nautical curse I slipped in there

) - and I suggested in another thread that it might be the fact that your glass is transmitting more IR than it's reflecting from the surroundings that makes it work better (ie it lets ambient IR light pass through better and reflects less up towards the detector directly) - if so black paper (black for IR that is) may work better ... have you got a marker pen you could draw a black spot with (or just any blue or black pen - both will absorb red light and stop it reflecting - a RED pen would be bad though, since it's likely to be equivalent to white as far as IR is concerned). Hope you don't mind the nautical curse I slipped in there

Cheers

Ray

) - and I suggested in another thread that it might be the fact that your glass is transmitting more IR than it's reflecting from the surroundings that makes it work better (ie it lets ambient IR light pass through better and reflects less up towards the detector directly) - if so black paper (black for IR that is) may work better ... have you got a marker pen you could draw a black spot with (or just any blue or black pen - both will absorb red light and stop it reflecting - a RED pen would be bad though, since it's likely to be equivalent to white as far as IR is concerned). Hope you don't mind the nautical curse I slipped in there

) - and I suggested in another thread that it might be the fact that your glass is transmitting more IR than it's reflecting from the surroundings that makes it work better (ie it lets ambient IR light pass through better and reflects less up towards the detector directly) - if so black paper (black for IR that is) may work better ... have you got a marker pen you could draw a black spot with (or just any blue or black pen - both will absorb red light and stop it reflecting - a RED pen would be bad though, since it's likely to be equivalent to white as far as IR is concerned). Hope you don't mind the nautical curse I slipped in there

Cheers

Ray

|

Re: While we wait on a functional auto-probing... February 20, 2014 07:51PM |

Registered: 10 years ago Posts: 859 |

Test 7 (Final Test)

Alterations White paper removed.... Replaced by a piece of Black Refuse sack (it's Satin Black nearest I have to Matt Black) otherwise standard setup.

Initial Home all ok... Threshold now set to 75.... 100% Repeatable....

Incandescent light test (torch shining on probe view point 2 feet away at about 45' angle)

Complete Failure.... Refused to Home.....

My views of this and the White paper test result earlier is that the Probe is both seeing through the Red Glass AND picking up a reflection

from the surface...... Polarized glass maybe??????

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Alterations White paper removed.... Replaced by a piece of Black Refuse sack (it's Satin Black nearest I have to Matt Black) otherwise standard setup.

Initial Home all ok... Threshold now set to 75.... 100% Repeatable....

Incandescent light test (torch shining on probe view point 2 feet away at about 45' angle)

Complete Failure.... Refused to Home.....

My views of this and the White paper test result earlier is that the Probe is both seeing through the Red Glass AND picking up a reflection

from the surface...... Polarized glass maybe??????

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: While we wait on a functional auto-probing... February 20, 2014 08:22PM |

Registered: 10 years ago Posts: 578 |

maybe ultrasound, or stop shining a torch at it

Polarised glass probably wouldn't be cost-effective, nor work unless it was anti-reflective coated for IR (at all angles - which would add a LOT to the cost), the LED probably isn't too well polarised to start with, so you'd be halving the signal, and most of the scattered and reflected light wouldn't be polarised, you'd just be knocking out the stuff that's coming in from near Brewster's angle (on second thoughts, that wouldn't be getting past the surface and into the polariser in the first place).

If you've got a system that works in your normal ambient environment, then don't worry until you're in another - chances are that the heat from the torch at 2 feet is much more than you'd get from a bulb at ten feet - get on with printing while you're onboard, then see how well the glass works when you get home.

Where did you buy it from by the way - does it have a spec sheet of any kind? I haven't used my IR sensor for quite a while now, but it worked quite well for Z and wasn't affected by the lighting in my office (it was in the way of other things I wanted to do, and my bed was pretty level anyhow so I got rid of it) - maybe other people with a Z probe problem could get hold of some and see if it solves it for them though.

Ray

Polarised glass probably wouldn't be cost-effective, nor work unless it was anti-reflective coated for IR (at all angles - which would add a LOT to the cost), the LED probably isn't too well polarised to start with, so you'd be halving the signal, and most of the scattered and reflected light wouldn't be polarised, you'd just be knocking out the stuff that's coming in from near Brewster's angle (on second thoughts, that wouldn't be getting past the surface and into the polariser in the first place).

If you've got a system that works in your normal ambient environment, then don't worry until you're in another - chances are that the heat from the torch at 2 feet is much more than you'd get from a bulb at ten feet - get on with printing while you're onboard, then see how well the glass works when you get home.

Where did you buy it from by the way - does it have a spec sheet of any kind? I haven't used my IR sensor for quite a while now, but it worked quite well for Z and wasn't affected by the lighting in my office (it was in the way of other things I wanted to do, and my bed was pretty level anyhow so I got rid of it) - maybe other people with a Z probe problem could get hold of some and see if it solves it for them though.

Ray

|

Re: While we wait on a functional auto-probing... February 21, 2014 04:11AM |

Registered: 10 years ago Posts: 265 |

Quote

ormerod168

Thoughts yes, but practical experience came first I'm afraid :-) - I had to try it of cause, I just had to and it was a bad idea..

Thank you for your courage Erik, I hope no irreversible harm has befallen your Ormerod!

I'd have been contemplating my original mod suggestion for a while now, and only distracted from trying it by the amount of printing I have been doing (onto my 5th 1kg reel now). Clearly your evidence shows that mounting dissimilar materials is a bad idea when heat is involved, I assume the different expansion rates of wood and aluminium caused the majority of the problems you experience.

Have you reverted back to your original construction?

I think ultimately replacing all wooden parts with aluminium (as other have done) is the way to go. this however is probably out of reach of my limited hardware tools.

thanks again for trying it =)

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

|

Re: While we wait on a functional auto-probing... February 21, 2014 04:27AM |

Registered: 10 years ago Posts: 314 |

DC42 posted a great picture of his hand sawn aluminium bed which is 'on my list' and a lot closer now our storms are decreasing!Quote

iamburny

I think ultimately replacing all wooden parts with aluminium (as other have done) is the way to go. this however is probably out of reach of my limited hardware tools.

Matt

Ormerod #007 (shaken but not stirred!)

|

Re: While we wait on a functional auto-probing... February 21, 2014 09:37AM |

Registered: 10 years ago Posts: 2,472 |

Black things are not necessarily black to IR. I played with a B&W CCTV camera that worked in both the visible and IR spectrum once, and was quite amazed that a person wearing a white top and black trousers looked as expected under visible illumination, but switching off the light so he was illuminated by only IR changed the displayed image so that he had white trousers that were brighter than his top. The colour of his trousers would change completely as if by magic just by switching the room light off and on (there was a low power constant IR source in the room and the camera adjusted its iris & CCD gain automatically so the image brightness did not change with the much brighter visible room light).

Dave

(#106)

Dave

(#106)

Sorry, only registered users may post in this forum.