New firmware

Posted by dc42

|

Re: New firmware February 28, 2014 07:15PM |

Registered: 10 years ago Posts: 48 |

I just installed dc42 firmware as well, and noticed that my Z homing did not work the same anymore. The cause seems to be that the firmware does not allow negative Y values, which, in my case, means it could not position the IR sensor over the middle of the paper tab anymore. Not a big deal, but it may play a part in your problem as well.

|

Re: New firmware February 28, 2014 07:37PM |

Registered: 10 years ago Posts: 578 |

I think once you've set "home", X and Y won't move negative (there's a small allowance for Z)- they also won't move past the end of the plate - this was a feature requested by more than one person and saves a lot of belt grinding - I was surprised the first time I hit +100 [edit when I meant -100] on Y and it stopped without grinding! and thankful too. If you NEED to get past the restriction, turn off the motors (M18 I think, but I use a button in the host software I use) then you can move the X/Y manually to a "negative" point.

Ray

Edited 1 time(s). Last edit at 02/28/2014 07:38PM by rayhicks.

Ray

Edited 1 time(s). Last edit at 02/28/2014 07:38PM by rayhicks.

|

Re: New firmware February 28, 2014 07:41PM |

Registered: 10 years ago Posts: 48 |

Quote

rayhicks

I think once you've set "home", X and Y won't move negative (there's a small allowance for Z)- they also won't move past the end of the plate - this was a feature requested by more than one person and saves a lot of belt grinding - I was surprised the first time I hit +100 [edit when I meant -100] on Y and it stopped without grinding! and thankful too. If you NEED to get past the restriction, turn off the motors (M18 I think, but I use a button in the host software I use) then you can move the X/Y manually to a "negative" point.

Ray

Thanks, Ray, that seems like a very sensible feature. Do you know if there is a way that I can reposition the Y zero point (or, equivalently, that the Y end-switch is defined to be at a different Y value)? That would move my Z-home position within Y range again.

|

Re: New firmware February 28, 2014 08:02PM |

Registered: 10 years ago Posts: 578 |

|

Re: New firmware March 01, 2014 02:47AM |

Registered: 11 years ago Posts: 103 |

Indeed I homed Y as well. (I usually do X, Y, G32...). I usee white paper below the kapton in the corners, has worked really well so far.

any more Ideas what I should try?

> ... they also won't move past the end of the plate

I will check whether my bed calibration points are "outside" maybe this is the reason. will report back.

[edit: just read that the moves are now restricted, will check if this affects my calibration points"]

Edited 1 time(s). Last edit at 03/01/2014 02:52AM by auser.

any more Ideas what I should try?

> ... they also won't move past the end of the plate

I will check whether my bed calibration points are "outside" maybe this is the reason. will report back.

[edit: just read that the moves are now restricted, will check if this affects my calibration points"]

Edited 1 time(s). Last edit at 03/01/2014 02:52AM by auser.

|

Re: New firmware March 01, 2014 03:23AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Flyskyhy

Do you know if there is a way that I can reposition the Y zero point (or, equivalently, that the Y end-switch is defined to be at a different Y value)? That would move my Z-home position within Y range again.

Use the M208 command to define the Y axis length, and hence the Y endstop position, before you home Y. For example, if your Y axis will currently travel from -5 to +200, then sending M208 Y5 will define the range as 0 to 205. You can put the M208 command in config.g.

You can override the travel limits imposed by the new firmware by including S1 in the G0 or G1 command. This also activates endstop detection, but it you are going to negative Y then there is no endstop switch in that direction anyway.

Edited 1 time(s). Last edit at 03/01/2014 03:25AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New firmware March 01, 2014 03:55AM |

Registered: 11 years ago Posts: 103 |

> I will check whether my bed calibration points are "outside" maybe this is the reason. will report back.

sure enough X only moves to 220 now and my calibration point is at X225.

sorry I mot really clear on how M208 is supposed to work.

according to the reprap-wiki these are limits for travel in the positive direction.

so I would set something like M208 X230 in my config.g.

But I understand

sure enough X only moves to 220 now and my calibration point is at X225.

sorry I mot really clear on how M208 is supposed to work.

according to the reprap-wiki these are limits for travel in the positive direction.

so I would set something like M208 X230 in my config.g.

But I understand

to mean that this is more of an offset adjustement. what is correct?Quote

dc42

if your Y axis will currently travel from -5 to +200, then sending M208 Y5 will define the range as 0 to 205.

|

Re: New firmware March 01, 2014 05:41AM |

Registered: 10 years ago Posts: 14,672 |

M208 tells the firmware what the axis travel is. On the Y axis, the endstop is at the top of the range instead of the bottom, therefore sending e.g. M208 Y5 will alter both the amount of travel and the origin.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New firmware March 02, 2014 05:05AM |

Registered: 11 years ago Posts: 103 |

thanks dc42!

I Set M208 X230 in my config.g now the bed compensation "does something". but I'm pretty convinced that there is something else worng.

- If I do my normal "setup-routine" (Heat everything, Home X, Y, G32) an then move to X100 Y100 the head is closer to 7mm above the bed instead of 5.

if i re-set Z with the "paper method" and start printing, I get bottom layers as shown in the picture.

-> compensation does something but not "the right thing" ;-(

in case anybody has an Idea how to debug further, this would be gratly appreciated!

I Set M208 X230 in my config.g now the bed compensation "does something". but I'm pretty convinced that there is something else worng.

- If I do my normal "setup-routine" (Heat everything, Home X, Y, G32) an then move to X100 Y100 the head is closer to 7mm above the bed instead of 5.

if i re-set Z with the "paper method" and start printing, I get bottom layers as shown in the picture.

-> compensation does something but not "the right thing" ;-(

in case anybody has an Idea how to debug further, this would be gratly appreciated!

|

Re: New firmware March 02, 2014 08:28AM |

Registered: 10 years ago Posts: 14,672 |

Check that your x-axis plate is straight, especially if you have one of the early kits. If it has a wave or bend in it, then the nozzle height will vary with x-axis position.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New firmware March 02, 2014 08:55AM |

Registered: 10 years ago Posts: 48 |

Have you tried manual bed leveling as described in the documentation? In most cases you just have to do that once and record the values in a setbed.g file. Then simply run the setbed.g file and reset the Z-height before each print.

The fully automated bed leveling really does not work properly with the current IR sensor. Hopefully dc42's ultrasonic mod will change that.

The fully automated bed leveling really does not work properly with the current IR sensor. Hopefully dc42's ultrasonic mod will change that.

|

Re: New firmware March 02, 2014 11:02AM |

Registered: 11 years ago Posts: 103 |

>The fully automated bed leveling really does not work properly with the current IR sensor.

It actually DID work OK...

I probably have to mention that the printer lives in the cellar which is fluoresent-lit.

ok off to check the x-rib. But i suspect it's not the culprit (broke on assembly & glued together was straight last tim I checked...)

It actually DID work OK...

I probably have to mention that the printer lives in the cellar which is fluoresent-lit.

ok off to check the x-rib. But i suspect it's not the culprit (broke on assembly & glued together was straight last tim I checked...)

|

Re: New firmware March 02, 2014 11:34AM |

Registered: 10 years ago Posts: 14,672 |

If it broke on assembly, it sounds like you had one of the early kits. I had one of those, and the spacing between the tabs on the x-rib didn't quite match the spacing between the slots on the x-plate. So unless you filed one of the tabs or slots, the parts would only fit together if you flexed the x-plate a little. This resulted in either a broken part or in a bend in the x-plate. This bend causes the nozzle height to vary with x-position.

I suggest you check whether the nozzle height is varying with x-position, which you can do using feeler gauges, or using a drill bit to compare nozzle heights above the bed at different positions, as suggested in the instructions for manual bed levelling.

RRP have been quite good at replacing acrylic parts that broke on assembly free of charge.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I suggest you check whether the nozzle height is varying with x-position, which you can do using feeler gauges, or using a drill bit to compare nozzle heights above the bed at different positions, as suggested in the instructions for manual bed levelling.

RRP have been quite good at replacing acrylic parts that broke on assembly free of charge.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New firmware March 02, 2014 12:11PM |

Registered: 11 years ago Posts: 103 |

looking @ x from top it looks like it may be 0.5mm or so curving to the left. other directions look straight. setting the head to e.g. 1mm above te bed and moving the head in increments shows that the bed is slanted along Y (higher @ the motor end) and along X (higher @ the front). but there is no "doming" easily recognizable.

What I really don't understand is, why after the G32 procedure the printer "thinks" it's @Z=5 but in actuall fact it is >7 even at the Z home (X60 Y5) and at the latest bed measurement point as well (X225 Y175).

Also when moving the head e.g. the full X-length bed compensation turns Z maybe 3/4 weher it would turn multiple times (at least 1.5, never counted) before

Edit: yes this is an early kit & yes X did not "fit" but as i broke it, i could then glue it "without the bend in".

What I really do not get is that I could print with the auto bed levelling for weeks and now I seem to have "broken" something but I can't really get my mind around what ( I'm a sad puppy now ;-(

Edit II: manually leveling does not really "cut it" IMHO as the bed is a bit of a "moving target" as many have found out. will probably have to give in and replace the bed with

alu or dibond... no clue where to get dibond here in CH.

Edited 2 time(s). Last edit at 03/02/2014 12:31PM by auser.

What I really don't understand is, why after the G32 procedure the printer "thinks" it's @Z=5 but in actuall fact it is >7 even at the Z home (X60 Y5) and at the latest bed measurement point as well (X225 Y175).

Also when moving the head e.g. the full X-length bed compensation turns Z maybe 3/4 weher it would turn multiple times (at least 1.5, never counted) before

Edit: yes this is an early kit & yes X did not "fit" but as i broke it, i could then glue it "without the bend in".

What I really do not get is that I could print with the auto bed levelling for weeks and now I seem to have "broken" something but I can't really get my mind around what ( I'm a sad puppy now ;-(

Edit II: manually leveling does not really "cut it" IMHO as the bed is a bit of a "moving target" as many have found out. will probably have to give in and replace the bed with

alu or dibond... no clue where to get dibond here in CH.

Edited 2 time(s). Last edit at 03/02/2014 12:31PM by auser.

|

Re: New firmware March 02, 2014 04:33PM |

Registered: 10 years ago Posts: 46 |

|

Re: New firmware March 02, 2014 06:41PM |

Registered: 10 years ago Posts: 14,672 |

Older firmware versions (including the RRP 0.57a official release) don't actually do z-homing when you do bed compensation, however the effect is the same. My newer versions home the Z axis on the first probe of a G32 command if it wasn't homed already.

For best results, home the Z axis at the centre of the bed AFTER doing G32. I do this with an ultrasonic probe, however you can also do this manually.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

For best results, home the Z axis at the centre of the bed AFTER doing G32. I do this with an ultrasonic probe, however you can also do this manually.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New firmware March 02, 2014 06:52PM |

Registered: 10 years ago Posts: 14,672 |

I've just released firmware version 057r-dc42 at [github.com]. Changes since 057q are:

- When checking endstops, wait for the move to complete before accepting further moves, otherwise subsequent moves use the wrong coordinates. [That's why the homex.g etc. files supplied by RRP have G92 commands after all the G1 S1 commands.]

- Thermistors and Z probe are now monitored continuously using a tick interrupt to kick off ADC conversions. ADC is now run in 12-bit mode. Thermistor readings are passed through averaging filters. Thermistors are monitored for overheat conditions and bad readings in the tick ISR and the appropriate heater is turned off (this is useful because the main loop sometimes gets suspended while trying to do USB communication, which can result in overheating). IR probe modulation frequency is increased from 83Hz to 250Hz. Number of Z probe readings averaged is increased from 8 to 16.

- Use watchdog timer to monitor the tick interrupt (needs patch to Arduino Due core library). Add facility to test watchdog timer (M111 S1001).

- Added an error status word to record that errors have occurred (e.g. over-temperature).

- M111 command changed so that S0 turns debug off, S1 turns debug on, S2 reports free memory - also now reports the type of the last restart and the error status word.

- Fixed problem whereby M111 debug reports were not sent to the web interface.

- Implemented M999 command, which resets the Duet.

- Changed extruder PID parameters and added more explanation for them. If the Duet is reset when the extruder is hot and it is commanded to heat up again without being allowed to cool, the temperature no longer undershoots badly. The downside is that the temperature may overshoot a little more or take a little longer to stabilise than before.

- Tidied up axis homing tracking so that the axes are not flagged as homed until either an endstop or the Z probe has been triggered, or a G92 has been executed.

- Removed an unused variable. Changed some more "char*" to "const char*".

Your feedback will be welcomed.

Edited 1 time(s). Last edit at 03/02/2014 06:54PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

- When checking endstops, wait for the move to complete before accepting further moves, otherwise subsequent moves use the wrong coordinates. [That's why the homex.g etc. files supplied by RRP have G92 commands after all the G1 S1 commands.]

- Thermistors and Z probe are now monitored continuously using a tick interrupt to kick off ADC conversions. ADC is now run in 12-bit mode. Thermistor readings are passed through averaging filters. Thermistors are monitored for overheat conditions and bad readings in the tick ISR and the appropriate heater is turned off (this is useful because the main loop sometimes gets suspended while trying to do USB communication, which can result in overheating). IR probe modulation frequency is increased from 83Hz to 250Hz. Number of Z probe readings averaged is increased from 8 to 16.

- Use watchdog timer to monitor the tick interrupt (needs patch to Arduino Due core library). Add facility to test watchdog timer (M111 S1001).

- Added an error status word to record that errors have occurred (e.g. over-temperature).

- M111 command changed so that S0 turns debug off, S1 turns debug on, S2 reports free memory - also now reports the type of the last restart and the error status word.

- Fixed problem whereby M111 debug reports were not sent to the web interface.

- Implemented M999 command, which resets the Duet.

- Changed extruder PID parameters and added more explanation for them. If the Duet is reset when the extruder is hot and it is commanded to heat up again without being allowed to cool, the temperature no longer undershoots badly. The downside is that the temperature may overshoot a little more or take a little longer to stabilise than before.

- Tidied up axis homing tracking so that the axes are not flagged as homed until either an endstop or the Z probe has been triggered, or a G92 has been executed.

- Removed an unused variable. Changed some more "char*" to "const char*".

Your feedback will be welcomed.

Edited 1 time(s). Last edit at 03/02/2014 06:54PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New firmware March 03, 2014 05:12AM |

Registered: 10 years ago Posts: 578 |

|

Re: New firmware March 03, 2014 05:46AM |

Registered: 10 years ago Posts: 275 |

|

Re: New firmware March 04, 2014 09:40AM |

Registered: 10 years ago Posts: 300 |

Quote

dc42

3. Added additional optional Z probe parameters: calibration temperature, and temperature coefficient of height. Example: G31 Z0.8 P600 T60 C0.0076. If you do not specify a T value, then the current bed temperature will be assumed unless the G31 command is being processed from a file.

Hi dc42, can you explain a little bit more about the temp.coefficient - i.e. the procedure required to obtain the figure for C and how it's used by the firmware

Quote

dc42

4. Z-probe parameters, Z-probe type, emulation mode and network IP addresses are now saved to flash memory so that they survive power-off and reset cycles. Note that whenever you load new firmware, the flash memory gets erased and all these parameters get reset to default values. Values read from config.g override the saved values.

I couldn't see anything that explained Z-probe type or how to set it... I'm currently using Ultrasound but in compatibility mode with the standard IR. Is there any additional support for this arrangment?

Great to see that the G31 probe height and threshold are now stored in non-volatile memory. These are constantly being fettled while playing with different Z probe techniques

RS Components Reprap Ormerod No. 481

|

Re: New firmware March 04, 2014 09:59AM |

Registered: 10 years ago Posts: 14,672 |

Hi Radian,

The supported Z-probe types are:

M558 P0 none

M558 P1 original IR probe, or anything that emulates it

M558 P2 modulated IR probe, with modulation controlled by the Duet

M558 P3 ultrasonic

If you specify a temperature coefficient, then when the target z-probe reading (G31 P parameter) is reached, the height that this is assumed to represent is (Z + (C * (Tb - T))) where Z is the the G31 Z parameter, C is the G31 C parameter, Tb is the current bed temperature, and T is the G31 T parameter. See the section on using the ultrasonic transducer neat the end of [miscsolutions.wordpress.com] for more details.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The supported Z-probe types are:

M558 P0 none

M558 P1 original IR probe, or anything that emulates it

M558 P2 modulated IR probe, with modulation controlled by the Duet

M558 P3 ultrasonic

If you specify a temperature coefficient, then when the target z-probe reading (G31 P parameter) is reached, the height that this is assumed to represent is (Z + (C * (Tb - T))) where Z is the the G31 Z parameter, C is the G31 C parameter, Tb is the current bed temperature, and T is the G31 T parameter. See the section on using the ultrasonic transducer neat the end of [miscsolutions.wordpress.com] for more details.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New firmware March 04, 2014 05:07PM |

Registered: 10 years ago Posts: 300 |

Thanks for that. So far, so good - the raw z-probe readings are noticeably more steady using 057r-dc42

Actually with the 12V Supply switched off, using USB supply only, the readings from my Ultrasound probe are either rock steady or dither by just one count. With the 12V on and the 5V switching reg. running, the dither is still only 3 counts. I wondered if vibration from the fan might be adding to the dither but it doesn't seem to improve if I unplug it.

RS Components Reprap Ormerod No. 481

Actually with the 12V Supply switched off, using USB supply only, the readings from my Ultrasound probe are either rock steady or dither by just one count. With the 12V on and the 5V switching reg. running, the dither is still only 3 counts. I wondered if vibration from the fan might be adding to the dither but it doesn't seem to improve if I unplug it.

RS Components Reprap Ormerod No. 481

|

Re: New firmware March 05, 2014 06:04AM |

Registered: 10 years ago Posts: 22 |

Hi dc42,

I've loaded the .057r version and I'm tryng to print ABS at 240°C for the extruder and 110°C for the bed.

If I set the head temperature at 240°C from the web interface, i see that the temperature reaches the setpoint, but after few minutes the temperature go low.

This appear to be not recoverable and i must reset the duet to restore functionality.

There is a maximum limit for the temperature extruder (>= 240°C) that can cause the alarm?

Roberto

RS Ormerod #117

I've loaded the .057r version and I'm tryng to print ABS at 240°C for the extruder and 110°C for the bed.

If I set the head temperature at 240°C from the web interface, i see that the temperature reaches the setpoint, but after few minutes the temperature go low.

This appear to be not recoverable and i must reset the duet to restore functionality.

There is a maximum limit for the temperature extruder (>= 240°C) that can cause the alarm?

Roberto

RS Ormerod #117

|

Re: New firmware March 05, 2014 06:17AM |

Registered: 10 years ago Posts: 14,672 |

Hi Roberto,

The temperature limit is set at 300C so it should not be getting triggered at 240C. I'll run some more tests at high temperatures. When you say that the "temperature go low", how low does it go? Do you see a message in the message log that there has been a temperature error? If so, there is a command (M562) that can be used to reset the temperature error.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The temperature limit is set at 300C so it should not be getting triggered at 240C. I'll run some more tests at high temperatures. When you say that the "temperature go low", how low does it go? Do you see a message in the message log that there has been a temperature error? If so, there is a command (M562) that can be used to reset the temperature error.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New firmware March 05, 2014 06:49AM |

Registered: 10 years ago Posts: 14,672 |

Roberto,

I've just run my extruder at 250C for 15 minutes without any problems. Perhaps your thermistor connection is intermittent? I had that problem because of poor connections in the 6-way plug and socket,.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I've just run my extruder at 250C for 15 minutes without any problems. Perhaps your thermistor connection is intermittent? I had that problem because of poor connections in the 6-way plug and socket,.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New firmware March 05, 2014 08:23AM |

Registered: 10 years ago Posts: 859 |

hihihihi I use my RED Glass....... It works for me....

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: New firmware March 05, 2014 10:49AM |

Registered: 10 years ago Posts: 22 |

dc42,

I've disconnected and reconnected the 6way, ATX supply and duet thermistor connector (thermistor is soldered),

Disconnected USB connector (not used because I use web connection, but still connected from yesterday when I've charged 0.57r fw).

All is working fine now, so it's not fw issue.

Maybe a poor connection, i don't know, but now i'm printing

Thanks

Roberto

RS Ormerod #117

I've disconnected and reconnected the 6way, ATX supply and duet thermistor connector (thermistor is soldered),

Disconnected USB connector (not used because I use web connection, but still connected from yesterday when I've charged 0.57r fw).

All is working fine now, so it's not fw issue.

Maybe a poor connection, i don't know, but now i'm printing

Thanks

Roberto

RS Ormerod #117

|

Re: New firmware March 05, 2014 03:59PM |

Registered: 10 years ago Posts: 14,672 |

I have just released version 052s-dc42 057t-dc42 of my fork of the Duet firmware. You can find it at [github.com] (don't forget to use the Raw button). Changes in this release:

1. Fixed bug introduced at version 057r whereby axis travel limits were not applied properly after homing..

2. Increased maximum travel on 2nd phase of Z-probing from 1mm to 10mm.

3. Added parameters R (thermistor 25C resistance) and B (thermistor beta) to M301 command.

4. Added support for M304 command with same parameters as M301 command.

5. PID and thermistor parameters are now saved to flash memory.

6. 1-bit oversampling is now used when measuring temperatures, providing greater resolution.

Item 2 alleviates an issue encountered by radian with his ultrasonic Z-probe. Item 3 allows different thermistors to be used for the hot end, or the standard thermistor to be calibrated. Item 4 allows the same for the bed thermistor. It also allows the bed heater to be operated in PID mode, although I don't think there is any real advantage in doing this (for anyone who wants to try, I suggest starting values P=100 I=5 D=500).

I have withdrawn version 0.57r-dc42 in the light of change 1.

Edited 4 time(s). Last edit at 03/05/2014 04:58PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Fixed bug introduced at version 057r whereby axis travel limits were not applied properly after homing..

2. Increased maximum travel on 2nd phase of Z-probing from 1mm to 10mm.

3. Added parameters R (thermistor 25C resistance) and B (thermistor beta) to M301 command.

4. Added support for M304 command with same parameters as M301 command.

5. PID and thermistor parameters are now saved to flash memory.

6. 1-bit oversampling is now used when measuring temperatures, providing greater resolution.

Item 2 alleviates an issue encountered by radian with his ultrasonic Z-probe. Item 3 allows different thermistors to be used for the hot end, or the standard thermistor to be calibrated. Item 4 allows the same for the bed thermistor. It also allows the bed heater to be operated in PID mode, although I don't think there is any real advantage in doing this (for anyone who wants to try, I suggest starting values P=100 I=5 D=500).

I have withdrawn version 0.57r-dc42 in the light of change 1.

Edited 4 time(s). Last edit at 03/05/2014 04:58PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New firmware March 05, 2014 04:20PM |

Registered: 10 years ago Posts: 859 |

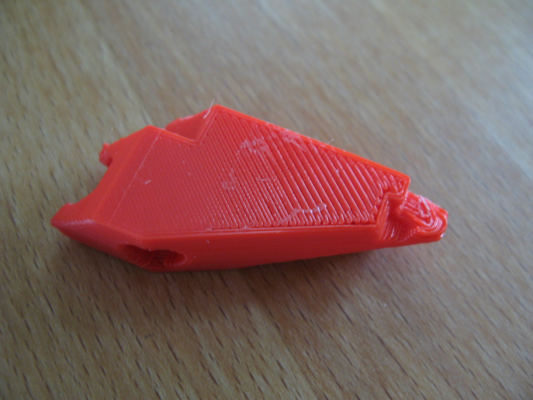

Hi David, I've just published the Adapter Plate for my Fan Duct to allow you to mount your I.R. Probe on the arm provided.

It's a clip on add on (if you fettle it properly), or you can use 5min Apoxy if you break the clips while fitting.

So if you strip the holes when fitting the probe, you can just print a replacement adapter plate.....

I've made the mounting plate approximately the same size as on IamBurnys fan housing, with a 2mm clearance for your connectors on top (but there is enough plastic there if you need to make more room).

Let me know if it needs adjusting to suit your probe....

Hope that helps.

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

It's a clip on add on (if you fettle it properly), or you can use 5min Apoxy if you break the clips while fitting.

So if you strip the holes when fitting the probe, you can just print a replacement adapter plate.....

I've made the mounting plate approximately the same size as on IamBurnys fan housing, with a 2mm clearance for your connectors on top (but there is enough plastic there if you need to make more room).

Let me know if it needs adjusting to suit your probe....

Hope that helps.

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: New firmware March 05, 2014 04:24PM |

Registered: 10 years ago Posts: 132 |

Sorry, only registered users may post in this forum.