"I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)"

Posted by KimBrown

"I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 26, 2014 07:41PM |

Registered: 10 years ago Posts: 859 |

I'm not going to give to much away just yet.... Let me Trial it which I hope to do tomorrow...

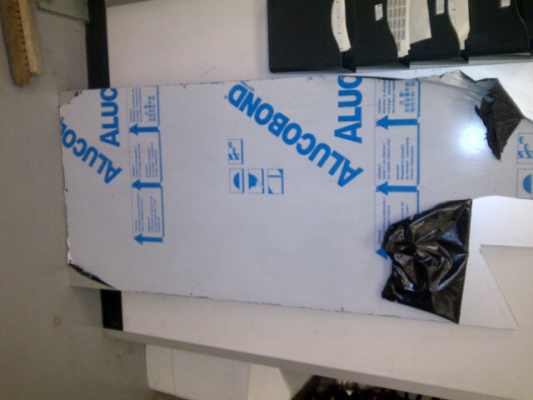

But I think I might have stumbled across the perfect material for the bottom plate of the HotBed.

1) It's lite.....(Low MASS, means faster movements) Similar weight to the 3mm MDF thing we get in the kit. But a whole lot liter than Ally..

So less strain on the Y axis drive.......

2) It's as stiff as 6 to 8mm ply, so is ridged enough to Jack the HotBed from..... The BIG plus point..

3) I've cut my prototype out with a Stanley Knife, and for the holes I'm using a chisel....

So it's a blessing to cut. Far easier than Ally...And using a jig saw. (We're on a Roll here)....

4) I'm going to try using the 'as supplied' basic frame for it first, before elaborating on it. (Maybe a plus, but I have some extra frames and a bearing in

waiting).... If I can get away without using an extra bearing and an extra frame or two I will, cos it'll cut down on drag.

5) Cheap as chips..... Cheaper than Ally.. (Magic!)....

I'm not going to say to much more till I've tested it... But the prospects are GOOD....

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

But I think I might have stumbled across the perfect material for the bottom plate of the HotBed.

1) It's lite.....(Low MASS, means faster movements) Similar weight to the 3mm MDF thing we get in the kit. But a whole lot liter than Ally..

So less strain on the Y axis drive.......

2) It's as stiff as 6 to 8mm ply, so is ridged enough to Jack the HotBed from..... The BIG plus point..

3) I've cut my prototype out with a Stanley Knife, and for the holes I'm using a chisel....

So it's a blessing to cut. Far easier than Ally...And using a jig saw. (We're on a Roll here)....

4) I'm going to try using the 'as supplied' basic frame for it first, before elaborating on it. (Maybe a plus, but I have some extra frames and a bearing in

waiting).... If I can get away without using an extra bearing and an extra frame or two I will, cos it'll cut down on drag.

5) Cheap as chips..... Cheaper than Ally.. (Magic!)....

I'm not going to say to much more till I've tested it... But the prospects are GOOD....

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 26, 2014 07:44PM |

Registered: 10 years ago Posts: 578 |

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 27, 2014 01:10AM |

Registered: 10 years ago Posts: 191 |

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 27, 2014 02:02AM |

Registered: 10 years ago Posts: 1,230 |

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 27, 2014 06:52AM |

Registered: 10 years ago Posts: 859 |

@Ray...... No...... LoL 19 to go......

@Erik...... It's cheap as chips.... I was going to see if I could find my small chisels to cut the holes for the alignment pegs

on the framework, but I'm feeling tired and lazy today, so going to use the original MDF plate under the new bed plate.

Have to take my sister out this afternoon, but hopefully I'll get a chance to complete the Bed later.

I've also found a really really quiet replacement cooling fan for £2.50 a time. I got 4 of these to use the others on some other projects

I have on the go. They don't pump out as much air as the original, but I think it'll be more than enough to keep things cooled down.

Fans from Ebay

The fan in my Ace power supply is noisier than these, so that's saying something.....

And they arrived the next day after ordering.....

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 27, 2014 08:15AM |

Registered: 10 years ago Posts: 52 |

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 27, 2014 08:54AM |

Registered: 10 years ago Posts: 145 |

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 27, 2014 10:17AM |

Registered: 10 years ago Posts: 1,230 |

Quote

KimBrown

.......They don't pump out as much air as the original, but I think it'll be more than enough to keep things cooled down.

..and with iamburny's brillant Replacement Fan Duct/Heatsink Duct (johneato added IR-holder included) it just might get more air through than the original setup

[forums.reprap.org]

Erik

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 27, 2014 01:02PM |

Registered: 10 years ago Posts: 145 |

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 27, 2014 04:23PM |

Registered: 10 years ago Posts: 9 |

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 27, 2014 04:54PM |

Registered: 10 years ago Posts: 275 |

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 27, 2014 04:57PM |

Registered: 10 years ago Posts: 859 |

Seaweed.... Darn, I could have made it even cheaper.......

Actually Greg is right.... It's a composite board... Two 0.5mm layers of Ally either side of about 2mm of plastic.

When I'm model making I get some of my plastic from a guy that makes signs. I wanted to make it from some

clear bullet proof plastic he used to have. But he doesn't keep it any more. The composite board is very cheap,

strong, and you can cut it with a stanley knife or a chisel very easily.

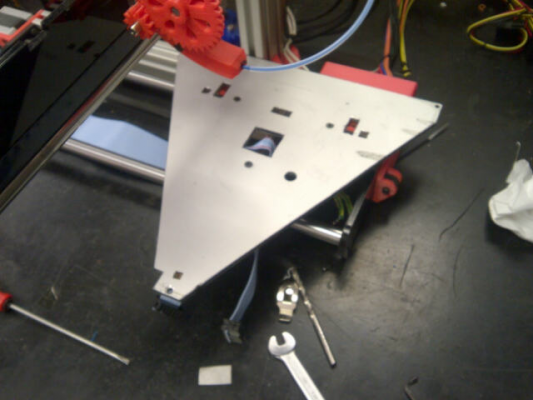

I've put that on top of the original MDF plate as the MDF plate does the aligning.

Fitting it to the framework was easy, and I've drilled out the holes in the HotBed heater and spreader to 3.5mm

to try and get it to lay flat on the new bed. But my HotBed heater is bowed I've realised. I don't know yet if it

will flatten out when it's hot or get worse... As all the bolts for leveling are connected together I started to think

about the electrical side of things, then I realised the only thing stopping the heat spreader from shorting the

Duet out is a thin layer of varnish. I think I'm going to slide a piece of paper between my heater plate and the spreader,

just incase.. Pictures tomorrow I think... Pub tonight... I need a pint..

Pictures tomorrow I think... Pub tonight... I need a pint..

Edited 1 time(s). Last edit at 02/27/2014 04:59PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Actually Greg is right.... It's a composite board... Two 0.5mm layers of Ally either side of about 2mm of plastic.

When I'm model making I get some of my plastic from a guy that makes signs. I wanted to make it from some

clear bullet proof plastic he used to have. But he doesn't keep it any more. The composite board is very cheap,

strong, and you can cut it with a stanley knife or a chisel very easily.

I've put that on top of the original MDF plate as the MDF plate does the aligning.

Fitting it to the framework was easy, and I've drilled out the holes in the HotBed heater and spreader to 3.5mm

to try and get it to lay flat on the new bed. But my HotBed heater is bowed I've realised. I don't know yet if it

will flatten out when it's hot or get worse... As all the bolts for leveling are connected together I started to think

about the electrical side of things, then I realised the only thing stopping the heat spreader from shorting the

Duet out is a thin layer of varnish. I think I'm going to slide a piece of paper between my heater plate and the spreader,

just incase..

Pictures tomorrow I think... Pub tonight... I need a pint..

Pictures tomorrow I think... Pub tonight... I need a pint..Edited 1 time(s). Last edit at 02/27/2014 04:59PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 27, 2014 05:31PM |

Registered: 10 years ago Posts: 578 |

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 27, 2014 05:47PM |

Registered: 10 years ago Posts: 275 |

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 28, 2014 02:07AM |

Registered: 10 years ago Posts: 20 |

I'm been using same stuff for last 3 weeks abeit with 3mm plastic as the centre, it does work and doesn't appear to have any problems with temperature. I'm not convinced it is the ultimate solution as it is still possible to bend but currently it is better than anything else as is light and can be cut with knife,jigsaw and file.

Regards

Chris H

Regards

Chris H

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 28, 2014 02:21AM |

Registered: 10 years ago Posts: 191 |

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 28, 2014 10:42AM |

Registered: 10 years ago Posts: 1,230 |

Quote

KimBrown

... It's a composite board... Two 0.5mm layers of Ally either side of about 2mm of plastic...

Funny that, I have a slice of the very same in 4mm standing in a corner 3 meters from my ormerod and it never crossed my mind to use it as bed material tsk. tsk.

..but aluminium on both sides, one side will be warmer than the other, will it go walkabout?

Erik

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 28, 2014 10:57AM |

Registered: 10 years ago Posts: 859 |

Hoping to get the bed back on the machine later today. Life get busy during my first week off, but I hope to be printing again later....

This hobby is addictive....

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

This hobby is addictive....

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 28, 2014 05:35PM |

Registered: 10 years ago Posts: 20 |

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 28, 2014 07:56PM |

Registered: 10 years ago Posts: 859 |

Hmmmm Well first the good news....

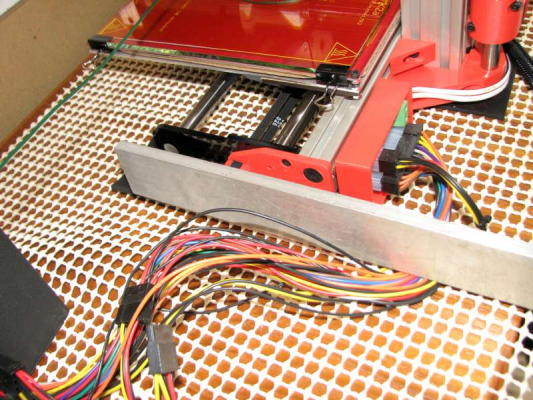

The bed plate is ok, and I now have lighting on my X carriage (a 3 LED strip wired up to the fan supply), which works well

and I can now see whats going on...

Now the bad news... When leveling the hotbed I noticed the back idler end of the bed was catching on the Z axis Ally extrusion.

When I got close to finishing the leveling I then noticed that the back adjuster for the bed was 4mm higher than the rest...

Time to have a good look around. Well I found the problem... The printed Y Idler bracket is sheared...

My z axis is doing impressions of the leaning tower of Pizza...

Just going to try and print one if it's not to far gone...

But the beds fairly level in a crooked way lol....

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

The bed plate is ok, and I now have lighting on my X carriage (a 3 LED strip wired up to the fan supply), which works well

and I can now see whats going on...

Now the bad news... When leveling the hotbed I noticed the back idler end of the bed was catching on the Z axis Ally extrusion.

When I got close to finishing the leveling I then noticed that the back adjuster for the bed was 4mm higher than the rest...

Time to have a good look around. Well I found the problem... The printed Y Idler bracket is sheared...

My z axis is doing impressions of the leaning tower of Pizza...

Just going to try and print one if it's not to far gone...

But the beds fairly level in a crooked way lol....

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 28, 2014 08:12PM |

Registered: 10 years ago Posts: 578 |

Quote

KimBrown

But the beds fairly level in a crooked way lol....

hehe, good that there's a bright side

If you send me a link to the stl of the part you need (if the one you try printing doesn't work), I'll print one for you and send it (providing you pm me a suitable address),

Cheers

Ray

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 28, 2014 08:37PM |

Registered: 10 years ago Posts: 859 |

Thanks Ray.... I'm going for my second attempt here... I had bad warping on the first one. Otherwise it was looking good which

all concidered is amazing... Going to run with the bed at 90' and see if it works..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

all concidered is amazing... Going to run with the bed at 90' and see if it works..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 28, 2014 08:48PM |

Registered: 10 years ago Posts: 578 |

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 28, 2014 08:50PM |

Registered: 10 years ago Posts: 859 |

Well I have a few things going for me now...

LEDs on the X-carriage, which are letting me see whats going on.

The Red Glass and the probe are working really well here at home.

The improved bed plate is managing to stay in place, and I don't dare even look to hard at the printer incase it moves...

Printing here with 190' HotEnd and 90' bed on freshed washed glass....

I'm having one of those stupid days... Where things are going wrong... You muddle throu, and it comes good in the end.

3rd Layer on the print, and all looks good.

Even the new fan is working well, but I'll have to design a better Backwash Duct for it...

At the moment I'm using the one I made a week or so ago, and it's amplifying the fan noise.

As the new fan is only half as thick as the old one, there's plenty of room for a new Duct type cover.

I'll try and upload some pictures while this is printing.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

LEDs on the X-carriage, which are letting me see whats going on.

The Red Glass and the probe are working really well here at home.

The improved bed plate is managing to stay in place, and I don't dare even look to hard at the printer incase it moves...

Printing here with 190' HotEnd and 90' bed on freshed washed glass....

I'm having one of those stupid days... Where things are going wrong... You muddle throu, and it comes good in the end.

3rd Layer on the print, and all looks good.

Even the new fan is working well, but I'll have to design a better Backwash Duct for it...

At the moment I'm using the one I made a week or so ago, and it's amplifying the fan noise.

As the new fan is only half as thick as the old one, there's plenty of room for a new Duct type cover.

I'll try and upload some pictures while this is printing.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 28, 2014 08:58PM |

Registered: 10 years ago Posts: 578 |

Good to hear the red glass is holding up against house bulbs - where did you source it from? "dark Red" isn't too easy to replicate I don't even know where my IR sensor is I took it off weeks ago and haven't seen it since, so I'm not going to rush out and buy some immediately, but it might be the triple whammy on top of dc42's modulation and Treth's top hat, and I'll look into getting some when dc42's new sensor board is shipping.

I don't even know where my IR sensor is I took it off weeks ago and haven't seen it since, so I'm not going to rush out and buy some immediately, but it might be the triple whammy on top of dc42's modulation and Treth's top hat, and I'll look into getting some when dc42's new sensor board is shipping.

Cheers

Ray

I don't even know where my IR sensor is I took it off weeks ago and haven't seen it since, so I'm not going to rush out and buy some immediately, but it might be the triple whammy on top of dc42's modulation and Treth's top hat, and I'll look into getting some when dc42's new sensor board is shipping.

I don't even know where my IR sensor is I took it off weeks ago and haven't seen it since, so I'm not going to rush out and buy some immediately, but it might be the triple whammy on top of dc42's modulation and Treth's top hat, and I'll look into getting some when dc42's new sensor board is shipping.Cheers

Ray

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" February 28, 2014 10:24PM |

Registered: 10 years ago Posts: 859 |

Hmmmm second attempt failed, due to warping at the other end of the print where the vents from the fan blow out.

And the print moved... It was 75% done to.... I've added a brim for attemped 3,

and I've gaffa taped the wents. Then drilled two holes in the top of the fan duct.

It doesn't look pretty at the moment, but if it works I'll reprint the ducting with an open top so the air can go upwards to get out.

I have nearly no air blowing in the prints direction now. I'll try and print it again tomorrow.

Don't get to excited about the Red Glass... I got it from the Glass shop around the corner. £12 for Dark Red Float Glass..

Yes it does improve things, but I haven't tried it under incandescent lighting yet.

I will do soon, but I need to fix the printer first. I know what I did wrong when I put the printer together now.

I over tightend the 6mm counter sunk screws in the Y Idler Bracket, and it's split.

I think maybe when I put the new one on (if I get it to print), I'll use regular Hex headed bolts with a washer under each

to stop it happening again.

Edited 1 time(s). Last edit at 02/28/2014 10:35PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

And the print moved... It was 75% done to.... I've added a brim for attemped 3,

and I've gaffa taped the wents. Then drilled two holes in the top of the fan duct.

It doesn't look pretty at the moment, but if it works I'll reprint the ducting with an open top so the air can go upwards to get out.

I have nearly no air blowing in the prints direction now. I'll try and print it again tomorrow.

Don't get to excited about the Red Glass... I got it from the Glass shop around the corner. £12 for Dark Red Float Glass..

Yes it does improve things, but I haven't tried it under incandescent lighting yet.

I will do soon, but I need to fix the printer first. I know what I did wrong when I put the printer together now.

I over tightend the 6mm counter sunk screws in the Y Idler Bracket, and it's split.

I think maybe when I put the new one on (if I get it to print), I'll use regular Hex headed bolts with a washer under each

to stop it happening again.

Edited 1 time(s). Last edit at 02/28/2014 10:35PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" March 01, 2014 05:24AM |

Registered: 10 years ago Posts: 1,230 |

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" March 01, 2014 08:00AM |

Registered: 10 years ago Posts: 1,230 |

Quote

KimBrown

... Well I found the problem... The printed Y Idler bracket is sheared...

Kim

How about strengthen your end plates with some 40x8 aluminium bolted directly to the extrusion with the acrylic y-axis end plates inside and the y-idler bracket and y-motor bracket outside (as in the aluminium in between)? - I think it would be best to shorten the printed end parts and fix them to the new aluminium end plates with screws only (counter sink the alu)

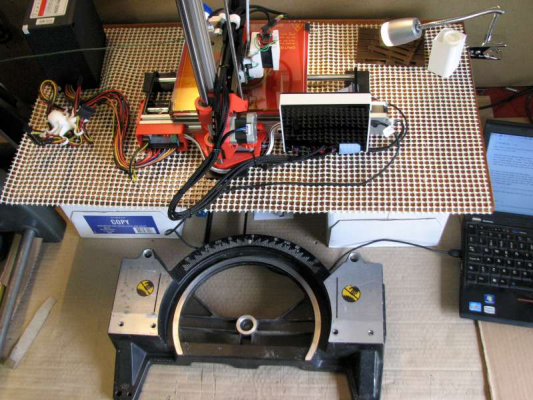

..or go all the way and make the ormerod really stable and transportable - look what I found at the local scrap yard!, cast aluminium, milled at both ends!

My plan is to bolt the Y axis frame (the Alumninium extrusion) down with T-nuts in both ends, adjusted with spacers

Make new end parts from 40x8mm aluminium, these will be bolted directly to the ends of the aluminium extrusion and bolted down to the new foundation, with the acrylic y-axis endplates inside and the y-idler bracket and y-motor bracket outside

..and of cause extend the extruded z-axis part down and fix it to the bottom of this über-stable-no-twist-table

Erik

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" March 01, 2014 08:28AM |

Registered: 10 years ago Posts: 859 |

LoL Erik.... We aren't allowed bottles.... Well none with anything interesting in...

Hmmm My Printer went mad this morning HotBed wouldn't come on, then the X axis was making horrible sounds.

Turned it all off, back on again... Perfect....

No idea why...

Have blocked the air vents, and going to give it one last shot today, while I get some work done on the car.

My main problem is time...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Hmmm My Printer went mad this morning HotBed wouldn't come on, then the X axis was making horrible sounds.

Turned it all off, back on again... Perfect....

No idea why...

Have blocked the air vents, and going to give it one last shot today, while I get some work done on the car.

My main problem is time...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Re: "I think! I might have found the ultimate Sub-Bed for the HotBed (Bigger than a maybe)" March 01, 2014 09:03AM |

Registered: 10 years ago Posts: 300 |

Sorry, only registered users may post in this forum.

)

)