The Ormerod 400 x 400 x 400

Posted by badman.teddy.edward

|

The Ormerod 400 x 400 x 400 March 07, 2014 04:59PM |

Registered: 10 years ago Posts: 32 |

A few of us are planning to scale up our Ormerods.

Total planned print area is 400mm x 400mm x 400mm.

Right now we seem to have arrived at using four mk2a heat beds (same type as the Ormerod ships with) with one central thermistor.

A second upright to support the x and z axis components.

Mosfets to control switching.

All ideas are welcome.

EDIT:

This has migrated from [forums.reprap.org]

Edited 1 time(s). Last edit at 03/07/2014 05:00PM by badman.teddy.edward.

Total planned print area is 400mm x 400mm x 400mm.

Right now we seem to have arrived at using four mk2a heat beds (same type as the Ormerod ships with) with one central thermistor.

A second upright to support the x and z axis components.

Mosfets to control switching.

All ideas are welcome.

EDIT:

This has migrated from [forums.reprap.org]

Edited 1 time(s). Last edit at 03/07/2014 05:00PM by badman.teddy.edward.

|

Re: The Ormerod 400 x 400 x 400 March 07, 2014 07:08PM |

Registered: 10 years ago Posts: 578 |

Hi Teddy - maybe the lowest footprint way of doing that build volume would be to move X and Y on a shared gantry, and then either raise the bed in Z or lower the X-Y gantry (this was one of the many options flying around in my head when I started buying hardware a couple of months ago - I bought some Igus Drylin track to keep the weight of the x/y gantry down, and bought ten motors form China in case I needed two per x and y and four for vertical movement). When the igus track arrived I started thinking about how one could slide on the 40X20 and decided 400x400 was out of reach as far as a bed went, etc etc and now I've pretty much decided to keep the Ormerod axis geometry - but I could be convinced otherwise!

If you haven't seen the x/y gantry idea before (or know it by a different name), take a look at this: [www.youtube.com] (there are many machines using this geometry, but this animation is pretty clear) they use smooth rod and bearings in this, I was thinking of a track with a "+" shaped union between the two tracks with the hotend sitting in one corner - either way the downside is you need synchronised drives each end of each axis to make sure that you don't get swing and possible binding (which you would get driving from one end only, and you can't drive from the centre, or you get in the way of the other axis). The drives can be from one motor(linked by belts for instance) or two directly driving, but then you need to ensure that if one motor loses steps, the other doesn't get carried away. The upside is that for a 500x500X500 mm frame, you'd get a 400X400X400 build volume pretty easily.

Using the Ormerod's axis geometry, you need to move the platform by its whole length on Y (ie if you have a bed 400mm long in Y you need an 800mm space) it doesn't all need to be enclosed in the frame, but you do need at least an 800 by 400 footprint on your desktop for a 400 by 400 bed - if I needed a bed that size, I'm pretty sure that alone would swing me towards the x/y gantry

Cheers

Ray

Edited 2 time(s). Last edit at 03/07/2014 07:10PM by rayhicks.

If you haven't seen the x/y gantry idea before (or know it by a different name), take a look at this: [www.youtube.com] (there are many machines using this geometry, but this animation is pretty clear) they use smooth rod and bearings in this, I was thinking of a track with a "+" shaped union between the two tracks with the hotend sitting in one corner - either way the downside is you need synchronised drives each end of each axis to make sure that you don't get swing and possible binding (which you would get driving from one end only, and you can't drive from the centre, or you get in the way of the other axis). The drives can be from one motor(linked by belts for instance) or two directly driving, but then you need to ensure that if one motor loses steps, the other doesn't get carried away. The upside is that for a 500x500X500 mm frame, you'd get a 400X400X400 build volume pretty easily.

Using the Ormerod's axis geometry, you need to move the platform by its whole length on Y (ie if you have a bed 400mm long in Y you need an 800mm space) it doesn't all need to be enclosed in the frame, but you do need at least an 800 by 400 footprint on your desktop for a 400 by 400 bed - if I needed a bed that size, I'm pretty sure that alone would swing me towards the x/y gantry

Cheers

Ray

Edited 2 time(s). Last edit at 03/07/2014 07:10PM by rayhicks.

|

Re: The Ormerod 400 x 400 x 400 March 08, 2014 03:40AM |

Registered: 10 years ago Posts: 776 |

If you remove the X belts and runners and place the motor on the gantry, you have pretty much got a standard CNC router/plasma table, just lighter in mass.

This is how I got into the 3d game show, I have recently built a small table 600x600 for plasma cutting metal, it was while waiting for the arrival of the cutting torch that I dabbled with extrusion printing on it. Just bought a cheap head from eBay, another axis drive for the controller and bolted it all together.

It was a disaster because I unknowingly bought a crap print head and it kept jamming solid in the nozzle tube. I now know that there was no ptfe tube in there and the are well known for being dodgy. Win some lose some

The torch has arrived now so it's metal cutting time for that machine and I have the ormerod for home fun

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

This is how I got into the 3d game show, I have recently built a small table 600x600 for plasma cutting metal, it was while waiting for the arrival of the cutting torch that I dabbled with extrusion printing on it. Just bought a cheap head from eBay, another axis drive for the controller and bolted it all together.

It was a disaster because I unknowingly bought a crap print head and it kept jamming solid in the nozzle tube. I now know that there was no ptfe tube in there and the are well known for being dodgy. Win some lose some

The torch has arrived now so it's metal cutting time for that machine and I have the ormerod for home fun

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: The Ormerod 400 x 400 x 400 March 08, 2014 07:19AM |

Registered: 10 years ago Posts: 36 |

Ok, I have been looking at a lot of the variations that are currently out there, so much choice, multi extruder, multi colour/material single extruder, slides, nylon bearings and so on AND ON AND ON. Richrap dot com has some interesting things!

I have ordered several extrusions, of 240mm, 480mm and 500mm along with a selection of connectors, feet, sliders and wheels, I have no idea if the sliders/wheels will fit into the slots, but I will find out soon enough. the next thing to find is motors and wiring, I do like the nema 14s that we have and assume that they will be suitable!??

After that it will be a case of a suitable bed support, and heated beds (I'm still concerned about the amount of power needed for 4 beds).

A couple of things to think about:

Anyways, time to get settled in for the 6 Nations.......

Mike.

I have ordered several extrusions, of 240mm, 480mm and 500mm along with a selection of connectors, feet, sliders and wheels, I have no idea if the sliders/wheels will fit into the slots, but I will find out soon enough. the next thing to find is motors and wiring, I do like the nema 14s that we have and assume that they will be suitable!??

After that it will be a case of a suitable bed support, and heated beds (I'm still concerned about the amount of power needed for 4 beds).

A couple of things to think about:

- How much power will we need in total? (I currently have a 32A 12v PSU). If the power is insufficient, I may opt to limit my X axis to 200mm to start with.

- Can the aluminium extrusion be used as a gantry (sliders in the top and the body of the extruder head formed around to below? The current X axis belt drive system could be used)

- Can 2 motors be run from a single driver to maintain accuracy, or is there a better way of controlling movement accurately?

- How do we change the parameters of the bed size for the controlling software?

- Probably a lot more that I haven't thought of!

Anyways, time to get settled in for the 6 Nations.......

Mike.

|

Re: The Ormerod 400 x 400 x 400 March 08, 2014 07:57AM |

Registered: 10 years ago Posts: 578 |

Hi Mike,

the motors are nema 17, not 14 (those are tiny), the longer nema17's might be a wise investment, they have more torque.

The beds have a cold resistance of around 1-1.2ohms, drawing 10-12 amp of 12V giving 120-144 Watt, four of them would push your PSU past the limit

Can the extrusion be used as a gantry? that's my plan, and it's looking so

Can two motors be used from a single driver ? yes, but with the caveat that if one slips the other won't know -you can wire them in series or parallel, if your driver can take it [forums.reprap.org] , googling "wiring two steppers in parallel" throws up a lot of info and discussion. There's an alternative approach here [reprap.org] where they use separate drivers but sync the motors using a custom board, schematic here [reprap.org] . There's a lot of stuff on using multiple motors per axis around, also using belt to move two or more leadscrews, and other approaches.

Build volume is defined in platform.h of the firmware:

Ray

the motors are nema 17, not 14 (those are tiny), the longer nema17's might be a wise investment, they have more torque.

The beds have a cold resistance of around 1-1.2ohms, drawing 10-12 amp of 12V giving 120-144 Watt, four of them would push your PSU past the limit

Can the extrusion be used as a gantry? that's my plan, and it's looking so

Can two motors be used from a single driver ? yes, but with the caveat that if one slips the other won't know -you can wire them in series or parallel, if your driver can take it [forums.reprap.org] , googling "wiring two steppers in parallel" throws up a lot of info and discussion. There's an alternative approach here [reprap.org] where they use separate drivers but sync the motors using a custom board, schematic here [reprap.org] . There's a lot of stuff on using multiple motors per axis around, also using belt to move two or more leadscrews, and other approaches.

Build volume is defined in platform.h of the firmware:

#define AXIS_LENGTHS {220, 200, 200} // mm

and can be set using M208 X Y Z - I'm not sure if M208 overrides the predefined maximum (ideally it does so you'll just need to edit the config.g)Ray

|

Re: The Ormerod 400 x 400 x 400 March 08, 2014 08:43AM |

Registered: 10 years ago Posts: 14,672 |

I think you will need a 600W power supply to drive 4 beds + 1 extruder + duet. It may be that 600W is enough for multiple extruders, depending on the resistance of the wires supplying power to the bed. There are several Chinese eBay suppliers offering these [www.ebay.co.uk]. This appears to be from the same range as the 12V 300W supply I am using.

EDIT: I think you would be better off running from 24V and putting 2 heated beds in series across the 24V supply, then you will only have to handle half as much current. The Duet board will supposedly handle up to 35V input. You could use this [www.ebay.co.uk].

EDIT 2: but then you would need a 24V cartridge heater and a 24V fan for the hot end, if you are running everything from the same supply. Alternatively, use a 12V supply for the Duet and hot end, and a 24V supply just for the heated bed.

Edited 4 time(s). Last edit at 03/08/2014 08:51AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

EDIT: I think you would be better off running from 24V and putting 2 heated beds in series across the 24V supply, then you will only have to handle half as much current. The Duet board will supposedly handle up to 35V input. You could use this [www.ebay.co.uk].

EDIT 2: but then you would need a 24V cartridge heater and a 24V fan for the hot end, if you are running everything from the same supply. Alternatively, use a 12V supply for the Duet and hot end, and a 24V supply just for the heated bed.

Edited 4 time(s). Last edit at 03/08/2014 08:51AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The Ormerod 400 x 400 x 400 March 08, 2014 08:44AM |

Registered: 10 years ago Posts: 14,672 |

Quote

rayhicks

I'm not sure if M208 overrides the predefined maximum (ideally it does so you'll just need to edit the config.g)

Yes, it does.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The Ormerod 400 x 400 x 400 March 08, 2014 04:58PM |

Registered: 10 years ago Posts: 32 |

Morning all.

Looking into amps, and confirmed above, I am going to use the 900w supply I have spare (overhead can't hurt).

The bed design ideas that have been put forward are great.

I was thinking that the cheap sketch I did looked like my cnc router...the more that goes through my head the more I think that is the path to go down.

Keeping the bed stationary and moving the gantry will reduce load on the stepper and probably avoid the need to upgrade it.

I was never a big lover of the belt drive for the Y axis (I tighten mine every 2 prints, sometimes 1) so another bonus will be using a worm drive for it too (again like the cnc).

The reduction of total footprint makes for a bundle of good - 900mm was going to start messing with my workspace.

I noticed there is a mk2b with 24v input. This, I assume, would mean faster heat times?

Does anyone know where there is a spec sheet for the duet? I can't seem to find one on the net..

I couldn't help myself and I have ordered a Duex for the extra print heads. Once DC42's board arrives I may start designing a triple head for this thing. Not that there is Ormerod software with DC's improvements available for it yet..

$8 from eBay for a mk2 heat bed. Ray, is that where you got your warped ones? How is your diy constructed bed coming along?

Looking into amps, and confirmed above, I am going to use the 900w supply I have spare (overhead can't hurt).

The bed design ideas that have been put forward are great.

I was thinking that the cheap sketch I did looked like my cnc router...the more that goes through my head the more I think that is the path to go down.

Keeping the bed stationary and moving the gantry will reduce load on the stepper and probably avoid the need to upgrade it.

I was never a big lover of the belt drive for the Y axis (I tighten mine every 2 prints, sometimes 1) so another bonus will be using a worm drive for it too (again like the cnc).

The reduction of total footprint makes for a bundle of good - 900mm was going to start messing with my workspace.

I noticed there is a mk2b with 24v input. This, I assume, would mean faster heat times?

Does anyone know where there is a spec sheet for the duet? I can't seem to find one on the net..

I couldn't help myself and I have ordered a Duex for the extra print heads. Once DC42's board arrives I may start designing a triple head for this thing. Not that there is Ormerod software with DC's improvements available for it yet..

$8 from eBay for a mk2 heat bed. Ray, is that where you got your warped ones? How is your diy constructed bed coming along?

|

Re: The Ormerod 400 x 400 x 400 March 08, 2014 05:06PM |

Registered: 10 years ago Posts: 32 |

|

Re: The Ormerod 400 x 400 x 400 March 08, 2014 07:22PM |

Registered: 10 years ago Posts: 578 |

Quote

badman.teddy.edward

$8 from eBay for a mk2 heat bed. Ray, is that where you got your warped ones? How is your diy constructed bed coming along?

No I bought mine from a UK seller for £9.99 - the curvature isn't VERY big, but it does let the glass plate rock a little (this really doesn't seem to affect the prints I've done on it though they're no higher than 2cm). The DIY one is coming on well - I ended up with a resistance a little lower than planned,0.6ohms in parallel, and in series 1.2ish, (there are two resistor strips, which can be soldered in series or parallel rather like the dual voltage Mk2b), I've only done the copper resistors on the glass substrate so far, need to back it (I've only had 2hrs of R&D time in total over two days, so not too bad progress. It'll draw 20A in parallel from 12V (giving 240W - a bit more than planned), or 10 in series giving 120W (less than planned), but I'll see how it performs when fully put together and given a full jolt. The criteria for this are that it will heat up reasonably quickly, without blowing the PSU (borderline on that front from the resistance!), and that it have a flat upper surface (hence glass as a substrate) and have parallel front and back surfaces so that it will adopt the angle of the carriage and not need vertical clamps (which induce curvature, which can't be "compensated"). It's going to have an insulating layer bonded under the copper then a stiff flat layer bonded under that so it'll end up being pretty much an entire bed rather than a heater that lies on the bed, and it will lie in a frame that acts as the carriage.

Lead screws are something I also planned to use (but I failed on my first purchase - I bought some with 2mm lead, X and Y need more like a 20mm lead to run fast enough, I'll be using the 2mm stuff for Z - I'll have some left over if you're interested), so initially I've used the belt supplied with the ormerod and am going to try rack and pinion for X and Y (then maybe invest in some long-lead screw if I go for the x/y gantry).

The Duet schematics are on github somewhere, I can't find them just now, but I'm sure someone will point you there

Cheers

Ray

Edited 1 time(s). Last edit at 03/08/2014 07:34PM by rayhicks.

|

Re: The Ormerod 400 x 400 x 400 March 08, 2014 09:28PM |

Registered: 10 years ago Posts: 859 |

I have a great respect for the guys above.... But.... One central thermister won't work.

The reason is, as good as they are the Bed Resistances aren't going to be matched to well.

Your better having 4 thermisters, each controlling one Bed.

Likewise (for the above reasons) connecting Beds in series is going to Magnify the problem.

The Bed with the Lowest resistance is going to be the coldest.

I think you will have more success with seperate thermisters for the Bed Plates.

Good Luck.... Sounds good thou... Please keep us informed of the progress.

Designing a twin filament head here at the moment... Give it a few weeks...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

The reason is, as good as they are the Bed Resistances aren't going to be matched to well.

Your better having 4 thermisters, each controlling one Bed.

Likewise (for the above reasons) connecting Beds in series is going to Magnify the problem.

The Bed with the Lowest resistance is going to be the coldest.

I think you will have more success with seperate thermisters for the Bed Plates.

Good Luck.... Sounds good thou... Please keep us informed of the progress.

Designing a twin filament head here at the moment... Give it a few weeks...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: The Ormerod 400 x 400 x 400 March 09, 2014 03:33AM |

Registered: 10 years ago Posts: 314 |

Just a thought, but with these bigger deviations from the original Ormerod shouldn't we get Ian to provide a new category?

Just thinking of those who might be buying the Ormerod now and looking for help in randomness of the posts....

Keep up the good discussions though, interesting ideas.

I agree with the thoughts on four separate temperature controllers, with the heater resistance tolerance power sharing will otherwise be difficult.

Ormerod #007 (shaken but not stirred!)

Just thinking of those who might be buying the Ormerod now and looking for help in randomness of the posts....

Keep up the good discussions though, interesting ideas.

I agree with the thoughts on four separate temperature controllers, with the heater resistance tolerance power sharing will otherwise be difficult.

Ormerod #007 (shaken but not stirred!)

|

Re: The Ormerod 400 x 400 x 400 March 09, 2014 05:15AM |

Registered: 10 years ago Posts: 58 |

Although I like my Ormerod a lot, I'm far from sure that supersizing it would work. The extra weight of all the moving parts might give too many problems that need addressing. My guess is that you would need a printbed that doesn't move, and you would want the printhead to be the part moving in all directions (like a with a delta style printer).

The bed leveling part might be worth taking to the new design, but using only 4 points to measure it might not be enough, as at these sizes the plate might be warped a bit, which you won't detect reasonably when using just 4 or 5 points for leveling.

I've seen a few kickstarter projects for a supersized printer, and despite the design they show, even they will for sure (still) have to deal with the challenges that supersizing brings.

I really hope I'm proven wrong, but for now I think the Ormerod design as it is, won't go much further beyond the current dimensions.

The bed leveling part might be worth taking to the new design, but using only 4 points to measure it might not be enough, as at these sizes the plate might be warped a bit, which you won't detect reasonably when using just 4 or 5 points for leveling.

I've seen a few kickstarter projects for a supersized printer, and despite the design they show, even they will for sure (still) have to deal with the challenges that supersizing brings.

I really hope I'm proven wrong, but for now I think the Ormerod design as it is, won't go much further beyond the current dimensions.

|

Re: The Ormerod 400 x 400 x 400 March 09, 2014 06:16AM |

Registered: 10 years ago Posts: 300 |

Quote

KimBrown

I have a great respect for the guys above.... But.... One central thermister won't work.

The reason is, as good as they are the Bed Resistances aren't going to be matched to well.

Your better having 4 thermisters, each controlling one Bed.

Likewise (for the above reasons) connecting Beds in series is going to Magnify the problem.

The Bed with the Lowest resistance is going to be the coldest.

I think you will have more success with seperate thermisters for the Bed Plates.

Good Luck.... Sounds good thou... Please keep us informed of the progress.

Designing a twin filament head here at the moment... Give it a few weeks...

True, but if I was stuck on a desert island with only one thermistor, 4 heat beds, and no other way off - I'd sort the boards in order of resistance (measure current at fixed supply voltage) and pair two sets of boards in series to achieve the closest balance. Any slack could be taken out with a little extra length of interconnecting wire. This is assuming two boards wired in series on a 24V PSU (one or two sets in parallel). 24V operation really is a no-brainer for larger heatbeds 48V would be even better but I notice that far fewer affordable PSU's are available for this voltage at 10A or more.

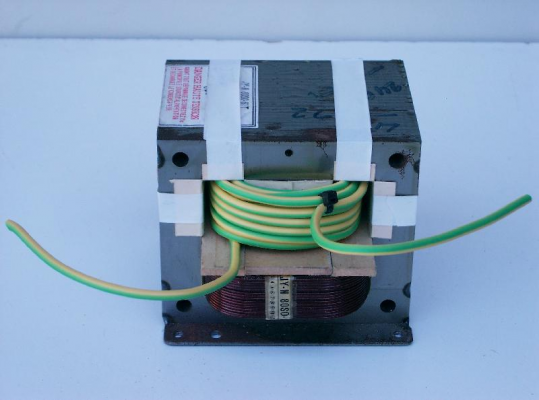

Maybe time to dig out the big old Microwave Oven Transformer...? The internet has plenty of instructables on re-purposing these ubiquitous transformers e.g: [www.users.on.net] Basically you end up with a transformer that could handle up to 1KW when used in the original oven, providing any voltage you want if you re-wind the secondary e.g. 40 to 50 turns for 48VRMS (depending on original oven type). Of course this is AC were getting out, but that's fine if we can switch it. The two options are to use a relay (Solid State Relay or Electromechanical) to switch the primary (low-current mains) or rectify the secondary and use the MOSFET (high current, isolated from mains). Switching the mains is probably the better option as the magnetizing current in the MOT is pretty substantial under no load. The SSR is also the way to go for switching the mains as it can be selected to be zero-crossing switching type which is highly desirable for this application. Scrap uWave, length of fat enameled copper wire, £5 SSR = ~500W heater PSU. What's not to like? (Apart from all kinds of safety issues!)

RS Components Reprap Ormerod No. 481

Sorry, only registered users may post in this forum.