What decent cooling can achieve!

Posted by iamburny

|

What decent cooling can achieve! March 12, 2014 05:30PM |

Registered: 10 years ago Posts: 265 |

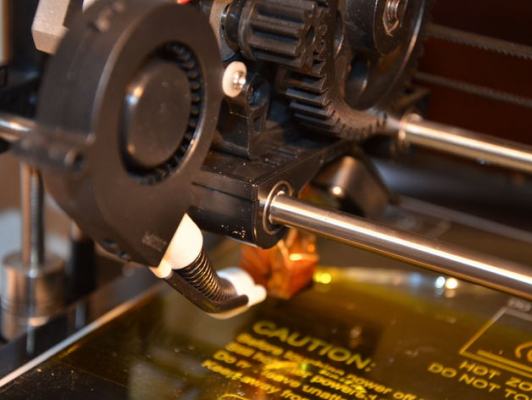

Pretty impressive, i'll definitely be re-designing the hot end air duct again probably to take a 1 larger fan maybe 60mm or 2 x 40mm ones.

[www.youtube.com]

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

[www.youtube.com]

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

|

Re: What decent cooling can achieve! March 13, 2014 01:20AM |

Registered: 10 years ago Posts: 58 |

I'm very impressed. What I noticed is that they shield the nozzle heater from the airflow of the fan, and only allow the air to cool the tip of the nozzle.

I think that increasing the fan to 60mm is a great idea, it allows for more silent fans to be used, and you can achieve a larger airflow.

I think that increasing the fan to 60mm is a great idea, it allows for more silent fans to be used, and you can achieve a larger airflow.

|

Re: What decent cooling can achieve! March 13, 2014 08:47AM |

Registered: 10 years ago Posts: 2,472 |

I'm assuming that the video is actual speed, and that it must print very slowly to allow the extrusion time to cool sufficiently to act as a support. Would it be possible to slow down to that speed when printing overhangs, but print at normal speed elsewhere? Perhaps the "bridges speed" or "gap fill" variables in Slic3r might achieve it. Cura does not appear to have equivalent variables (BICBW).

If so, it means that it would be possible to print pretty large horizontal overhangs with little or no support, and bridging should work almost perfectly over 100mm or more, vastly increasing the design possibilities, though to prevent any sag at all would need the capability of raising the Z height a small predetermined amount during the bridge and dropping it back to layer height when arriving at the far side. Perhaps future slicing software will have such a capability.

On the Ormerod it would definitely need a second fan, which is switched off or greatly reduced in speed for normal printing moves. Having that degree of cooling all the time would prevent the plastic from bonding properly to the previous layer, so I think it should only be turned on when printing in air.

Dave

(#106)

If so, it means that it would be possible to print pretty large horizontal overhangs with little or no support, and bridging should work almost perfectly over 100mm or more, vastly increasing the design possibilities, though to prevent any sag at all would need the capability of raising the Z height a small predetermined amount during the bridge and dropping it back to layer height when arriving at the far side. Perhaps future slicing software will have such a capability.

On the Ormerod it would definitely need a second fan, which is switched off or greatly reduced in speed for normal printing moves. Having that degree of cooling all the time would prevent the plastic from bonding properly to the previous layer, so I think it should only be turned on when printing in air.

Dave

(#106)

|

Re: What decent cooling can achieve! March 13, 2014 07:12PM |

Registered: 10 years ago Posts: 19 |

|

Re: What decent cooling can achieve! March 14, 2014 08:49AM |

Registered: 10 years ago Posts: 2,472 |

Quote

moka

As far as extrusion goes upwards (Z+), then it will be ok. As even with sufficient cooling horizontal bridges will not be possible - that is for sure - filament will bend downwards..

If it can print an upward hanging thread, then with just the right amount (less) of Z+, it must be possible to print a horizontal hanging thread. The problem being that the Z will have to be brought back down to the layer height when it gets back over "solid land" again.

Dave

(#106)

|

Re: What decent cooling can achieve! March 14, 2014 03:45PM |

Registered: 10 years ago Posts: 19 |

|

Re: What decent cooling can achieve! March 14, 2014 07:56PM |

Registered: 10 years ago Posts: 14,672 |

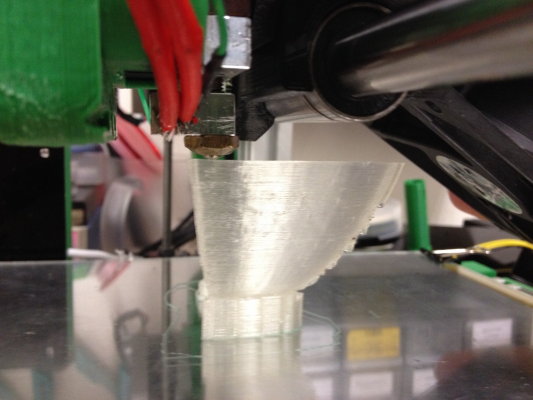

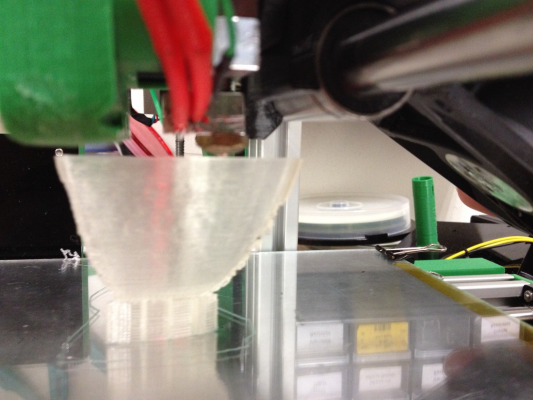

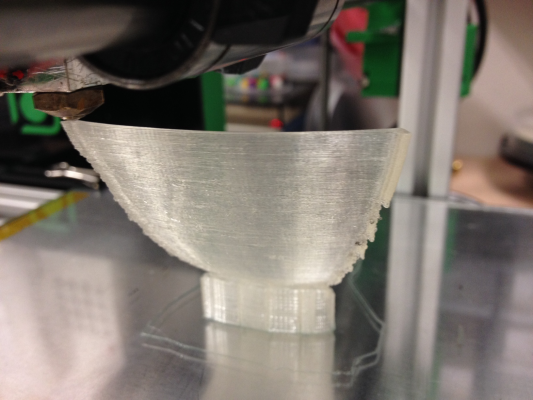

I've been quite successful doing small (17mm) bridges, as you can see from this print:

This was done using my standard slic3r settings, and the original heatsink duct and fan duct. Getting the extrusion temperature just right is important..

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

This was done using my standard slic3r settings, and the original heatsink duct and fan duct. Getting the extrusion temperature just right is important..

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: What decent cooling can achieve! March 16, 2014 10:02AM |

Registered: 10 years ago Posts: 1,230 |

Quote

dmould

...On the Ormerod it would definitely need a second fan, which is switched off or greatly reduced in speed for normal printing moves. Having that degree of cooling all the time would prevent the plastic from bonding properly to the previous layer, so I think it should only be turned on when printing in air.

Dave

(#106)

Something like this?

50mm x 15mm 12v DC blower fan model 5015S

[www.thingiverse.com]

Erik

|

Re: What decent cooling can achieve! March 26, 2014 02:59AM |

Registered: 10 years ago Posts: 29 |

|

Re: What decent cooling can achieve! March 26, 2014 11:07AM |

Registered: 10 years ago Posts: 135 |

|

Re: What decent cooling can achieve! March 26, 2014 11:44AM |

Registered: 10 years ago Posts: 14,672 |

I'm using the slic3r default bridge speed which is 20mm/sec and a temperature of 190C apart from the first layer. You can see some of the results of experimenting with printing this model in this thread [forums.reprap.org]. The temperatures I reported there were before the hot end thermistor beta was corrected in the firmware, so they were being reported about 7C too high.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: What decent cooling can achieve! March 27, 2014 01:57AM |

Registered: 10 years ago Posts: 15 |

I tried to "fan" the printing object and it did make show some improvement

The bottom edge on the right hand side fail before I had the cooling fan, and it looks good after the fan is ON.

Or maybe I wasn't calibrate my temperature correctly.

Edited 1 time(s). Last edit at 03/27/2014 01:59AM by mancinism.

The bottom edge on the right hand side fail before I had the cooling fan, and it looks good after the fan is ON.

Or maybe I wasn't calibrate my temperature correctly.

Edited 1 time(s). Last edit at 03/27/2014 01:59AM by mancinism.

|

Re: What decent cooling can achieve! March 27, 2014 01:52PM |

Registered: 10 years ago Posts: 780 |

Matt,

I have been looking at your one piece hot end in scad, I wanted to raise the outside chamfers on the 2 vents and reduce the height of the 2 inner walls. The reason for this is to direct some cooling onto the nozzle.

However, being a newby to any form of cad I just can't seem to work out what I need to do to achieve this. If you have some time could you point me in the right direction please

Thank you for your efforts

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I have been looking at your one piece hot end in scad, I wanted to raise the outside chamfers on the 2 vents and reduce the height of the 2 inner walls. The reason for this is to direct some cooling onto the nozzle.

However, being a newby to any form of cad I just can't seem to work out what I need to do to achieve this. If you have some time could you point me in the right direction please

Thank you for your efforts

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: What decent cooling can achieve! March 28, 2014 09:50AM |

Registered: 10 years ago Posts: 29 |

|

Re: What decent cooling can achieve! March 28, 2014 11:50AM |

Registered: 10 years ago Posts: 209 |

|

Re: What decent cooling can achieve! March 28, 2014 01:42PM |

Registered: 10 years ago Posts: 780 |

If anybody modifies the hot end to direct cooling more to the nozzle would they be kind enough to explain the steps they took so I can learn from a real world example.

Thank you

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

Thank you

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: What decent cooling can achieve! March 31, 2014 08:30AM |

Registered: 10 years ago Posts: 780 |

Matt and tracyb, did you manage to amend the hot end so some of the air could be directed towards the nozzle?

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

Sorry, only registered users may post in this forum.