Z-height sensor - inductive?

Posted by Treth

|

Re: Z-height sensor - inductive? April 30, 2014 08:32PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Pointy

Quote

dc42

So I'll try the Dambusters-style solution first. It's potentially cheaper than the solenoid solution, given the cost of the tubular solenoid and spring.

Can we have the music with it please?

Les

Certainly. CAUTION: HIGH EXPLOSIVES! Home axes before running, and run at your own risk!

Edited 3 time(s). Last edit at 04/30/2014 08:54PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z-height sensor - inductive? May 01, 2014 02:52AM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Z-height sensor - inductive? May 01, 2014 03:22AM |

Registered: 10 years ago Posts: 314 |

@DC42,

If you go back to the push solenoid method then this solenoid is approx 12x11x20mm (coil frame) and a stroke around 5mm PLUS it has the return spring all for £5.10.

[www.kitronik.co.uk]

Ormerod #007 (shaken but not stirred!)

If you go back to the push solenoid method then this solenoid is approx 12x11x20mm (coil frame) and a stroke around 5mm PLUS it has the return spring all for £5.10.

[www.kitronik.co.uk]

Ormerod #007 (shaken but not stirred!)

|

Re: Z-height sensor - inductive? May 01, 2014 04:42AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Treth

@DC42,

If you go back to the push solenoid method then this solenoid is approx 12x11x20mm (coil frame) and a stroke around 5mm PLUS it has the return spring all for £5.10.

[www.kitronik.co.uk]

I found that series a couple of days ago. Unfortunately nobody seems to be able to supply the 12V version from stock, and the minimum order quantity from the manufacturer is 500 AFAIR. I guess it would be possible to use the 5V version, but less efficient.

I have a sample of a spring that may do the job on its way to me. Also on its way is a low-cost 12V solenoid with built-in return spring from China.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z-height sensor - inductive? May 01, 2014 09:07AM |

Registered: 10 years ago Posts: 145 |

|

Re: Z-height sensor - inductive? May 01, 2014 09:55AM |

Registered: 10 years ago Posts: 14,672 |

Well there is supposed to be an explosion at the end! How else could I represent the bomb sinking?

I considered sending the secret Ormerd self-destruct gcode at the end, but decided that would be going a little too far.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I considered sending the secret Ormerd self-destruct gcode at the end, but decided that would be going a little too far.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z-height sensor - inductive? May 01, 2014 10:00AM |

Registered: 10 years ago Posts: 2,472 |

Quote

dc42

Hi Radian,

I am indeed using a different capacitive sensing technique. My prototype uses the Atmel charge transfer technique, which doesn't rely on a constant-current source, but does rely on a reference capacitor (I'm using a temperature-stable one), and requires 2 pins to be connected directly or indirectly to the sense plate (increasing the pin capacitance). I am also using one of my PCBs designed for ultrasonic sensing, which has long traces attached to those pins that run most of the length of the board, hence more stray capacitance.

Would you care to take and post sets of readings taken at (a) bed at room temperature, and (b) bed temperature 70C or higher? With Z=0 calibrated manually before each set of readings, once the bed has reached a stable temperature. From what you have already said, I believe you are getting a lower temperature sensitivity than I am, but I would like to know how much lower.

Also, from the readings you are taking, are you able to calculate the ratio of sense plate capacitance variation to total capacitance?

I wonder whether using a 555 or even transistor multivibe (with the sense capacitor changing its mark/space ratio) would work? Feed the output (likely to be in the low RF range) to a simple RC low pass filter and connect directly to the Duet's A/D input. A bit of messing around with thermistors in the frequency determining circuits could probably balance out any temperature effects.

Dave

(#106)

|

Re: Z-height sensor - inductive? May 01, 2014 11:25AM |

Registered: 10 years ago Posts: 14,672 |

Initial tests on the dambusters-style LED solution look good. I'm getting a good enough reflection off bare glass to make the technique usable. My current thought is to make it behave as an on/off switch, so the only calibration needed will be to set the height at which it switches.

Here are my current thoughts on LED vs. solenoid-activated mechanical probe:

* LED pros: the sensor parts needed are inexpensive. Should also work for x-homing. Can make it work like a switch (i.e. digital output), so no need for G31 P values, just a height value, and output not sensitive to electrical interference. No moving parts.

* LED cons: needs a microcontroller (which can also be used to control the fan). May be difficult to get consistent heights with non-uniform surfaces, e.g. solvent cement (will have to build it and see). Needs an extra wire from the Duet to signal start of z-homing. Sensor might get saturated if direct bright sunlight falls on the bed (as with the current IR sensors).

* Solenoid pros: can use a very simple circuit (2 transistors to activate solenoid and regulate current, and photo-interrupter to produce output). Independent of the surface, as long as the surface is firm. Insensitive to light.

* Solenoid cons: expensive parts (solenoid, spring) unless I can use a cheap Chinese solenoid instead of the current one. Has moving parts that could jam if not lubricated. More complicated mechanical assembly (need to attach solenoid to circuit board). May make small indentations on bed if it is covered with a soft material e.g. Kapton tape. Not suitable for x-homing, so a separate sensor (e.g. microswitch) will be needed. Increase in hot end weight due to solenoid. Needs an extra wire from the Duet to turn solenoid on/off. Solenoid will get hot if left on for too long.

If I manufacture boards, then the LED solution should come at about the same price as my previous kit 4+ boards, possibly a little less. The solenoid solution including fan control would cost at least GBP 15 more, so somewhat more than my previous kit 5+ boards. Either way, I would sell an upgrade kit for users of my existing kit 3/4/5 boards, who would use the wiring and connectors they already have.

What do Ormerod users want? Maybe everyone is complete satisfied with my IR/ultrasonic boards and doesn't think anything else is needed?

PS - the reason I am no longer looking at capacitive or inductive solutions is that I think a solution that measures height to the top of the glass is preferable. That way, the calibration is not affected by changing the glass plate, thermal expansion of the glass, or uneven contact between the glass and the heat spreader or bed heater.

Edited 2 time(s). Last edit at 05/01/2014 11:55AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Here are my current thoughts on LED vs. solenoid-activated mechanical probe:

* LED pros: the sensor parts needed are inexpensive. Should also work for x-homing. Can make it work like a switch (i.e. digital output), so no need for G31 P values, just a height value, and output not sensitive to electrical interference. No moving parts.

* LED cons: needs a microcontroller (which can also be used to control the fan). May be difficult to get consistent heights with non-uniform surfaces, e.g. solvent cement (will have to build it and see). Needs an extra wire from the Duet to signal start of z-homing. Sensor might get saturated if direct bright sunlight falls on the bed (as with the current IR sensors).

* Solenoid pros: can use a very simple circuit (2 transistors to activate solenoid and regulate current, and photo-interrupter to produce output). Independent of the surface, as long as the surface is firm. Insensitive to light.

* Solenoid cons: expensive parts (solenoid, spring) unless I can use a cheap Chinese solenoid instead of the current one. Has moving parts that could jam if not lubricated. More complicated mechanical assembly (need to attach solenoid to circuit board). May make small indentations on bed if it is covered with a soft material e.g. Kapton tape. Not suitable for x-homing, so a separate sensor (e.g. microswitch) will be needed. Increase in hot end weight due to solenoid. Needs an extra wire from the Duet to turn solenoid on/off. Solenoid will get hot if left on for too long.

If I manufacture boards, then the LED solution should come at about the same price as my previous kit 4+ boards, possibly a little less. The solenoid solution including fan control would cost at least GBP 15 more, so somewhat more than my previous kit 5+ boards. Either way, I would sell an upgrade kit for users of my existing kit 3/4/5 boards, who would use the wiring and connectors they already have.

What do Ormerod users want? Maybe everyone is complete satisfied with my IR/ultrasonic boards and doesn't think anything else is needed?

PS - the reason I am no longer looking at capacitive or inductive solutions is that I think a solution that measures height to the top of the glass is preferable. That way, the calibration is not affected by changing the glass plate, thermal expansion of the glass, or uneven contact between the glass and the heat spreader or bed heater.

Edited 2 time(s). Last edit at 05/01/2014 11:55AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z-height sensor - inductive? May 01, 2014 12:30PM |

Registered: 10 years ago Posts: 1,230 |

Quote

dc42

..What do Ormerod users want? Maybe everyone is complete satisfied with my IR/ultrasonic boards and doesn't think anything else is needed?..

Can only speak for myself and I'm completely satisfied with the IR/ultrasonic, IR for homing only and ultrasonic anywhere on the bed, but I say leave no stone unturned (as if you ever would), especially on probing all over the bed as it is useful for all kind of printers - I like the simplicity of the dambuster idea and I like to have choices so if you go for it I'm in for two upgrades

Erik

|

Re: Z-height sensor - inductive? May 01, 2014 12:41PM |

Registered: 10 years ago Posts: 1,230 |

Quote

GregL

..Do I need armour plated glass?

Greg

Just install the windows glass defender, the 15mm version is quite stable

Erik

|

Re: Z-height sensor - inductive? May 01, 2014 12:49PM |

Registered: 10 years ago Posts: 780 |

I just want something that will be reliable 100% of the time for Z height and bed levelling.

dc's board 5 works well but I still have not managed to get consistent results when setting Z0 or bed levelling. It is much better than the original ir sensor supplied with the kit.

So I would prefer to spend a little more on a system that will be most reliable. Which I think will be the Solenoid solution but I am willing to give the LED solution a try.

Thanks for your efforts

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

dc's board 5 works well but I still have not managed to get consistent results when setting Z0 or bed levelling. It is much better than the original ir sensor supplied with the kit.

So I would prefer to spend a little more on a system that will be most reliable. Which I think will be the Solenoid solution but I am willing to give the LED solution a try.

Thanks for your efforts

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Z-height sensor - inductive? May 01, 2014 01:29PM |

Registered: 9 years ago Posts: 12 |

I got my Ormerod last week and it only been running for about 4 days. I like the idea of having automatic Z-zeroing. Unfortunately the current IR sensors does not really work if you have any daylight (where I am anyway).

I do electronics in my day job and we use sensors quite a lot, unfortunately not position sensing. I gave this quite a bit of thought before I read this thread and I would suggest dc42's option 7" Force sensing. Lower the head on to the bed and detect the reduction in weight of the head when it touches, e.g. by monitoring the sideways force on the x-runner bearing support. Not tried yet. Would work anywhere on the bed, but like manual height setting, it would be sensitive to any solidified filament on the end of the nozzle."

My reasons are as follows:

1) with all other options you need some kind of calibration to determine the difference in offset between the head and the sensor.

2) It will probably drift less with time and temperature than the other sensors (depending on where it is mounted and how it is used)

3) The mechanics is simpler than having a solenoid operated contact probe (solinoid will be heavy,more complicated and I think more expensive)

4) Over all it might take more work but should be quite inexpensive.

The solidified filament can be easily solved by heating the head before calibration.

For the sensing element there are 2 options: force sense resistors (see [sensitronics.com] and [www.sparkfun.com]) or piezo sensors.

Both have advantages and disadvantages:

Pros: Force sense resistors are easier to integrate into this system but piezo sensors are cheap.

Cons: The force sensors are made from some kind of plastic so they might degrade over time (they are specified to 200F)? Piezo sensors only give out an AC signal and will need some other electronics for signal conditioning and protection.

I will give it a bit more thought an see if I can come up with a mechanical design that will work well.

I do electronics in my day job and we use sensors quite a lot, unfortunately not position sensing. I gave this quite a bit of thought before I read this thread and I would suggest dc42's option 7" Force sensing. Lower the head on to the bed and detect the reduction in weight of the head when it touches, e.g. by monitoring the sideways force on the x-runner bearing support. Not tried yet. Would work anywhere on the bed, but like manual height setting, it would be sensitive to any solidified filament on the end of the nozzle."

My reasons are as follows:

1) with all other options you need some kind of calibration to determine the difference in offset between the head and the sensor.

2) It will probably drift less with time and temperature than the other sensors (depending on where it is mounted and how it is used)

3) The mechanics is simpler than having a solenoid operated contact probe (solinoid will be heavy,more complicated and I think more expensive)

4) Over all it might take more work but should be quite inexpensive.

The solidified filament can be easily solved by heating the head before calibration.

For the sensing element there are 2 options: force sense resistors (see [sensitronics.com] and [www.sparkfun.com]) or piezo sensors.

Both have advantages and disadvantages:

Pros: Force sense resistors are easier to integrate into this system but piezo sensors are cheap.

Cons: The force sensors are made from some kind of plastic so they might degrade over time (they are specified to 200F)? Piezo sensors only give out an AC signal and will need some other electronics for signal conditioning and protection.

I will give it a bit more thought an see if I can come up with a mechanical design that will work well.

|

Re: Z-height sensor - inductive? May 01, 2014 01:35PM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Z-height sensor - inductive? May 01, 2014 01:55PM |

Registered: 10 years ago Posts: 14,672 |

OttoES, I have already acquired a force sensitive resistor. It could be used in my existing kit 4/5 board with a little reprogramming and a few component changes. The reason I haven't done anything with it yet is the complexity of designing an x-carriage to incorporate it. I've got part way there, so I attach the openscad file I have so far, in case you or anyone else wants to finish it.

What I had planned is to have the Duet signal the start of z-probing using the extra wire to the board, then have the on-board microcontroller look for an increase in resistance to indicate that contact had been made.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

What I had planned is to have the Duet signal the start of z-probing using the extra wire to the board, then have the on-board microcontroller look for an increase in resistance to indicate that contact had been made.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z-height sensor - inductive? May 02, 2014 03:41AM |

Registered: 10 years ago Posts: 314 |

@DC42 Nice summary on pros and cons.

I also prefer an absolute position switch and don't see a need for any actual position readings, except perhaps for helping with diagnosis should something not work quite right.

Like most, I just want something simple and reliable, which for me may be your current modulated IR sensor, but what happens when I move to a different location (shed in sunny garden!).

The above pros and cons sells the LED version to me, provided it is reliable with 'normal' sunlight for glass and kapton tape.

Could you do a pros and cons of the current modulated IR reflective sensor and the Dambuster version.

My 'gut feeling' is a low mass direct contact probe mounted close to the extruder nozzle has a nice ring about it.

I'm surprised nobody commented on my low cost rotary version of the linear solenoid solution!

Cheap motor, can use slotted-opto on the rotating arm, low weight, low force of sensing on bed, easy to obtain motor, sensing position can be close to nozzle, arm and mount can be 3D printed. Is there a glaring error or did I miss something or is this too off the mark?

Ormerod #007 (shaken but not stirred!)

I also prefer an absolute position switch and don't see a need for any actual position readings, except perhaps for helping with diagnosis should something not work quite right.

Like most, I just want something simple and reliable, which for me may be your current modulated IR sensor, but what happens when I move to a different location (shed in sunny garden!).

The above pros and cons sells the LED version to me, provided it is reliable with 'normal' sunlight for glass and kapton tape.

Could you do a pros and cons of the current modulated IR reflective sensor and the Dambuster version.

My 'gut feeling' is a low mass direct contact probe mounted close to the extruder nozzle has a nice ring about it.

I'm surprised nobody commented on my low cost rotary version of the linear solenoid solution!

Cheap motor, can use slotted-opto on the rotating arm, low weight, low force of sensing on bed, easy to obtain motor, sensing position can be close to nozzle, arm and mount can be 3D printed. Is there a glaring error or did I miss something or is this too off the mark?

Ormerod #007 (shaken but not stirred!)

|

Re: Z-height sensor - inductive? May 02, 2014 04:20AM |

Registered: 10 years ago Posts: 300 |

Quote

dc42

Hi Radian,

I am indeed using a different capacitive sensing technique. My prototype uses the Atmel charge transfer technique, which doesn't rely on a constant-current source, but does rely on a reference capacitor (I'm using a temperature-stable one), and requires 2 pins to be connected directly or indirectly to the sense plate (increasing the pin capacitance). I am also using one of my PCBs designed for ultrasonic sensing, which has long traces attached to those pins that run most of the length of the board, hence more stray capacitance.

Would you care to take and post sets of readings taken at (a) bed at room temperature, and (b) bed temperature 70C or higher? With Z=0 calibrated manually before each set of readings, once the bed has reached a stable temperature. From what you have already said, I believe you are getting a lower temperature sensitivity than I am, but I would like to know how much lower.

Also, from the readings you are taking, are you able to calculate the ratio of sense plate capacitance variation to total capacitance?

Unfortunately I'm not in a position to run tests until I get back to base at the end of this month. IMO the capsense module in the particular PIC I used (12F1822/3) is about as good as you can get with the tempco. being effectively determined by the XTAL alone.

RS Components Reprap Ormerod No. 481

|

Re: Z-height sensor - inductive? May 02, 2014 04:44AM |

Registered: 10 years ago Posts: 14,672 |

Treth, the disadvantage of the modulated IR sensor is that it is sensitive to the surface condition of the bed. So it normally requires targets, which means it can't be used for final z calibration at the centre of the bed just before starting a print. The dual LED solution looks at the balance between the reflected light from two LEDs rather than the absolute intensity of the reflected light.

Regarding the rotary probe idea, I prefer the mechanically simpler solution of the linear solenoid. I don't think you could use a printed part for the probe because it would soften and deform after repeated contact with the hot bed.

Edited 2 time(s). Last edit at 05/02/2014 04:50AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Regarding the rotary probe idea, I prefer the mechanically simpler solution of the linear solenoid. I don't think you could use a printed part for the probe because it would soften and deform after repeated contact with the hot bed.

Edited 2 time(s). Last edit at 05/02/2014 04:50AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z-height sensor - inductive? May 02, 2014 04:54AM |

Registered: 10 years ago Posts: 314 |

Can you clarify how the Dambusters version works then, I thought it was the similar but with two beams and you are looking for maximum intensity?Quote

dc42

Treth, the disadvantage of the modulated IR sensor is that it is sensitive to the surface condition of the bed. So it normally requires targets, which means it can't be used for final z calibration at the centre of the bed just before starting a print.

Or is that it you look for plateau, but I'm surprised that is precise enough. Sorry for questions, just trying to understand

Yes agree re probe, I really meant the fixture to the shaft holding the probe (long screw, or similar as probe) but guess there will still be heat transfer.Quote

dc42

Regarding the rotary probe idea, I prefer the mechanically simpler solution of the linear solenoid. I don't think you could use a printed part for the probe because it would soften and deform after repeated contact with the hot bed.

Ormerod #007 (shaken but not stirred!)

|

Re: Z-height sensor - inductive? May 02, 2014 04:59AM |

Registered: 10 years ago Posts: 14,672 |

Radian, I think the charge transfer capacitance measurement technique should be temperature stable. It measures the ratio between the unknown and reference capacitors, and I am using a reference capacitor with very low temperature coefficient. The mcu clock frequency should not have a significant effect. What I think I am seeing is variation of the PCB trace capacitance with temperature, and possibly other effects. The capacitance appears to increase with temperature.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z-height sensor - inductive? May 02, 2014 08:00AM |

Registered: 10 years ago Posts: 256 |

Quote

dc42

Andy, see this post [forums.reprap.org]. An opto sensor would have the same issue with flexing of the plate.

Ah my bad!

I realise the thread has moved on but as an aside.... You can stiffen the acrylic x axis considerably by gluing the two parts with superglue all along the joint. I would highly recommend that mod!

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Z-height sensor - inductive? May 02, 2014 10:32AM |

Registered: 10 years ago Posts: 14,672 |

Andy, thanks for the advice. I've got one of Dave's alu x plate kits on order so I'll probably just fit that.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z-height sensor - inductive? May 02, 2014 10:36AM |

Registered: 10 years ago Posts: 14,672 |

I've just ordered 10 PCBs for the dambusters-style LED and phototransistor height sensor. It was looking rather hard to prototype properly without a PCB. The part count is quite a lot lower than for the IR+ultrasonic board.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z-height sensor - inductive? May 03, 2014 02:31PM |

Registered: 9 years ago Posts: 12 |

dc42

Thanks for the link to the x-carriage files for z-axis probing. I have done a quick test with a piezo today because that is what I have available. I did not make a new x-carriage, just mounted it between on the carriage with tape and a weight and connected a scope to it. The readings were a bit noisy when the printer was switched on, about 100-200mV. I am not sure where the noise comes from (not 50Hz but forgot to write down exacly what it was, will repeat the test later). A tap on the weight produced a signal but was damped a lot by the plastic and, because the piezo only gives out an AC signal, it died out relatively quickly - 1V about 2-10mS. I do not think that is very usefully for detection. Next I will try the force sensitive resistor. I had one in my junk box for year but now that I need it it is missing ....

Thanks for the link to the x-carriage files for z-axis probing. I have done a quick test with a piezo today because that is what I have available. I did not make a new x-carriage, just mounted it between on the carriage with tape and a weight and connected a scope to it. The readings were a bit noisy when the printer was switched on, about 100-200mV. I am not sure where the noise comes from (not 50Hz but forgot to write down exacly what it was, will repeat the test later). A tap on the weight produced a signal but was damped a lot by the plastic and, because the piezo only gives out an AC signal, it died out relatively quickly - 1V about 2-10mS. I do not think that is very usefully for detection. Next I will try the force sensitive resistor. I had one in my junk box for year but now that I need it it is missing ....

|

Re: Z-height sensor - inductive? May 03, 2014 03:04PM |

Registered: 10 years ago Posts: 14,672 |

My aluminium x-plate arrived today, so when I've fitted it, I'll try out the contact method again i.e. measuring the resistance between the x-plate and the screw that holds the x-runner bearing.

However, I'm hoping to get good results from the differential IR sensor, when the PCBs arrive about 2 weeks from now.

I also received samples today of a spring for the solenoid method. The spring is still a little stronger than I would like because it needs about 11V/270mA on the solenoid to compress it, and at 11V the solenoid gets quite hot. But it should be usable.

Edited 1 time(s). Last edit at 05/03/2014 03:05PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

However, I'm hoping to get good results from the differential IR sensor, when the PCBs arrive about 2 weeks from now.

I also received samples today of a spring for the solenoid method. The spring is still a little stronger than I would like because it needs about 11V/270mA on the solenoid to compress it, and at 11V the solenoid gets quite hot. But it should be usable.

Edited 1 time(s). Last edit at 05/03/2014 03:05PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z-height sensor - inductive? May 04, 2014 06:51PM |

Registered: 10 years ago Posts: 14,672 |

Two updates:

1. I've fitted the aluminium x-plate and rib from DaveK and re-tested the x-runner contact method. As before, the resistance when the head is not touching the bed varies widely, so I have to look for a high resistance (1Mohm or greater) to be sure of loss of contact when the bed is taking the weight of the head. Although the situation has improved compared to when I was using the acrylic x-plate, to get an indication of positive disconnection I have to drive the head to -0.45mm. I think this is due to springiness in the plastic x-carriage and nozzle mount. When I lower the head I often see a disconnection before -0.45mm, then the connection comes back again after a second or less. So unfortunately this does not appear to me to be a viable method of sensing height. A force-sensitive resistor would likely also be affected by this springiness, although probably to a lesser extent.

2. I have received samples of a spring to use with the tubular solenoid. The spring is weak enough to be usable provided that there is at least 11V available to drive the solenoid, which (allowing for a current sense resistor) means having at least 11.5V supply voltage available. So this might be just about usable. However, I have limited time to work on this, so I intend to work on the differential IR sensor first. I will look at the solenoid probe solution again if that doesn't offer a significant improvement over the ultrasonic sensor.

Right now I'm taking a break from this, pending arrival of the prototype PCBs for the differential IR sensor.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. I've fitted the aluminium x-plate and rib from DaveK and re-tested the x-runner contact method. As before, the resistance when the head is not touching the bed varies widely, so I have to look for a high resistance (1Mohm or greater) to be sure of loss of contact when the bed is taking the weight of the head. Although the situation has improved compared to when I was using the acrylic x-plate, to get an indication of positive disconnection I have to drive the head to -0.45mm. I think this is due to springiness in the plastic x-carriage and nozzle mount. When I lower the head I often see a disconnection before -0.45mm, then the connection comes back again after a second or less. So unfortunately this does not appear to me to be a viable method of sensing height. A force-sensitive resistor would likely also be affected by this springiness, although probably to a lesser extent.

2. I have received samples of a spring to use with the tubular solenoid. The spring is weak enough to be usable provided that there is at least 11V available to drive the solenoid, which (allowing for a current sense resistor) means having at least 11.5V supply voltage available. So this might be just about usable. However, I have limited time to work on this, so I intend to work on the differential IR sensor first. I will look at the solenoid probe solution again if that doesn't offer a significant improvement over the ultrasonic sensor.

Right now I'm taking a break from this, pending arrival of the prototype PCBs for the differential IR sensor.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z-height sensor - inductive? May 08, 2014 03:14AM |

Registered: 10 years ago Posts: 314 |

@Radian, you probably are aware of these, but I came across these links while researching something else....

[www.analog.com]

and this links to a single probe capacitance to digital IC [www.analog.com]

available from RS Components at just under £8 [uk.rs-online.com]

Just FYI.

Ormerod #007 (shaken but not stirred!)

[www.analog.com]

and this links to a single probe capacitance to digital IC [www.analog.com]

available from RS Components at just under £8 [uk.rs-online.com]

Just FYI.

Ormerod #007 (shaken but not stirred!)

|

Re: Z-height sensor - inductive? May 08, 2014 07:13PM |

Registered: 10 years ago Posts: 859 |

[forums.reprap.org]

Mine is 100% now... But I print on glass...No Probes...Just MicroSwitches..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Mine is 100% now... But I print on glass...No Probes...Just MicroSwitches..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Z-height sensor - inductive? May 09, 2014 04:28PM |

Registered: 10 years ago Posts: 14,672 |

Three updates:

* The PCBs I ordered for prototyping the differential IR sensor are on their way to me

* I have received an inexpensive Chinese solenoid that includes a return spring and appears to be suitable for a solenoid-activated mechanical probe. It's a little larger than I would like, in particular it will be difficult to find room for an opto switch to sense the plunger extension.

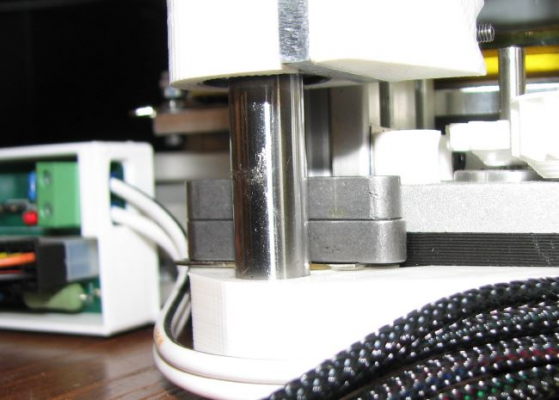

* I finally got round to designing and printing an x-carriage which includes a slot for a force-sensitive resistor behind the mount for the x-runner bearing:

I hope to find time to try it out this weekend.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

* The PCBs I ordered for prototyping the differential IR sensor are on their way to me

* I have received an inexpensive Chinese solenoid that includes a return spring and appears to be suitable for a solenoid-activated mechanical probe. It's a little larger than I would like, in particular it will be difficult to find room for an opto switch to sense the plunger extension.

* I finally got round to designing and printing an x-carriage which includes a slot for a force-sensitive resistor behind the mount for the x-runner bearing:

I hope to find time to try it out this weekend.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.