Best User Upgrades?

Posted by Pointy

|

Best User Upgrades? April 05, 2014 05:36AM |

Registered: 10 years ago Posts: 327 |

Hi Guys,

I have almost finished building my Ormerod and I am hoping to start printing over the weekend. As I only have the filament that came with the kit I don't want to waste it printing rubbish and would rather print some sensible upgrade parts.

So in order of importance what would you suggest I print? (What do you think has made the biggest improvement)

I already have the aluminium bed from this thread and I am tempted by DC42's sensor upgrade

From a personal point of view, I am really not keen on the ATX PSU. Apart from the mess of unused wires, Alpine and Ace are the cheapest brands going, and while I sold and used lots of them during my time running my own PC repair shop and never had any go bang, the fan bearings don't seem to last long. (I only ever used them as replacements in old lo spec systems though, so they weren't pushed too hard) I have already ordered a suitable switching supply from Ebay and I will hopefully get that fitted by next weekend.

Regards,

Les

I have almost finished building my Ormerod and I am hoping to start printing over the weekend. As I only have the filament that came with the kit I don't want to waste it printing rubbish and would rather print some sensible upgrade parts.

So in order of importance what would you suggest I print? (What do you think has made the biggest improvement)

I already have the aluminium bed from this thread and I am tempted by DC42's sensor upgrade

From a personal point of view, I am really not keen on the ATX PSU. Apart from the mess of unused wires, Alpine and Ace are the cheapest brands going, and while I sold and used lots of them during my time running my own PC repair shop and never had any go bang, the fan bearings don't seem to last long. (I only ever used them as replacements in old lo spec systems though, so they weren't pushed too hard) I have already ordered a suitable switching supply from Ebay and I will hopefully get that fitted by next weekend.

Regards,

Les

|

Re: Best User Upgrades? April 05, 2014 05:39AM |

Registered: 10 years ago Posts: 65 |

The first things I did were iamburnys helical gear sets for the Z-axis and extruder.

Also, the 'extruder tongue' - it's quite annoying having the extruder Bowden cable pop out half way through a print!

[github.com]

Edited 2 time(s). Last edit at 04/05/2014 05:41AM by stevelup.

Also, the 'extruder tongue' - it's quite annoying having the extruder Bowden cable pop out half way through a print!

[github.com]

Edited 2 time(s). Last edit at 04/05/2014 05:41AM by stevelup.

|

Re: Best User Upgrades? April 05, 2014 06:02AM |

Registered: 10 years ago Posts: 14,672 |

So far as printed parts are concerned, I recommend Matt's y-belt clamps [github.com] along with my spacers [github.com] to get the y-belt secure and correctly tensioned, and a fan inlet duct such as [github.com] to eliminate fan backwash and avoid injuring your fingers on the rotating fan blades.

As far as other parts go, I suggest my z-sensor/lighting/fan control board (obviously!), and replacing the mdf bed support with something more stable, or reinforcing the original one.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

As far as other parts go, I suggest my z-sensor/lighting/fan control board (obviously!), and replacing the mdf bed support with something more stable, or reinforcing the original one.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Best User Upgrades? April 05, 2014 06:58AM |

Registered: 10 years ago Posts: 1,230 |

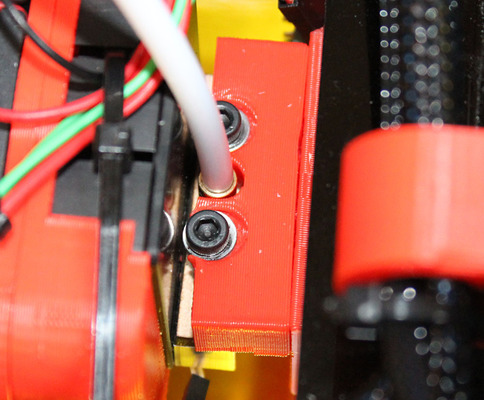

Another upgrade I will recommend, Thank You Simon / Number 192!

From this:

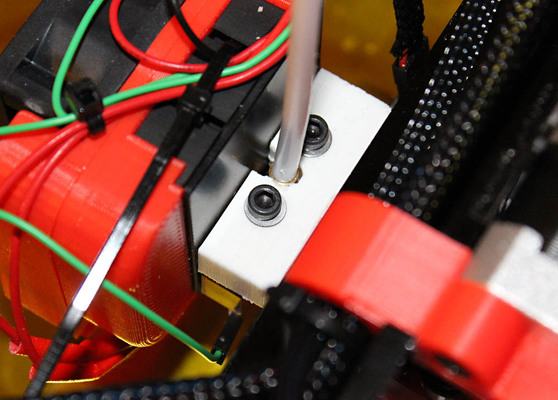

To this:

[forums.reprap.org]

Erik

From this:

To this:

[forums.reprap.org]

Erik

|

Re: Best User Upgrades? April 05, 2014 07:19AM |

Registered: 10 years ago Posts: 14,672 |

Good point Erik, I am using that nozzle mount too and I had forgotten about it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Best User Upgrades? April 05, 2014 07:46AM |

Registered: 10 years ago Posts: 1,230 |

Another fine and important upgrade - the extruder block takes a lot of wear from the filament, will start to make squeaky sounds and eventually grind right through that part, so I find Mr.burns mod with the ptfe insert another must print item - you will have to make sure your printer is setup perfectly as to get no "downhang" i in the channel for the filament or you will not be able to get the ptfe tube in there

Extruder wear:

[forums.reprap.org]

I just use the extra ptfe tube supplied with the ormerod, but also read this tread for bobtidey's suggestion for an alternative dimension of ptfe tube:

[forums.reprap.org]

Erik

Extruder wear:

[forums.reprap.org]

I just use the extra ptfe tube supplied with the ormerod, but also read this tread for bobtidey's suggestion for an alternative dimension of ptfe tube:

[forums.reprap.org]

Erik

|

Re: Best User Upgrades? April 05, 2014 12:11PM |

Registered: 10 years ago Posts: 327 |

Quote

ormerod168

Another upgrade I will recommend, Thank You Simon / Number 192!

From this:

[attachment 30061 nozzlemountorg.jpeg]

To this:

[attachment 30062 newmountfitted.jpeg]

[forums.reprap.org]

Erik

Thanks for the replies guys but I should have known it was optimistic to ask about what to print before it was up and running!

Anyway after a day of messing about it is finally printing the orthogonal axis compensation test pieces, but the above piece may solve the first problem I had with the Z sensor being slightly lower than the hot end nozzle! In the end I put a washer between the aluminium cooling block and the MDF heat insulator on each screw, which seems to have done the trick.

Regards,

Les

|

Re: Best User Upgrades? April 07, 2014 06:15AM |

Registered: 10 years ago Posts: 327 |

I have managed to print a few bits with success but at the moment I am struggling to get consistent results.

I managed to print the new nozzle mount which solved the problem of the sensor board being lower than the nozzle. I then noticed that the bottom of the fan was lower than the nozzle, which I think is referred to as head sag. There was a lot of play between the back MR93ZZ bearing and X Rib. I have ordered some 10mm bearings, which I hope will solve that problem. For the time being I have taped a 1mm thick piece of plastic to the X Rib.

I then had 2 attempts at printing the helical gears, but they came out a bit rough. After reading all 20+ pages of this forum and gathering as much info as possible I tweaked some settings and had another go. They came out much better and I have fitted them, but I think they could be a fraction better. I then managed to print the Y Belt clamps, which I thought came out really well. (Although I haven't fitted then yet)

Thinking I had cracked it I went to print the fan deflector it was looking good and then just stopped at 96%, Pronterface has crashed. (I had been using it over USB for all prints so far) Next few prints I tried just plain refused to stick to the bed (Kapton, 1st layer, bed 65 then 60, extruder 195 then 190) even though I cleaned down the same as before and was using the same settings.

(I had been using it over USB for all prints so far) Next few prints I tried just plain refused to stick to the bed (Kapton, 1st layer, bed 65 then 60, extruder 195 then 190) even though I cleaned down the same as before and was using the same settings.

After that I decided to get iamburny's web interface up and running, no problems there, I flashed to DC's latest firmware too. The next print I tried by uploading to the SD card via the web, it seemed to go through all the motions but refused to start printing , even though the nozzle and bed were up to temperature. By then it was late so I gave up.

Some more observations thus far...

Thankfully this is a great community with lots of helpful folks, it could do with a few stickies to help out newbies with common problems though.

Hoping to do some more testing later.

Regards,

Les

I managed to print the new nozzle mount which solved the problem of the sensor board being lower than the nozzle. I then noticed that the bottom of the fan was lower than the nozzle, which I think is referred to as head sag. There was a lot of play between the back MR93ZZ bearing and X Rib. I have ordered some 10mm bearings, which I hope will solve that problem. For the time being I have taped a 1mm thick piece of plastic to the X Rib.

I then had 2 attempts at printing the helical gears, but they came out a bit rough. After reading all 20+ pages of this forum and gathering as much info as possible I tweaked some settings and had another go. They came out much better and I have fitted them, but I think they could be a fraction better. I then managed to print the Y Belt clamps, which I thought came out really well. (Although I haven't fitted then yet)

Thinking I had cracked it I went to print the fan deflector it was looking good and then just stopped at 96%, Pronterface has crashed.

(I had been using it over USB for all prints so far) Next few prints I tried just plain refused to stick to the bed (Kapton, 1st layer, bed 65 then 60, extruder 195 then 190) even though I cleaned down the same as before and was using the same settings.

(I had been using it over USB for all prints so far) Next few prints I tried just plain refused to stick to the bed (Kapton, 1st layer, bed 65 then 60, extruder 195 then 190) even though I cleaned down the same as before and was using the same settings.After that I decided to get iamburny's web interface up and running, no problems there, I flashed to DC's latest firmware too. The next print I tried by uploading to the SD card via the web, it seemed to go through all the motions but refused to start printing , even though the nozzle and bed were up to temperature. By then it was late so I gave up.

Some more observations thus far...

- It seems strange the the back bearing on the X Rib is 9mm, when it looks like a 10mm will be much better suited. If the head isn't upright, due to play in the bearing, then the fan drags on the bed.

- Getting the bed as level as possible helps. Mine is out by about 1mm from front to back (this is with the aluminium bed)

- The 5mm threaded rod is quite bent on mine and I have ordered some replacement along with the longer M5 nut as suggested by Kim.

- The kapton tape is a bugger to get nice and flat, even when doing it wet, and I am sure that this is the reason for some of my prints not sticking. I have since ordered a roll of 200mm wide stuff.

- I have ordered a replacement PSU. I have gone for the 360W, which is probably overkill. (I can here a distinct change in speed of the 40mm fan when my bed heater kicks in using the Alpine PSU, which suggests a bit of a voltage drop)

Thankfully this is a great community with lots of helpful folks, it could do with a few stickies to help out newbies with common problems though.

Hoping to do some more testing later.

Regards,

Les

|

Re: Best User Upgrades? April 07, 2014 06:35AM |

Registered: 10 years ago Posts: 859 |

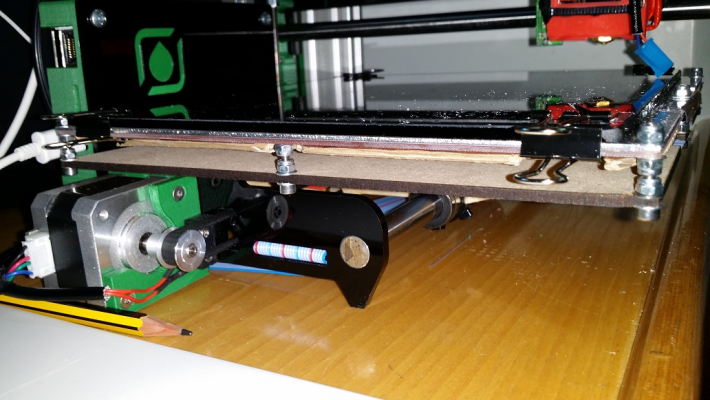

@Les.... Hmmmmm not sure how your bed is out by 1mm front to back... (Unless the rear bearings aren't bolted level).

I raised mine on longer bolts.... It's now within 0.1mm all over...

(Note since the picture I added the Ally Composit board above the MDF.... The best thing I ever did....).

One time I did measure height from the rear of the Ally Comp. bed to the rear profile when I was setting it up and found that from +Y to -Y the sub bed was out by about 2mm. I soon realised that I hadn't done this measurement before and that it was out because the bearing clamps weren't bolted to the rear frame level. I sorted that, then leveled the bed...

As for the Long nut I use. I like to oil it with a WD40 pen about once every 3 weeks or so, and it's be perfect.

Kim..

Edited 1 time(s). Last edit at 04/07/2014 06:36AM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

I raised mine on longer bolts.... It's now within 0.1mm all over...

(Note since the picture I added the Ally Composit board above the MDF.... The best thing I ever did....).

One time I did measure height from the rear of the Ally Comp. bed to the rear profile when I was setting it up and found that from +Y to -Y the sub bed was out by about 2mm. I soon realised that I hadn't done this measurement before and that it was out because the bearing clamps weren't bolted to the rear frame level. I sorted that, then leveled the bed...

As for the Long nut I use. I like to oil it with a WD40 pen about once every 3 weeks or so, and it's be perfect.

Kim..

Edited 1 time(s). Last edit at 04/07/2014 06:36AM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Best User Upgrades? April 09, 2014 03:48AM |

Registered: 10 years ago Posts: 327 |

The 10mm bearings arrived yesterday, so I replaced the 9mm one on the X carriage. This meant I could get rid of the piece of plastic I had taped on, which has got rid of then nasty squeaky noise I had. There is still a tiny bit of play but hopefully a modified X carriage will sort that out.

Having solved my printing problem I can get on and print some upgrade parts, and when the rest of the parts I've ordered arrive I should hopefully be able so solve all the minor little niggles I have with this printer and start fine tuning it.

Regards,

Les

Having solved my printing problem I can get on and print some upgrade parts, and when the rest of the parts I've ordered arrive I should hopefully be able so solve all the minor little niggles I have with this printer and start fine tuning it.

Regards,

Les

|

Re: Best User Upgrades? April 09, 2014 03:57AM |

Registered: 10 years ago Posts: 14,672 |

There should be some play in the x axis runner. The important thing is that the print head is horizontal, not sagging. To achieve this, you may need to print the improved nozzle mount as well as using the 10mm bearing.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Best User Upgrades? April 09, 2014 04:49AM |

Registered: 10 years ago Posts: 327 |

Quote

dc42

There should be some play in the x axis runner. The important thing is that the print head is horizontal, not sagging. To achieve this, you may need to print the improved nozzle mount as well as using the 10mm bearing.

I don't think it's far off level now, the bottom of the fan duct doesn't drag in the print any more with the new bearing. I don't think I have any feeler gauges to measure the play, but it's maybe 0.5mm max. I did already print the improved nozzle mount, in fact I think it was the first upgrade part I fitted.

Regards,

Les

|

Re: Best User Upgrades? April 09, 2014 05:26AM |

Registered: 10 years ago Posts: 132 |

I agree with DC there should be play in the x-axis.. At one point my axis was binding due to it being too tight causing steps to be missed. You can have any amount of play as long as the print head is not drooping. I redesigned the nozzle mount so that the mounting face was slightly angled up so even with the pint head drooping the head sat horizontal. If anyone is interested I can supply the stl.

|

Re: Best User Upgrades? April 10, 2014 04:05AM |

Registered: 10 years ago Posts: 64 |

The "blades" on this duct appear to be backwards to the fans blades. Assuming this is on purpose, could you please explain the idea behind it? Won't it increase the noise of the airflow?Quote

dc42

... and a fan inlet duct such as [github.com] to eliminate fan backwash and avoid injuring your fingers on the rotating fan blades..

Edit: Nevermind, I realized it wasn't made for my 5 blade fan!

Edited 1 time(s). Last edit at 04/10/2014 04:10AM by michaelljunggren.

|

Re: Best User Upgrades? April 10, 2014 04:21AM |

Registered: 10 years ago Posts: 14,672 |

The fan is loaded more heavily than it's designed for because of the small outlet slots. This means that the speed of airflow through it is slower than the design value. This in turn means that the blade pitch is too course, which is why there is so much backwash. The blades on the inlet duct cause the air to swirl in the same direction as the blades rotate, which has the same effect as making the pitch finer.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Best User Upgrades? April 10, 2014 05:45AM |

Registered: 10 years ago Posts: 327 |

Quote

johneato

I agree with DC there should be play in the x-axis.. At one point my axis was binding due to it being too tight causing steps to be missed. You can have any amount of play as long as the print head is not drooping. I redesigned the nozzle mount so that the mounting face was slightly angled up so even with the pint head drooping the head sat horizontal. If anyone is interested I can supply the stl.

Yes please John.

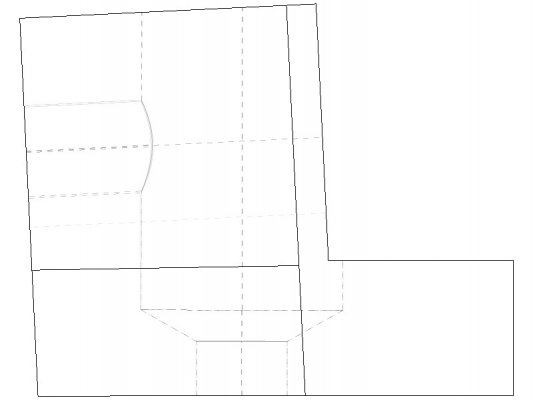

I am still not happy with mine, the bottom of the fan duct still just catches every now and then. I have some small gaps between parts (see attached photo), which probably doesn't help, but I am not sure how to get rid of them yet.

Regards,

Les

|

Re: Best User Upgrades? April 10, 2014 06:07AM |

Registered: 10 years ago Posts: 132 |

Here you go Les. If you want the angle adjusting let me know

John

John

|

Re: Best User Upgrades? April 10, 2014 06:14AM |

Registered: 10 years ago Posts: 14,672 |

There should be no gap between the heatsink duct and the fan duct, so I suggest you look into what is causing that. You can also sand a little off the bottom of the fan duct.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Best User Upgrades? April 10, 2014 08:11AM |

Registered: 10 years ago Posts: 327 |

Quote

johneato

Here you go Les. If you want the angle adjusting let me know

John

[attachment 30444 AngledModified-nozzle-mount.jpg]

Thanks John.

Quote

dc42

There should be no gap between the heatsink duct and the fan duct, so I suggest you look into what is causing that. You can also sand a little off the bottom of the fan duct.

It's actually just a gap in one corner, I think the pieces aren't quite square.

I'll print John's nozzle mount and then strip it down and check everything.

Regards,

Les

|

Re: Best User Upgrades? April 10, 2014 09:24AM |

Registered: 10 years ago Posts: 145 |

Is there an upgrade for the x-carriage?

Recently, my one seems to have lost its grip on the bearing.

Several failures resulting from a positive X movement causing the carriage to leave the bearing behind, and the head to crash onto the print.

I suspect the carriage has softened/relaxed with the heat.

Need some sort of clamp/catch to hold the bearing in place.

Greg

Ormerod #17

Recently, my one seems to have lost its grip on the bearing.

Several failures resulting from a positive X movement causing the carriage to leave the bearing behind, and the head to crash onto the print.

I suspect the carriage has softened/relaxed with the heat.

Need some sort of clamp/catch to hold the bearing in place.

Greg

Ormerod #17

|

Re: Best User Upgrades? April 10, 2014 01:28PM |

Registered: 10 years ago Posts: 23 |

Quote

GregL

Is there an upgrade for the x-carriage?

Recently, my one seems to have lost its grip on the bearing.

Several failures resulting from a positive X movement causing the carriage to leave the bearing behind, and the head to crash onto the print.

I suspect the carriage has softened/relaxed with the heat.

Need some sort of clamp/catch to hold the bearing in place.

Greg

I have this problem!!! Superglue didn't work. It's pretty annoying

|

Re: Best User Upgrades? April 10, 2014 01:38PM |

Registered: 10 years ago Posts: 327 |

Quote

GregL

Is there an upgrade for the x-carriage?

Recently, my one seems to have lost its grip on the bearing.

Several failures resulting from a positive X movement causing the carriage to leave the bearing behind, and the head to crash onto the print.

I suspect the carriage has softened/relaxed with the heat.

Need some sort of clamp/catch to hold the bearing in place.

Greg

There was an old discussion about this here. Some tape on the bearing or just a reprint the carraige?

Regards,

Les

|

Re: Best User Upgrades? April 11, 2014 04:22AM |

Registered: 10 years ago Posts: 145 |

Thanks Les.

Looking at the carriage, I am thinking that a solution might be as follows:

Drill a pin sized hole vertically down through the bit of the carriage which mounts the sensor board.

The hole would break throgh the inner curve of the bearing housing - such that a pin would positively locate in the circlip groove of the bearing.

Job done.

Greg

Ormerod #17

Looking at the carriage, I am thinking that a solution might be as follows:

Drill a pin sized hole vertically down through the bit of the carriage which mounts the sensor board.

The hole would break throgh the inner curve of the bearing housing - such that a pin would positively locate in the circlip groove of the bearing.

Job done.

Greg

Ormerod #17

|

Re: Best User Upgrades? April 12, 2014 09:49AM |

Registered: 10 years ago Posts: 23 |

|

Re: Best User Upgrades? April 12, 2014 10:30AM |

Registered: 10 years ago Posts: 145 |

I discovered that the main problem was really lack of lubrication on the bearing. It was decidedly sticky when reversing direction, and that probably overcame the grip from the x-carriage.

Bearing nicely moving now after some 'lock lube' - but I also drilled down behind the sensor, and jammed a bit of paper clip in the hole to locate the circlip groove in the bearing.

The paper clip portion will be easy to remove when re-building - but I need to print loads of ABS parts first.

I do have an early dc42 fan cover to fit first, but it slightly fouls the Duet enclosure - so I will move that first.

I am still not quite sure exactly which bits to print as I will be fitting dc42's kit 5, and I haven't quite worked out the best arangement for the fan and housing ..

Meanwhile I am back to printing - until that damned Bowden peg jumps out again!!!

Greg

Ormerod #17

Bearing nicely moving now after some 'lock lube' - but I also drilled down behind the sensor, and jammed a bit of paper clip in the hole to locate the circlip groove in the bearing.

The paper clip portion will be easy to remove when re-building - but I need to print loads of ABS parts first.

I do have an early dc42 fan cover to fit first, but it slightly fouls the Duet enclosure - so I will move that first.

I am still not quite sure exactly which bits to print as I will be fitting dc42's kit 5, and I haven't quite worked out the best arangement for the fan and housing ..

Meanwhile I am back to printing - until that damned Bowden peg jumps out again!!!

Greg

Ormerod #17

|

Re: Best User Upgrades? April 12, 2014 10:48AM |

Registered: 10 years ago Posts: 65 |

|

Re: Best User Upgrades? April 12, 2014 11:19AM |

Registered: 10 years ago Posts: 14,672 |

Quote

GregL

I do have an early dc42 fan cover to fit first, but it slightly fouls the Duet enclosure - so I will move that first.

After loosely attaching the Duet board to the y-extrusion, I rotate the T-nut in the extrusion at the end near the y-motor, and only then push the Duet board right up to the end of the extrusion. This gains a couple more mm clearance.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Best User Upgrades? April 14, 2014 04:15AM |

Registered: 10 years ago Posts: 327 |

I have printed quite a few bits now, and while I am still green, I think I have learnt quite a bit.

These are the upgrades I recommend so far...

Other parts include my Heater PCB Front Cover (photo), 7.5mm Swiss Clips to hold the glass down.

I have been using Davek0974's Aluminium Bed since the beginning, so don't know what it was like to print with the mdf bed, but this is a paid upgrade.

The above parts have made a huge difference to the print quality and helped produce consistent prints.

I'll keep adding to this list as I find more parts.

Regards,

Les

These are the upgrades I recommend so far...

- iamburny's Y Belt Tensioners with dc42's spacers if needed

- johneato's Angled Nozzle Block a few post up in this thread or Number 192's Nozzle Block

- iamburny's Double Helix Z-Gears (All iamburny's upgrades can all be found at github)

- iamburny's Double Helix Extruder Gears

- kwikius's Fan Deflector

- Mr Burns Extruder Drive Block

Other parts include my Heater PCB Front Cover (photo), 7.5mm Swiss Clips to hold the glass down.

I have been using Davek0974's Aluminium Bed since the beginning, so don't know what it was like to print with the mdf bed, but this is a paid upgrade.

The above parts have made a huge difference to the print quality and helped produce consistent prints.

I'll keep adding to this list as I find more parts.

Regards,

Les

|

Re: Best User Upgrades? July 25, 2017 08:31AM |

Registered: 6 years ago Posts: 174 |

Sorry, only registered users may post in this forum.