Control air to the nozzles

Posted by johneato

|

Control air to the nozzles April 07, 2014 02:32AM |

Registered: 10 years ago Posts: 132 |

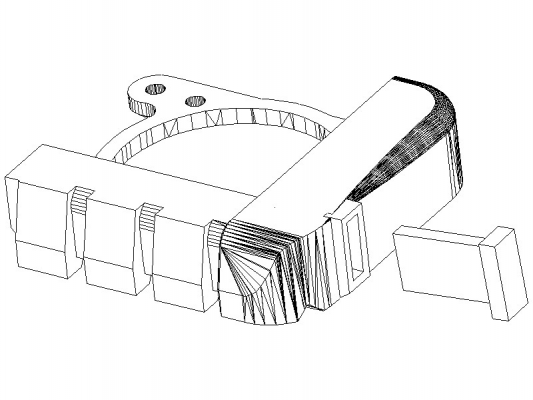

I wanted to control the air flow to the nozzles to be able to provide cooling to PLA but not to ABS. Kim is working on a similar design for his duct [forums.reprap.org]. The hot air exhaust can either exit through the nozzles or be diverted to a chimney in the fan duct. I have modified the original fan duct to accommodate a plate that can be inserted to block the path to the nozzles. I have added a chimney to the heatsink duct that I originally modified for DC’s new IR sensor. If cooling is required through the nozzles then a stopper is inserted in the chimney and the plate extracted part way to allow air to pass to the nozzles. If cooling is not required then the plate is inserted in the fan duct to block off the nozzles and the stopper is removed from the chimney to allow the warm air to exit at the top.

|

Re: Control air to the nozzles April 13, 2014 08:23AM |

Registered: 10 years ago Posts: 35 |

|

Re: Control air to the nozzles April 13, 2014 09:24AM |

Registered: 10 years ago Posts: 132 |

|

Re: Control air to the nozzles April 13, 2014 10:25AM |

Registered: 10 years ago Posts: 859 |

Hi John, I like the design, there's a lot of work gone in to it I can see.

I did think about having a valve or plug on the air supply to the nozzles, then decided against it because:-

1) While we can print well, the fit of the valve might not be that good.

2) I didn't want any leaking air to blow on the print...

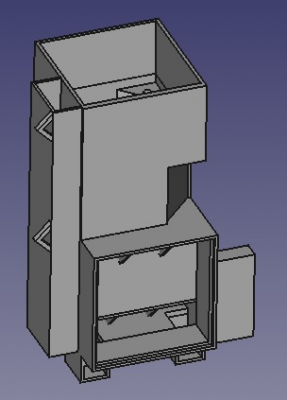

So.... What I decided was to have the Exhaust air connected all the time and control the amount of air going to the cooling nozzles by metering the amount of air able to go out up the exhaust. ANd then if you wanted to stop ALL the air to have plugs for the nozzles. That way there's no fiddley fitting of valves....

Big Blue uses that idea. I'm just printing the final protype of BB that will allow DC's probe to be fitted to the side...

Once I'm happy that the print is good I hope to release it and may well remove my older designs. Then I'll be designing the plugs, and meter covers for the exhausts, as at the moment people have to use tape. I'm using a Big Blue to print a Big Blue at the moment....

The biggest challenge I find is trying to design stuff with the minimum fettling to clean it up ready to use....

Edited 2 time(s). Last edit at 04/13/2014 11:44AM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

I did think about having a valve or plug on the air supply to the nozzles, then decided against it because:-

1) While we can print well, the fit of the valve might not be that good.

2) I didn't want any leaking air to blow on the print...

So.... What I decided was to have the Exhaust air connected all the time and control the amount of air going to the cooling nozzles by metering the amount of air able to go out up the exhaust. ANd then if you wanted to stop ALL the air to have plugs for the nozzles. That way there's no fiddley fitting of valves....

Big Blue uses that idea. I'm just printing the final protype of BB that will allow DC's probe to be fitted to the side...

Once I'm happy that the print is good I hope to release it and may well remove my older designs. Then I'll be designing the plugs, and meter covers for the exhausts, as at the moment people have to use tape. I'm using a Big Blue to print a Big Blue at the moment....

The biggest challenge I find is trying to design stuff with the minimum fettling to clean it up ready to use....

Edited 2 time(s). Last edit at 04/13/2014 11:44AM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Control air to the nozzles April 13, 2014 02:57PM |

Registered: 10 years ago Posts: 35 |

|

Re: Control air to the nozzles April 13, 2014 03:26PM |

Registered: 10 years ago Posts: 859 |

Sounds like you do a similar job to me then Ben......

Hull City??????

Hmmmmm well I had hoped to have finished printing the prototype by now, then near the end, it reminded me I had forgotten an unsupported overhang....Grrrrrrr! I missed that... Which reminds me.... I must get to designing my granulator and extruder....

Which reminds me.... I must get to designing my granulator and extruder....

Oh well.. Back to the drawing board then.... Nearly finished it.... I enjoy the challenge... Just wish I wasn't so impatient waiting for the print to finish.... I have some other stuff waiting in the wings now to be printed....

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Hull City??????

Hmmmmm well I had hoped to have finished printing the prototype by now, then near the end, it reminded me I had forgotten an unsupported overhang....Grrrrrrr! I missed that...

Which reminds me.... I must get to designing my granulator and extruder....

Which reminds me.... I must get to designing my granulator and extruder....Oh well.. Back to the drawing board then.... Nearly finished it.... I enjoy the challenge... Just wish I wasn't so impatient waiting for the print to finish.... I have some other stuff waiting in the wings now to be printed....

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Control air to the nozzles January 29, 2015 07:19AM |

Registered: 9 years ago Posts: 92 |

|

Re: Control air to the nozzles January 29, 2015 02:14PM |

Registered: 10 years ago Posts: 132 |

JamesQuote

jamesf

Great design, will this work on the Ormerod 2? Looking at the STL they are not too different

To be honest I don't realy know, I don't have access to an Omerod 2 and dont know the differences. But I would be happy to have a look at the STLs and modify them if necessary.

I have modified the design slightly to increase the width of a couple of walls. I can repost the the stls if there is any interest

Let me know.

Regards

John

|

Re: Control air to the nozzles January 29, 2015 03:12PM |

Registered: 9 years ago Posts: 92 |

Hi John

here is a link to Ormerod 2 documentation. There are minor differences but I think it should work, unless I'm missing some small detail.

[reprappro.com]

thanks

James

here is a link to Ormerod 2 documentation. There are minor differences but I think it should work, unless I'm missing some small detail.

[reprappro.com]

thanks

James

|

Re: Control air to the nozzles January 29, 2015 06:09PM |

Registered: 9 years ago Posts: 102 |

Hi

Have you seen the thread where i posted my venting mod. It uses a flap and a 6 cm fan.

I would be really interested if you could print a small object like this:

haus2.stl

haus2.scad

I found it to be a good benchmark for nozzle cooling. The stock cooling failed for me completly.

Just print one house so that there is no much time for cooling. If its not sufficient its directly

visible on the roof. Besides that object is so small that not much time/plastic is wasted with printing

plus you can use it for a board game of your choice :-).

Can you also print ABS with these mods?

Best regards

Tim

Have you seen the thread where i posted my venting mod. It uses a flap and a 6 cm fan.

I would be really interested if you could print a small object like this:

haus2.stl

haus2.scad

I found it to be a good benchmark for nozzle cooling. The stock cooling failed for me completly.

Just print one house so that there is no much time for cooling. If its not sufficient its directly

visible on the roof. Besides that object is so small that not much time/plastic is wasted with printing

plus you can use it for a board game of your choice :-).

Can you also print ABS with these mods?

Best regards

Tim

|

Re: Control air to the nozzles January 30, 2015 12:50AM |

Registered: 9 years ago Posts: 92 |

|

Re: Control air to the nozzles January 30, 2015 06:05AM |

Registered: 9 years ago Posts: 102 |

Hi James

with first test prints i am pretty happy.

available next week.

Best regards

Tim

The latest version i failed to upload is adapted to dc42's ir sensors. Its a little crowded and the vent channel could be a little larger butQuote

jamesf

Yes I saw your thread. I am looking for a duct that will fit with DC43's IR sensor which I am waiting for. Does yours support that?

with first test prints i am pretty happy.

Unfortunatly i am traveling right now (fosdem.org) and i have no connection to my desktop at home, so i am sorry that i can make it onlyQuote

jamesf

I should have some printer time this weekend. Will try your house print

available next week.

Best regards

Tim

|

Re: Control air to the nozzles January 30, 2015 06:08AM |

Registered: 9 years ago Posts: 92 |

|

Re: Control air to the nozzles February 02, 2015 03:52PM |

Registered: 9 years ago Posts: 102 |

Hi James

I just uploaded the fanduct parts to my repository:ormerod parts.

Its still not as good as the my non dc52 for small PLA parts. For ABS printing you must have the backwash protector (thanks dc42 for the hint btw.). So i guess this wont be my last version of this fanduct but still from my limited printing experience, especially with ABS i think its a already a good compromise and better than the stock venting.

Tim

I just uploaded the fanduct parts to my repository:ormerod parts.

Its still not as good as the my non dc52 for small PLA parts. For ABS printing you must have the backwash protector (thanks dc42 for the hint btw.). So i guess this wont be my last version of this fanduct but still from my limited printing experience, especially with ABS i think its a already a good compromise and better than the stock venting.

Tim

Sorry, only registered users may post in this forum.