Yap, it prints

Posted by Sardi

Yap, it prints  April 29, 2014 10:09AM |

Registered: 10 years ago Posts: 466 |

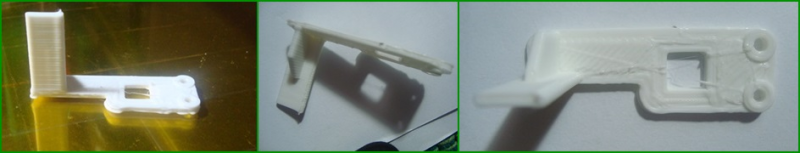

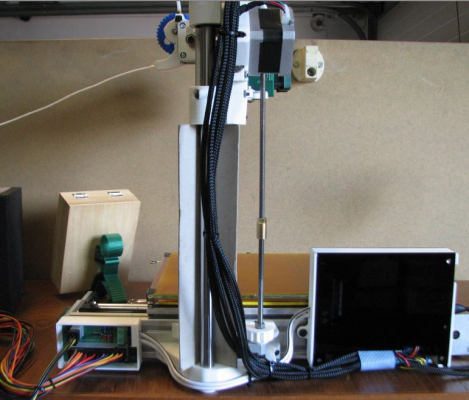

So after about a month of working arround, the green beast started to create shapes out of melted plastic!

Feelin proud! And the print looks really good, I know its my first one, but I am pleased

Now I would like some tips from you on further printing, like, can I just remove this model and simply continue to print with another one? Do I need to clean the print bed first? And such things.

I did google about this, but some say clean, some say dont, some say "spray the model with canned air to take it of".. But I would like the opinions of ormerod user

Thank you,

Antonio

Feelin proud! And the print looks really good, I know its my first one, but I am pleased

Now I would like some tips from you on further printing, like, can I just remove this model and simply continue to print with another one? Do I need to clean the print bed first? And such things.

I did google about this, but some say clean, some say dont, some say "spray the model with canned air to take it of".. But I would like the opinions of ormerod user

Thank you,

Antonio

Re: Yap, it prints  April 29, 2014 10:20AM |

Registered: 10 years ago Posts: 14,672 |

Antonio, I'm glad to see you got this far! If you are using a Kapton bed then cleaning it with isopropanol or acetone between prints is generally a good idea. You may get away without if you avoid finger-marking the bed.

From the right-most photo, I think your extruder temperature may be a little too high. I use 195C for the first layer and 185 or 190C for the rest.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

From the right-most photo, I think your extruder temperature may be a little too high. I use 195C for the first layer and 185 or 190C for the rest.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: Yap, it prints  April 29, 2014 10:31AM |

Registered: 10 years ago Posts: 466 |

I am not using kapton, decided to print on the glass directly.

The temperature was set to 200 (pronterface default), but I did notice that my web Ormerod control showed the temperature high as 235, and only after a few layers droping to 200. I am not sure why that happened.

EDIT: for the first and second layer temperature - do I input the temperature manually or can that be automated? I am not familiar with that.

Edited 1 time(s). Last edit at 04/29/2014 10:32AM by Sardi.

The temperature was set to 200 (pronterface default), but I did notice that my web Ormerod control showed the temperature high as 235, and only after a few layers droping to 200. I am not sure why that happened.

EDIT: for the first and second layer temperature - do I input the temperature manually or can that be automated? I am not familiar with that.

Edited 1 time(s). Last edit at 04/29/2014 10:32AM by Sardi.

Re: Yap, it prints  April 29, 2014 10:41AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Sardi

I am not using kapton, decided to print on the glass directly.

In that case, do not use acetone or isopropanol to clean the bed, just prime it with vinegar between prints. When prints will no longer stick, take it off and wash it in hot soapy water.

Quote

Sardi

The temperature was set to 200 (pronterface default), but I did notice that my web Ormerod control showed the temperature high as 235, and only after a few layers droping to 200. I am not sure why that happened.

EDIT: for the first and second layer temperature - do I input the temperature manually or can that be automated? I am not familiar with that.

Check your filament settings in slic3r. There are separate settings for the first layer and other layers.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: Yap, it prints  April 29, 2014 11:12AM |

Registered: 10 years ago Posts: 1,230 |

Hi Antonio

There ya go!, really great looking first print!

After the print I let the nozzle cool down, then cut of any filament hanging from the nozzle with a razor blade while taking care in holding it totally horizontal, like dc42 I then clean the bed again just for safety, taking care not to leave any dust from the paper on the bed, besides that I always re-zero the nozzle before printing again

Sometime you may find that your print just won't stick, on new kapton or old - those day I sand the kapton lightly with sandpaper P350-P400, then wipe the bed over with iso or ace to clean for dust and then, just like magic, the print will stick again

Before cleaning the nozzle I lift the x-axis to the top (the nut is a lose fit in the z-nut-trap) and mount a long angled spacer to hold it up as to get a clear view while cleaning the nozzle

Erik

There ya go!, really great looking first print!

After the print I let the nozzle cool down, then cut of any filament hanging from the nozzle with a razor blade while taking care in holding it totally horizontal, like dc42 I then clean the bed again just for safety, taking care not to leave any dust from the paper on the bed, besides that I always re-zero the nozzle before printing again

Sometime you may find that your print just won't stick, on new kapton or old - those day I sand the kapton lightly with sandpaper P350-P400, then wipe the bed over with iso or ace to clean for dust and then, just like magic, the print will stick again

Before cleaning the nozzle I lift the x-axis to the top (the nut is a lose fit in the z-nut-trap) and mount a long angled spacer to hold it up as to get a clear view while cleaning the nozzle

Erik

Re: Yap, it prints  April 29, 2014 11:15AM |

Registered: 10 years ago Posts: 2,472 |

Re: Yap, it prints  April 29, 2014 11:21AM |

Registered: 10 years ago Posts: 466 |

Thanks for the tips, did just what you told me, now lets see how the second print goes

About printing, do I need to turn the heating for the hot end manualy, or will it turn on when I sent the file to print? I am asking this because of the 1st and 2nd layer temperature setting in slicer, therefore I think that the head will start heating when I send the print command.

About printing, do I need to turn the heating for the hot end manualy, or will it turn on when I sent the file to print? I am asking this because of the 1st and 2nd layer temperature setting in slicer, therefore I think that the head will start heating when I send the print command.

Re: Yap, it prints  April 29, 2014 11:31AM |

Registered: 10 years ago Posts: 14,672 |

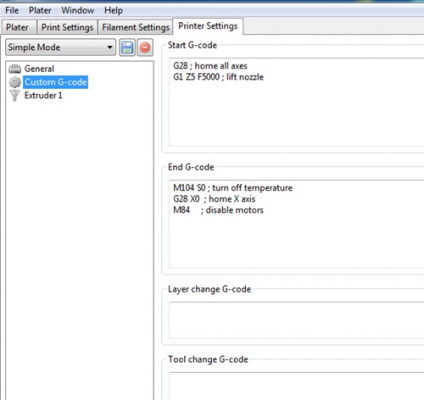

Check the "Custom G code" in the slic3r print settings. It should look something like this:

The M116 command will ensure that it heats up before printing.

Edited 2 time(s). Last edit at 04/29/2014 11:33AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

G21 ; set units to millimeters G90 ; use absolute coordinates M83 ; use relative distances for extrusion G1 Z5 F200 ; lift nozzle G1 X2 Y50 F4000; Go to wait for warm position M116; Wait for all temperatures T0; Select extruder M116; Wait for all temperature

The M116 command will ensure that it heats up before printing.

Edited 2 time(s). Last edit at 04/29/2014 11:33AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: Yap, it prints  April 29, 2014 11:42AM |

Registered: 10 years ago Posts: 466 |

This is what I have at Custom G code. It was all there by default, I didnt add anything.

Re: Yap, it prints  April 29, 2014 12:50PM |

Registered: 10 years ago Posts: 14,672 |

Looks like you didn't load RepRapPro's slic3r settings then.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: Yap, it prints  April 29, 2014 12:56PM |

Registered: 10 years ago Posts: 466 |

Re: Yap, it prints  April 29, 2014 12:57PM |

Registered: 10 years ago Posts: 14,672 |

[reprappro.com]

PS - unless RRP have changed them, you need to make some adjustments after loading them:

- increase retraction to 4mm

- reduce first layer temp to about 195 and other layer temp to 190 or below

I also increase the skirt clearance and set the minimum filament to use for the skirt to 20mm. I've increased some of the speeds too, but wait until you get good prints before you do that.

Edited 1 time(s). Last edit at 04/29/2014 01:01PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

PS - unless RRP have changed them, you need to make some adjustments after loading them:

- increase retraction to 4mm

- reduce first layer temp to about 195 and other layer temp to 190 or below

I also increase the skirt clearance and set the minimum filament to use for the skirt to 20mm. I've increased some of the speeds too, but wait until you get good prints before you do that.

Edited 1 time(s). Last edit at 04/29/2014 01:01PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: Yap, it prints  April 29, 2014 01:16PM |

Registered: 10 years ago Posts: 466 |

Re: Yap, it prints  April 29, 2014 03:15PM |

Registered: 10 years ago Posts: 14,672 |

Good luck!

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: Yap, it prints  April 29, 2014 03:32PM |

Registered: 10 years ago Posts: 859 |

@Erik

Hi Erik... I wouldn't use a knife to clean the nozzle, it will kill it one day...

I use a clean soft leather gardening glove, and it brings it up like new... They are cheap as chips, but last a long time... I cut a bit off one for my cleaner...

I like the angle iron idea.... I'm going to make one here....

@Sardi

Nice to see it works... It looks a bit hot to me... After the first layer try 195/190...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Hi Erik... I wouldn't use a knife to clean the nozzle, it will kill it one day...

I use a clean soft leather gardening glove, and it brings it up like new... They are cheap as chips, but last a long time... I cut a bit off one for my cleaner...

I like the angle iron idea.... I'm going to make one here....

@Sardi

Nice to see it works... It looks a bit hot to me... After the first layer try 195/190...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Re: Yap, it prints  April 29, 2014 03:48PM |

Registered: 10 years ago Posts: 466 |

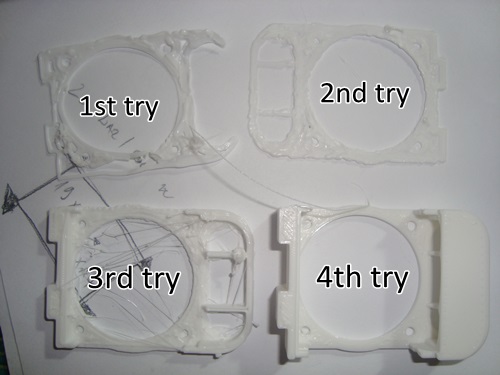

And the results

You can see on the first left picture, the model got a bit warped. Any ideas why?

EDIT:

I am having some issues after updating Slic3r to RepRap settings. Will open a new topic later on.

Edited 1 time(s). Last edit at 04/29/2014 03:50PM by Sardi.

You can see on the first left picture, the model got a bit warped. Any ideas why?

EDIT:

I am having some issues after updating Slic3r to RepRap settings. Will open a new topic later on.

Edited 1 time(s). Last edit at 04/29/2014 03:50PM by Sardi.

Re: Yap, it prints  April 29, 2014 04:40PM |

Registered: 10 years ago Posts: 1,230 |

Quote

KimBrown

@Erik

Hi Erik... I wouldn't use a knife to clean the nozzle, it will kill it one day...

Yes I know but as I wrote: "..while taking care in holding it totally horizontal"

Quote

..I like the angle iron idea.... I'm going to make one here....

Its actually angled cardboard, very strong, almost MDF! (LOL) - the angled form make it slip right in, and most importantly, stay put

..but I do (when I print) have a 15mm steel bit in there at the bottom, just to make sure the nozzle don't drill the bed by accident

Erik

Re: Yap, it prints  April 29, 2014 06:45PM |

Registered: 10 years ago Posts: 14,672 |

Warping is typically caused by a combination of poor adhesion to the bed and draughts or backwash from the fan (although I would not expect backwash to be a big issue with a part as small as that). Print a fan backwash deflector when you can. The one I use is here [github.com]. As you are printing direct on glass, use a bed temperature of at least 65C. Wash the glass in hot soapy water, then avoid finger-marking it and wipe it with a clean tissue moistened in vinegar before each print. It also helps to wait 2 minutes after the bed reaches temperature before you start printing, because the temperature on the top surface of the glass lags the temperature indicated by the bed thermistor.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.