Ormerod reviews

Posted by droftarts

|

Ormerod reviews April 30, 2014 05:50AM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Ormerod reviews April 30, 2014 04:15PM |

Registered: 10 years ago Posts: 665 |

Hello Ian,

ever since I got my Ormerod kit, I've been fighting countless issues. After the first two weeks, I was very close to throwing it out the window (or returning it), but meanwhile everything is working better and better. And because it is open-source, it allows me (and other users) to modify both hardware parts and the firmware, which is really great IMO. I didn't know much about 3D printing before I got my Ormerod, but that has certainly changed to some degree.

Anyway, I've been writing down all modifications and issues I've had with my RRP Ormerod as some kind of review (not on RS, but here on this forum), and I'd really like to see a statement by RRP about at least these three points:

- What's the reason RRP ships all kits with an ATX PSU? The kit doesn't provide connectors to 5V or ATX_ON out of the box, so why not ship a regular 12V supply instead? Also, the 12V output on that ATX PSU will always be less than 12V, and this caused me some problems when trying to heat up the bed to 110°C for ABS (which is bad since it was labelled to be capable of printing ABS when I bought it). Now I'm running my Ormerod with a 300W 12V LED PSU for ~25€, and this one even allows me to adjust the output voltage. Since replacement, I haven't had any problems reaching the target temperature, even if it is higher than 90°C.

- Wouldn't it make sense to get rid of that MDF bed construction? I wrote down some notes on how to rebuild it for ~15€ and since I replaced it, I really haven't got any more sagging at all. There are several other approaches on this forum, and pretty much everyone on this forum complains about the stock MDF construction.

- What's the deal with the IR probe? I've never been able to get the IR probe working consistently for more than 6 hours perhaps, so replacing that one with an ultrasonic sensor as designed by dc42 would make sense IMHO.

When I bought my kit, I honestly didn't expect a fully-working machine out of the box, but if I hadn't had so much spare time, I would have probably returned my Ormerod. Please don't see this criticism too negative, I still love the idea of open-source projects and I'm just trying to improve it for future users

Christian

P.S. Please do me a favour and alter the "Axis compensation" documentation page a bit. There's one sentence in the part about "Setting the Z probe" saying "Now move the Z axis down so that the nozzle is a tiny bit above the bed and you can just see light between the two". Please add a comment saying Z=0 is exactly 0.1mm above the heated bed. It took me quite some time to realize that

ever since I got my Ormerod kit, I've been fighting countless issues. After the first two weeks, I was very close to throwing it out the window (or returning it), but meanwhile everything is working better and better. And because it is open-source, it allows me (and other users) to modify both hardware parts and the firmware, which is really great IMO. I didn't know much about 3D printing before I got my Ormerod, but that has certainly changed to some degree.

Anyway, I've been writing down all modifications and issues I've had with my RRP Ormerod as some kind of review (not on RS, but here on this forum), and I'd really like to see a statement by RRP about at least these three points:

- What's the reason RRP ships all kits with an ATX PSU? The kit doesn't provide connectors to 5V or ATX_ON out of the box, so why not ship a regular 12V supply instead? Also, the 12V output on that ATX PSU will always be less than 12V, and this caused me some problems when trying to heat up the bed to 110°C for ABS (which is bad since it was labelled to be capable of printing ABS when I bought it). Now I'm running my Ormerod with a 300W 12V LED PSU for ~25€, and this one even allows me to adjust the output voltage. Since replacement, I haven't had any problems reaching the target temperature, even if it is higher than 90°C.

- Wouldn't it make sense to get rid of that MDF bed construction? I wrote down some notes on how to rebuild it for ~15€ and since I replaced it, I really haven't got any more sagging at all. There are several other approaches on this forum, and pretty much everyone on this forum complains about the stock MDF construction.

- What's the deal with the IR probe? I've never been able to get the IR probe working consistently for more than 6 hours perhaps, so replacing that one with an ultrasonic sensor as designed by dc42 would make sense IMHO.

When I bought my kit, I honestly didn't expect a fully-working machine out of the box, but if I hadn't had so much spare time, I would have probably returned my Ormerod. Please don't see this criticism too negative, I still love the idea of open-source projects and I'm just trying to improve it for future users

Christian

P.S. Please do me a favour and alter the "Axis compensation" documentation page a bit. There's one sentence in the part about "Setting the Z probe" saying "Now move the Z axis down so that the nozzle is a tiny bit above the bed and you can just see light between the two". Please add a comment saying Z=0 is exactly 0.1mm above the heated bed. It took me quite some time to realize that

|

Re: Ormerod reviews May 01, 2014 08:27AM |

Registered: 10 years ago Posts: 2,472 |

Quote

zombiepantslol

P.S. Please do me a favour and alter the "Axis compensation" documentation page a bit. There's one sentence in the part about "Setting the Z probe" saying "Now move the Z axis down so that the nozzle is a tiny bit above the bed and you can just see light between the two". Please add a comment saying Z=0 is exactly 0.1mm above the heated bed. It took me quite some time to realize that

It isn't as far as I am aware. Z=0 should theoretically be where the nozzle is exactly touching the bed but exerting no pressure whatsoever on the bed. You will see that the G file sets the Z height to exactly the first layer height at the start of a print, not 0.1mm lower. Using the sheet of paper method is the easiest way to set the nozzle to a distance that is as near as dammit touching the glass after the paper is removed - the paper will keep the nozzle about 0.1mm above the glass while it is there, but is also exerting a slight downward force on the glass and upward force on the nozzle, so they move a bit closer together when the paper is removed.

Dave

(#106)

|

Re: Ormerod reviews May 01, 2014 06:59PM |

Registered: 12 years ago Posts: 1,611 |

Sorry for the slow reply, busy day...

zombiepantslol, to reply to your three questions:

1. We use the 12V LED-style PSUs on our Mendel machines, but the power wiring has always been a barrier to entry for some people - it just looks a bit scary, see: [reprappro.com]

So we wanted something a bit more 'consumer friendly' and went for the ATX PSU, because they have a built-in switch, common mains plug and simple plugs to supply power. Other RepRap printers use them. We tested them in-house, and for some reason we didn't (and still don't) have a problem printing with Ultimachine ABS on our printers in-house, with a standard bed heated to just around 100C, with the ATX PSU. We have produced a guide for printing ABS in our extensive troubleshooting section ( [reprappro.com] ) which acknowledges the problems and pitfalls, but unlike other companies we don't put any artificial limits on changes people can make to their printers, to do what they want with them.

2. Building a fully-featured 3D printer to a specific budget, and particularly when you're trying to innovate, inevitably means compromise. We tried to be a bit clever with the bed, but some (and certainly not all) people have problems with it. I print on a standard bed, but have long screws in the 2 points at the back (along the Y extrusion) and one at the front, between the bed terminals, so it's mounted on 3 points. The screws are 25mm cap screws, that go down through the aluminium heat spreader, then bed PCB, then have an M3 washer and M3 nyloc nut. A nyloc nut is threaded on lower down, and acts as a height adjuster. Then it goes through the MDF, and a plain M3 nut on the back, to lock the it in place. The outer corners just have a short cap screw though the heat spreader and PCB, with an M3 nyloc on the back, which doesn't touch the MDF below. I have the cardboard taped to the back of the PCB, as per the instructions. This means the outer two corners don't support the bed, and I have adjustment over the bed plane. I advise people who contact me with bed problems to do this, because mostly it's the two unsupported corners of the MDF that cause the problems if the MDF warps. There is scope for the back two corners to droop a bit, but nowhere near as much as the front corners. You can even cut the front two corners off the MDF if you want, leaving the MDF as a 'T' shape. Another tip is to do your bed compensation with the bed at working temperature; if it's going to move, it'll do it when it changes temperature. This may relate to your last comment, and Dave (dmould) is essentially correct in his reply.

3. We wanted a probe that gave more control and feedback than an endstop microswitch, because we believe that the way forward was to compensate for alignment issues, and to do it automatically as much as possible. I know it means little to most Ormerod owners, but you really haven't felt pain until you've had to align and level a Mendel frame... It's why we went to a cantilever design, without the limitations of the Mendel. We went through all the different types of sensors - Hall sensors, ultrasonic, force sensors, bed contacts (already did this on the Huxley) and IR sensors. IR sensors seemed to offer the best price/performance compromise, so we developed it... in a room with north facing windows and florescent lighting, in winter. We didn't notice for a long time that we had problems with other InfraRed sources, and then we just didn't have the option to change it. The only option was to provide caveats in the instructions. We have been slow to finalise the modulated IR sensor, but we now have this working very well (my Ormerod sits in near-direct sunlight and homes Z spot-on each time), and finally have production samples.

Ultimately, all of the above are decisions made due to development, production, performance, time and cost constraints, though this is true of every part. We had to launch at some point, or we would still be fiddling around with it now. In fact, we still ARE still fiddling about with the Ormerod; we're fettling and finessing it. Something else we didn't foresee was that RS customers have different expectations compared to the hobbyists that RepRap-style 3D printing has attracted before, which took both us and RS by surprise. However, we've built up a good relationship, and we'll continue to be RS's DIY/hobbyist offering.

I hope that helps explain where we're coming from...

Ian

RepRapPro tech support

zombiepantslol, to reply to your three questions:

1. We use the 12V LED-style PSUs on our Mendel machines, but the power wiring has always been a barrier to entry for some people - it just looks a bit scary, see: [reprappro.com]

So we wanted something a bit more 'consumer friendly' and went for the ATX PSU, because they have a built-in switch, common mains plug and simple plugs to supply power. Other RepRap printers use them. We tested them in-house, and for some reason we didn't (and still don't) have a problem printing with Ultimachine ABS on our printers in-house, with a standard bed heated to just around 100C, with the ATX PSU. We have produced a guide for printing ABS in our extensive troubleshooting section ( [reprappro.com] ) which acknowledges the problems and pitfalls, but unlike other companies we don't put any artificial limits on changes people can make to their printers, to do what they want with them.

2. Building a fully-featured 3D printer to a specific budget, and particularly when you're trying to innovate, inevitably means compromise. We tried to be a bit clever with the bed, but some (and certainly not all) people have problems with it. I print on a standard bed, but have long screws in the 2 points at the back (along the Y extrusion) and one at the front, between the bed terminals, so it's mounted on 3 points. The screws are 25mm cap screws, that go down through the aluminium heat spreader, then bed PCB, then have an M3 washer and M3 nyloc nut. A nyloc nut is threaded on lower down, and acts as a height adjuster. Then it goes through the MDF, and a plain M3 nut on the back, to lock the it in place. The outer corners just have a short cap screw though the heat spreader and PCB, with an M3 nyloc on the back, which doesn't touch the MDF below. I have the cardboard taped to the back of the PCB, as per the instructions. This means the outer two corners don't support the bed, and I have adjustment over the bed plane. I advise people who contact me with bed problems to do this, because mostly it's the two unsupported corners of the MDF that cause the problems if the MDF warps. There is scope for the back two corners to droop a bit, but nowhere near as much as the front corners. You can even cut the front two corners off the MDF if you want, leaving the MDF as a 'T' shape. Another tip is to do your bed compensation with the bed at working temperature; if it's going to move, it'll do it when it changes temperature. This may relate to your last comment, and Dave (dmould) is essentially correct in his reply.

3. We wanted a probe that gave more control and feedback than an endstop microswitch, because we believe that the way forward was to compensate for alignment issues, and to do it automatically as much as possible. I know it means little to most Ormerod owners, but you really haven't felt pain until you've had to align and level a Mendel frame... It's why we went to a cantilever design, without the limitations of the Mendel. We went through all the different types of sensors - Hall sensors, ultrasonic, force sensors, bed contacts (already did this on the Huxley) and IR sensors. IR sensors seemed to offer the best price/performance compromise, so we developed it... in a room with north facing windows and florescent lighting, in winter. We didn't notice for a long time that we had problems with other InfraRed sources, and then we just didn't have the option to change it. The only option was to provide caveats in the instructions. We have been slow to finalise the modulated IR sensor, but we now have this working very well (my Ormerod sits in near-direct sunlight and homes Z spot-on each time), and finally have production samples.

Ultimately, all of the above are decisions made due to development, production, performance, time and cost constraints, though this is true of every part. We had to launch at some point, or we would still be fiddling around with it now. In fact, we still ARE still fiddling about with the Ormerod; we're fettling and finessing it. Something else we didn't foresee was that RS customers have different expectations compared to the hobbyists that RepRap-style 3D printing has attracted before, which took both us and RS by surprise. However, we've built up a good relationship, and we'll continue to be RS's DIY/hobbyist offering.

I hope that helps explain where we're coming from...

Ian

RepRapPro tech support

|

Re: Ormerod reviews May 02, 2014 10:23AM |

Registered: 10 years ago Posts: 2,472 |

Maybe not something an engineer would foresee, but a marketing person or businessman should have easily predicted it. Someone who starts a DIY project to build something he knows is a somewhat experimental and community developed product from plans published on the Internet has a completely different mindset to a person who buys a commercially advertised DIY kit from a major retailer. If you were to build a washing machine from plans you got off the Internet, you'd be prepared to spend a lot of time and effort to get it working properly, but if a machine bought from Currys didn't produce a good wash the first time it was used, you would be most irate if Currys suggested that you should take the back off and modify the mechanism. And a mistake in the length of bolt in a bill of materials on an Internet design would not get you nearly as frustrated as finding the same error when you start putting together a flatpack bed from Ikea.Quote

droftarts

Something else we didn't foresee was that RS customers have different expectations compared to the hobbyists that RepRap-style 3D printing has attracted before, which took both us and RS by surprise. However, we've built up a good relationship, and we'll continue to be RS's DIY/hobbyist offering.

In short it depends not on how good or bad the product is, but how closely it matches the customer's expectations.

Dave

(#106)

Edited 1 time(s). Last edit at 05/02/2014 10:24AM by dmould.

|

Re: Ormerod reviews May 03, 2014 05:18PM |

Registered: 12 years ago Posts: 1,611 |

Yes Dave, that's true. We're a company of engineers, rather than marketeers! Particularly at the beginning, RS didn't really understand the product they were getting, and their marketing was off. We badgered them for ages to try and get them to change it, which they eventually did. It's probably still not clear enough, though. We have spoken at length with RS about managing customer expectations, now!

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: Ormerod reviews May 03, 2014 06:59PM |

Registered: 10 years ago Posts: 2,472 |

Quote

droftarts

Yes Dave, that's true. We're a company of engineers, rather than marketeers! Particularly at the beginning, RS didn't really understand the product they were getting, and their marketing was off. We badgered them for ages to try and get them to change it, which they eventually did. It's probably still not clear enough, though. We have spoken at length with RS about managing customer expectations, now!

Ian

RepRapPro tech support

I'm an engineer as well, but I've had to learn a little about the "Real World" from the marketing guys and bean counters - and am quite happy to leave them to get on with that side of the business! Unfortunately customers are not as logical as gears and transistors. OTOH they can be just as predictable to a person who understands the field (i.e. not myself). One peculiarity is that a company that sells products that always work perfectly will not get as good a reputation as a company that sometimes sells faulty product but jumps around and fixes the problem for the customer very quickly. Apparently the reason many of us don't understand marketing too well is because we engineers are quite likely to have autistic tendencies. So I don't let salespeople near my tools, and they don't let me near their customers, and we get on perfectly!

Dave

(#106)

|

Re: Ormerod reviews May 03, 2014 11:53PM |

Registered: 10 years ago Posts: 859 |

Ian, you wouldn't like my review......

Poor support from Rep-Rap.

Almost impossible to order spares, as they don't respond.

Until Ian taps them on the shoulder.

Why aren't the UPGRADES WE are designing, being passed on to NewBees Buying the macines.

A few people like, DC42, Iamburny, and few of US others have HELPed progress the machine,

but have NO!!!!!! credit from Rep-Rap....

Shame on you........

DC42 seems never to sleep to try and progress things on the firmware

but WE all get little support from you.

I feel pretty anti Rep-Rap right now, as while they say they want US guys to progress the basic design,

they won't give US credit or adopt our designs/firmware in their new kits.

I feel you are turning your backs on all of us that are trying to develope the machine.

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Poor support from Rep-Rap.

Almost impossible to order spares, as they don't respond.

Until Ian taps them on the shoulder.

Why aren't the UPGRADES WE are designing, being passed on to NewBees Buying the macines.

A few people like, DC42, Iamburny, and few of US others have HELPed progress the machine,

but have NO!!!!!! credit from Rep-Rap....

Shame on you........

DC42 seems never to sleep to try and progress things on the firmware

but WE all get little support from you.

I feel pretty anti Rep-Rap right now, as while they say they want US guys to progress the basic design,

they won't give US credit or adopt our designs/firmware in their new kits.

I feel you are turning your backs on all of us that are trying to develope the machine.

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Ormerod reviews May 04, 2014 03:54AM |

Registered: 10 years ago Posts: 776 |

Wow, that seems a bit harsh Kim. Personally I'm quite happy in the way that they have not taken on board the many modifications, it keeps the price down, keeps the community talking and more importantly thinking, allows much faster development, the list goes on.

For our mods to be taken on, I guess they would need testing, fine tuning, and more before getting RRP's endorsement and inclusion, then we would change the design a little, improve this or that and it would be back to square one.

Not everyone wants an aluminium x arm or a big fan duct or an ultrasonic probe etc, having a basic but mostly working model allows us to customise at will and that for me is a big bonus.

As to poor support, well I must say when I bought my kit, I emailed RRP and it did take a week to get a reply, that was only asking for a PDF build manual!

So that could really be improved I feel.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

For our mods to be taken on, I guess they would need testing, fine tuning, and more before getting RRP's endorsement and inclusion, then we would change the design a little, improve this or that and it would be back to square one.

Not everyone wants an aluminium x arm or a big fan duct or an ultrasonic probe etc, having a basic but mostly working model allows us to customise at will and that for me is a big bonus.

As to poor support, well I must say when I bought my kit, I emailed RRP and it did take a week to get a reply, that was only asking for a PDF build manual!

So that could really be improved I feel.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Ormerod reviews May 04, 2014 04:23AM |

Registered: 10 years ago Posts: 46 |

I posted one to the Danish site long ago (don't recall the wording, but relatively positive except for the fact that RS didn't carry spares themselves, and they started off making it sound as if everyone could assemble it in two hours), but it never turned op -- perhaps some people at RS are less than objective in acecpting the reviews?

I noticed that a few of the UK reviews start with the paragraph "This message has been moderated.". Makes you wonder...

Edited 1 time(s). Last edit at 05/04/2014 04:24AM by ZeAllan.

I noticed that a few of the UK reviews start with the paragraph "This message has been moderated.". Makes you wonder...

Edited 1 time(s). Last edit at 05/04/2014 04:24AM by ZeAllan.

|

Re: Ormerod reviews May 04, 2014 04:43AM |

Registered: 10 years ago Posts: 43 |

Kim thats an bit hard dont you think ??

Since the Printer is an open source and the idea is that People DO Upgrades on themself, also each one who thinks thats an Printer from the box out shouldnt buy it. (Sorry for my bad English)

For me i whas one who wanted to give up and whas so mad i would trow it in the trash but then after some Upgrades and help from here i get really really good works !!

Well it would be nice if they could add the Upgrades in the new Kits but its more fun for someone who really want to work on the Printer to make themself, when i remember i did the first print on the Z Gears from Iamburny i whas like yeah finally somethink what did work.

Hope i could bring my view over to you guys an bit even i cant write perfectly English ^^

Greetings Mario

PS: The Spare Support on RepRapPro whas great for me, i ordered from Sally 2 Times got all i needed and it whas fast shipment, i cant say they have an bad Support after all.

Edit: I had Forget to mention that my Ormerod is printing now same or even better Quality as the Renkforce1000 from Conrad and that means something big to me. From were i know this you ask ? I can tell you my Buddy Buyed it for 2000 Euros (finished Model) and is printing now the same Quality as mine, i think mine is even an bit more finer then his Renkforce one and thats an 2000 Euro Vs 800 Euro Printer !!

For all who dosnt know the Renkforce Printer: [www.youtube.com]

Edited 1 time(s). Last edit at 05/04/2014 04:51AM by Blitza.

Since the Printer is an open source and the idea is that People DO Upgrades on themself, also each one who thinks thats an Printer from the box out shouldnt buy it. (Sorry for my bad English)

For me i whas one who wanted to give up and whas so mad i would trow it in the trash but then after some Upgrades and help from here i get really really good works !!

Well it would be nice if they could add the Upgrades in the new Kits but its more fun for someone who really want to work on the Printer to make themself, when i remember i did the first print on the Z Gears from Iamburny i whas like yeah finally somethink what did work.

Hope i could bring my view over to you guys an bit even i cant write perfectly English ^^

Greetings Mario

PS: The Spare Support on RepRapPro whas great for me, i ordered from Sally 2 Times got all i needed and it whas fast shipment, i cant say they have an bad Support after all.

Edit: I had Forget to mention that my Ormerod is printing now same or even better Quality as the Renkforce1000 from Conrad and that means something big to me. From were i know this you ask ? I can tell you my Buddy Buyed it for 2000 Euros (finished Model) and is printing now the same Quality as mine, i think mine is even an bit more finer then his Renkforce one and thats an 2000 Euro Vs 800 Euro Printer !!

For all who dosnt know the Renkforce Printer: [www.youtube.com]

Edited 1 time(s). Last edit at 05/04/2014 04:51AM by Blitza.

|

Re: Ormerod reviews May 04, 2014 04:59AM |

Registered: 10 years ago Posts: 14,672 |

I think I should point out that RRP did take my firmware changes in the early days and they expressed their gratitude.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ormerod reviews May 04, 2014 06:17AM |

Registered: 10 years ago Posts: 275 |

Hi, Ian

I closed all business relationships with RS.

I do not agree on their way to "sell" the product!

Ormerod was the last with them.

Thanks to the RepRap and the community I'm very happy now!

Ormerod is a beautiful kit with some little changes....

Thanks to Adrian ( a genius!)

Thanks Ian (Tibetan patience!)

Thanks David ....I'll contact you for a production...

Dario

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

I closed all business relationships with RS.

I do not agree on their way to "sell" the product!

Ormerod was the last with them.

Thanks to the RepRap and the community I'm very happy now!

Ormerod is a beautiful kit with some little changes....

Thanks to Adrian ( a genius!)

Thanks Ian (Tibetan patience!)

Thanks David ....I'll contact you for a production...

Dario

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

|

Re: Ormerod reviews May 04, 2014 07:08AM |

Registered: 10 years ago Posts: 209 |

Reprap support were pretty responsive for me on the two occasions I contacted them; first to get my early Duet with twisted resistors replaced and second to get a quote and order a spare stepper motor.

The design concept works well for me, and I did not have any great difficulties getting decent quality prints even with the kit as supplied. I can see that anybody expecting to get a working printer assembled fast was going to be disappointed. Looking at the box of bits it was clear to me that this was a much longer job and that going at it slowly and carefully would pay dividends.

The mechanical improvements suggested by the excellent work on these forums definitely make a big difference to the machine. I have benefited from the stability introduced by the aluminium bed and x arm. I can see it's a bit difficult for reprap to incorporate many of these as there have been different approaches taken. I would guess they like to keep a lot of manufacturing capability in house and that might explain use of easily laser cut materials like mdf and acrylic. A change to the bed would be the one item I would see as making the most difference to the kit as supplied. Although I could get decent prints from the mdf one, it was a case of checking and re-adjusting much too often for comfort.

The software side, I feel they could be more responsive on. I know DC42 has generously said they incorporated and acknowledged some improvements early on, but it has been very quiet on that front since January despite many further significant improvements being made (e.g. acceleration control corrections). The web control as supplied was also not really fit for purpose and that is being generous. With the new firmware and iamburny web development it now fulfills its promise of total web control.

Overall, I am very pleased with the machine, but I suspect that without the support and work of this forum it would be a very different story.

The design concept works well for me, and I did not have any great difficulties getting decent quality prints even with the kit as supplied. I can see that anybody expecting to get a working printer assembled fast was going to be disappointed. Looking at the box of bits it was clear to me that this was a much longer job and that going at it slowly and carefully would pay dividends.

The mechanical improvements suggested by the excellent work on these forums definitely make a big difference to the machine. I have benefited from the stability introduced by the aluminium bed and x arm. I can see it's a bit difficult for reprap to incorporate many of these as there have been different approaches taken. I would guess they like to keep a lot of manufacturing capability in house and that might explain use of easily laser cut materials like mdf and acrylic. A change to the bed would be the one item I would see as making the most difference to the kit as supplied. Although I could get decent prints from the mdf one, it was a case of checking and re-adjusting much too often for comfort.

The software side, I feel they could be more responsive on. I know DC42 has generously said they incorporated and acknowledged some improvements early on, but it has been very quiet on that front since January despite many further significant improvements being made (e.g. acceleration control corrections). The web control as supplied was also not really fit for purpose and that is being generous. With the new firmware and iamburny web development it now fulfills its promise of total web control.

Overall, I am very pleased with the machine, but I suspect that without the support and work of this forum it would be a very different story.

|

Re: Ormerod reviews May 04, 2014 08:07AM |

Registered: 10 years ago Posts: 176 |

Hi all,

Yeah, Most of us here are engineers background I believe. I did wrote a review in my broken english months ago, with a lot of pictures too. I decided not to publish them because when I list out pros and cons, I have a few pros and a page full of cons. I enjoy Ormerod now, after a lot of tweaks and mod. I almost give up at the beginning, and not to mentioned that RS actually cancelled my Ormerod orders several times without informing me, I finally received it after dozens of frustrated calls to RS, and that was 2 months after my first order date. Indeed, droftarts ( Ian ) did try his best to answered all my questions and try to help me out.

I'm glad to see members here are willing to help and I wont be printing now without you guys , ( DC42, Iamburny, Dmould, Kim, and Kevin, aka.Treth, who sent me parts for free across the pond, and a lot of you guys ) Thank you!

Ew

Edited 1 time(s). Last edit at 05/04/2014 10:53AM by tru168.

Yeah, Most of us here are engineers background I believe. I did wrote a review in my broken english months ago, with a lot of pictures too. I decided not to publish them because when I list out pros and cons, I have a few pros and a page full of cons. I enjoy Ormerod now, after a lot of tweaks and mod. I almost give up at the beginning, and not to mentioned that RS actually cancelled my Ormerod orders several times without informing me, I finally received it after dozens of frustrated calls to RS, and that was 2 months after my first order date. Indeed, droftarts ( Ian ) did try his best to answered all my questions and try to help me out.

I'm glad to see members here are willing to help and I wont be printing now without you guys , ( DC42, Iamburny, Dmould, Kim, and Kevin, aka.Treth, who sent me parts for free across the pond, and a lot of you guys ) Thank you!

Ew

Edited 1 time(s). Last edit at 05/04/2014 10:53AM by tru168.

|

Re: Ormerod reviews May 04, 2014 08:41AM |

Registered: 10 years ago Posts: 327 |

I did plan on writing a review on my blog, but I wanted to spend some time with the Ormerod first. I personally am very happy with my purchase. You can get ok results out of the box with some time and patience, but just adding a few simple user made upgrades makes a huge difference. What really sold it for me was this community.

I have contacted RepRap support and got a response quite quickly, I am still waiting for a replacement Duet as my SD card socket is very temperamental, but at least I have it working for now.

Regards,

Les

Pointy's Things

Pointy's Blog

I have contacted RepRap support and got a response quite quickly, I am still waiting for a replacement Duet as my SD card socket is very temperamental, but at least I have it working for now.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Ormerod reviews May 04, 2014 09:12AM |

Registered: 10 years ago Posts: 13 |

I bought the Ormerod because of the opensoure and that a full kit was available. The fact RS sold the kit was not a major plus for me. I thought about buying all the parts from here there and every where but decided a full kit was the way to go. I realised there would be problems has with all new things, 3d printing is still a new technology and by the end of this year there will be new 3d printers with better facilities and cheaper than the Ormerod, fully built.

That said I was not prepared to wait and after nearly two months have now got the Ormerod to a point where I can site down and have it printing within 30 mins or so. RRP have done a remarkable and brave thing in selling this kit and I for one are thankful, over time the kit will evolve I'm sure. If the bed level and z sensor was improved I'm sure I would have managed a quality print first time after build.

Les

Printer :- RS Ormerod since March 2014

Firmware :- 0.57a Duet 16-1-2014

Printer Software :- Repetier-Host 0.95F for windows

That said I was not prepared to wait and after nearly two months have now got the Ormerod to a point where I can site down and have it printing within 30 mins or so. RRP have done a remarkable and brave thing in selling this kit and I for one are thankful, over time the kit will evolve I'm sure. If the bed level and z sensor was improved I'm sure I would have managed a quality print first time after build.

Les

Printer :- RS Ormerod since March 2014

Firmware :- 0.57a Duet 16-1-2014

Printer Software :- Repetier-Host 0.95F for windows

|

Re: Ormerod reviews May 04, 2014 04:59PM |

Registered: 10 years ago Posts: 11 |

I also had some issues with my Ormerod. I have no problem in putting time in the setup of the printer, but once its ok, it should keep on working... The Ormerod is not there yet.

After a lot of replacements, improvements and patience I had the machine and software working, but then my Duet broke down. RepRap tried everything to put the blame on me and finally didn't replace my board. Luckily everything broke down that fast, that I could ask for a complete replacement from RS. They even send me the new kit before I send back the old one (this made it more easy to replace only the broken parts). 1 for RS, 0 for RRP!!!

I still like the Ormerod, but hope the product placement will be done more adequate in the future. With product I mean the printer, firmware, software,... The hardware on it's own is just a pile of electronics. This will avoid a lot of frustration to users that need a 3D printer for printing parts instead of experimenting with the printer itself.

After a lot of replacements, improvements and patience I had the machine and software working, but then my Duet broke down. RepRap tried everything to put the blame on me and finally didn't replace my board. Luckily everything broke down that fast, that I could ask for a complete replacement from RS. They even send me the new kit before I send back the old one (this made it more easy to replace only the broken parts). 1 for RS, 0 for RRP!!!

I still like the Ormerod, but hope the product placement will be done more adequate in the future. With product I mean the printer, firmware, software,... The hardware on it's own is just a pile of electronics. This will avoid a lot of frustration to users that need a 3D printer for printing parts instead of experimenting with the printer itself.

|

Re: Ormerod reviews May 04, 2014 06:53PM |

Registered: 10 years ago Posts: 378 |

Before anyone reads this post as just a negative rant, I just want to be clear that I really like my Ormerod. I enjoyed building and tweaking it, and now it prints really well. I would just love to see it become an even better printer "as default", and think there is plenty of room for improvement. Basically, just take the best bits of what's in the community, and bring it back into the regular kit.

It seems to me that while the Ormerod is a good basic design for a 3D printer, there are a few details that make it rather difficult to get up and running properly. While pretty much all RepRap machines are best suited for someone willing and able to tinker and fiddle with it, the Ormerod in it's current state requires a bit more of that, and being a pretty new design with a smaller userbase it is not as easy to find information and help, and there is way less in way of "best practice" solutions. I wasn't around for the earlier days of Mendels and Huxleys and the like, but it seems to me they have gotten a lot of issues ironed out over time.

If I were in any way "in charge" of making and selling Ormerods, I'd do something like this:

It seems to me that while the Ormerod is a good basic design for a 3D printer, there are a few details that make it rather difficult to get up and running properly. While pretty much all RepRap machines are best suited for someone willing and able to tinker and fiddle with it, the Ormerod in it's current state requires a bit more of that, and being a pretty new design with a smaller userbase it is not as easy to find information and help, and there is way less in way of "best practice" solutions. I wasn't around for the earlier days of Mendels and Huxleys and the like, but it seems to me they have gotten a lot of issues ironed out over time.

If I were in any way "in charge" of making and selling Ormerods, I'd do something like this:

- Be very very clear when marketing/selling it that it is still an early design being tried out, and that there is some amount of engineering work (other than plain assembly) required get it operational.

- Upgrade the kit (and call it a new revision or something), with some of the community-designed parts in it. Y-belt clamps, herringbone gears for Z and extruder, that clip for the bowden tube, a better fan duct, some modded version of the Z-nut trap (in about that order of priority). Would get the whole thing in better shape for good-quality printing.

- Do something about the flimsy MDF print bed support (the horizontal plate). It's too weak, and no matter how well things are levelled, it moves around. If the aluminium replacement part is too expensive or something, then a piece of laser-cut plywood would probably be a lot better. Or maybe a redesign of the whole carriage (there are some versions available on these very forums with printed cantilevers).

- Include parts for using "old-fashioned" endstops for X and Z axis, and make the IR probe an optional upgrade. Microswitches or opto endstops are much easier to troubleshoot and comprehend what they're doing, and the standard IR-probe has some issues. Maybe even offer the choice of dc42's sensor board. If so, I'd remove the sensor mount from the supplied X-carriage, and sell one with the appropriate sensor mount together with the sensor. While the auto-bed-levelling seems nice, I never got it working reliably with the stock bed+sensor, and without that feature, the IR sensor isn't really that important. Even more so with a better bed support that is easier to get level.

- Update the "official" firmware (what's supplied with the board, and in the RepRapPro repository). Basically go with all the stuff in dc42's branch.

- Update the assembly instructions. There are some other things in there that would benefit from some clarification as well (though it was a while since I looked at them). Also, if there are multiple revisions of the Ormerod, things would be a lot easier to follow if it is one separate document per revision.

|

Re: Ormerod reviews May 04, 2014 07:39PM |

Registered: 10 years ago Posts: 14,672 |

In my view there are a few essential Ormerod improvements and several nice-to-have improvements. The essential improvements are:

1. Replace or reinforce the MDF bed support. Even if you modify it so that the front corners are not providing support, the back corners still droop a variable amount with temperature.

2. Do something to secure the y-belt effectively and allow the tension to be adjusted. I use Matt's y-belt clamps to secure the belt, and my own printed spacers (https://github.com/dc42/OrmerodSensorBoard/tree/master/OtherPrintedPartsForOrmerod) to adjust the tension.

3. Do something about the height sensor. One option is to replace the unmodulated IR sensor by a better one such as the modulated IR + optional ultrasonic ones I have been selling. Another is to add bed-levelling screws such that (in conjunction with a better bed support) no bed compensation is needed, and set Z=0 manually before printing. I'm still working on developing the ideal height sensor, one that will work anywhere on the bed, on any printing surface without needing recalibration, and will accommodate different thicknesses of glass automatically.

4. Low-profile quick-release bed clips. I have a really good set now made from picture frame clips and 2mm fibreglass.

5. Upgrade the firmware and web interface software to a combination that works effectively. I think we're almost there now.

6. Anti-sag nozzle mount.

The nice-to-haves are:

8. Duet board mods to improve brownout tolerance and reduce electrical noise.

9. Better power supply, especially for those who want to print ABS and need higher bed temperatures.

10. Get rid of the unreliable floating 6-pin hot end connector. I've integrated those connections on my replacement sensor board.

11. Anti-backwash fan inlet duct/finger guard.

12. Aluminium X-plate and X-rib. I was printing fine with the acrylic ones, but while looking at alternative height sensors I noticed how much the acrylic x-plate was flexing as the head travelled along it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Replace or reinforce the MDF bed support. Even if you modify it so that the front corners are not providing support, the back corners still droop a variable amount with temperature.

2. Do something to secure the y-belt effectively and allow the tension to be adjusted. I use Matt's y-belt clamps to secure the belt, and my own printed spacers (https://github.com/dc42/OrmerodSensorBoard/tree/master/OtherPrintedPartsForOrmerod) to adjust the tension.

3. Do something about the height sensor. One option is to replace the unmodulated IR sensor by a better one such as the modulated IR + optional ultrasonic ones I have been selling. Another is to add bed-levelling screws such that (in conjunction with a better bed support) no bed compensation is needed, and set Z=0 manually before printing. I'm still working on developing the ideal height sensor, one that will work anywhere on the bed, on any printing surface without needing recalibration, and will accommodate different thicknesses of glass automatically.

4. Low-profile quick-release bed clips. I have a really good set now made from picture frame clips and 2mm fibreglass.

5. Upgrade the firmware and web interface software to a combination that works effectively. I think we're almost there now.

6. Anti-sag nozzle mount.

The nice-to-haves are:

8. Duet board mods to improve brownout tolerance and reduce electrical noise.

9. Better power supply, especially for those who want to print ABS and need higher bed temperatures.

10. Get rid of the unreliable floating 6-pin hot end connector. I've integrated those connections on my replacement sensor board.

11. Anti-backwash fan inlet duct/finger guard.

12. Aluminium X-plate and X-rib. I was printing fine with the acrylic ones, but while looking at alternative height sensors I noticed how much the acrylic x-plate was flexing as the head travelled along it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ormerod reviews May 04, 2014 09:29PM |

Registered: 12 years ago Posts: 1,611 |

Thanks all for the feedback, both negative and positive. I didn't mean to start a flame war, sorry if I pricked a few nerves with my first post, I clearly misjudged my initial comment.

A lot of work is continuing behind the scenes, though progress does seem very slow - we are a very small team of people. We take a great deal of notice of the community, but we aren't able to continually change the kit - it has to be carefully managed, particularly major changes. We are at the very final stages of preparing a new version, which does cover points 1 to 5, 9 and 10 of dc42's list, and a few more things besides. 8 is on it's way, but will take time. We can't do 12, unfortunately, and keep the price of the kit down. What happened to 7 in the list, dc?! And 6 - why do so many people have problems adjusting the bearing on the back of the x-carriage? We elongated the slot ages ago, which gives plenty of adjustment. We built 4 Ormerods last week, and none of them exhibit nozzle droop!

Regarding acknowledging the input of the community, we do this, and contact people to work with them directly. We don't entirely agree with the modifications some people make, so we're not going to pick up everything people do, but then that's the beauty of open source - people can change what they want, to get whatever results they want. We often look at an idea, then play around with it and re-engineer it our way, to see if it works. It seems to take a long time for any RepRap kit to become stable - the original Darwin never really did, the Sells Mendel was very tricky to get printing right for a long time, and really only took off when the Prusa Mendel came out (which also had it's problems, and revisions). The original Huxley also didn't work well, and took a complete redesign, and then incremental improvements for another year, to get stable. This is repeated all the time with new products - it really is difficult to get it right first time. Open source just means everyone is aware of the deficiencies! There is a big crop of printer designs that either have taken ages to get even close to being finished (some never do), or are launched and then disappear. Or companies grow, and start producing fully built kits for £1500+. We're trying not to be like any of them.

Regarding this forum, I try to get to answer people's problems, but I'm usually beaten to it! I have the responsibility of answering emails, writing documentation (yes, it has been updated a lot recently), testing firmware, printing parts, building and testing printers, contributing to engineering... then I get around to the forum. Others in the company are just as busy. I'm not trying to garner sympathy, just letting you know what we do all day (and night)!

Sorry if either support or sales has been slow to respond; we've been doing a lot of internal systems changes over the last couple of months. Certain periods (like after weekends, or when I go on holiday) tend to get busy for support, and emails stack up, but we usually try and respond with 48 hours, and are aiming for 24 hours.

It is a joy to see such a busy community, despite the 'warts and all' nature of it!

Ian

RepRapPro tech support

A lot of work is continuing behind the scenes, though progress does seem very slow - we are a very small team of people. We take a great deal of notice of the community, but we aren't able to continually change the kit - it has to be carefully managed, particularly major changes. We are at the very final stages of preparing a new version, which does cover points 1 to 5, 9 and 10 of dc42's list, and a few more things besides. 8 is on it's way, but will take time. We can't do 12, unfortunately, and keep the price of the kit down. What happened to 7 in the list, dc?! And 6 - why do so many people have problems adjusting the bearing on the back of the x-carriage? We elongated the slot ages ago, which gives plenty of adjustment. We built 4 Ormerods last week, and none of them exhibit nozzle droop!

Regarding acknowledging the input of the community, we do this, and contact people to work with them directly. We don't entirely agree with the modifications some people make, so we're not going to pick up everything people do, but then that's the beauty of open source - people can change what they want, to get whatever results they want. We often look at an idea, then play around with it and re-engineer it our way, to see if it works. It seems to take a long time for any RepRap kit to become stable - the original Darwin never really did, the Sells Mendel was very tricky to get printing right for a long time, and really only took off when the Prusa Mendel came out (which also had it's problems, and revisions). The original Huxley also didn't work well, and took a complete redesign, and then incremental improvements for another year, to get stable. This is repeated all the time with new products - it really is difficult to get it right first time. Open source just means everyone is aware of the deficiencies! There is a big crop of printer designs that either have taken ages to get even close to being finished (some never do), or are launched and then disappear. Or companies grow, and start producing fully built kits for £1500+. We're trying not to be like any of them.

Regarding this forum, I try to get to answer people's problems, but I'm usually beaten to it! I have the responsibility of answering emails, writing documentation (yes, it has been updated a lot recently), testing firmware, printing parts, building and testing printers, contributing to engineering... then I get around to the forum. Others in the company are just as busy. I'm not trying to garner sympathy, just letting you know what we do all day (and night)!

Sorry if either support or sales has been slow to respond; we've been doing a lot of internal systems changes over the last couple of months. Certain periods (like after weekends, or when I go on holiday) tend to get busy for support, and emails stack up, but we usually try and respond with 48 hours, and are aiming for 24 hours.

It is a joy to see such a busy community, despite the 'warts and all' nature of it!

Ian

RepRapPro tech support

|

Re: Ormerod reviews May 05, 2014 02:19AM |

Registered: 10 years ago Posts: 378 |

Quote

droftarts

We are at the very final stages of preparing a new version

Huzzah!!!

Quote

droftarts

It seems to take a long time for any RepRap kit to become stable

Indeed, and continuous improvement is what it's all about. I never used any early-stage RepRaps of other models, but talking to those who did it seems to me the Ormerod is still in pretty good shape for being such a young design. Fixing some of the commonly experienced issues with it should make it a much better machine.

|

Re: Ormerod reviews May 05, 2014 03:20AM |

Registered: 10 years ago Posts: 14,672 |

Hi Ian, good to hear you are addressing the points I regard as essential, and some others. The issue with the nozzle mount is that the version shipped with the kit has slots and countersinks that don't fit the screws well. With use and heat the PLA softens, the slots open out and the head sags. It's very easily fixed by using a nozzle mount with a flat top and screw holes without slots.

If you've put a longer slot in the x-carriage, why haven't you published the new design on github?

Keep up the good work.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

If you've put a longer slot in the x-carriage, why haven't you published the new design on github?

Keep up the good work.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ormerod reviews May 05, 2014 03:30AM |

Registered: 10 years ago Posts: 1,230 |

Quote

dc42

..The issue with the nozzle mount is that the version shipped with the kit has slots and countersinks that don't fit the screws well. With use and heat the PLA softens, the slots open out and the head sags...

Quote

dc42

..It's very easily fixed by using a nozzle mount with a flat top and screw holes without slots...

Erik

|

Re: Ormerod reviews May 05, 2014 04:57AM |

Registered: 10 years ago Posts: 145 |

|

Re: Ormerod reviews May 05, 2014 05:14AM |

Registered: 10 years ago Posts: 1,230 |

Quote

GregL

Erik,

Would you post that file again for the nozzle mount.

I've looked, but failed to find it!

Greg

here, Simon, thread "Head sagging again":

[forums.reprap.org]

Edit: also see thread "Best User Upgrades?", johneato's angled version

[forums.reprap.org]

Erik

Edited 1 time(s). Last edit at 05/05/2014 05:20AM by ormerod168.

|

Re: Ormerod reviews May 05, 2014 10:51AM |

Registered: 12 years ago Posts: 1,611 |

Ah, right, okay, so it's the nozzle mount rather than the bearing on the back that is the problem. The nozzle-mount is designed to make it easy to remove the hot end from the carriage, as you don't need to remove the mounting screws entirely from the hot end. It's fiddly getting the screws in behind the hot end otherwise. The shape of the holes the head of the screws fit into, though it looks like it's designed for a countersunk screw, is to centre the screw in the hole. A cap head screw fits just as well as a countersunk screw; it doesn't make any difference what screw you use. We supply cap heads because they take a bigger Allen key, which are usually longer, and easier to use in the awkward space. The screws that hold the hot end on the nozzle mount shouldn't get hot enough to melt the nozzle mount. Our Mendel nozzle mount is much the same - [reprappro.com] - and both only cause problems when the cooling isn't working correctly, and the mounting screws get hot. Then it doesn't matter if the nozzle mount is open or closed, it's going to melt and move anyway.

The only other way to fix this is to have the nozzle mount machined out of PEEK, which is a high temperature insulating plastic - you don't want to make it out of aluminium, or the heat will just be transferred to the next plastic part, which is the x-carriage. However, this incurs an extra cost, and just masks the problem of inefficient cooling, and heat rising up the nozzle. This will eventually cause an increase in pressure required to extrude, and block the nozzle.

So these are the design reasons, and why we haven't changed it, and a good example of an instance where we disagree that there is a problem with this part - we haven't seen an issue with it in our testing - the problem is elsewhere, that causes a failure in this part. Again, I'm not trying to start a flame war, just explaining our design rational.

Ian

RepRapPro tech support

The only other way to fix this is to have the nozzle mount machined out of PEEK, which is a high temperature insulating plastic - you don't want to make it out of aluminium, or the heat will just be transferred to the next plastic part, which is the x-carriage. However, this incurs an extra cost, and just masks the problem of inefficient cooling, and heat rising up the nozzle. This will eventually cause an increase in pressure required to extrude, and block the nozzle.

So these are the design reasons, and why we haven't changed it, and a good example of an instance where we disagree that there is a problem with this part - we haven't seen an issue with it in our testing - the problem is elsewhere, that causes a failure in this part. Again, I'm not trying to start a flame war, just explaining our design rational.

Ian

RepRapPro tech support

|

Re: Ormerod reviews May 05, 2014 11:11AM |

Registered: 10 years ago Posts: 665 |

Ian, thanks for your comments. In my opinion, some upgrades, such as the replacement Z and extruder gears, don't need to be included in the official RRP kit. It might be a good idea to point people reading the official Ormerod documentation to a list of all community-driven upgrades, though, since it is getting a little hard to follow all community-driven upgrades (especially for new-comers). I didn't know much about 3D printing before I bought my Ormerod kit, but I was expecting to get a basic printing kit, which gives me room for custom improvements. Basically I got what I expected, but some things - such as the MDF bed, the IR sensor and the stock PSU - were simply not sufficient for my requirements and should be changed in future Ormerod kits. For me, most of the other parts (including the X axis and the extruder assembly) are working well. Another thing I haven't seen here yet is the Z nut - I've exchanged the original one with a brass M5 nut, which effectively reduces wear and allows the Z axis to run much smoother.

Anyway, I'd like to say a few words about your comments.

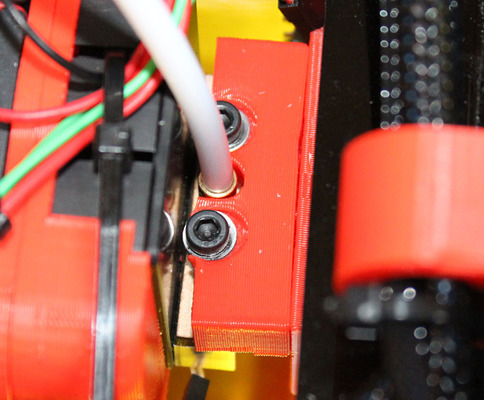

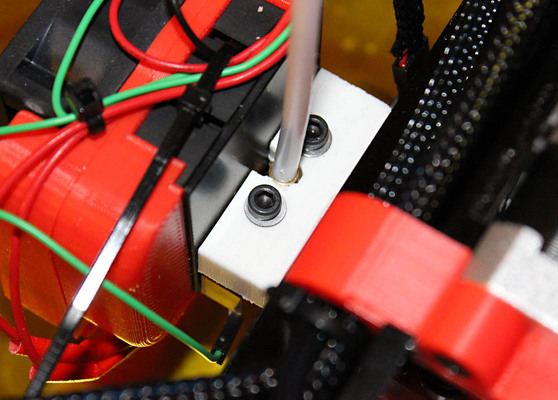

1. I don't get why the power wiring should be a barrier for some people, especially because some electric parts (such as the hotend) do require additional crimping. Basically I'm using the same PSU as seen in the Mendel documentation, but instead of using plain wires, I'm using ring wire end connectors like these instead to keep my power wiring clean:

2. The Ormerod documentation has been improved (which is good), but the bed assembly parts remain the same. I remember when assembling my printer, I had lots of problems getting the heated bed to stay together properly. The Y plate was not flat and was difficult to attach to the Y rib, and the Y bearings slipped out of the bearing clamps after moving the Y axis a few times. That was the first time I had to improvise before the printer was completely assembled. Also, the front Y bearing didn't stay in line with the Y rib at all, so a cable tie was necessary to keep it in place. In my new alu bed design, these bearings are tied to the bearing clamps much nicer because the new bearing clamps grab into the bearing notches, so it's almost impossible they will loosen again.

As for the Z calibration, I've been using 0.2mm thick paper to calibrate the Z axis. When I do that, I set Z to 0.1mm when I can push some of that paper below the nozzle without any extra force and of course my nozzle is clean when I do so. This made me think an offset of 0.1mm between the heated bed and the nozzle is reasonable. If I do it the same way, but set Z to 0.2mm instead, my first layers always looks bad and my parts aren't printed as nicely.

3. I understand RRP tested that design, but in my case the IR probe just didn't work reliably. I remember after finishing the initial assembly, I had really bad problems homing the X axis, because the IR probe didn't recognize the endstop (even when using alu foil to mark it). Now I'm using a microswitch for the X axis instead and it has been working nicely. When I tried to set up the IR probe for Z homing, I always needed to verify the nozzle height, because the actual height was always a little off, and sometimes the IR probe didn't even stop because the probe reported too low readings, ie. less than 600 when it was already touching the heated bed. Besides, the IR probe got stuck a few times at the rear right bed clip, causing big prints to fail. That's another reason I banned it from my Ormerod.

I'm still experimenting with an alternative Z calibration method, but I wouldn't call this approach stable yet. I will get some thicker self-adhesive copper foil soon and see how well that one works, but in any case I will report my experience on this forum.

Anyway, I'd like to say a few words about your comments.

1. I don't get why the power wiring should be a barrier for some people, especially because some electric parts (such as the hotend) do require additional crimping. Basically I'm using the same PSU as seen in the Mendel documentation, but instead of using plain wires, I'm using ring wire end connectors like these instead to keep my power wiring clean:

2. The Ormerod documentation has been improved (which is good), but the bed assembly parts remain the same. I remember when assembling my printer, I had lots of problems getting the heated bed to stay together properly. The Y plate was not flat and was difficult to attach to the Y rib, and the Y bearings slipped out of the bearing clamps after moving the Y axis a few times. That was the first time I had to improvise before the printer was completely assembled. Also, the front Y bearing didn't stay in line with the Y rib at all, so a cable tie was necessary to keep it in place. In my new alu bed design, these bearings are tied to the bearing clamps much nicer because the new bearing clamps grab into the bearing notches, so it's almost impossible they will loosen again.

As for the Z calibration, I've been using 0.2mm thick paper to calibrate the Z axis. When I do that, I set Z to 0.1mm when I can push some of that paper below the nozzle without any extra force and of course my nozzle is clean when I do so. This made me think an offset of 0.1mm between the heated bed and the nozzle is reasonable. If I do it the same way, but set Z to 0.2mm instead, my first layers always looks bad and my parts aren't printed as nicely.

3. I understand RRP tested that design, but in my case the IR probe just didn't work reliably. I remember after finishing the initial assembly, I had really bad problems homing the X axis, because the IR probe didn't recognize the endstop (even when using alu foil to mark it). Now I'm using a microswitch for the X axis instead and it has been working nicely. When I tried to set up the IR probe for Z homing, I always needed to verify the nozzle height, because the actual height was always a little off, and sometimes the IR probe didn't even stop because the probe reported too low readings, ie. less than 600 when it was already touching the heated bed. Besides, the IR probe got stuck a few times at the rear right bed clip, causing big prints to fail. That's another reason I banned it from my Ormerod.

I'm still experimenting with an alternative Z calibration method, but I wouldn't call this approach stable yet. I will get some thicker self-adhesive copper foil soon and see how well that one works, but in any case I will report my experience on this forum.

|

Re: Ormerod reviews May 05, 2014 11:15AM |

Registered: 10 years ago Posts: 76 |

|

Re: Ormerod reviews May 05, 2014 11:33AM |

Registered: 12 years ago Posts: 1,611 |

I've created a page on the reprap.org wiki, to collect improvements, and have populated it with a couple of entries. I think this is better as a community-driven page, rather than relying on me to put it in the Ormerod instructions, though I will link to it from there. Feel free to add more! I'll post a new thread about this, too.

[reprap.org]

Ian

RepRapPro tech support

Edited 1 time(s). Last edit at 05/05/2014 11:34AM by droftarts.

[reprap.org]

Ian

RepRapPro tech support

Edited 1 time(s). Last edit at 05/05/2014 11:34AM by droftarts.

Sorry, only registered users may post in this forum.