Another alternative Hot-end cooling duct.

Posted by Form232-tek

|

Another alternative Hot-end cooling duct. May 09, 2014 05:05PM |

Registered: 9 years ago Posts: 12 |

Hello folks.

My Ormerod has the same problems as all the others, so before I start, want to thank you guys in this forum. It has helped me a lot.

'I've been here reading for a while, and now it's my turn to make a small contribution.

The whole idea with this project is to remove the flow stopping 90 deg turns, get rid of the half heated air from cooling the hot end, and get plenty of fresh cold air to cool down the printed part.

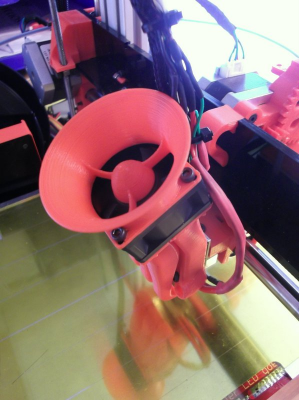

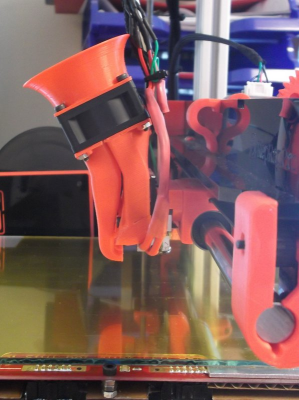

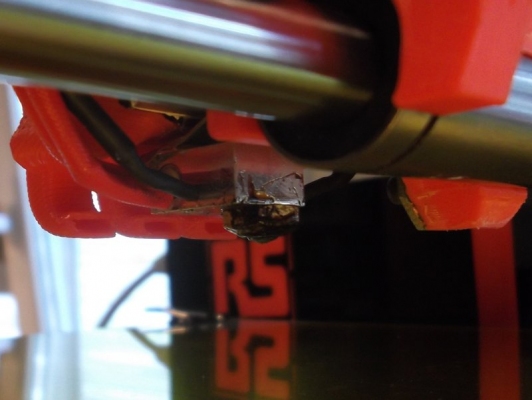

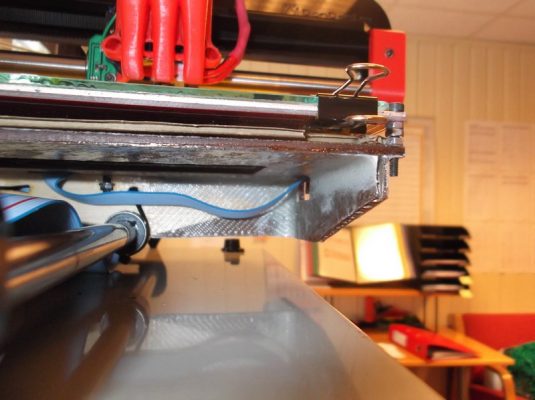

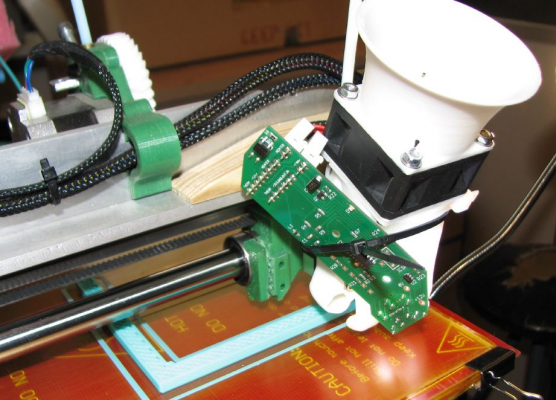

The first four pictures;

This is of my version of a improved cooling duct. It's made out of three parts. The trumpet is made mostly for show, but according to a pro it does improve the air flow. The cooling duct is made out of two parts. I use 2/5 of the fan area to cool down the aluminum ribs, while the remaining 3/5 is used to cool down the print. This is not a print and play conversion. I have cut away 1/3 of the aluminium cooling ribs, and drilled a new hole in it. The cooling rib is also rotated 90 deg. Since the plastic is fairly close to the hot end, I have also made a small heat shield between the hot aluminium and the plastic. A small hole in the plastic cools down the heat shield. The air used to cool down the hot end, is flowing out in the direction of the Y- axis, away from the nozzle. It's not too much to tell about the plastic print cooling ducts.

But I can mention that the cross area and placement of the nozzles is exactly the same as the original. The exhaust air on both sides has enough speed to blow out the flame of a lighter.

The result of this hack is that I could increase the hot end temp by 15 degrees to maintain good bounding on the print.

A big part who buckled before, can now be printed dead straight without any problems.

The next improvement;

This is my version of the belt tensioner. This is a two piece, print and play conversion. No drilling needed. I guess the picture tells how it works.

The last two pictures;

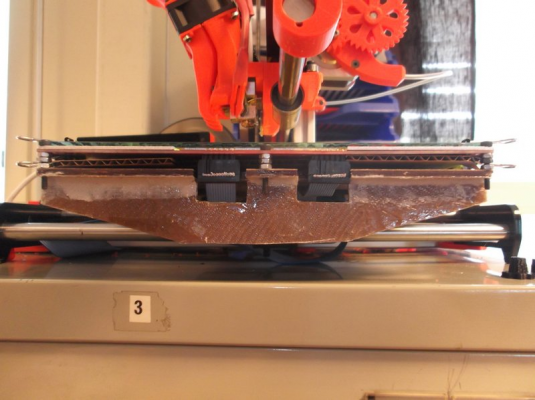

This shows an easy way to improve the stiffness mdf board holding the bed.

All I have done is to make a composite of the board, simply by laminating woven glass fiber to each side of the board. I use some filler to make a small radius in the inside corners, to avoid air bubbles under the glass-fiber. I also laminated a cardboard to make the reinforcement you can see in front. The result is a bed stiff enough for me. It can be done better for sure, but it is a good result compared to job.

What do you folks think? Any ideas for more improvements?

My Ormerod has the same problems as all the others, so before I start, want to thank you guys in this forum. It has helped me a lot.

'I've been here reading for a while, and now it's my turn to make a small contribution.

The whole idea with this project is to remove the flow stopping 90 deg turns, get rid of the half heated air from cooling the hot end, and get plenty of fresh cold air to cool down the printed part.

The first four pictures;

This is of my version of a improved cooling duct. It's made out of three parts. The trumpet is made mostly for show, but according to a pro it does improve the air flow. The cooling duct is made out of two parts. I use 2/5 of the fan area to cool down the aluminum ribs, while the remaining 3/5 is used to cool down the print. This is not a print and play conversion. I have cut away 1/3 of the aluminium cooling ribs, and drilled a new hole in it. The cooling rib is also rotated 90 deg. Since the plastic is fairly close to the hot end, I have also made a small heat shield between the hot aluminium and the plastic. A small hole in the plastic cools down the heat shield. The air used to cool down the hot end, is flowing out in the direction of the Y- axis, away from the nozzle. It's not too much to tell about the plastic print cooling ducts.

But I can mention that the cross area and placement of the nozzles is exactly the same as the original. The exhaust air on both sides has enough speed to blow out the flame of a lighter.

The result of this hack is that I could increase the hot end temp by 15 degrees to maintain good bounding on the print.

A big part who buckled before, can now be printed dead straight without any problems.

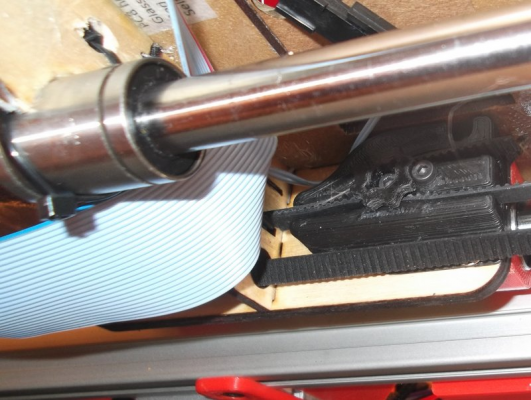

The next improvement;

This is my version of the belt tensioner. This is a two piece, print and play conversion. No drilling needed. I guess the picture tells how it works.

The last two pictures;

This shows an easy way to improve the stiffness mdf board holding the bed.

All I have done is to make a composite of the board, simply by laminating woven glass fiber to each side of the board. I use some filler to make a small radius in the inside corners, to avoid air bubbles under the glass-fiber. I also laminated a cardboard to make the reinforcement you can see in front. The result is a bed stiff enough for me. It can be done better for sure, but it is a good result compared to job.

What do you folks think? Any ideas for more improvements?

|

Re: Another alternative Hot-end cooling duct. May 09, 2014 06:05PM |

Registered: 10 years ago Posts: 859 |

Hi, I see in one of the pictures you've cable tied the front Bearing.... At one time I did that... Thinking it would keep it located.

I later did some work on the table (a belt tensioner and stiffend it at the same time and luckily I didn't put the cable tie back on the bearing.

(BTW My printer travels 1200 miles a month).

Anyway a print failed, the machine had locked up late at night, So the Hotend was down printing when it happend.

I left it for the next morning, and not thinking went to raise the HotEnd without heating it.

I was gob smacked to watch the table raising up towards the X-axis.... Had the bearing been cable tied, I think allot of damage would have resulted....

My fault for not putting the Heater on.... You might want to re-consider that cable tie now...

I intend to print a locator bracket to hold the bearing under the frame and stop it wandering off. But I'll never lock it down again..

Kim..

Edited 1 time(s). Last edit at 05/09/2014 06:05PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

I later did some work on the table (a belt tensioner and stiffend it at the same time and luckily I didn't put the cable tie back on the bearing.

(BTW My printer travels 1200 miles a month).

Anyway a print failed, the machine had locked up late at night, So the Hotend was down printing when it happend.

I left it for the next morning, and not thinking went to raise the HotEnd without heating it.

I was gob smacked to watch the table raising up towards the X-axis.... Had the bearing been cable tied, I think allot of damage would have resulted....

My fault for not putting the Heater on.... You might want to re-consider that cable tie now...

I intend to print a locator bracket to hold the bearing under the frame and stop it wandering off. But I'll never lock it down again..

Kim..

Edited 1 time(s). Last edit at 05/09/2014 06:05PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Another alternative Hot-end cooling duct. May 09, 2014 07:44PM |

Registered: 9 years ago Posts: 12 |

|

Re: Another alternative Hot-end cooling duct. May 11, 2014 08:55AM |

Registered: 9 years ago Posts: 34 |

|

Re: Another alternative Hot-end cooling duct. May 11, 2014 09:19AM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Another alternative Hot-end cooling duct. May 11, 2014 09:35AM |

Registered: 9 years ago Posts: 12 |

|

Re: Another alternative Hot-end cooling duct. June 10, 2014 04:26PM |

Registered: 10 years ago Posts: 58 |

|

Re: Another alternative Hot-end cooling duct. June 20, 2014 02:31PM |

Registered: 9 years ago Posts: 26 |

|

Re: Another alternative Hot-end cooling duct. July 02, 2014 05:25PM |

Registered: 9 years ago Posts: 12 |

|

Re: Another alternative Hot-end cooling duct. July 02, 2014 05:29PM |

Registered: 9 years ago Posts: 26 |

upload them on thingiverse.com ?

otherwise --> [stackoverflow.com]

Edited 1 time(s). Last edit at 07/03/2014 02:47AM by x4FF3.

otherwise --> [stackoverflow.com]

Edited 1 time(s). Last edit at 07/03/2014 02:47AM by x4FF3.

|

Re: Another alternative Hot-end cooling duct. July 03, 2014 06:57AM |

Registered: 9 years ago Posts: 12 |

I have tried to upload the files again, and I think I made it this time.

Feel free to test it out, and please give me feedback on any adjustments.

[github.com]

You need all the 3 Cthulhu stl.files to make the hot end in the pictures.

Cheers

Joar.

Feel free to test it out, and please give me feedback on any adjustments.

[github.com]

You need all the 3 Cthulhu stl.files to make the hot end in the pictures.

Cheers

Joar.

|

Re: Another alternative Hot-end cooling duct. July 03, 2014 08:10PM |

Registered: 10 years ago Posts: 58 |

|

Re: Another alternative Hot-end cooling duct. July 04, 2014 03:20AM |

Registered: 10 years ago Posts: 378 |

|

Re: Another alternative Hot-end cooling duct. July 04, 2014 05:26AM |

Registered: 9 years ago Posts: 12 |

|

Re: Another alternative Hot-end cooling duct. July 04, 2014 10:20AM |

Registered: 10 years ago Posts: 66 |

Printed without support here too. Some great design work here 232, many thanks! My Ormerod now has a jet engine strapped to the front of it.

I did notice that the parts are rotated slightly in the x-axis. I adjusted the bellhouse by 0.1 and the cooling duct by -0.2 degrees in netfabb to get it to slice nicely and print 'face flat' on the bed.

I did notice that the parts are rotated slightly in the x-axis. I adjusted the bellhouse by 0.1 and the cooling duct by -0.2 degrees in netfabb to get it to slice nicely and print 'face flat' on the bed.

|

Re: Another alternative Hot-end cooling duct. July 31, 2014 07:03AM |

Registered: 9 years ago Posts: 26 |

|

Re: Another alternative Hot-end cooling duct. July 31, 2014 08:21AM |

Registered: 10 years ago Posts: 378 |

Quote

x4FF3

is this normal, that slic3r only creates one perimeter?

It is, if slic3r settings are to just do one perimeter, or if you have the "spiral vase" option checked (both in print settings -> layers and perimeters, "vertical shells" section). It will also do just one perimeter if the wall of the object is too thin to fit more.

|

Re: Another alternative Hot-end cooling duct. August 08, 2014 05:40PM |

Registered: 10 years ago Posts: 66 |

Turns out my rotated STLs are over 614kb so I can't upload them here, but netfabb is easy enough to use and it has a free version: Netfabb basic

Just open the STL in netfabb, click Part > Rotate and enter the value (0.1 for the bellhouse, -0.2 for the cooling duct) and check the X-axis radio button, then click the Rotate button. Then you can click Part > Export Part > As STL and save your rotated part.

I used 90% perimeter width in slic3r and cut my speeds down a bit to get a nice finish.

Just open the STL in netfabb, click Part > Rotate and enter the value (0.1 for the bellhouse, -0.2 for the cooling duct) and check the X-axis radio button, then click the Rotate button. Then you can click Part > Export Part > As STL and save your rotated part.

I used 90% perimeter width in slic3r and cut my speeds down a bit to get a nice finish.

|

Re: Another alternative Hot-end cooling duct. August 11, 2014 11:29AM |

Registered: 10 years ago Posts: 2,472 |

Quote

static65

Turns out my rotated STLs are over 614kb so I can't upload them here, but netfabb is easy enough to use and it has a free version: Netfabb basic

Just open the STL in netfabb, click Part > Rotate and enter the value (0.1 for the bellhouse, -0.2 for the cooling duct) and check the X-axis radio button, then click the Rotate button. Then you can click Part > Export Part > As STL and save your rotated part.

I used 90% perimeter width in slic3r and cut my speeds down a bit to get a nice finish.

WinRar can usually compress large STLs down to a much smaller RAR file.

Dave

(#106)

|

Re: Another alternative Hot-end cooling duct. December 06, 2018 07:08PM |

Registered: 6 years ago Posts: 174 |

|

Re: Another alternative Hot-end cooling duct. December 07, 2018 02:19AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Karoo Klong

Hello!!!

Forgotten Treasure!!!

I really like this cooling duct!!!

Yes its cool but and a bit scary :-)

Did a long post on it but cant find it, was fun to print and install but the airflow was not that great and for PLA only

Erik

|

Re: Another alternative Hot-end cooling duct. December 07, 2018 02:57AM |

Registered: 6 years ago Posts: 174 |

|

Re: Another alternative Hot-end cooling duct. December 08, 2018 03:23AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Karoo Klong

Hahaha

Oh so you have been there, done that?

Dit it really suck (Blow) that bad?

I highly admire the design so had to print it - the airflow from the axial fan is divided between cooling the hotend and nozzle tip though small tunnels so better than the original I think but not what I wanted - but again the design is amazing - lots of kudo's to the maker!

Erik

|

Re: Another alternative Hot-end cooling duct. December 08, 2018 08:50AM |

Registered: 6 years ago Posts: 174 |

|

Re: Another alternative Hot-end cooling duct. December 08, 2018 02:48PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Karoo Klong

Last Question.

What is the best hotend cooling setup for ABS Exclusive printing?

1. With Standard Ormerod Hotend (Also what is the nozzle type if I want to buy 0.4 or 0.3mm nozzles? what thread tipe)

For ABS only the best would be to change the original fan duct, model a frame around the heat sink with air outlet at the top like this one found on thingiverse:

Ormerod simple ABS fan/heatsink dukt

[www.thingiverse.com]

....and turn the heat sink 90 degrees so no cooling air get to the printed parts, that's what I did so can print ABS just fine with the Cobra not running - or I can loosen one screw and take the Cobra off for better visual to the print

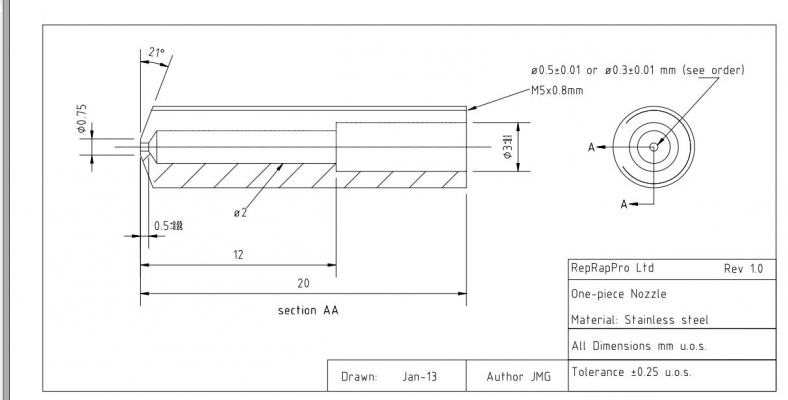

Treads are 5x0.8

Your can order those at reprapltd.com, emaker.io etc.

Quote

2. With other alternative hotends?

Dunno, never needed another :-)

Edited 1 time(s). Last edit at 12/09/2018 03:55AM by ormerod168.

|

Re: Another alternative Hot-end cooling duct. December 11, 2018 01:47AM |

Registered: 6 years ago Posts: 174 |

|

Re: Another alternative Hot-end cooling duct. December 11, 2018 03:44AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Karoo Klong

I am looking for a nozzle to do railroad figure prints for my friend.

Should I look for 0.3 nozzle? or smaller?

Have not printed with anything but 0.5 so can't talk from experience, maybe others could chip in??

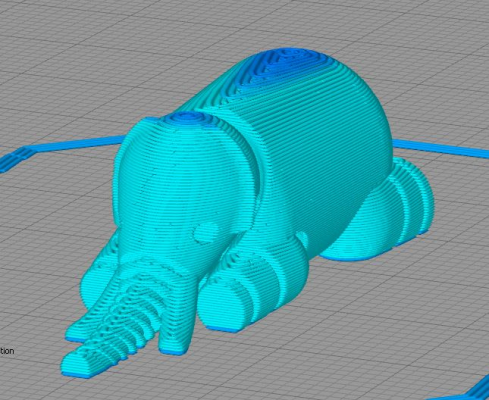

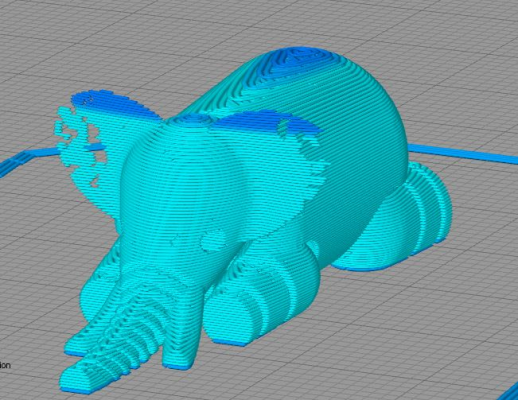

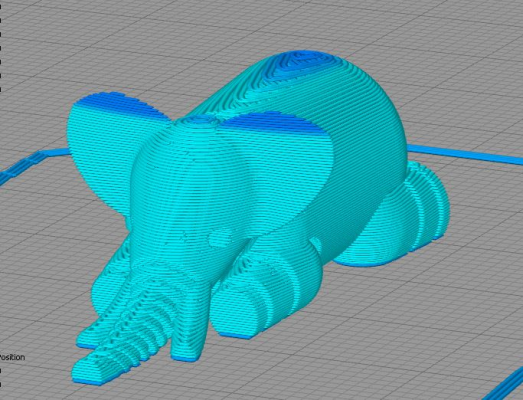

But basically how small the nozzle would have to be depends of the smallest detail you will print, if a detail is smaller than the slicing program accept a single perimeters to be set at, the detail will not show - an example, "LeFabShop Elephant with thicker trunk" from thingiverse, downsized to 50%:

Nozzle 0.5, perimeter 0.60:

Nozzle 0.5, perimeter 0.50:

Nozzle 0.5, perimeter 0.45:

So you could start by importing the most detailed models in your slicer and see how they turn out, then if any details is missing, go down in nozzle size, you can force smaller perimeters by going "manual" instead of "auto" but under nozzle width is not recommended

Erik

|

Re: Another alternative Hot-end cooling duct. December 12, 2018 02:36AM |

Registered: 6 years ago Posts: 174 |

Sorry, only registered users may post in this forum.