heatshields for abs printing, need printer complete cad model

Posted by Ludo91

|

heatshields for abs printing, need printer complete cad model May 13, 2014 05:35AM |

Registered: 9 years ago Posts: 40 |

Hello,

I want to print a LOT of abs parts, about 5/6 hrs/day of printing but with abs instead of pla.

So Id like to make heatshields covered with aluminium foil and with a fan keeping air moving on the compoment-to-protect-side.

Where can I find the complete 3D assembly of the printer?

What do you think of the idea? Suggestions?

I want to print a LOT of abs parts, about 5/6 hrs/day of printing but with abs instead of pla.

So Id like to make heatshields covered with aluminium foil and with a fan keeping air moving on the compoment-to-protect-side.

Where can I find the complete 3D assembly of the printer?

What do you think of the idea? Suggestions?

|

Re: heatshields for abs printing, need printer complete cad model May 13, 2014 08:39AM |

Registered: 10 years ago Posts: 101 |

|

Re: heatshields for abs printing, need printer complete cad model May 13, 2014 09:01AM |

Registered: 12 years ago Posts: 1,611 |

|

Re: heatshields for abs printing, need printer complete cad model May 13, 2014 10:24AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Ludo91

Hello,

I want to print a LOT of abs parts, about 5/6 hrs/day of printing but with abs instead of pla.

So Id like to make heatshields covered with aluminium foil and with a fan keeping air moving on the compoment-to-protect-side.Quote

Why not print all the parts of the Ormerod that might be affected by heat in ABS first? If the Hotend parts, X carriage and extruder body are replaced with ABS prints, they will stand up to continual ABS printing with no need for any heat shields. The PLA parts should survive long enough to get those few ABS parts printed (print in the order I listed).

Dave

(#106)

|

Re: heatshields for abs printing, need printer complete cad model May 13, 2014 10:54AM |

Registered: 12 years ago Posts: 1,611 |

If you're going to do a lot of ABS printing, see the guide here: [reprappro.com]

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: heatshields for abs printing, need printer complete cad model May 13, 2014 12:12PM |

Registered: 10 years ago Posts: 1,230 |

Quote

dmould

Why not print all the parts of the Ormerod that might be affected by heat in ABS first? If the Hotend parts, X carriage and extruder body are replaced with ABS prints, they will stand up to continual ABS printing with no need for any heat shields. The PLA parts should survive long enough to get those few ABS parts printed (print in the order I listed).

Dave

(#106)

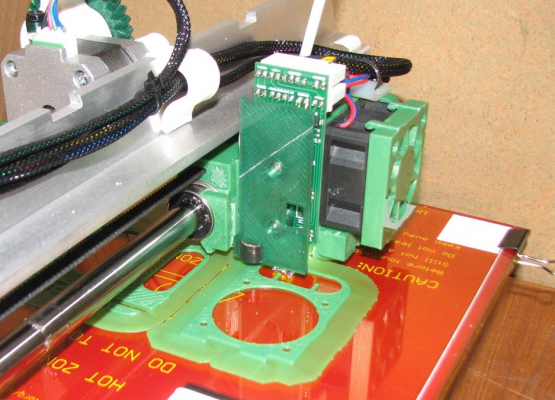

Agree and actually did just that yesterday, my very first ABS print ever, got lot of tips from reading the forum (esp. your postings, thank you) so was prepared, blocked the air outlet on Matt's heatsink duct and drilled two holes on top as to get the heat out without disturbing the print

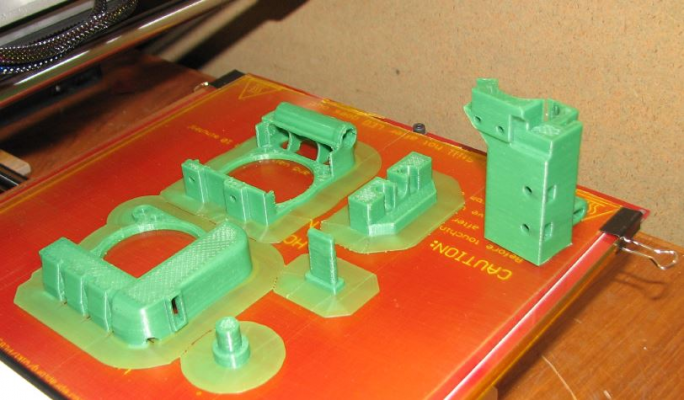

Here are the part I printed, I chose to print johneato's brilliant heatsink-duct (did not dare go for Kim's big blue as my first ABS print), notice the choice in this mod of either exhausting the air trough the nozzles or the chimney - and no the parts are not perfect but will do just fine

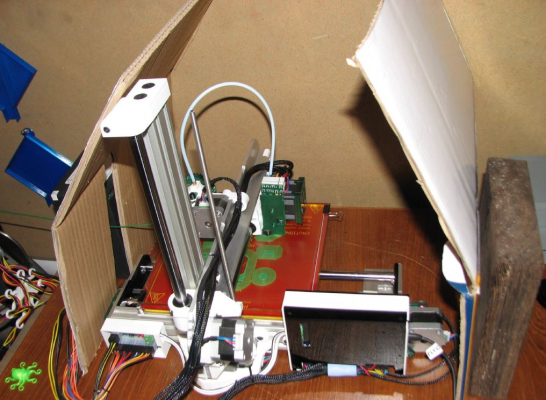

also made a Q & D tent to protect the print from draft

Had no problems with PLA parts during the print but did notice the PLA x-carriage had a very lose fit when I changed it for the ABS ditto after the print, was secured with a spring though

so here's the Ormerod with the new ABS hot end parts installed, busy printing extra ABS hot end parts (with dc42's probe and firmware, kvikius's fandeflector, johnaeto's heatsink-duct, Dave's aluminum x-rib, Matt's herringbone gear, Mr. Burn's extruder with ptfe insert, Thank You all)

Edit: Matt's PLA air duct did get a bit hot during this ABS print

Erik

Edited 1 time(s). Last edit at 05/13/2014 12:40PM by ormerod168.

|

Re: heatshields for abs printing, need printer complete cad model July 12, 2014 12:08PM |

Registered: 9 years ago Posts: 40 |

Hello!

I praticed a bit with printing ABS and I think I found a "poor man`s way to print abs".

What I did is:

-Extruder temperature to 255c

-Bed perfectly compensated

-Bed temperature to 75c

-Fan covered except for 10 mm of its width, one of the venting hole closed.

-Speeds down to 15mm/s

-15mm brim width in Slicer

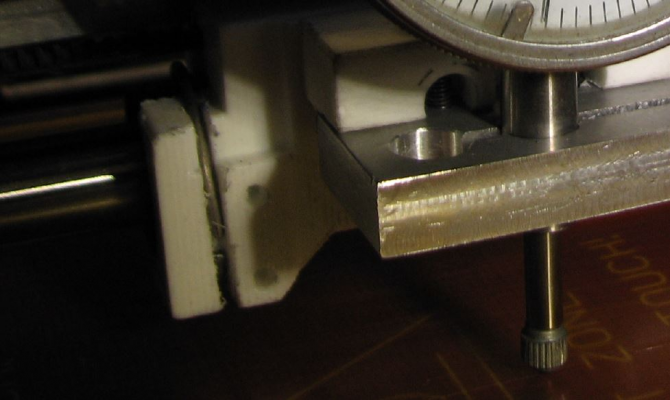

Also, in order to prevent the machine for "melting" (I printed a few PLA spare parts, but seems they are not needed) I modified the extruder support as shown in the attached pictures. It is really easy and takes just 15 mins.

Tops temperatures I got are 35c for the Z carriage, 38c for the piece where the two long screws are attached and 55c for the fan housing. I should be by far in the safe zone, right?

The prints are solid, I`d say like pla, maybe a bit less, Still, this totally fits for me since my main purpose of using ABS is being able to finish the parts with acetone.

I praticed a bit with printing ABS and I think I found a "poor man`s way to print abs".

What I did is:

-Extruder temperature to 255c

-Bed perfectly compensated

-Bed temperature to 75c

-Fan covered except for 10 mm of its width, one of the venting hole closed.

-Speeds down to 15mm/s

-15mm brim width in Slicer

Also, in order to prevent the machine for "melting" (I printed a few PLA spare parts, but seems they are not needed) I modified the extruder support as shown in the attached pictures. It is really easy and takes just 15 mins.

Tops temperatures I got are 35c for the Z carriage, 38c for the piece where the two long screws are attached and 55c for the fan housing. I should be by far in the safe zone, right?

The prints are solid, I`d say like pla, maybe a bit less, Still, this totally fits for me since my main purpose of using ABS is being able to finish the parts with acetone.

|

Re: heatshields for abs printing, need printer complete cad model July 14, 2014 09:32AM |

Registered: 10 years ago Posts: 2,472 |

I discovered that giving an ABS part a good rub over (all sides) or a very brief dunking and shake-off in acetone makes it stronger in the Z direction. I think that the acetone seeps between the layers and "melts" them together, forming a stronger bond than the original hot fusing did. Before the acetone evaporates thin walls can become soft and pliable, so be careful with it while its drying. Acetone is also great for ABS repairs (especially if the part has small layer splits, perhaps due to slight warping). Coat the broken sections with acetone and hold together for 5 minutes, or drop acetone in a split and clamp it closed for 30 minutes or so - don't clamp or hold too tightly else you'll get a bulge at the place where the break/split was.

Dave

(#106)

Dave

(#106)

Sorry, only registered users may post in this forum.