first time ABS printing issues

Posted by 88Zombies

|

first time ABS printing issues June 05, 2014 07:14AM |

Registered: 10 years ago Posts: 135 |

Attempted my first ABS prints last night, results not that great but usable...

I have read a couple of posts floating about with tips and tricks. Read them all thoroughly before attempting to print..

- I drilled holes as recommended [forums.reprap.org]

- used a slurry of ABS+Acetone atop a light spraying of hairspray

my slic3r settings were;

first layer, extruder 245°c / bed 105°c

other leyers, extruder 235°c / bed 95°c

Issue 1 - Warping

The print seemed to be going ok but then I could hear a 'clicking'. Turns out this was the corners of the print warping upwards away from the heatbed, pulling off the dried ABS-solution with it. 'Warping 1.jpg'.

In Warping 2 you can see the print is warped... what can i do to prevent this? (as i have already drilled the holes in the fan. The print was at nice room temperature & no draft.)

Issue 2 - bubbling.

As shown in the 'blubbling.jpg' image..... there are bubbles. I think this is something todo with the G-Code as on my PLA version i can see slight imperfections in the same area, just not as bad as this ABS print...

there are also slight gaps between layers that can be seen in image 'warping 2.jpg'

any help is much appreciated!!!

Edited 5 time(s). Last edit at 06/05/2014 07:33AM by 88Zombies.

I have read a couple of posts floating about with tips and tricks. Read them all thoroughly before attempting to print..

- I drilled holes as recommended [forums.reprap.org]

- used a slurry of ABS+Acetone atop a light spraying of hairspray

my slic3r settings were;

first layer, extruder 245°c / bed 105°c

other leyers, extruder 235°c / bed 95°c

Issue 1 - Warping

The print seemed to be going ok but then I could hear a 'clicking'. Turns out this was the corners of the print warping upwards away from the heatbed, pulling off the dried ABS-solution with it. 'Warping 1.jpg'.

In Warping 2 you can see the print is warped... what can i do to prevent this? (as i have already drilled the holes in the fan. The print was at nice room temperature & no draft.)

Issue 2 - bubbling.

As shown in the 'blubbling.jpg' image..... there are bubbles. I think this is something todo with the G-Code as on my PLA version i can see slight imperfections in the same area, just not as bad as this ABS print...

there are also slight gaps between layers that can be seen in image 'warping 2.jpg'

any help is much appreciated!!!

Edited 5 time(s). Last edit at 06/05/2014 07:33AM by 88Zombies.

|

Re: first time ABS printing issues June 05, 2014 07:50AM |

Registered: 10 years ago Posts: 14,672 |

Hi 88,

Did you also add a fan inlet duct to prevent fan backwash, and block up the air outlets at the bottom of the fan duct?

I'm not sure that it is a good idea to reduce the bed temperature after the first layer.

Edited 4 time(s). Last edit at 06/05/2014 07:54AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Did you also add a fan inlet duct to prevent fan backwash, and block up the air outlets at the bottom of the fan duct?

I'm not sure that it is a good idea to reduce the bed temperature after the first layer.

Edited 4 time(s). Last edit at 06/05/2014 07:54AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: first time ABS printing issues June 05, 2014 08:55AM |

Registered: 10 years ago Posts: 135 |

Hi DC,

- No i don't have a fan inlet, ive seen them on peoples images but couldn't find the files on thingiverse.

just found the thread for them [forums.reprap.org]

- Nor did i block the outlets at teh bottom! didnt realise that, woops... ill get the kapton tape out and cover those!!

I'll print one of these tonight, (even after fully reading, not entirely sure which to go for.. my fan is the original 5 bladed one that sounds like a lawn mower, so i think ill trrrrry Andy's?)

I will keep the bed temp the same on these prints and see if it makes much different before applyng the inlet.

Just hope my PLA parts hold out a little longer

Thanks for the advice, it's greatly appreciated!

Edited 1 time(s). Last edit at 06/05/2014 08:59AM by 88Zombies.

- No i don't have a fan inlet, ive seen them on peoples images but couldn't find the files on thingiverse.

just found the thread for them [forums.reprap.org]

- Nor did i block the outlets at teh bottom! didnt realise that, woops... ill get the kapton tape out and cover those!!

I'll print one of these tonight, (even after fully reading, not entirely sure which to go for.. my fan is the original 5 bladed one that sounds like a lawn mower, so i think ill trrrrry Andy's?)

I will keep the bed temp the same on these prints and see if it makes much different before applyng the inlet.

Just hope my PLA parts hold out a little longer

Thanks for the advice, it's greatly appreciated!

Edited 1 time(s). Last edit at 06/05/2014 08:59AM by 88Zombies.

|

Re: first time ABS printing issues June 05, 2014 09:01AM |

Registered: 10 years ago Posts: 14,672 |

My latest variant of Andy's fan duct is here [github.com]. The main difference is that it is held on by screws instead of plastic tabs, which I found too fragile. Like my original version, it is thin enough to allow the head to slide behind the Duet box. It should be OK with the 5-bladed fan. You need long countersunk M3 screws to fit it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: first time ABS printing issues June 05, 2014 09:02AM |

Registered: 10 years ago Posts: 665 |

Issue 1: See "ABS adhesion problems" in my post here: [forums.reprap.org]

Issue 2: Try setting your retraction length to 4mm and enable "Wipe on retract" if you're using the latest RRP firmware or dc42's 0.65e firmware. I found out that unchecking "External perimeters first" increases print quality as well.

Issue 2: Try setting your retraction length to 4mm and enable "Wipe on retract" if you're using the latest RRP firmware or dc42's 0.65e firmware. I found out that unchecking "External perimeters first" increases print quality as well.

|

Re: first time ABS printing issues June 05, 2014 09:53AM |

Registered: 10 years ago Posts: 1,230 |

Quote

88Zombies

- used a slurry of ABS+Acetone atop a light spraying of hairspray

I would stick (!) to the Slurry on glass only if I were you, quote from the trouble shooting guide:

...the favourite around here are super strength hold hairspray

[reprappro.com]

I don't think you need a "super strength hold", that will delay the shrinking and that you do not want as it will bend the part - what you want is a hold that will allow the ABS to float, slide while shrinking, and this is what I see happening while printing on slurry, the white part around the print is not from warping but from the printed part shrinking:

Quote

88Zombies

my slic3r settings were;

first layer, extruder 245°c / bed 105°c

other leyers, extruder 235°c / bed 95°c

My normal ABS settings, all layers as I don't think it is a good idea to change temperature during the print, extruder 240°c / bed 110°c

Could be that you bed temp is too low as to allow you print to shrink/float ?

Quote

88Zombies

Issue 2 - bubbling.

As shown in the 'blubbling.jpg' image..... there are bubbles. I think this is something todo with the G-Code as on my PLA version i can see slight imperfections in the same area, just not as bad as this ABS print...

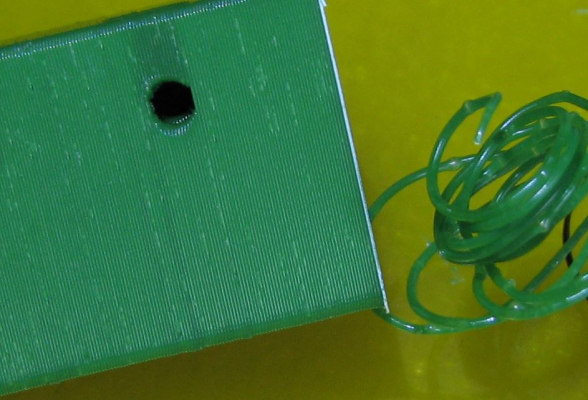

I experience the same, but then I don't expect much from this lot of filament, here some pictures of filament extruded, lots of air bubbles in the green ABS here compared to black PLA

..and yet the print came out relatively fine, just some visual white strings

Erik

|

Re: first time ABS printing issues June 05, 2014 11:29AM |

Registered: 10 years ago Posts: 135 |

@DC

Ahh thanks, I think I'd prefer to attch with screws and i can see it's going to be a tight fit with the duet enclosue in the standard position...

@Zombiepants

If anything I'd say it adhears too much, was fairly difficult to remove, i used;

- kapton tape, with hairspray (sanded down), with ABS+Acetone slurry layers untill misty looking.... when i removed the print (the 2nd time) it actually ripped the kapton tape off!! 0.0

I have the retraction set to 4mm, I havn't tried unchecking the external parameters first though, nor have I checked 'wipe on retract'

Im currently on DC's 0.59d firmware. Will give the 'unchecking the external parameters first' a go.

@Erik

I used hairspray because of that Prusa tutorial [www.flickr.com]

I did this all ontop of Kapton tape as its fairly easy to clean if needed by just tearing off. does it not damage the glass removing the slurry between prints?

Ahh thanks, I think I'd prefer to attch with screws and i can see it's going to be a tight fit with the duet enclosue in the standard position...

@Zombiepants

If anything I'd say it adhears too much, was fairly difficult to remove, i used;

- kapton tape, with hairspray (sanded down), with ABS+Acetone slurry layers untill misty looking.... when i removed the print (the 2nd time) it actually ripped the kapton tape off!! 0.0

I have the retraction set to 4mm, I havn't tried unchecking the external parameters first though, nor have I checked 'wipe on retract'

Im currently on DC's 0.59d firmware. Will give the 'unchecking the external parameters first' a go.

@Erik

I used hairspray because of that Prusa tutorial [www.flickr.com]

I did this all ontop of Kapton tape as its fairly easy to clean if needed by just tearing off. does it not damage the glass removing the slurry between prints?

|

Re: first time ABS printing issues June 05, 2014 12:25PM |

Registered: 10 years ago Posts: 1,230 |

|

Re: first time ABS printing issues June 05, 2014 12:26PM |

Registered: 10 years ago Posts: 14,672 |

Quote

88Zombies

@DC

Ahh thanks, I think I'd prefer to attch with screws and i can see it's going to be a tight fit with the duet enclosue in the standard position...

One tip: before tightening the screws that hold the Duet box on to the y-extrusion, rotate the t-nut nearest the y-motor into position. Then you can slide the enclosure a little further towards the y-motor, before tightening the screws.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: first time ABS printing issues June 05, 2014 05:10PM |

Registered: 9 years ago Posts: 176 |

Some things I've learnt from printing ABS:

ABS seems to absorb a lot of moisture from the air - keep it in a sealed bag with desiccant. Printing with ABS that has been left out for a while causes bubbles in the print (you can actually hear them popping sometimes).

The terms change between slicer programs, but print with a raft or a grid between the object and the plate with a wide brim. This platform decreases corners warping upwards, however thick objects still might warp .

.

I've found that reducing the temperature during a print sometimes causes the part to detach from the plate and doesn't seem to provide any benefit.

The blubbing can be caused by the head dripping just a little when moving between areas - the next time past it wipes past the drip and catches a little more - tends to cause little 'towers' Retraction helps a lot here!

Retraction helps a lot here!

Slowly but surely you will need to replace most of the hot end and underbed and x-axis parts with ABS counterparts, but start immediately with the things around the hot end.

ABS seems to absorb a lot of moisture from the air - keep it in a sealed bag with desiccant. Printing with ABS that has been left out for a while causes bubbles in the print (you can actually hear them popping sometimes).

The terms change between slicer programs, but print with a raft or a grid between the object and the plate with a wide brim. This platform decreases corners warping upwards, however thick objects still might warp

.

.I've found that reducing the temperature during a print sometimes causes the part to detach from the plate and doesn't seem to provide any benefit.

The blubbing can be caused by the head dripping just a little when moving between areas - the next time past it wipes past the drip and catches a little more - tends to cause little 'towers'

Retraction helps a lot here!

Retraction helps a lot here!Slowly but surely you will need to replace most of the hot end and underbed and x-axis parts with ABS counterparts, but start immediately with the things around the hot end.

|

Re: first time ABS printing issues June 06, 2014 01:28AM |

Registered: 9 years ago Posts: 16 |

I mostly print ABS and have found that the warping only happens if there is a quick change in temp from the filament to the environment.

You must have a fan duct and try and remove as much as possible of the residue air. I also remove the DUET enclosure so there is no place for a convection to happen against.

I print directly on glass just using hair spray

I add a 3mm Brim to all ABS prints

I keep the head temp at 235 and the bed at 85 for the entire print

Print only one part at a time, as the length of exposure to the potential difference in temp also causes warping

After doing all of the above most if not all my warping issues are gone. I have now almost reprinted 2 sets of Ormerod replacement parts all from ABS

All my bed modifications are ABS as well from here [www.thingiverse.com]

Attached is my 2nd printer in assembly. All the neon green parts are ABS printed from the first printer with no warping

You must have a fan duct and try and remove as much as possible of the residue air. I also remove the DUET enclosure so there is no place for a convection to happen against.

I print directly on glass just using hair spray

I add a 3mm Brim to all ABS prints

I keep the head temp at 235 and the bed at 85 for the entire print

Print only one part at a time, as the length of exposure to the potential difference in temp also causes warping

After doing all of the above most if not all my warping issues are gone. I have now almost reprinted 2 sets of Ormerod replacement parts all from ABS

All my bed modifications are ABS as well from here [www.thingiverse.com]

Attached is my 2nd printer in assembly. All the neon green parts are ABS printed from the first printer with no warping

|

Re: first time ABS printing issues June 06, 2014 09:56AM |

Registered: 10 years ago Posts: 2,472 |

While you cannot do much about existing STLs, when you design parts to be printed in ABS, try to avoid sharp corners on thin walls. A large hollow box 30mm high would always either warp or exhibit delamination near its corners until I changed the design to give the corners a 10mm radius.

Dave

(#106)

Dave

(#106)

|

Re: first time ABS printing issues June 07, 2014 09:10AM |

Registered: 10 years ago Posts: 135 |

I didn't have much time so i was unable to do seperate prints showing trial and error of all suggestions, but instead made the following ammendments all together as suggested...

- Kept the bed temp & nozzle at a constant temperature..

- Printed and fitted the DC42 fan outlet

- blocked the fan duct at the bottom

- Printed a 5mm brim around the object..

- unckecked print external parapeters first.

the overall surface quality was somewhat similar but the warping on the base did improved. Still experimenting...

thank you all for your input & help

Edited 1 time(s). Last edit at 06/07/2014 09:17AM by 88Zombies.

- Kept the bed temp & nozzle at a constant temperature..

- Printed and fitted the DC42 fan outlet

- blocked the fan duct at the bottom

- Printed a 5mm brim around the object..

- unckecked print external parapeters first.

the overall surface quality was somewhat similar but the warping on the base did improved. Still experimenting...

thank you all for your input & help

Edited 1 time(s). Last edit at 06/07/2014 09:17AM by 88Zombies.

|

Re: first time ABS printing issues June 08, 2014 10:36PM |

Registered: 10 years ago Posts: 176 |

[attachment 34325 bubbles4.JPG]

Erik[/quote]

From the "bubble" picture, I think your ABS suffered from moisture problem. you can try to cut a few short length of your filaments and inspect its cut surface, if you can see holes in it, thats means you have water in your filament. I attach an example here, you can see water in the holes.

[www.dropbox.com]

Erik[/quote]

From the "bubble" picture, I think your ABS suffered from moisture problem. you can try to cut a few short length of your filaments and inspect its cut surface, if you can see holes in it, thats means you have water in your filament. I attach an example here, you can see water in the holes.

[www.dropbox.com]

Sorry, only registered users may post in this forum.