Can this bottom curve be improved?

Posted by appjaws1

|

Can this bottom curve be improved? June 09, 2014 11:38AM |

Registered: 10 years ago Posts: 780 |

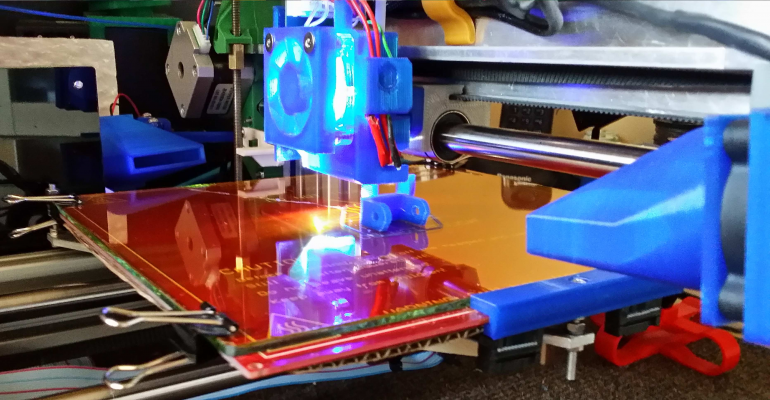

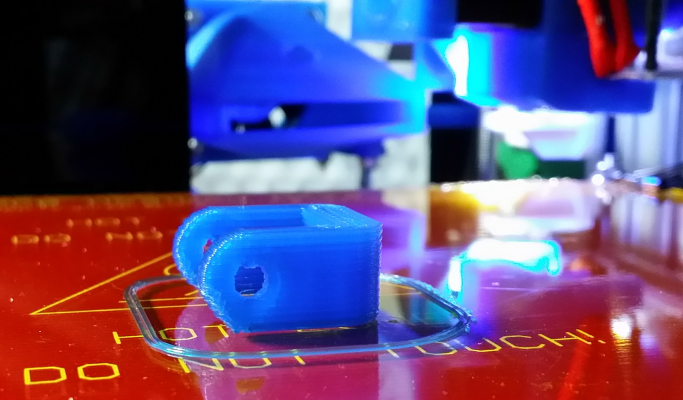

This has always happened and I have put up with it. The top of the curve prints OK but the bottom just doesn't follow the design correctly

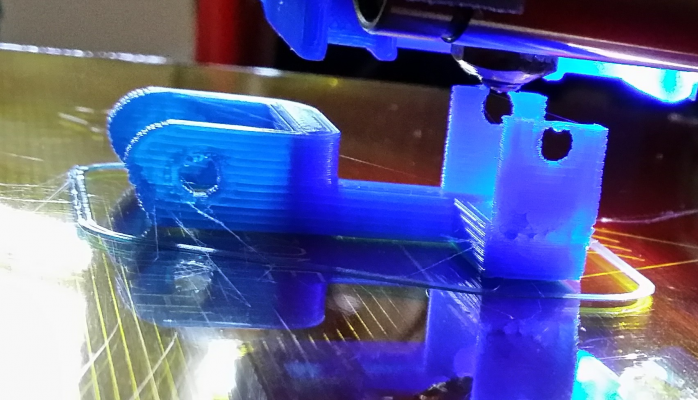

As you can see the bottom curve is almost straight, it should mirror the top curve.

I have played around with cooling, hot-end and bed temperatures, slic3r settings and nothing seems to work.

I am starting to think that maybe this is a problem with slic3r and not an ormerod problem at all.

Any advice and help will be much appreciated.

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

As you can see the bottom curve is almost straight, it should mirror the top curve.

I have played around with cooling, hot-end and bed temperatures, slic3r settings and nothing seems to work.

I am starting to think that maybe this is a problem with slic3r and not an ormerod problem at all.

Any advice and help will be much appreciated.

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Can this bottom curve be improved? June 09, 2014 02:12PM |

Registered: 9 years ago Posts: 176 |

|

Re: Can this bottom curve be improved? June 09, 2014 03:43PM |

Registered: 10 years ago Posts: 780 |

No support, it is such a small item. Would support work on a 5 mm curve?

I have the extrude temperature set at 194 after the fist layer. I also have secondary cooling fans.

I have never used support, it just didn't occur to me that that could help, perhaps I'll try it in the morning.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I have the extrude temperature set at 194 after the fist layer. I also have secondary cooling fans.

I have never used support, it just didn't occur to me that that could help, perhaps I'll try it in the morning.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Can this bottom curve be improved? June 09, 2014 04:55PM |

Registered: 9 years ago Posts: 176 |

If I'm designing things that I want to print without the use of supporting material, then I'll make sure that overhangs don't exceed 45 degrees from vertical. Much more than that and the material will either droop or be dragged around by the head a little!

So a curve like the one you show there would start with a 45 degree, then curve nicely towards the top.

Occasionally I'll have to use support mainly because I can't think of any way of sticking to the 45 degree rule, but I prefer not using it as it requires removal which can be difficult and leave traces.

I'm also intrigued by the near bottom right hand side of the model you're printing - what is happening there?

So a curve like the one you show there would start with a 45 degree, then curve nicely towards the top.

Occasionally I'll have to use support mainly because I can't think of any way of sticking to the 45 degree rule, but I prefer not using it as it requires removal which can be difficult and leave traces.

I'm also intrigued by the near bottom right hand side of the model you're printing - what is happening there?

|

Re: Can this bottom curve be improved? June 09, 2014 05:04PM |

Registered: 10 years ago Posts: 780 |

VortyZA , Thank you for your comments

I'm not sure what you mean, the bottom right is just a straight 90 degree angle, the two uprights are finished off with a nice curve above the screw holes.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I'm not sure what you mean, the bottom right is just a straight 90 degree angle, the two uprights are finished off with a nice curve above the screw holes.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Can this bottom curve be improved? June 10, 2014 03:11AM |

Registered: 10 years ago Posts: 327 |

Hi Paul,

For what it's worth I have always struggled printing upwards slopes or curves. The original Z Nut Trap piece is a good example of this and I had to print it several times to get a good one. I think it's a cooling issue as I seemed to get better results when the slope is facing the fan duct. I noticed that the upward slope would always curl upwards which meant it went lumpy and would make the nozzle jump.

Try rotating your piece 90 degrees so that the curves face the fan duct and also lower your hotend temps, your print looks stringy which is a sign of too much heat. I use 190 for first layer and the 185 for the rest.

The other interesting thing is that we both use a very similar fan duct...

Maybe we can make a test piece that others can print to verify the problem. Whatis the dimensions of the piece with the curve?

Regards,

Les

Pointy's Things

Pointy's Blog

For what it's worth I have always struggled printing upwards slopes or curves. The original Z Nut Trap piece is a good example of this and I had to print it several times to get a good one. I think it's a cooling issue as I seemed to get better results when the slope is facing the fan duct. I noticed that the upward slope would always curl upwards which meant it went lumpy and would make the nozzle jump.

Try rotating your piece 90 degrees so that the curves face the fan duct and also lower your hotend temps, your print looks stringy which is a sign of too much heat. I use 190 for first layer and the 185 for the rest.

The other interesting thing is that we both use a very similar fan duct...

Maybe we can make a test piece that others can print to verify the problem. Whatis the dimensions of the piece with the curve?

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Can this bottom curve be improved? June 10, 2014 04:50AM |

Registered: 10 years ago Posts: 780 |

Quote

Pointy

Try rotating your piece 90 degrees so that the curves face the fan duct and also lower your hotend temps, your print looks stringy which is a sign of too much heat. I use 190 for first layer and the 185 for the rest.

The other interesting thing is that we both use a very similar fan duct...

Maybe we can make a test piece that others can print to verify the problem. Whatis the dimensions of the piece with the curve?

Les

Les,

I will try turning the item through 90 degrees and see if that helps..

My fan duct has 3 outputs, centre directed at the nozzle and the 2 outside directed forward and downwards. I'm going to try the original fan again because I think I need more airflow.

The end of the item is a U shape 10mm tall, 23x21mm with 4mm thick walls and a radius of 5mm on the ends

We should do some tests.

I'll try later but I only have today to work on this.

Thank you for your interest

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Can this bottom curve be improved? June 10, 2014 06:09AM |

Registered: 10 years ago Posts: 780 |

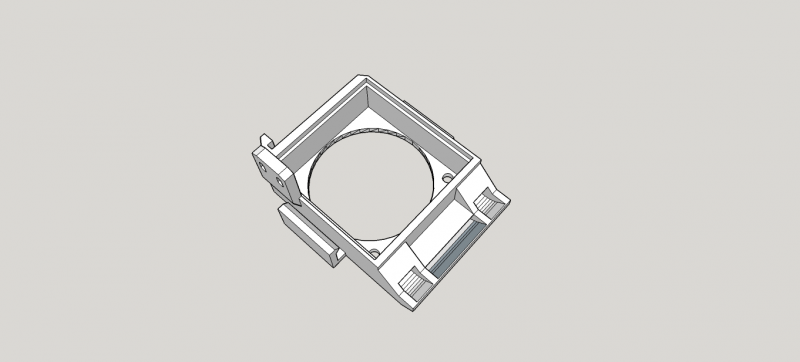

Part of the item for testing.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Can this bottom curve be improved? June 10, 2014 07:07AM |

Registered: 10 years ago Posts: 327 |

I just printed that piece with my default settings...

Sorry, it's not the best picture, but it didn't come out too bad. It's definitely not as round on the bottom, but it's not as bad as yours. I also didn't rotate it, so it was printed the same direction as in your photo.

Regards,

Les

Pointy's Things

Pointy's Blog

Sorry, it's not the best picture, but it didn't come out too bad. It's definitely not as round on the bottom, but it's not as bad as yours. I also didn't rotate it, so it was printed the same direction as in your photo.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Can this bottom curve be improved? June 10, 2014 07:31AM |

Registered: 10 years ago Posts: 14,672 |

I think printing a piece like that with a large radius curve on the bottom is asking for trouble. Can you not add a small fillet to partly fill in the gap at the bottom, so that you have a 45 degree overhang instead of an overhang that starts at (in the limit of zero extrusion width) 90 degrees?

Edited 1 time(s). Last edit at 06/10/2014 07:32AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 06/10/2014 07:32AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Can this bottom curve be improved? June 10, 2014 07:38AM |

Registered: 10 years ago Posts: 780 |

Les,

Can I have a copy of your settings to try please.

Looking at your picture, he ones I have printed today are as good, but it would be interesting to compare settings

I have dropped the temperature by 2 degrees and I think that has made the difference, an improvement over yesterdays.

I have printed 1 rotated 90 degrees - an improvement but still a straight line.

Also printed with support selected in slic3r but I can not see any support on the print, again a straight line.

Not ever having used support what should the settings be?

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

Can I have a copy of your settings to try please.

Looking at your picture, he ones I have printed today are as good, but it would be interesting to compare settings

I have dropped the temperature by 2 degrees and I think that has made the difference, an improvement over yesterdays.

I have printed 1 rotated 90 degrees - an improvement but still a straight line.

Also printed with support selected in slic3r but I can not see any support on the print, again a straight line.

Not ever having used support what should the settings be?

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Can this bottom curve be improved? June 10, 2014 07:50AM |

Registered: 10 years ago Posts: 2,472 |

One other thing to try is to reduce the layer height. That will result in less overhang distance per layer. Also make sure you uncheck the Slic3r option "Print external perimeters first" (Last option in "Print Settings/Layers and perimeters"). If the inner perimeter is printed first, it provides some sort of side support for the outer perimeter even if the outer perimeter is unsupported underneath.

Dave

(#106)

Dave

(#106)

|

Re: Can this bottom curve be improved? June 10, 2014 08:16AM |

Registered: 10 years ago Posts: 327 |

Quote

appjaws1

Les,

Can I have a copy of your settings to try please.

Looking at your picture, he ones I have printed today are as good, but it would be interesting to compare settings

I have dropped the temperature by 2 degrees and I think that has made the difference, an improvement over yesterdays.

I have printed 1 rotated 90 degrees - an improvement but still a straight line.

Also printed with support selected in slic3r but I can not see any support on the print, again a straight line.

Not ever having used support what should the settings be?

Paul

I have attached my Slic3r settings. I have never used support either so can't help with that.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: Can this bottom curve be improved? June 10, 2014 08:21AM |

Registered: 9 years ago Posts: 34 |

|

Re: Can this bottom curve be improved? June 10, 2014 09:46AM |

Registered: 10 years ago Posts: 859 |

Hmmmm it's interesting hearing about this.

Reducing the layer thickness would help.

When I print stuff like that I put in my own snapable supports. The Big Blue has allot of thin support walls under it to hold it up while printing, that are thin enough to snap out with your fingers afterwards.

I wouldn't use Slic3rs support structures on anything, as I find they are terrible.

To support those downward curves I would place a very thin wall at each edge, so the print head could Bridge between them as the curve builds up.

Add them to your design, then you know where the supports are, and that they won't interfere with your design, and you can make them easy to remove. If Slic3r does it, then it'll be a mess...

I wouldn't use external fans either, as your picture shows signs of Warping, and they will just make it worse.

With the Big Blue, the second fan on my duct is under Slic3r control, and it does a pretty good job at warm areas with a Bulk of plastic, by blowing extra air through the ducts.

The temps I run with are 195' and 57'

It would be interesting to see your machine run the Bridging test... With and without the external fans.

Edited 1 time(s). Last edit at 06/10/2014 09:54AM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Reducing the layer thickness would help.

When I print stuff like that I put in my own snapable supports. The Big Blue has allot of thin support walls under it to hold it up while printing, that are thin enough to snap out with your fingers afterwards.

I wouldn't use Slic3rs support structures on anything, as I find they are terrible.

To support those downward curves I would place a very thin wall at each edge, so the print head could Bridge between them as the curve builds up.

Add them to your design, then you know where the supports are, and that they won't interfere with your design, and you can make them easy to remove. If Slic3r does it, then it'll be a mess...

I wouldn't use external fans either, as your picture shows signs of Warping, and they will just make it worse.

With the Big Blue, the second fan on my duct is under Slic3r control, and it does a pretty good job at warm areas with a Bulk of plastic, by blowing extra air through the ducts.

The temps I run with are 195' and 57'

It would be interesting to see your machine run the Bridging test... With and without the external fans.

Edited 1 time(s). Last edit at 06/10/2014 09:54AM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Can this bottom curve be improved? June 10, 2014 09:54AM |

Registered: 10 years ago Posts: 780 |

Quote

dmould

One other thing to try is to reduce the layer height. That will result in less overhang distance per layer. Also make sure you uncheck the Slic3r option "Print external perimeters first" (Last option in "Print Settings/Layers and perimeters"). If the inner perimeter is printed first, it provides some sort of side support for the outer perimeter even if the outer perimeter is unsupported underneath.

Dave

(#106)

Dave,

I completed a print with layer height of .1 and the problem is exactly the same, see photo. I also have the settings that you suggest.

Pointy - Thank you for your settings, they are very close to mine, the only difference is the speed of some items.

JMC - I think we have all used slic3r to slice the test stl.. What version are you using?

I have reverted to using 1.1.3, as 1.1.4 had problems. Does the part show in slic3r's viewer?

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Can this bottom curve be improved? June 10, 2014 12:38PM |

Registered: 9 years ago Posts: 34 |

Quote

appjaws1

Quote

dmould

One other thing to try is to reduce the layer height. That will result in less overhang distance per layer. Also make sure you uncheck the Slic3r option "Print external perimeters first" (Last option in "Print Settings/Layers and perimeters"). If the inner perimeter is printed first, it provides some sort of side support for the outer perimeter even if the outer perimeter is unsupported underneath.

Dave

(#106)

Dave,

I completed a print with layer height of .1 and the problem is exactly the same, see photo. I also have the settings that you suggest.

[attachment 34638 point-one-layer-height-test.jpg]

Pointy - Thank you for your settings, they are very close to mine, the only difference is the speed of some items.

JMC - I think we have all used slic3r to slice the test stl.. What version are you using?

I have reverted to using 1.1.3, as 1.1.4 had problems. Does the part show in slic3r's viewer?

Paul

Havent updated in a while so am using an older version. Is a bit academic at the moment sins i have busted somthing so can not print now any way. But from your pictur it looks like a problem i had when i was using a large external fan for print cooling and was only colling from one direction. if i watched closely while printing i could see the very edge warping a little whitch tended to make the underside of curves more of a diagonal. To fix this i got a very powerful little blower fan and ducted the air so the print was cooled from 4 sides in a kind of spiral fashion. Another mod that seemes to help stop edges curling is to use warme air to cool the print this way you can blow more air across the print without cooling doun the hot bed. My previos rig had the air blowing on to the print at about 45C. will print your test shape as soon as i find out what is shorting out my power supply

|

Re: Can this bottom curve be improved? June 10, 2014 02:25PM |

Registered: 9 years ago Posts: 34 |

Its a bit hard to take a good pictur

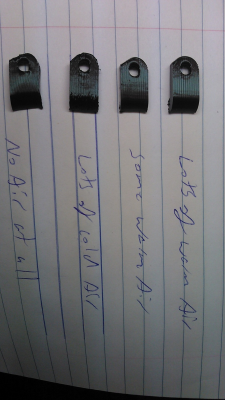

The upper and lower sides of the curve are not completly symmetrical but there close. Have printed several tests with diffrent amounts cooling but its 2 am and i have to work in the morning so will post them tomorro.

The upper and lower sides of the curve are not completly symmetrical but there close. Have printed several tests with diffrent amounts cooling but its 2 am and i have to work in the morning so will post them tomorro.

|

Re: Can this bottom curve be improved? June 10, 2014 02:40PM |

Registered: 10 years ago Posts: 780 |

Quote

JMC

Its a bit hard to take a good pictur

[attachment 34675 WP_000483.jpg]

The upper and lower sides of the curve are not completly symmetrical but there close. Have printed several tests with diffrent amounts cooling but its 2 am and i have to work in the morning so will post them tomorro.

From what I can see the result looks good, better than mine.

Unfortunately I'm not around for the next few weeks but will be very interested in anything you come up with to improve the curves.

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Can this bottom curve be improved? June 10, 2014 03:55PM |

Registered: 10 years ago Posts: 780 |

Reverted to the original ormerod fan which produces a much better air flow compared to the quiet fan I was using.

The result is a great improvement on the lower curves, still not correct but much better.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

The result is a great improvement on the lower curves, still not correct but much better.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Can this bottom curve be improved? June 11, 2014 03:55AM |

Registered: 9 years ago Posts: 34 |

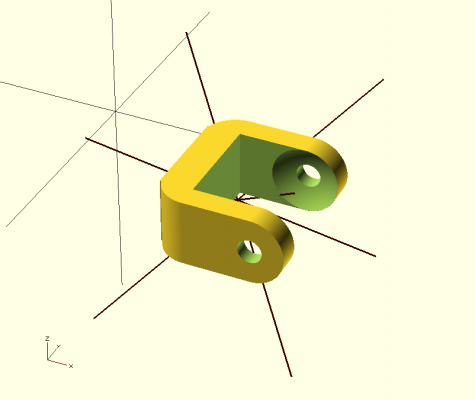

Here are 4 tests i printed with diffrent cooling. all are at a layer hight of .24 a bed heat of 60C and a hot end temp of 180C (first layer 70C and 200C)

I cut the ends off to get better pictures (the center holes are all round tho they dont look it in the pic).

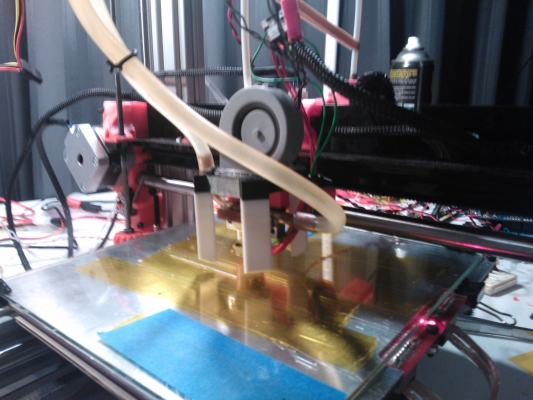

This is the cooling rig i used that blows air on to all sides of the print.

I have modifide it since this to create more of a whirlwind affect and to allow for hot air to be used.

I cut the ends off to get better pictures (the center holes are all round tho they dont look it in the pic).

This is the cooling rig i used that blows air on to all sides of the print.

I have modifide it since this to create more of a whirlwind affect and to allow for hot air to be used.

|

Re: Can this bottom curve be improved? June 11, 2014 05:48AM |

Registered: 11 years ago Posts: 103 |

|

Re: Can this bottom curve be improved? June 11, 2014 11:23PM |

Registered: 9 years ago Posts: 34 |

|

Re: Can this bottom curve be improved? June 12, 2014 11:16AM |

Registered: 11 years ago Posts: 103 |

|

Re: Can this bottom curve be improved? June 12, 2014 03:10PM |

Registered: 10 years ago Posts: 76 |

Quote

appjaws1

Reverted to the original ormerod fan which produces a much better air flow compared to the quiet fan I was using.

The result is a great improvement on the lower curves, still not correct but much better.

[attachment 34692 test-original-fan.jpg]

Mine happened to be exactly the same result as yours. Looking fir solution for this for a while yet stil

not found any setting that can get it better. Hope there is an answer to this issue soon.

|

Re: Can this bottom curve be improved? June 12, 2014 05:33PM |

Registered: 10 years ago Posts: 790 |

Have you properly leveled your bed? It almost looks like your bed is too low, but I haven't really looked at other parts of the print.

Edit: Looked, you've got some bad z-banding. What screw, if any, are you using for Z axis? Steps per mm you have set?

Edited 1 time(s). Last edit at 06/12/2014 05:34PM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Edit: Looked, you've got some bad z-banding. What screw, if any, are you using for Z axis? Steps per mm you have set?

Edited 1 time(s). Last edit at 06/12/2014 05:34PM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Can this bottom curve be improved? July 15, 2014 10:01AM |

Registered: 9 years ago Posts: 6 |

As the radius gets larger for bigger parts, this issues is just going to have a larger effect. The larger the radius, the more layer are below 45 deg. Do you think there is a good solution for printing these curved parts without support for all situations? Imagine printing a sphere for example.

I'm interested in printing tubular structures that would have portions forced to be printed horizontally.

Edited 1 time(s). Last edit at 07/15/2014 10:06AM by paradiddle65.

I'm interested in printing tubular structures that would have portions forced to be printed horizontally.

Edited 1 time(s). Last edit at 07/15/2014 10:06AM by paradiddle65.

|

Re: Can this bottom curve be improved? July 15, 2014 11:45AM |

Registered: 10 years ago Posts: 2,472 |

No, larger curves (and horizontal holes) need to be printed with support. Cura does a better job of generating support that snaps off easily than Slic3r. With holes, you need to select "print support everywhere" in Cura otherwise holes wont get any support.

The support often makes the print appear to be a complete mess, but it's surprising how easily it can be removed to reveal a good print underneath.

Dave

(#106)

The support often makes the print appear to be a complete mess, but it's surprising how easily it can be removed to reveal a good print underneath.

Dave

(#106)

Sorry, only registered users may post in this forum.