Tall-merod

Posted by droftarts

|

Tall-merod June 21, 2014 05:09PM |

Registered: 12 years ago Posts: 1,611 |

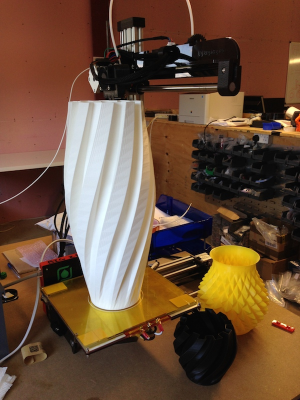

I've been talking about building a tall printer for ages, and finally got around to it. It's done a few small prints, but this is the first tall thing... 340mm, to be exact! And it still has about 40mm spare... Model boat hulls, Eiffel tower, Big Ben, Statue of Liberty, Nelson's column have all been suggested as the next print - any other suggestions?!

The yellow spiky vase is the tallest thing we could build on a Tricolour Mendel - it's 140mm tall.

Ian

RepRapPro tech support

Edited 1 time(s). Last edit at 06/21/2014 05:12PM by droftarts.

The yellow spiky vase is the tallest thing we could build on a Tricolour Mendel - it's 140mm tall.

Ian

RepRapPro tech support

Edited 1 time(s). Last edit at 06/21/2014 05:12PM by droftarts.

|

Re: Tall-merod June 21, 2014 05:35PM |

Registered: 10 years ago Posts: 14,672 |

Looks nice! How long did it take to print?

I've managed without axis compensation so far, but for a print that tall, I guess you probably need it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I've managed without axis compensation so far, but for a print that tall, I guess you probably need it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Tall-merod June 21, 2014 05:57PM |

Registered: 12 years ago Posts: 1,611 |

Not sure how long it took to print, probably around 8 hours. I started it at 12.30pm yesterday, it had done 200mm by 5pm. I popped into work today to see if it had survived! I didn't use any bed or orthogonal compensation - the frame is pretty straight, and it doesn't matter too much with more organic forms! And even a barely measurable axis inaccuracy can be quite large at that height.

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: Tall-merod June 22, 2014 12:23AM |

Registered: 10 years ago Posts: 256 |

Quote

droftarts

... as the next print - any other suggestions?!

http://www.amrc.co.uk/featuredstudy/printed-uav/

(From the pic, looks like it was printed vertically)

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Tall-merod June 22, 2014 03:56AM |

Registered: 10 years ago Posts: 314 |

Hi Ian,

That looks very impressive.

I presume that there are only minor changes to the firmware required to drive the longer axis?

Before anyone takes the following comment as a criticism of the Ormerod, I love my Ormerod, it's great and is a very cost effective and precise printer!

Now my question/comment:

Looking at the photo and thinking of the limits as dimensions tend to infinity.... No my workshop isn't big enough either!

It does show that the optimum design is not to move the bed and only move the 'light weight' filament.

Keeping the Ormerod general structure, has anyone considered putting the z-axis on a belt driven slide?

Guess ultimately as issues of 'pendulum' effects and rigidity are designed out you end up with a 3D printer in a frame/box structure.

Think I'll stick with my current Ormerod......

Please feel free to delete this post if it is detracting from the great tall 3D print you have just achieved, but it did make me think!

Ormerod #007 (shaken but not stirred!)

That looks very impressive.

I presume that there are only minor changes to the firmware required to drive the longer axis?

Before anyone takes the following comment as a criticism of the Ormerod, I love my Ormerod, it's great and is a very cost effective and precise printer!

Now my question/comment:

Looking at the photo and thinking of the limits as dimensions tend to infinity.... No my workshop isn't big enough either!

It does show that the optimum design is not to move the bed and only move the 'light weight' filament.

Keeping the Ormerod general structure, has anyone considered putting the z-axis on a belt driven slide?

Guess ultimately as issues of 'pendulum' effects and rigidity are designed out you end up with a 3D printer in a frame/box structure.

Think I'll stick with my current Ormerod......

Please feel free to delete this post if it is detracting from the great tall 3D print you have just achieved, but it did make me think!

Ormerod #007 (shaken but not stirred!)

|

Re: Tall-merod June 22, 2014 04:26AM |

Registered: 10 years ago Posts: 776 |

Personally, I would lean towards making the bed drop for the Z axis and putting the extruder on a x/y gantry, pretty much like my CNC plasma table but with added z drop.

That way, all axes are pretty firm and stable. I would not even think of mounting an ormerod z axis on a trolley, too unstable.

That tall print is pretty impressive though

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

That way, all axes are pretty firm and stable. I would not even think of mounting an ormerod z axis on a trolley, too unstable.

That tall print is pretty impressive though

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Tall-merod June 22, 2014 05:07AM |

Registered: 10 years ago Posts: 275 |

Hi Ian,

I am preparing the third ....high ....

[www.dropbox.com]

200x200x450

Dario

Edited 1 time(s). Last edit at 06/22/2014 05:28AM by Ormerod187.

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

I am preparing the third ....high ....

[www.dropbox.com]

200x200x450

Dario

Edited 1 time(s). Last edit at 06/22/2014 05:28AM by Ormerod187.

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

|

Re: Tall-merod June 22, 2014 07:39AM |

Registered: 12 years ago Posts: 1,611 |

Andy - Nice, now I need a wider printing printer too!

Treth - It's pretty easy to extend the Z axis, just longer extrusion from [www.kjnltd.co.uk], smooth rod [www.worldofcnc.com] and M5 leadscrew, which I unfortunately bought from toolstation, and has a thread pitch of 0.825mm rather than 0.8mm! Then it's just changing the volume size (M208 Z400). I could change the Z homing macro too, but it's better to move it down first - homing is really slow if you do it from the top!

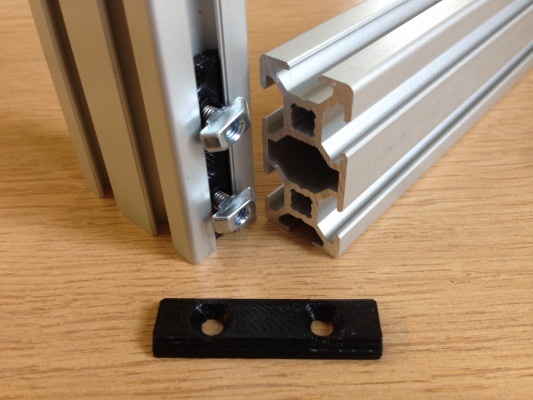

I've attached the openscad and stl file of the part I use to strengthen the connection between the Y and Z axis. It just holds two M4x10mm countersunk screws, with T-nuts on the end. It slides into the end of the Z axis, and connects to the Y axis. You need to put it on before the z-lower-mount and z-motor. To access the countersunk screws, you need to drill two holes through the aluminium extrusion. You can use the part as a drill guide, too. The holes are not shown in the attached picture, but come in from the back of the vertical extrusion. Also printed in black, so not very clear what it does!

Dario - bah, that's bigger than mine! Well done, looks good. For Ormerod 2 (not long now...) we're mounting a very similar PSU (no more ATX) in a very similar place.

Erik - There are many different ways of orientating the axes, and for a normal Cartesian robot it always means stacking at least one axis on top of another at some point. So we stack the X on Z, with the Y separate, as it seems to be the most efficient and lightweight way of doing it. Other printers stack X on Y for the bed, with Z separate for the extruder (Velleman, original Makerbot Cupcake) or have the bed move in Z and the nozzle move in X and Y (current Makerbot, Ultimaker). Most of these need a lot of structure to contain forces; the X and Y axes have to be braced against each other when they are mounted on each other. Generally we try and minimise the stacking of axes, so that there isn't interaction between them, and it's always a compromise. There are a number of other types of machines that use their axes in different ways - Delta, SCARA and the like (one of my favourites is the Simpson [reprap.org] and LISA Simpson [reprap.org] ) - but each generally has some drawback. Not to say Ormerod is perfect - just it's the compromise we chose!

Ian

RepRapPro tech support

Treth - It's pretty easy to extend the Z axis, just longer extrusion from [www.kjnltd.co.uk], smooth rod [www.worldofcnc.com] and M5 leadscrew, which I unfortunately bought from toolstation, and has a thread pitch of 0.825mm rather than 0.8mm! Then it's just changing the volume size (M208 Z400). I could change the Z homing macro too, but it's better to move it down first - homing is really slow if you do it from the top!

I've attached the openscad and stl file of the part I use to strengthen the connection between the Y and Z axis. It just holds two M4x10mm countersunk screws, with T-nuts on the end. It slides into the end of the Z axis, and connects to the Y axis. You need to put it on before the z-lower-mount and z-motor. To access the countersunk screws, you need to drill two holes through the aluminium extrusion. You can use the part as a drill guide, too. The holes are not shown in the attached picture, but come in from the back of the vertical extrusion. Also printed in black, so not very clear what it does!

Dario - bah, that's bigger than mine! Well done, looks good. For Ormerod 2 (not long now...) we're mounting a very similar PSU (no more ATX) in a very similar place.

Erik - There are many different ways of orientating the axes, and for a normal Cartesian robot it always means stacking at least one axis on top of another at some point. So we stack the X on Z, with the Y separate, as it seems to be the most efficient and lightweight way of doing it. Other printers stack X on Y for the bed, with Z separate for the extruder (Velleman, original Makerbot Cupcake) or have the bed move in Z and the nozzle move in X and Y (current Makerbot, Ultimaker). Most of these need a lot of structure to contain forces; the X and Y axes have to be braced against each other when they are mounted on each other. Generally we try and minimise the stacking of axes, so that there isn't interaction between them, and it's always a compromise. There are a number of other types of machines that use their axes in different ways - Delta, SCARA and the like (one of my favourites is the Simpson [reprap.org] and LISA Simpson [reprap.org] ) - but each generally has some drawback. Not to say Ormerod is perfect - just it's the compromise we chose!

Ian

RepRapPro tech support

|

Re: Tall-merod June 23, 2014 03:12AM |

Registered: 10 years ago Posts: 19 |

Did you consider printing the whole X-axis?

I understand it's a lot of plastic and printing time to get rid of some lasercut acrylic, but it's also a lot of new possibilities: fancy axis structure designs to experiment with, integrated air duct to convey air from a static fan, integrated tubing guides for the extruder or even the gears...

As regards the flat surface needed for sliding the X-runner, gluing a little aluminium or glass strip could work (or even a printed part, as the face laying on the glass looks smooth and straight enough for testing. Laying the kapton diagonally, a long-enough bar can be printed)

OK, may be I've got too far, but you got the spirit of it ;-)

I understand it's a lot of plastic and printing time to get rid of some lasercut acrylic, but it's also a lot of new possibilities: fancy axis structure designs to experiment with, integrated air duct to convey air from a static fan, integrated tubing guides for the extruder or even the gears...

As regards the flat surface needed for sliding the X-runner, gluing a little aluminium or glass strip could work (or even a printed part, as the face laying on the glass looks smooth and straight enough for testing. Laying the kapton diagonally, a long-enough bar can be printed)

OK, may be I've got too far, but you got the spirit of it ;-)

|

Re: Tall-merod June 23, 2014 04:07AM |

Registered: 10 years ago Posts: 14,672 |

I suspect that a printed x-axis would be less rigid than the acrylic unless it were a lot thicker, and it might also droop over time due to the heat rising from the bed. I didn't have much problem with the original acrylic x-axis, just a very slight bend that I think caused the nozzle height to vary by a small fraction of a mm over the length of the x-axis. I'm now using DaveK's excellent aluminium x-plate and rib, but I can see that this would be too expensive to include in the basic kit. Perhaps thicker acrylic could be used for the x-plate in the kit, e.g. 6mm or even 8mm? The parts I received were not even 5mm thick, they were 4.6 to 4.7mm.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Tall-merod June 23, 2014 07:44AM |

Registered: 10 years ago Posts: 2,472 |

Quote

kwikius

Quote

droftarts

... as the next print - any other suggestions?!

http://www.amrc.co.uk/featuredstudy/printed-uav/

(From the pic, looks like it was printed vertically)

regards

Andy

Darn! They don't seem to have an STL download.

Dave

(#106)

|

Re: Tall-merod June 23, 2014 07:53AM |

Registered: 10 years ago Posts: 19 |

Apparently, PLA is more rigid than acrylic: Young's modulus for PLA or ABS is 3.5 GPa, Perspex is 3.2.

I'm no expert in construction physics, but from what I understand from Wikipedia, the higher the modulus, the better the rigidity (by comparison, rubber Young's module is less than 0.1 and Graphene is more than 1000).

Even better, a printed part can optimize the shape, which determines in large part a structure's rigidity, placing material were it is needed. We all know that a sheet of paper collapses under its own weight, but a few folds here and there (or just making it a tube) transform it in a completely different structure.

Again I'm no expert and I can easily miss the basics, sorry if I digress, just brainstorming and thinking out loud! I really enjoy experimenting and learning from this fantastic community.

I'm no expert in construction physics, but from what I understand from Wikipedia, the higher the modulus, the better the rigidity (by comparison, rubber Young's module is less than 0.1 and Graphene is more than 1000).

Even better, a printed part can optimize the shape, which determines in large part a structure's rigidity, placing material were it is needed. We all know that a sheet of paper collapses under its own weight, but a few folds here and there (or just making it a tube) transform it in a completely different structure.

Again I'm no expert and I can easily miss the basics, sorry if I digress, just brainstorming and thinking out loud! I really enjoy experimenting and learning from this fantastic community.

|

Re: Tall-merod June 23, 2014 10:35AM |

Registered: 10 years ago Posts: 256 |

Quote

droftarts

Andy - Nice, now I need a wider printing printer too!

t

Maybe not. You could chop it into a couple of sections ( so the leading edge part at the root is one section and the trailing edeg part is the other)

Where the two sections meet would be a good place to put a spar.. I've already done the design

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Tall-merod June 23, 2014 11:34AM |

Registered: 10 years ago Posts: 14,672 |

Quote

droftarts

Andy - Nice, now I need a wider printing printer too!

Shouldn't be difficult:

* Replace the Y extrusion and ground rods with ones about 220mm longer

* Build a bed using 2 heater PCBs and a larger heat spreader and bed support, perhaps with 3 support & height adjusting screws for each half

* User longer MXL belt and ribbon cable

* Wire the 2 bed thermistors in parallel and use the M305 command to account for the halving of the effective bed thermistor resistance

I suggest wiring the two bed heaters in series, so that the existing arrangement of ribbon cable can be used to power them and the Duet power connector can handle the power involved. I found a 24V 360W PSU on eBay for £18.80, which I think should just about be sufficient, bearing in mind that the stepper motor, Duet board and cartridge heater currents will halve. You will also need a 24V version of the cartridge heater and a 24V fan, but these appear to be readily available.

If the two bed heater PCBs have slightly different resistances, then the one with higher resistance will heat up more than the other one; but you can compensate for this by putting a resistor in parallel with it.

Edited 1 time(s). Last edit at 06/23/2014 11:35AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Tall-merod June 23, 2014 11:51AM |

Registered: 12 years ago Posts: 1,611 |

Andy: Nice! Looks wicked fast, and I'd like to see the FPV daisy-cutter view...

dc: I've got a friend who's building a double-length Y and Z machine (dubbed 'MoreRod'), with the Y pretty much as you suggest. Not sure how he's doing the bed heating, though. Hopefully he'll get around to posting on here...

Ian

RepRapPro tech support

dc: I've got a friend who's building a double-length Y and Z machine (dubbed 'MoreRod'), with the Y pretty much as you suggest. Not sure how he's doing the bed heating, though. Hopefully he'll get around to posting on here...

Ian

RepRapPro tech support

|

Re: Tall-merod June 24, 2014 07:36AM |

Registered: 10 years ago Posts: 19 |

Dario,

I like your clothespin tensioner! Looks like an easy way to ensure proper belt tension, how is it actually performing?

I like your clothespin tensioner! Looks like an easy way to ensure proper belt tension, how is it actually performing?

|

Re: Tall-merod June 24, 2014 08:14AM |

Registered: 10 years ago Posts: 275 |

Hi ellipse,

it works....in my grandfather's memory, but I prefer the new version .... more accurate

[www.dropbox.com]

Dario

it works....in my grandfather's memory, but I prefer the new version .... more accurate

[www.dropbox.com]

Dario

|

Re: Tall-merod July 05, 2014 11:14AM |

Registered: 10 years ago Posts: 66 |

After seeing the post in RRP's news I just knew I had to get in on this, I've bought smooth rods, aluminium extrusions and an M5 leadscrew (not sure of pitch until it turns up) for both Y and Z extensions. Might print up some kind of fancy folding tray to deal with the slack wires coming down from the X arm.

Just started looking at getting a 24V PSU to give a bigger heatbed some more grunt - what are the implications of this for the Duet and other components? dc42 mentioned replacing the cartridge heater and fan with 24V versions, does that mean the Duet can handle stepping down a supply of 24V for the electronics while passing 24V to the heaters/fan?

Then there's the heatbed and glass - currently pondering this as a cheap bed extension: ebay, but I have no idea where to get some glass from. I'm assuming it needs to be a particular heat resistant type. Has anyone got the spec for it (/Droftarts where do you get yours?).

Also considering ways to mount a lerger heated bed, at the very least a new aluminium bed support plate is in order. Currently using the one davek had made up.

I'm eyeing up davek's X-arm upgrade on ebay since I'm doing all this other work...

Any help greatly appreciated

Just started looking at getting a 24V PSU to give a bigger heatbed some more grunt - what are the implications of this for the Duet and other components? dc42 mentioned replacing the cartridge heater and fan with 24V versions, does that mean the Duet can handle stepping down a supply of 24V for the electronics while passing 24V to the heaters/fan?

Then there's the heatbed and glass - currently pondering this as a cheap bed extension: ebay, but I have no idea where to get some glass from. I'm assuming it needs to be a particular heat resistant type. Has anyone got the spec for it (/Droftarts where do you get yours?).

Also considering ways to mount a lerger heated bed, at the very least a new aluminium bed support plate is in order. Currently using the one davek had made up.

I'm eyeing up davek's X-arm upgrade on ebay since I'm doing all this other work...

Any help greatly appreciated

|

Re: Tall-merod July 05, 2014 11:44AM |

Registered: 10 years ago Posts: 1,230 |

Quote

static65

...but I have no idea where to get some glass from. I'm assuming it needs to be a particular heat resistant type. Has anyone got the spec for it (/Droftarts where do you get yours?)...

Is not special heat resistant glass, just normal float glass, got some made locally in 4mm

Erik

|

Re: Tall-merod July 05, 2014 06:25PM |

Registered: 10 years ago Posts: 14,672 |

Yes, the glass is ordinary float glass. I believe the Duet board is rated for 35V abs. max. input voltage, so 24V should be fine.

One thing I hadn't realised until I read it in another thread is that the 12V 5mm diameter cartridge heater is specially made for RRP. I found a 24V 5mm cartridge here [www.amazon.com] although it looks too long for the Ormerod. Alternatively, if you talk to DaveK, he may be able to machine you a slightly larger heater block to take a 6mm cartridge. You can get a 24V 6mm cartridge heater on eBay.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

One thing I hadn't realised until I read it in another thread is that the 12V 5mm diameter cartridge heater is specially made for RRP. I found a 24V 5mm cartridge here [www.amazon.com] although it looks too long for the Ormerod. Alternatively, if you talk to DaveK, he may be able to machine you a slightly larger heater block to take a 6mm cartridge. You can get a 24V 6mm cartridge heater on eBay.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Tall-merod July 07, 2014 08:14AM |

Registered: 10 years ago Posts: 66 |

Thanks for the assistance, parts now ordered:

Aluminium extrusions

Smooth rods

M5 leadscrew

Long M5 nut

X arm upgrade kit

200x300mm bed

6mm 24V 40W heater cartridge

1M 26 way flat ribbon cable

In discussion with DaveK on custom heater block and bed mounting plate

Just need a power supply and a longer Y axis belt and I'm good to go!

Aluminium extrusions

Smooth rods

M5 leadscrew

Long M5 nut

X arm upgrade kit

200x300mm bed

6mm 24V 40W heater cartridge

1M 26 way flat ribbon cable

In discussion with DaveK on custom heater block and bed mounting plate

Just need a power supply and a longer Y axis belt and I'm good to go!

|

Re: Tall-merod July 07, 2014 09:22AM |

Registered: 10 years ago Posts: 14,672 |

For the power supply, you might consider the 24V 20A one here [www.ebay.co.uk]. The 24V 15A ones are about half the price, but might be slightly underpowered in this application.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Tall-merod July 09, 2014 07:07PM |

Registered: 10 years ago Posts: 66 |

Did a bit of dumpster diving at work and came up with a 24V fan of the right size, but unfortunately no power supply. Hopefully RRP can supply a belt and a few other bits I want. Found a local glass supplier. Will post some pics when I've got it all put together.

Thanks again for all the pointers!

Thanks again for all the pointers!

Sorry, only registered users may post in this forum.