Software support for multiextruder

Posted by colsenfoto

|

Software support for multiextruder June 27, 2014 02:29AM |

Registered: 10 years ago Posts: 101 |

So I finally got an extra extruder wired up eysterday - via the duet extension board.

Unfortunately I did not manage to turn the motor or get the heat on - probably as expected for a Quick and dirty crash-test[

Can anybody point me in the right direction regarding firmware?

I'm running DC42's latest experimental build.

Which commands should I use to control the extra extruder?

What kind of firmware changes are needed (on a High-level basis)?

I would be very happy if I could get some hints about where to start.

Thank you very much.

Best regards

Carsten

Unfortunately I did not manage to turn the motor or get the heat on - probably as expected for a Quick and dirty crash-test[

Can anybody point me in the right direction regarding firmware?

I'm running DC42's latest experimental build.

Which commands should I use to control the extra extruder?

What kind of firmware changes are needed (on a High-level basis)?

I would be very happy if I could get some hints about where to start.

Thank you very much.

Best regards

Carsten

|

Re: Software support for multiextruder June 27, 2014 05:02AM |

Registered: 10 years ago Posts: 378 |

The man to talk to about all things firmware is dc42, but I think the later (065-based) ones have the support needed. The g-code commands needed should just be setting both extruders up with G10, and then using T1 and T2 to switch between them. Any G1 E-commands should then just affect the "selected" one.

|

Re: Software support for multiextruder June 27, 2014 05:38AM |

Registered: 10 years ago Posts: 14,672 |

I don't yet have multi-extruder support in my firmware fork, but I plan to add it soon. In the meantime you might want to look at [github.com].

You could also look at [github.com] which appears to support additional steppers. Ian should be able to tell you the extent to which it supports multiple extruders.

Edited 1 time(s). Last edit at 06/27/2014 09:07AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

You could also look at [github.com] which appears to support additional steppers. Ian should be able to tell you the extent to which it supports multiple extruders.

Edited 1 time(s). Last edit at 06/27/2014 09:07AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Software support for multiextruder June 27, 2014 08:52AM |

Registered: 10 years ago Posts: 101 |

|

Re: Software support for multiextruder June 27, 2014 09:44AM |

Registered: 12 years ago Posts: 1,611 |

jstck - a bit harsh... Adrian Bowyer wrote much of the firmware, I expect he has a fair idea what's going on too... and I'm no slouch...

Hi Carsten

Use firmware 0.78 or later from the RepRapFirmware repository for multiextruder support. We're testing this version, so it's in the 'test' branch, while development continues in the 'dev' branch.

Some notes from other posts and emails:

From 0.65e, we changed the numbering of the first tool to T1, rather than T0, for consistency, as the bed is usually referred to as heater 0, while the first hot end is usually heater 1. This also allows us to use T0 (or any other non-defined tool number) as a command to put all extruder/hot ends/tools into standby. The multihead support has only recently been added to the RepRap Firmware, so we're still working out how to get everything working correctly.

There is a gcode to define the 'tools'; it's M563 - [reprap.org] . You can see how it's used in the config.g in our 'dev' branch - [reprap.org]

You define what tools (ie mix of hot ends and extruder) you want, and select the tool with T[tool number]. At the moment in firmware 0.78 (which is in testing), we cannot put the tool number in config.g - the code for nested macros (calling one macro from within another, and returning it to the same point at the end) has not been written. When you start having multiple hot ends, which have a standby temperature, you don't really want them all activating when you turn the machine on, anyway! However, we'll update the instructions, to remind people that you always need to select the tool number before manually setting hot end temperature, and that the tool should be added to the the Slic3r configuration. I think a log message is generated (rather than a crash) if a hot end temperature is set, but no tool is selected.

When you select (or deselect) a tool, it can run a macro (set of commands); these are the tpre1.g, tpost1.g and tfree1.g files in the sys folder (firmware version 0.81 and later only).

Use G10 to set active and standby temperatures for each tool - [reprap.org]

This lets you send working and standby temperatures. When you change tool, the active tool drops to the standby temperature.

G10 X and Y offsets have yet to be implemented. However, you can set the nozzle offset (to account for the physically different position of each) in Slic3r

To set up Slic3r for extra nozzles:

1. Go to Printer Settings > General > Capabilities > Extruders and set to '2'

2. On the Plater tab, select a filament profile for the second extruder.

3. We're currently using the offset in Slic3r, in Printer Settings > Extruder 2 > Extruder offset

4. We use a loop around the outside of the object to catch any ooze, that builds to the full height of the part, by Slic3r setting: Print settings > Skirt and brim > Skirt > Loops: 2 and Skirt height: 999. This builds a 'curtain' around the whole object, and acts as a wiper for the nozzle that is not in use. However, the nozzles can catch it and then move it, destroying the print, particularly on tall objects. Fine tuning retraction and temperatures and not building the loop around the outside is better.

5. We move the nozzles away to a corner using the tpre1.g and tpost1.g macros.

You'll need two stl files, one for each colour to be printed, which should not overlap. From these, you create an AMF file; see: [reprappro.com]

Proper documentation for multiextruder setups is 'developing', regard it as experimental at the moment! Feel free to ask any questions, I'll try and answer them.

Ian

RepRapPro tech support

Hi Carsten

Use firmware 0.78 or later from the RepRapFirmware repository for multiextruder support. We're testing this version, so it's in the 'test' branch, while development continues in the 'dev' branch.

Some notes from other posts and emails:

From 0.65e, we changed the numbering of the first tool to T1, rather than T0, for consistency, as the bed is usually referred to as heater 0, while the first hot end is usually heater 1. This also allows us to use T0 (or any other non-defined tool number) as a command to put all extruder/hot ends/tools into standby. The multihead support has only recently been added to the RepRap Firmware, so we're still working out how to get everything working correctly.

There is a gcode to define the 'tools'; it's M563 - [reprap.org] . You can see how it's used in the config.g in our 'dev' branch - [reprap.org]

You define what tools (ie mix of hot ends and extruder) you want, and select the tool with T[tool number]. At the moment in firmware 0.78 (which is in testing), we cannot put the tool number in config.g - the code for nested macros (calling one macro from within another, and returning it to the same point at the end) has not been written. When you start having multiple hot ends, which have a standby temperature, you don't really want them all activating when you turn the machine on, anyway! However, we'll update the instructions, to remind people that you always need to select the tool number before manually setting hot end temperature, and that the tool should be added to the the Slic3r configuration. I think a log message is generated (rather than a crash) if a hot end temperature is set, but no tool is selected.

When you select (or deselect) a tool, it can run a macro (set of commands); these are the tpre1.g, tpost1.g and tfree1.g files in the sys folder (firmware version 0.81 and later only).

Use G10 to set active and standby temperatures for each tool - [reprap.org]

This lets you send working and standby temperatures. When you change tool, the active tool drops to the standby temperature.

G10 X and Y offsets have yet to be implemented. However, you can set the nozzle offset (to account for the physically different position of each) in Slic3r

To set up Slic3r for extra nozzles:

1. Go to Printer Settings > General > Capabilities > Extruders and set to '2'

2. On the Plater tab, select a filament profile for the second extruder.

3. We're currently using the offset in Slic3r, in Printer Settings > Extruder 2 > Extruder offset

4. We use a loop around the outside of the object to catch any ooze, that builds to the full height of the part, by Slic3r setting: Print settings > Skirt and brim > Skirt > Loops: 2 and Skirt height: 999. This builds a 'curtain' around the whole object, and acts as a wiper for the nozzle that is not in use. However, the nozzles can catch it and then move it, destroying the print, particularly on tall objects. Fine tuning retraction and temperatures and not building the loop around the outside is better.

5. We move the nozzles away to a corner using the tpre1.g and tpost1.g macros.

You'll need two stl files, one for each colour to be printed, which should not overlap. From these, you create an AMF file; see: [reprappro.com]

Proper documentation for multiextruder setups is 'developing', regard it as experimental at the moment! Feel free to ask any questions, I'll try and answer them.

Ian

RepRapPro tech support

|

Re: Software support for multiextruder June 27, 2014 10:44AM |

Registered: 10 years ago Posts: 101 |

|

Re: Software support for multiextruder June 27, 2014 11:43AM |

Registered: 9 years ago Posts: 138 |

|

Re: Software support for multiextruder June 28, 2014 03:21PM |

Registered: 10 years ago Posts: 101 |

Hi Ian,

I got an extra extruder up and running today with the 0.78 firmware. I can control both the motor and the heater - and also get some readings from the thermistor. I would not have been this far, if it wasn't for your explanation - thanks again.

Unfortunately I'm having some trouble with the thermistor readings. At the moment I think it's a firmware problem.

For example, heater number 2 seems to be affected by the reading from heater number 1. They were physically separated, so it's not caused by the heating.

Have you actually tested the thermistor-readings and heater control in this version?

I spent some time in the source-code. It looks like there's a bug in the averaging code for the temperature readings - but I might have misunderstood something.

I did not find any code that should cause the cross-talk, though.

Please let me know, what you have actually tested regarding the heat-control and thermistor reading.

Thank you very much.

Best regards,

Carsten

I got an extra extruder up and running today with the 0.78 firmware. I can control both the motor and the heater - and also get some readings from the thermistor. I would not have been this far, if it wasn't for your explanation - thanks again.

Unfortunately I'm having some trouble with the thermistor readings. At the moment I think it's a firmware problem.

For example, heater number 2 seems to be affected by the reading from heater number 1. They were physically separated, so it's not caused by the heating.

Have you actually tested the thermistor-readings and heater control in this version?

I spent some time in the source-code. It looks like there's a bug in the averaging code for the temperature readings - but I might have misunderstood something.

I did not find any code that should cause the cross-talk, though.

Please let me know, what you have actually tested regarding the heat-control and thermistor reading.

Thank you very much.

Best regards,

Carsten

|

Re: Software support for multiextruder June 30, 2014 03:42PM |

Registered: 10 years ago Posts: 101 |

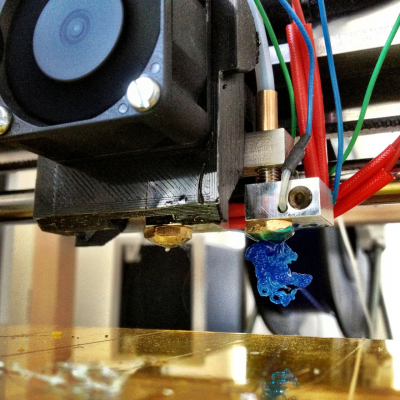

After fighting Eclipse for a couple of days, I finally decided to just make a crash-test - couldn't wait any longer....

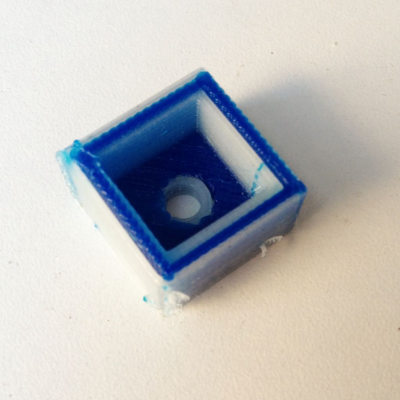

I just used a small 2 x 2 x 1 cm calibration-cube, I have made for testing filament settings. Slic3r was set up to use Extruder 1 for Perimeters and Extruder 2 for Infill. No need to push too hard the first time.

First Attempt

Second Attempt - now with correct Slic3r filament settings

To my big surprise, it actually worked. I absolutely did not expect that.

There are a ton of calibration-issues and other problems, that I have to solve, but the basic functionality is already there.

I think that anybody who can build an Ormerod and has a bit of money left plus a basic understanding of G-codes can do the same. Testing the setup involves a lot of M- and G-codes command-line typing.

I'll post some more information about the setup in near future.

Best regards,

Carsten

I just used a small 2 x 2 x 1 cm calibration-cube, I have made for testing filament settings. Slic3r was set up to use Extruder 1 for Perimeters and Extruder 2 for Infill. No need to push too hard the first time.

First Attempt

Second Attempt - now with correct Slic3r filament settings

To my big surprise, it actually worked. I absolutely did not expect that.

There are a ton of calibration-issues and other problems, that I have to solve, but the basic functionality is already there.

I think that anybody who can build an Ormerod and has a bit of money left plus a basic understanding of G-codes can do the same. Testing the setup involves a lot of M- and G-codes command-line typing.

I'll post some more information about the setup in near future.

Best regards,

Carsten

|

Re: Software support for multiextruder June 30, 2014 04:15PM |

Registered: 10 years ago Posts: 378 |

Quote

droftarts

jstck - a bit harsh... Adrian Bowyer wrote much of the firmware, I expect he has a fair idea what's going on too... and I'm no slouch...

Sorry, I didn't mean to step on any toes, and I did get some things mixed up. I was actually (somewhat vaguely) referring to the 065-firmware series from RepRapPro, which I guess is Adrians main branch of it, and I thought dc also had done some of the multi-extruder stuff.

|

Re: Software support for multiextruder July 01, 2014 10:02AM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Software support for multiextruder July 01, 2014 10:45AM |

Registered: 9 years ago Posts: 30 |

|

Re: Software support for multiextruder July 01, 2014 10:48AM |

Registered: 9 years ago Posts: 176 |

|

Re: Software support for multiextruder July 01, 2014 03:26PM |

Registered: 10 years ago Posts: 101 |

Thank you very much, Ian and VortyZA.

I think the biggest challenge right now is on the software side. I was missing a lot of dc42's new features and especially the stability of his branch. I had the 0.78 firmware crash countless times, where I could not talk to the Ormerod.

Best regards,

Carsten

I think the biggest challenge right now is on the software side. I was missing a lot of dc42's new features and especially the stability of his branch. I had the 0.78 firmware crash countless times, where I could not talk to the Ormerod.

Best regards,

Carsten

|

Re: Software support for multiextruder July 02, 2014 07:07AM |

Registered: 12 years ago Posts: 1,611 |

Really? 0.78 has been really solid for us. Can you give me some examples?

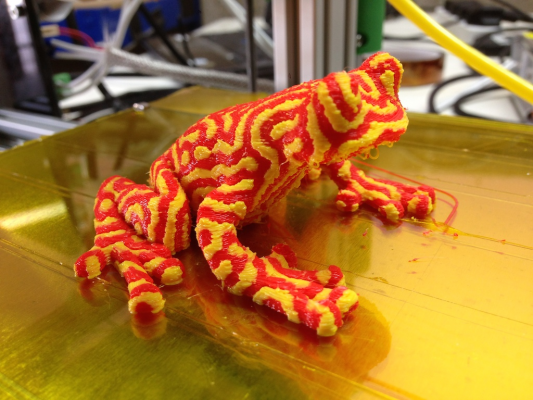

Also... [www.thingiverse.com]

Printed with 2 x 0.3mm nozzles, but quite a coarse 0.24mm layer height. We're going to do it again at 0.1mm layer height. The overhang was quite brutal!

Ian

RepRapPro

Also... [www.thingiverse.com]

Printed with 2 x 0.3mm nozzles, but quite a coarse 0.24mm layer height. We're going to do it again at 0.1mm layer height. The overhang was quite brutal!

Ian

RepRapPro

|

Re: Software support for multiextruder July 02, 2014 07:18AM |

Registered: 10 years ago Posts: 101 |

Hi Ian,

I'm not sure what happened. Let's just say that I was messing around a lot :-)

I'll pay more attention during my next experiments - and get back to you.

Could you email me your config.g and the gcode-file for one of your dual-color prints.

I would love to see how you setup the extruder temperatures at power-on and at the start of the print. A working example would be a great help.

Thank you.

Best regards,

Carsten

I'm not sure what happened. Let's just say that I was messing around a lot :-)

I'll pay more attention during my next experiments - and get back to you.

Could you email me your config.g and the gcode-file for one of your dual-color prints.

I would love to see how you setup the extruder temperatures at power-on and at the start of the print. A working example would be a great help.

Thank you.

Best regards,

Carsten

|

Re: Software support for multiextruder July 08, 2014 05:39PM |

Registered: 10 years ago Posts: 14,672 |

Hi Carsten,

In case you haven't noticed, I've released firmware 0.78-dc42, which includes RRP's multi-extruder support from their 0.78 build. See [forums.reprap.org].

I'm currently thinking about how the web interface should be modified for multi-extruder support. I'll start a new thread to discuss that.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

In case you haven't noticed, I've released firmware 0.78-dc42, which includes RRP's multi-extruder support from their 0.78 build. See [forums.reprap.org].

I'm currently thinking about how the web interface should be modified for multi-extruder support. I'll start a new thread to discuss that.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Software support for multiextruder July 09, 2014 02:21AM |

Registered: 10 years ago Posts: 101 |

Hi dc42,

Yes, I have noticed :-)

I will switch to your firmware one of the next days. I'm totally missing the long filenames for the SD-card.

My multi extruder experiments died when I broke the wires of one of the heater cartridges. As soon as I receive a package from RepRapPro, I'm on it again.

Best regards,

Carsten

Yes, I have noticed :-)

I will switch to your firmware one of the next days. I'm totally missing the long filenames for the SD-card.

My multi extruder experiments died when I broke the wires of one of the heater cartridges. As soon as I receive a package from RepRapPro, I'm on it again.

Best regards,

Carsten

|

Re: Software support for multiextruder July 09, 2014 08:11AM |

Registered: 10 years ago Posts: 780 |

Quote

droftarts

Really? 0.78 has been really solid for us. Can you give me some examples?

Also... [www.thingiverse.com]

[attachment 35821 IMG_0873.JPG]

Printed with 2 x 0.3mm nozzles, but quite a coarse 0.24mm layer height. We're going to do it again at 0.1mm layer height. The overhang was quite brutal!

Ian

RepRapPro

Ian,

This looks fantastic.

What do I need to buy to be able to produce this so that I can join in the fun of developing and testing multi colour ormerod (colomerod)

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Software support for multiextruder July 09, 2014 09:26AM |

Registered: 10 years ago Posts: 14,672 |

Paul, having gone through this myself and not got it quite right first time, this is what I think you need:

1. Two Ormerod hot end kits, [reprappro.com]. I am assuming that you want to keep your existing single-nozzle hot end as a backup, and perhaps for single-nozzle mixing extruder experiments. In fact two hot end kits provide more than you need, you will have a heatsink and fan left over, but it is slightly cheaper than buying one hot end kit and the extra parts.

2. One Duet X4 expansion board, [www.think3dprint3d.com].

3. One Ormerod extruder kit. I haven't found this on the RepRapPro shop, but I expect Sally can give you a price.

4. One Ormerod hot end loom (unless you make it up yourself). I haven't found this on the RepRapPro shop either.

5. For the 2-nozzle heatsink block, there are a few possibilities. You can ask DaveK if he can quote you a price for a copy of the 2-nozzle heatsink block that he made for me, and use it with the modified nozzle mount I published here [github.com]. Or you can bolt two standard heatsink blocks together at the back of the hot end, with what were the nozzle mounting screws in one of them drilled out and tapped for the nozzles.

I'll post a photo when I have finished assembling it.

Edited 1 time(s). Last edit at 07/09/2014 09:30AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Two Ormerod hot end kits, [reprappro.com]. I am assuming that you want to keep your existing single-nozzle hot end as a backup, and perhaps for single-nozzle mixing extruder experiments. In fact two hot end kits provide more than you need, you will have a heatsink and fan left over, but it is slightly cheaper than buying one hot end kit and the extra parts.

2. One Duet X4 expansion board, [www.think3dprint3d.com].

3. One Ormerod extruder kit. I haven't found this on the RepRapPro shop, but I expect Sally can give you a price.

4. One Ormerod hot end loom (unless you make it up yourself). I haven't found this on the RepRapPro shop either.

5. For the 2-nozzle heatsink block, there are a few possibilities. You can ask DaveK if he can quote you a price for a copy of the 2-nozzle heatsink block that he made for me, and use it with the modified nozzle mount I published here [github.com]. Or you can bolt two standard heatsink blocks together at the back of the hot end, with what were the nozzle mounting screws in one of them drilled out and tapped for the nozzles.

I'll post a photo when I have finished assembling it.

Edited 1 time(s). Last edit at 07/09/2014 09:30AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Software support for multiextruder July 11, 2014 06:46AM |

Registered: 10 years ago Posts: 780 |

Quote

dc42

1. Two Ormerod hot end kits, [reprappro.com]. I am assuming that you want to keep your existing single-nozzle hot end as a backup, and perhaps for single-nozzle mixing extruder experiments. In fact two hot end kits provide more than you need, you will have a heatsink and fan left over, but it is slightly cheaper than buying one hot end kit and the extra parts.

2. One Duet X4 expansion board, [www.think3dprint3d.com].

3. One Ormerod extruder kit. I haven't found this on the RepRapPro shop, but I expect Sally can give you a price.

4. One Ormerod hot end loom (unless you make it up yourself). I haven't found this on the RepRapPro shop either.

5. For the 2-nozzle heatsink block, there are a few possibilities. You can ask DaveK if he can quote you a price for a copy of the 2-nozzle heatsink block that he made for me, and use it with the modified nozzle mount I published here [github.com]. Or you can bolt two standard heatsink blocks together at the back of the hot end, with what were the nozzle mounting screws in one of them drilled out and tapped for the nozzles.

I'll post a photo when I have finished assembling it.

Well I have taken the plunge and ordered all of the parts, here is the full list.

From [www.think3dprint3d.com]

One Duet X4 expansion board

From Sally at RepRap

Hobbed insert

623 bearing

M3x25mm hex head screw

three M3x12mm countersunk socket screw

MR93ZZ bearing

One Nema 17 plus standard loom

One Ormerod hot end loom

2 Ormerod hot end kits

Still waiting to hear from DaveK with regard to the 2-nozzle heatsink block

I think that is all that is needed, not sure about power.

dc42 My expansion board arrived today. What is the best way to provide it with 12volt power? Will the ATX, supplied power supply, be sufficient to power a multi head machine? If not could you provide details of what you use. Thank you

Paul

Edited 1 time(s). Last edit at 07/11/2014 11:23AM by appjaws1.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Software support for multiextruder July 11, 2014 07:09AM |

Registered: 10 years ago Posts: 101 |

Hi Paul,

I posted pictures and a bit of description of my setup in this thread: [forums.reprap.org]

My hope is to collect peoples questions and early experience in that thread, so please ask and comment as much as you like

Good luck - and let us know how it goes.

Best regards,

Carsten

I posted pictures and a bit of description of my setup in this thread: [forums.reprap.org]

My hope is to collect peoples questions and early experience in that thread, so please ask and comment as much as you like

Good luck - and let us know how it goes.

Best regards,

Carsten

|

Re: Software support for multiextruder July 11, 2014 08:21AM |

Registered: 10 years ago Posts: 14,672 |

Quote

appjaws1

Well I have taken the plunge and ordered all of the parts, here is the full list.

From [www.think3dprint3d.com]

One Duet X4 expansion board

From Sally at RepRap

Hobbed insert

623 bearing

M3x25mm hex head screw

three M3x12mm countersunk socket screw

MR93ZZ bearing

One Nema 17 plus standard loom

One Ormerod hot end loom

Did you also order 2 Ormerod hot end kits?

Quote

appjaws1

dc42 My expansion board arrived today. What is the best way to provide it with 12volt power? Will the ATX, supplied power supply, be sufficient to power a multi head machine? If not could you provide details of what you use. Thank you

Paul

You might get away with using the supplied ATX PSU, however the extra load might be a little too much and it may shut down. There have been a few reports of ATX PSUs shutting down even on single-head machines. Adding extra load to the +5V output may help, because it is likely to be overvoltage on +5V that is causing the shot down.

The PSU I use is the 300W one here [www.ebay.co.uk]. I haven't powered it up with 2 extruders yet, but it should be more than adequate. The 360W and 400W versions cost only a little more. However the 300W version is fanless, and I don't know about the others.

You may also find a some designs in my repo at [github.com] useful. The PSU box covers the end of the power supply with the connections. It has cutouts for a snap-in mains inlet, a 20A connector for the 12V output, and an indicator neon - all sourced from my local Maplin. The cable I use for carrying the 12V is the second thickest loudspeaker wire that Maplin sells. The Duet enclosure accepts both X4 and the Duet boards, back to back. Also there is the nozzle mount for the dual nozzles.

Edited 1 time(s). Last edit at 07/11/2014 08:22AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Software support for multiextruder July 11, 2014 09:01AM |

Registered: 10 years ago Posts: 14,672 |

A couple of other things you will need:

* A small piece of MDF, hardboard or similar for the spacer between the heatsink block and the nozzle mount. Or you might be able to cut about 1/3 off one end of each of the pieces that comes with the hot end kit, drill a new hole in each of the remaining pieces for a mounting screw, and use those two pieces together.

* Heatshrink to cover the soldered joints between the thermistors and the connecting wires. I don't think there is enough space to use the connectors supplied, but I prefer to solder them anyway.

I'll put some more photos of my dual-head build in this thread: [forums.reprap.org].

Edited 1 time(s). Last edit at 07/11/2014 09:04AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

* A small piece of MDF, hardboard or similar for the spacer between the heatsink block and the nozzle mount. Or you might be able to cut about 1/3 off one end of each of the pieces that comes with the hot end kit, drill a new hole in each of the remaining pieces for a mounting screw, and use those two pieces together.

* Heatshrink to cover the soldered joints between the thermistors and the connecting wires. I don't think there is enough space to use the connectors supplied, but I prefer to solder them anyway.

I'll put some more photos of my dual-head build in this thread: [forums.reprap.org].

Edited 1 time(s). Last edit at 07/11/2014 09:04AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Software support for multiextruder July 11, 2014 04:11PM |

Registered: 10 years ago Posts: 780 |

Quote

dc42

The cable I use for carrying the 12V is the second thickest loudspeaker wire that Maplin sells. The Duet enclosure accepts both X4 and the Duet boards, back to back. Also there is the nozzle mount for the dual nozzles.

Davis I have found the items on Maplin site but am unsure of the cable. Was this the one you bought?

Shark Loudspeaker Connection Cable High Quality OFC S12 (priced per metre)

Will it carry the current of the ormerod plus upto 2 extra extruders and heaters do you think?

I don't want to buy the wrong cable and will build your unit after all it is tried and tested.

I think these are the other items I need:-

220-240Vac Snap In Neon Amber

10A Fused Snap In IEC Chassis Plug with Switch

Neutrik PowerCon 20A 3 Pole Mains In Line Female

Neutrik PowerCon® 20A Inlet Chassis Male

Thanks

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Software support for multiextruder July 11, 2014 04:43PM |

Registered: 10 years ago Posts: 101 |

Hi Paul,

Cable current carrying capacity is a matter of voltage drop and lifetime (temperature).

All you really need is a 2.5mm^2 (American AWG13) installation-cable. I measured the current consumption of the Ormerod a while ago. It's max current is in the vicinity of 20A . A 2.5mm^2 cable can carry between 20A and 27A (depending on how enclosed it is, ambient temperature, standards and country-rules). This is why you can find a lot of very different numbers for current capacity on the internet.

The cable you have found is about 3mm^2. No problems with the current capacity, but totally overkill on the copper-quality As you only need 1 meter, there's not a lot of money to save by going after something cheaper.

As you only need 1 meter, there's not a lot of money to save by going after something cheaper.

The biggest power-cable problem in the Ormerod is the ribbon cable for the heated bed. A couple of watts is lost in that cable - so really no big deal.

Carsten

Carsten

Cable current carrying capacity is a matter of voltage drop and lifetime (temperature).

All you really need is a 2.5mm^2 (American AWG13) installation-cable. I measured the current consumption of the Ormerod a while ago. It's max current is in the vicinity of 20A . A 2.5mm^2 cable can carry between 20A and 27A (depending on how enclosed it is, ambient temperature, standards and country-rules). This is why you can find a lot of very different numbers for current capacity on the internet.

The cable you have found is about 3mm^2. No problems with the current capacity, but totally overkill on the copper-quality

As you only need 1 meter, there's not a lot of money to save by going after something cheaper.

As you only need 1 meter, there's not a lot of money to save by going after something cheaper.The biggest power-cable problem in the Ormerod is the ribbon cable for the heated bed. A couple of watts is lost in that cable - so really no big deal.

Carsten

Carsten

|

Re: Software support for multiextruder July 11, 2014 05:22PM |

Registered: 10 years ago Posts: 14,672 |

Hi Paul,

Yes the cable I am using is Maplin OFC speaker cable, and I'm fairly sure it is the S12 variety. I don't believe in that OFC stuff, but high-current 2-core flexible cable isn't easy to come buy, and as Carsten says, you only need a metre or so of it. The important thing is that it has low enough resistance so as to have a low voltage drop. Speaker cable like the thin stuff supplied by RRP with the kit has too high a resistance for the run to the PSU, which is why I went for something thicker.

The cable I chose fits the 20A connector OK, but it's too large to fit the Duet terminals. In any case, you will need to create a junction to feed the X4 as well. I use a 2-way piece of chocolate-block connector and a very short length of the 2 cores from some 30A ring main cable to connect the speaker cable to the Duet. For the X4, I will connect another pair of conductors of ring main cable into the same chocolate block connector.

PS - ideally I would have used the Neutrik female chassis socket and male cable-mounting plug, as befits a power outlet. However, Maplin doesn't sell those, although Farnell does. The whole connector is shrouded, so it doesn't really matter.

Edited 1 time(s). Last edit at 07/11/2014 05:31PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Yes the cable I am using is Maplin OFC speaker cable, and I'm fairly sure it is the S12 variety. I don't believe in that OFC stuff, but high-current 2-core flexible cable isn't easy to come buy, and as Carsten says, you only need a metre or so of it. The important thing is that it has low enough resistance so as to have a low voltage drop. Speaker cable like the thin stuff supplied by RRP with the kit has too high a resistance for the run to the PSU, which is why I went for something thicker.

The cable I chose fits the 20A connector OK, but it's too large to fit the Duet terminals. In any case, you will need to create a junction to feed the X4 as well. I use a 2-way piece of chocolate-block connector and a very short length of the 2 cores from some 30A ring main cable to connect the speaker cable to the Duet. For the X4, I will connect another pair of conductors of ring main cable into the same chocolate block connector.

PS - ideally I would have used the Neutrik female chassis socket and male cable-mounting plug, as befits a power outlet. However, Maplin doesn't sell those, although Farnell does. The whole connector is shrouded, so it doesn't really matter.

Edited 1 time(s). Last edit at 07/11/2014 05:31PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Software support for multiextruder July 12, 2014 06:41AM |

Registered: 10 years ago Posts: 780 |

Thank you for all your help David and colsenfoto, I'm well on my way now.

David, I have been looking to modify my one piece hot end and noticed that your nozzle mount was 50mm long, looking at your scad file I changed it to be 40mm and spaced the heatsink block to nozzle mount holes a little further away, the result looked good. Was there a reason to extend the block from 40mm to 50mm?

I would prefer to use 40mm if I can get away with it.

What do you think?

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

David, I have been looking to modify my one piece hot end and noticed that your nozzle mount was 50mm long, looking at your scad file I changed it to be 40mm and spaced the heatsink block to nozzle mount holes a little further away, the result looked good. Was there a reason to extend the block from 40mm to 50mm?

I would prefer to use 40mm if I can get away with it.

What do you think?

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Software support for multiextruder July 12, 2014 07:28AM |

Registered: 10 years ago Posts: 14,672 |

Paul, the nozzle mounting screws on my heatsink block are 40mm apart so as to be outside the heatsink mounting screw holes and to clear them. My heatsink block is 46mm wide and the nozzle mount is 50mm wide, so that the holes are not too close to the edges.

There might be just enough room to put the nozzle mounting holes between each nozzle hole and the heatsink mounting hole on that side, bearing in mind that the heads of the nozzle mounting screws need to clear the brass Bowden end. If so, you could keep the width of the heatsink block and nozzle mount at 40mm. To make this easier to do, the spacing between the nozzles could be reduced from 14mm to 12mm, which would still leave 0.5mm clearance between the two tapered brass nuts at their widest points.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

There might be just enough room to put the nozzle mounting holes between each nozzle hole and the heatsink mounting hole on that side, bearing in mind that the heads of the nozzle mounting screws need to clear the brass Bowden end. If so, you could keep the width of the heatsink block and nozzle mount at 40mm. To make this easier to do, the spacing between the nozzles could be reduced from 14mm to 12mm, which would still leave 0.5mm clearance between the two tapered brass nuts at their widest points.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Software support for multiextruder July 14, 2014 07:39AM |

Registered: 10 years ago Posts: 2,472 |

Having recently begun building quadcopters as a hobby, it struck me that many of the electrical connectors and wires sold for hobbyists are low voltage high current (some models draw over 40 amps) and reasonably immune to vibration, so perfect for this application as well. Hobbyking sell a fair range of specialist high current wire by the metre (up to 8 AWG) and also various high current connectors. The wire is exceptionally flexible (huge number of strands) and insulated with silicon so it can withstand high temperatures as well. Only available as single wires, but a pair could easily be enclosed in some "mesh guard" (also sold by Hobbyking). If in the UK, make sure you select the UK warehouse if you place an order with Hobbyking, otherwise it will take weeks to arrive. There may well be other hobby shops that sell similar wire & connectors. Silicon insulation strips easily, but be careful when stripping because it is easy to cut some of the very fine wires, so strip by cutting only part way through the insulation. Link to wire & mesh: [www.hobbyking.com]

Dave

(#106)

Dave

(#106)

Sorry, only registered users may post in this forum.