Bed leveling issue - how is this even possible?

Posted by Sardi

|

Bed leveling issue - how is this even possible? June 28, 2014 06:32PM |

Registered: 10 years ago Posts: 466 |

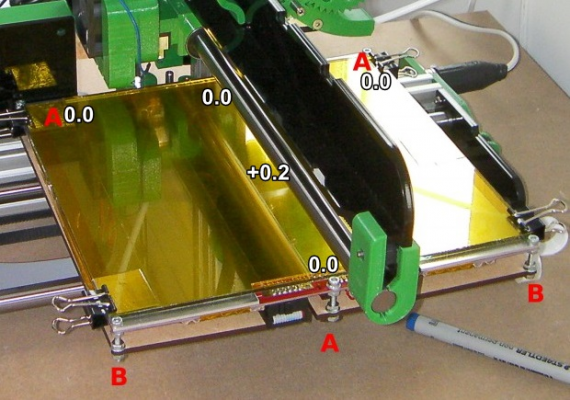

I am doing bed leveling by hand, with longer screws and extra m3 nuts, but please - how is something like this even possible??

The bed is level on 4 points, but in the middle - its +0.2 - I have to raise the nozzle by 0.2mm to get it to 0.0. I have no idea how is this even remotely possible and my glass is not bent in any way.

EDIT: Now come to think of it, I have zeroed the Z only once in that middle point, that was all way at the beginning of my prints. Ever since then I used the 4 corners, or 3 points in this case. So I am a bit confused, was it like this all the time?

Edited 1 time(s). Last edit at 06/28/2014 06:43PM by Sardi.

The bed is level on 4 points, but in the middle - its +0.2 - I have to raise the nozzle by 0.2mm to get it to 0.0. I have no idea how is this even remotely possible and my glass is not bent in any way.

EDIT: Now come to think of it, I have zeroed the Z only once in that middle point, that was all way at the beginning of my prints. Ever since then I used the 4 corners, or 3 points in this case. So I am a bit confused, was it like this all the time?

Edited 1 time(s). Last edit at 06/28/2014 06:43PM by Sardi.

|

Re: Bed leveling issue - how is this even possible? June 28, 2014 09:03PM |

Registered: 10 years ago Posts: 378 |

Even though it is possible to bend glass a little bit, I don't think the glass is actually curved (float glass is usually ridiculously close to perfectly flat).

Could be that the X-arm is flexing a little bit from the weight of the hot-end (the acrylic plastic, or the Z extrusion moving a bit relative to the Y extrusion). That would mean the hotend is actually moving along a curved path and not a straight line, which would make it seem just like the glass was not flat. However, I would think that that effect would cause it to be in the other direction; the hotend "drooping down" at the far end (high X) would make it be "higher up" in the middle which would make the glass seem like it is "lower down".

Another cause could be the MDF bed support (which a lot of us have been having problems with). When you level the bed with a piece of paper or something between the bed and the hotend, you do put some pressure on the bed, and that can cause the whole thing to move. Is it the same in other locations (Y near either edge of the bed)?

Could be that the X-arm is flexing a little bit from the weight of the hot-end (the acrylic plastic, or the Z extrusion moving a bit relative to the Y extrusion). That would mean the hotend is actually moving along a curved path and not a straight line, which would make it seem just like the glass was not flat. However, I would think that that effect would cause it to be in the other direction; the hotend "drooping down" at the far end (high X) would make it be "higher up" in the middle which would make the glass seem like it is "lower down".

Another cause could be the MDF bed support (which a lot of us have been having problems with). When you level the bed with a piece of paper or something between the bed and the hotend, you do put some pressure on the bed, and that can cause the whole thing to move. Is it the same in other locations (Y near either edge of the bed)?

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 03:57AM |

Registered: 10 years ago Posts: 466 |

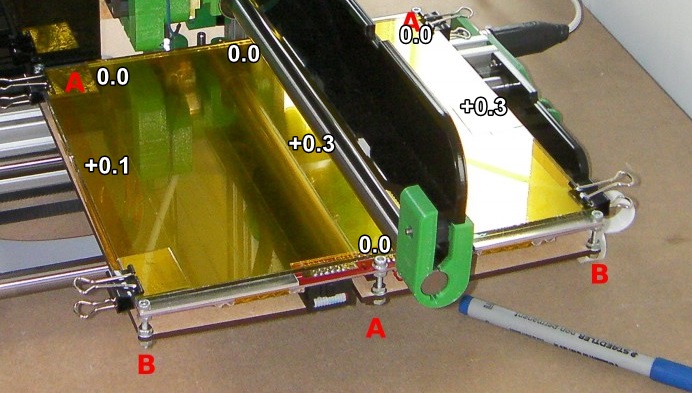

I have measured it at Y length and it looks like this

When I zero the Z, I do not put any pressure to the glass, I have a longer piece of paper so the part that I am holding is in the air

However, the MDF bed plane is awfull and does not help at all. I am thinking about moving 2 foldback clips to the middle of the glass.

I am not even sure where should I zero the Z to even think about having something printed.. In the middle (x100 y100) or at one of the white markers..

Edited 1 time(s). Last edit at 06/29/2014 04:09AM by Sardi.

When I zero the Z, I do not put any pressure to the glass, I have a longer piece of paper so the part that I am holding is in the air

However, the MDF bed plane is awfull and does not help at all. I am thinking about moving 2 foldback clips to the middle of the glass.

I am not even sure where should I zero the Z to even think about having something printed.. In the middle (x100 y100) or at one of the white markers..

Edited 1 time(s). Last edit at 06/29/2014 04:09AM by Sardi.

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 04:08AM |

Registered: 10 years ago Posts: 378 |

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 04:12AM |

Registered: 10 years ago Posts: 466 |

Quote

jstck

What I meant was that even the slight pressure from the hotend nozzle on the paper can be enough to slightly move the bed.

Well, I go for the -0.1 to check that it grips the paper, and that at 0.0 the nozzle does not grip the paper. But if that is enough to move the bed then Im throwing this printer away asap.

It seems like something is bulged here, and to the right side. Dont know what or how, but I think the X rod is still functioning ok, without bending.

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 04:14AM |

Registered: 10 years ago Posts: 14,672 |

You may have a slight bend in your X plate, as I had. This causes the distance between the X plate and the ground rod to vary slightly, which causes the head angle and hence the nozzle height to vary with x-position.

Even if the x-plate is initially flat, the bowden tube exerts a horizontal force on the head that varies with x-position. If you have the extruder hung on the middle slot, then this force is greatest near the middle of the x-axis, which causes the effect you observe.

I've considered adding additional bed compensation to allow for this effect, which several users have observed.

I have now installed Davek's aluminium x-plate and rib, which provides greater rigidity.

Edited 1 time(s). Last edit at 06/29/2014 04:15AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Even if the x-plate is initially flat, the bowden tube exerts a horizontal force on the head that varies with x-position. If you have the extruder hung on the middle slot, then this force is greatest near the middle of the x-axis, which causes the effect you observe.

I've considered adding additional bed compensation to allow for this effect, which several users have observed.

I have now installed Davek's aluminium x-plate and rib, which provides greater rigidity.

Edited 1 time(s). Last edit at 06/29/2014 04:15AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 04:20AM |

Registered: 10 years ago Posts: 466 |

Quote

dc42

Even if the x-plate is initially flat, the bowden tube exerts a horizontal force on the head that varies with x-position. If you have the extruder hung on the middle slot, then this force is greatest near the middle of the x-axis, which causes the effect you observe.

My extruder is on the far edge of the X rod, near the RepRapPro logo.

Where do you suggest I zero the Z? In the middle (x100 y100) or at the corners?

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 04:23AM |

Registered: 10 years ago Posts: 776 |

Hi, I can very seriously recommend one of my aluminium bed support plates, it really is very difficult near impossible to align the bed to the accuracy needed when using the MDF one.

The hump in the middle can be caused by the heated bed sometimes, get the glass off and using a steel rule and thin paper, test the heater plate for flatness.

Glass can flex easily by 0.2mm this is a very small amount, also make sure the paper squares go right under the clips as if not it can halo force the middle of the glass up when the clips are applied. Try taking your measurements again with the clips off.

The pressure from the Bowden tube and filament it carries is at it's maximum when the head is in line with the extruder drive, I.e.in the middle of the bed when the extruder drive is mounted centrally. This can flex the acrylic x arm down by a small amount. Try moving the extruder to the mount nearest the z axis support I.e.inboard position and retake your measurements.

This is all academic anyway as your settings WILL change very soon due to that MDF bed support, you really need to lose it for reliable results I'm afraid, every user that has one of the aluminium supports has reported excellent improvements, it really transforms the machine.

I also do an aluminium x-arm kit which firms up the head travel by getting rid of the acrylic arm, this seems to stop the head drooping or twisting and also makes it easier to mount multiple heads.

Dave

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

The hump in the middle can be caused by the heated bed sometimes, get the glass off and using a steel rule and thin paper, test the heater plate for flatness.

Glass can flex easily by 0.2mm this is a very small amount, also make sure the paper squares go right under the clips as if not it can halo force the middle of the glass up when the clips are applied. Try taking your measurements again with the clips off.

The pressure from the Bowden tube and filament it carries is at it's maximum when the head is in line with the extruder drive, I.e.in the middle of the bed when the extruder drive is mounted centrally. This can flex the acrylic x arm down by a small amount. Try moving the extruder to the mount nearest the z axis support I.e.inboard position and retake your measurements.

This is all academic anyway as your settings WILL change very soon due to that MDF bed support, you really need to lose it for reliable results I'm afraid, every user that has one of the aluminium supports has reported excellent improvements, it really transforms the machine.

I also do an aluminium x-arm kit which firms up the head travel by getting rid of the acrylic arm, this seems to stop the head drooping or twisting and also makes it easier to mount multiple heads.

Dave

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 04:29AM |

Registered: 10 years ago Posts: 101 |

I had exactly the same problem. As already stated, it's the black acrylic that is not straight. Changing it to aluminium solved the problem - although I had to fiddle a little bit to get the aluminium totally straight also.

In my opinion, there's no way you can get the acrylic straight enough, as it is bending and twisting in several directions.

Best regards,

Carsten

In my opinion, there's no way you can get the acrylic straight enough, as it is bending and twisting in several directions.

Best regards,

Carsten

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 05:03AM |

Registered: 10 years ago Posts: 466 |

It seems to me that this printer is a lot of work. Ive bought it for home fun, but must admit Ive spent more time tuning it then printing. I already have DC42s sensor, modified heat sinks, Z rod gears, extruder gears.. and now I need an aluminium bed plane and maybe aluminium X rib... Does this ever end?

I know this is a kit, but when you need to purchase and print a bunch of additional parts for it to work properly, than it just isnt worth the money or the time. Will think about daveks aluminium plate, but then I can just hope that this is the last update Ill need.

Ive literllay spent more time fixing this machine than enjoying the prints.

OT:

I have zeroed the Z in the middle (x100 y100) and it seems to do just fine. For now at least.

I know this is a kit, but when you need to purchase and print a bunch of additional parts for it to work properly, than it just isnt worth the money or the time. Will think about daveks aluminium plate, but then I can just hope that this is the last update Ill need.

Ive literllay spent more time fixing this machine than enjoying the prints.

OT:

I have zeroed the Z in the middle (x100 y100) and it seems to do just fine. For now at least.

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 08:01AM |

Registered: 10 years ago Posts: 776 |

Yes, many buyers have mentioned these points but personally I accepted them as 3d printing is still pretty cutting edge stuff and to be able to do it home for what is still not too much money is pretty exciting I think.

Yes, the z rod and standard nut is a very poor design, the wide brass nut is an instant fix and should really be in the kit.

The probe, well, I never managed to get mine to work so I got the mk1 version from dc42 and I have just ordered the mk2 version as it addresses the shortcomings of the mk1 probe.

I took up the idea of producing the aluminium parts as metal engineering is my main hobby and I have access to suppliers and machinery that enable me to do this, I could see the shortcomings in the design and was able to offer an upgrade, pretty much the same as dc42 with the probe kits and firmware etc.

Yes there are fully working machines available but the cost is still way more than an ormerod with all the upgrades included. They are also larger in size so need more space. For the money I think the ormerod is still pretty competitive and if you only printed small parts would likely work as it comes, but when you want to do bigger things the problems arise and some adjustment is needed either by constant fiddling or by upgrades.

I have only fitted my machine with my aluminium parts and dc42s probe, I am still running the standard cooling duct and noisy fan, I also fitted the herringbone extruder gears as I liked the look of them

These machines are good but good does not come as standard I feel,

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Yes, the z rod and standard nut is a very poor design, the wide brass nut is an instant fix and should really be in the kit.

The probe, well, I never managed to get mine to work so I got the mk1 version from dc42 and I have just ordered the mk2 version as it addresses the shortcomings of the mk1 probe.

I took up the idea of producing the aluminium parts as metal engineering is my main hobby and I have access to suppliers and machinery that enable me to do this, I could see the shortcomings in the design and was able to offer an upgrade, pretty much the same as dc42 with the probe kits and firmware etc.

Yes there are fully working machines available but the cost is still way more than an ormerod with all the upgrades included. They are also larger in size so need more space. For the money I think the ormerod is still pretty competitive and if you only printed small parts would likely work as it comes, but when you want to do bigger things the problems arise and some adjustment is needed either by constant fiddling or by upgrades.

I have only fitted my machine with my aluminium parts and dc42s probe, I am still running the standard cooling duct and noisy fan, I also fitted the herringbone extruder gears as I liked the look of them

These machines are good but good does not come as standard I feel,

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 08:53AM |

Registered: 10 years ago Posts: 466 |

You do have good points there for Ormerod. Ormerod is good when it comes to basic price + upgrades VS next rival (what I think is Ultimaker 2 at 2000€, without option for multiple extrusion). I had fun and anger putting it together from scratch, and I use it at home, mostly printing smaller parts. All I dont want to is to have to adjust something every few prints because something has moved from set position.

That is very good that you used your hobby to improve this machine

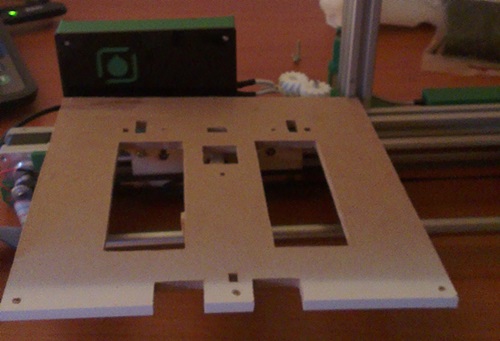

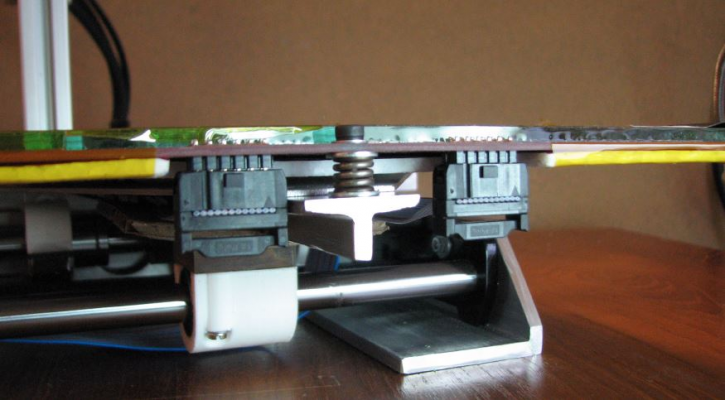

I have a friend that works with wood, and he had an idea to make the bed out of MDA but at least 0.5cm thick, and also thicker Y axis cross rib, this is what he brought me today:

This is the prototype, so we will see soon how does it work cause I dont have the time to print and align the Z now. Just by the feel of it, this could work excellent, its really light and stiff and the cross rib does not let the bed "fall" an inch to the side.

That is very good that you used your hobby to improve this machine

I have a friend that works with wood, and he had an idea to make the bed out of MDA but at least 0.5cm thick, and also thicker Y axis cross rib, this is what he brought me today:

This is the prototype, so we will see soon how does it work cause I dont have the time to print and align the Z now. Just by the feel of it, this could work excellent, its really light and stiff and the cross rib does not let the bed "fall" an inch to the side.

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 10:19AM |

Registered: 10 years ago Posts: 776 |

Nice ideas with the wood there, should be a whole lot better for you.

Don't glue the parts together though, you would find it very hard to fit parts under the bed if were glued, although glueing would help with rigidity.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Don't glue the parts together though, you would find it very hard to fit parts under the bed if were glued, although glueing would help with rigidity.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 10:42AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Sardi

...I have a friend that works with wood, and he had an idea to make the bed out of MDA but at least 0.5cm thick, and also thicker Y axis cross rib, this is what he brought me today:

My take: forget about 4-point adjustment of the glass, forget about the bed all together, the glass is the bed, go for the most direct line between the bearings and the adjusting screws, go for 3-point adjustment, the y-rib is OK IMHO, the support of the y-cross-rib not so much and should be extended out to the corners, here's a cheap fix, no it will not be as solid as Dave's alu upgrade, yes is will bend down a little if you put any force on the inner corners, but it will spring back to same position and not move over time like the silly MDF:

Sagging MDF, the Q & D fix that anyone can do

[forums.reprap.org]

..if the glass appear twisted (e.g. P1 Z0.0, P2 Z0.0, P3 Z-0.2, P4 Z0.2), adjust your y-end-plates:

[forums.reprap.org]

..if the glass do not appear flat, change your x-rib for a stiffer one, I see no other way to fix the problems with the fluffy acrylic x-rib and the force from the bowden cable:

"..if your bed is perfectly flat, then you are measuring your reference point.."

[forums.reprap.org]

The visual:

[forums.reprap.org]

the glass may move a bit with temperature but not much:

"The heat will make the glass bulge"

[forums.reprap.org]

Erik

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 10:49AM |

Registered: 9 years ago Posts: 176 |

I found that where the X-axis arm and horizontal support tab together, the tab was out by .? of a mm - this caused the arm to be ever so slightly bowed which causes the appearance of a curve to the plate. Looking down the x-axis I could see that it was slightly curved, so I took it off and filed the tab down slightly so it fitted better and resolved my issues.

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 11:13AM |

Registered: 10 years ago Posts: 466 |

Quote

ormerod168

Notice how the force of the tube is at its hight in the middle of the bed

X25 Z0.0

X50 Z0.1

X75 Z0.1

X100 Z0.2

X125 Z0.2

X150 Z0.1

X175 Z0.05

X200 Z0.0

So my starting point is no longer to make the bed stable and flat, it is to make the x-axis ditto

..or to rewrite spoon-boys Matrix quote:

"Then you'll see, that it is not the glass that bends, it is only your x-axis."

Erik

Exactly my problem! I never believed that the glass warped or something.

So does this mean the X-axis needs replacement?

Maybe it could go ok if I center the Z in the middle (x100 y100) now that I am sure that the bed is level, and that the whole bed section is more massive and rigid.

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 11:42AM |

Registered: 10 years ago Posts: 14,672 |

I recall that someone reported glueing the x-plate and x-rib together (presumably when it was not under load) and reported that it reduced flexing of the x-plate.

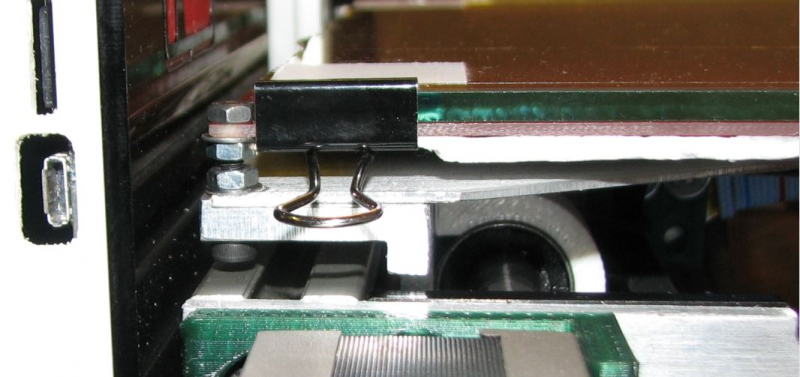

Another thing I did was to put a nut and some washers between the x-carriage and the x-runner bearing, and then to use a countersunk screw instead of a cap-headed screw to prevent the head fouling on the extruder motor. I think this helps in two ways: (1) the bearing runs closer to where the x-plate is supported by the x-rib, so the x-plate will bend less from the force exerted by the bearing; (2) a given sideways movement of the x-runner bearing will cause a little less vertical nozzle movement.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Another thing I did was to put a nut and some washers between the x-carriage and the x-runner bearing, and then to use a countersunk screw instead of a cap-headed screw to prevent the head fouling on the extruder motor. I think this helps in two ways: (1) the bearing runs closer to where the x-plate is supported by the x-rib, so the x-plate will bend less from the force exerted by the bearing; (2) a given sideways movement of the x-runner bearing will cause a little less vertical nozzle movement.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 02:53PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Sardi

Exactly my problem! I never believed that the glass warped or something.

So does this mean the X-axis needs replacement?

You could try to straighten the x-rib, super glue the x-axis-plate and the x-rib together in a perfectly straight position (I think it was Kwikius that recommended super glue)...then move the extruder from the x-rib to e.g. the z-extrusion in a position that keep the moves of the bowden cable along the x-rib

An all over bed probing/compensation would ditto fix the problem in getting the first layer to stick but would leave the bottom of the print all but flat

My choice would be to change the acrylic rib for the alu one

Quote

Maybe it could go ok if I center the Z in the middle (x100 y100) now that I am sure that the bed is level, and that the whole bed section is more massive and rigid.

Yes, smaller things will then print just fine and I did manage to print bigger parts like the x-motor-bracket with the acrylic x-rib, its all about getting the first layer to stick, the trick is to zero the nozzle at the middle of the bed and as low as possible - even with a rock solid setup it makes sense to zero at the middle as the glass will sag a bit because of the greater heat loss from the top

My bed leveling routine - I do not adjust corners, the inner corners cannot move because of the solid alu y-cross-rib that go all the way to and carry the adjustment screws, the outer ones follow the inner ones through the stiffness of the glass (4mm) - I do not adjust anything between prints, only when changing the glass

First point at X35 Y100, that will put the nozzle just over the inner smooth y-rod, the point that varies the least while adjusting the outer screw, I zero the nozzle G92 Z0 on a piece of paper

Second point at X180 Y100, lower the nozzle to Z0 and raise/lower the glass with the outer adjustment screw til I get the same feel on same paper

Then, just before a print and with the bed at printing temp, I zero the nozzle at the middle of the bed just to make sure

BTW, here's a nice bed leveling test file:

[www.youmagine.com]

Erik

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 03:04PM |

Registered: 9 years ago Posts: 138 |

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 03:33PM |

Registered: 10 years ago Posts: 1,230 |

Quote

muggi

Hi ormerod168,

nice alu y-rib and Y-cross rib.

I want these...... any hint where to get this?

Hi muggi

Its home made, a trip to the scrapyard will get you the materials, then you will need a hacksaw, some drills and files a lot of time..and any old milling machine would be of great help

But you can do fine with less, the most important thing is to extend the y-cross-rib and make it stronger all the way out to the adjusting screws

Erik

|

Re: Bed leveling issue - how is this even possible? June 29, 2014 10:38PM |

Registered: 10 years ago Posts: 859 |

Hi, Ally beds are the way to go. I used a composit board ally/plastic, and it was great till I stuck the hotend to a print, then raised the hotend COLD.....

Afterwards, I had a 3mm bed in the table....

My fault.

As for your pics of the readings... Use a DTI to set up your table, its much better than messing with feeler gauges..

Also, you have a bend in either your glass or the Heated Bed....

In which case, due to your readings.... Only use two clips in the Middle..... Then re measure....

When I first leveled my bed I found that the main rear bed frame was crooked....

The bearing securing bolt holes aren't 100%. Remove the heated bed, and measure the sub-bed.... Get that level, and it makes it easy...

Hope that helps...

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Afterwards, I had a 3mm bed in the table....

My fault.

As for your pics of the readings... Use a DTI to set up your table, its much better than messing with feeler gauges..

Also, you have a bend in either your glass or the Heated Bed....

In which case, due to your readings.... Only use two clips in the Middle..... Then re measure....

When I first leveled my bed I found that the main rear bed frame was crooked....

The bearing securing bolt holes aren't 100%. Remove the heated bed, and measure the sub-bed.... Get that level, and it makes it easy...

Hope that helps...

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Bed leveling issue - how is this even possible? June 30, 2014 04:06AM |

Registered: 10 years ago Posts: 466 |

Erik, thank you for a thural explanation, but this is what confuses me the most

I find it very hard to belive that this long piece of acryl would bend only in the middle. I find it more logical for it to bend on the far end and downwards, but only in the middle? That is what confuses me.

Couldnt it be that the smooth rod, on wich the whole weight of the hot end sits, gets bent in the middle?

ps my extruder is hooked on the last slot, near the far end.

Edited 2 time(s). Last edit at 06/30/2014 04:12AM by Sardi.

Quote

ormerod168

My choice would be to change the acrylic rib for the alu one

I find it very hard to belive that this long piece of acryl would bend only in the middle. I find it more logical for it to bend on the far end and downwards, but only in the middle? That is what confuses me.

Couldnt it be that the smooth rod, on wich the whole weight of the hot end sits, gets bent in the middle?

ps my extruder is hooked on the last slot, near the far end.

Edited 2 time(s). Last edit at 06/30/2014 04:12AM by Sardi.

|

Re: Bed leveling issue - how is this even possible? June 30, 2014 09:14AM |

Registered: 10 years ago Posts: 378 |

The rod _could_ be bent, but those are usually machined with pretty high precision, and darned stiff. It won't move anywhere near 0.2mm under the weight of the hotend, for sure. If it is not quite straight, you could test that by rolling it on a flat surface, or just rotating it 180 degrees in place and see if the error gets "inverted". I'm willing to bet it won't.

One thing that would have the same effect though is if the acrylic is a bit warped or uneven. That would make the bearing on the back of the x carriage to move relative to the rod, and that causes the carriage to rotate, lifting or dropping the nozzle. That bearing also pushes on the X arm with some force (maybe not quite the weight of the hotend, but something nearby). The acrylic would be the most "bendy" from that pressure in the middle, where it's furthest from where it is anchored to the rod.

One thing that would have the same effect though is if the acrylic is a bit warped or uneven. That would make the bearing on the back of the x carriage to move relative to the rod, and that causes the carriage to rotate, lifting or dropping the nozzle. That bearing also pushes on the X arm with some force (maybe not quite the weight of the hotend, but something nearby). The acrylic would be the most "bendy" from that pressure in the middle, where it's furthest from where it is anchored to the rod.

|

Re: Bed leveling issue - how is this even possible? June 30, 2014 01:25PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Sardi

..I find it very hard to belive that this long piece of acryl would bend only in the middle. I find it more logical for it to bend on the far end and downwards, but only in the middle? That is what confuses me.

As jstck writes, the middle is the most unsupported part, bend may not be the right expression, "twisting from the sideway forces" may be better

the profile of the acrylic parts combined has vertical and horizontal strength but not much twisting strength, you can easily twist the profile to either side if you grab the x-idler-bracket with two fingers (the printed x-idler-bracket and x-motor-bracket is not able to bite into the smooth rod no matter how hard you fasten the screw)

..so no surprise for me that it twist a bit at the middle, if you look at the acrylic part from the x-idler-bracket end you have the extruder 250g, hanging out from top right, that's a clockwise twist - the hotend 447g hanging on the bearing that run along the bottom right, that's also a clockwise twisting force

..and then you have the push between extruder and hotend from the bowden cable but that (92g) is included in the 447g

Quote

Couldnt it be that the smooth rod, on wich the whole weight of the hot end sits, gets bent in the middle?

Everything will give more or less, yes it carries the weight of the hotend but that weight is no match for the smooth rod, my guess is it will bend less than 0.01mm, and not straight down, half sideways as there is leverage 1:1 with the x-carriage bearing

Quote

ps my extruder is hooked on the last slot, near the far end.

That would mean less twisting forces, won't be better if you mount it in the middle then

Erik

|

Re: Bed leveling issue - how is this even possible? June 30, 2014 01:34PM |

Registered: 10 years ago Posts: 1,230 |

Quote

jstck

..The rod _could_ be bent, but those are usually machined with pretty high precision, and darned stiff. It won't move anywhere near 0.2mm under the weight of the hotend, for sure. If it is not quite straight, you could test that by rolling it on a flat surface, or just rotating it 180 degrees in place and see if the error gets "inverted". I'm willing to bet it won't...

Agree, I checked all with micro meter, lathe and DTI before assembly and all was true and measurements was spot on 11.99mm - a quality product IMHO

Erik

|

Re: Bed leveling issue - how is this even possible? June 30, 2014 02:09PM |

Registered: 10 years ago Posts: 776 |

I've just been messing with my spare acrylic parts and it does take very little force to twist it such small amounts, I'm not drawing it out so I can calculate the leverage but I think the bearing runner to round rod distance is smaller than the round rod to extruder distance so if you were seeing say 0.2mm variation in extruder height, the acrylic may only have to twist less than 0.1mm to create it.

The good thing with the aluminium arm is that if care is taken to carefully fine tune fit of the rib to the arm, it can be assembled in a very straight fashion, the good side then is that it will not change unless a very large force is exerted on it.

We are dealing with very fine tolerances here. I have found that a variation of 0.1mm makes little difference to the first layer, much more and it either does not stick or the extruded material builds up round the nozzle and blobs everywhere.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

The good thing with the aluminium arm is that if care is taken to carefully fine tune fit of the rib to the arm, it can be assembled in a very straight fashion, the good side then is that it will not change unless a very large force is exerted on it.

We are dealing with very fine tolerances here. I have found that a variation of 0.1mm makes little difference to the first layer, much more and it either does not stick or the extruded material builds up round the nozzle and blobs everywhere.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Bed leveling issue - how is this even possible? June 30, 2014 03:04PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Davek0974

..The good thing with the aluminium arm is that if care is taken to carefully fine tune fit of the rib to the arm, it can be assembled in a very straight fashion..

One could also fine tune and super glue the acrylic part, give it a preload, a twist in opposite direction to compensate for the weight but would take a lot of time with trail and error and yet only suit the present weight and location of extruder - I would rather super glue the parts together in a perfectly straight position, move the extruder to another position and live with rest of the twist, gluing the part together will give more strength against twisting forces, but how much I do not know

The aluminium x-rib is money well spend imho

Erik

|

Re: Bed leveling issue - how is this even possible? July 08, 2014 05:15PM |

Registered: 10 years ago Posts: 466 |

I have been away from my laptop for a while, and I just first want to say THANK YOU to all that participated in this topic. I had a bunch of it to read, and now things are much clearer for me.

So yes, my X-Rib is bent. I have tried a couple of different ideas in measuring everything possible with bed/hot end combination, and the X-Rib is def bent. Its 0.0mm on the far ends of the glass X190 (X20) Y100, as soon as I move the head towards the middle it gets to +0.1mm, then +0.2mm, and back to +0.1mm and again to 0.0mm at the edge.

My bed is completely level now, as I have replaced the faulty MDF board with, also from wood, but a stiffer, better bed and have adjusted it via 3 screws.

Curently I use only the middle of the bed for printing, as I do mostly smaller parts, but will for sure order Daveks alu x-rib just to be at peace in the future.

Again, thanks to everyone in this thread. Hope it will help others too.

Edited 1 time(s). Last edit at 07/08/2014 05:17PM by Sardi.

So yes, my X-Rib is bent. I have tried a couple of different ideas in measuring everything possible with bed/hot end combination, and the X-Rib is def bent. Its 0.0mm on the far ends of the glass X190 (X20) Y100, as soon as I move the head towards the middle it gets to +0.1mm, then +0.2mm, and back to +0.1mm and again to 0.0mm at the edge.

My bed is completely level now, as I have replaced the faulty MDF board with, also from wood, but a stiffer, better bed and have adjusted it via 3 screws.

Curently I use only the middle of the bed for printing, as I do mostly smaller parts, but will for sure order Daveks alu x-rib just to be at peace in the future.

Again, thanks to everyone in this thread. Hope it will help others too.

Edited 1 time(s). Last edit at 07/08/2014 05:17PM by Sardi.

|

Re: Bed leveling issue - how is this even possible? July 09, 2014 07:33AM |

Registered: 10 years ago Posts: 2,472 |

If you are replacing things with thicker wood rather than metal, plywood would be a far better choice than MDF. Not only is it stiffer and stronger, but will last longer and not absorb moisture to nearly the same extent. It can be sealed with a coat of epoxy or even covered with very thin glass fibre cloth (put on with epoxy in preference to polyester resin). Wood is easier to work than metal if you only have hand tools, but I think aluminium is the best choice.

Dave

(#106)

Dave

(#106)

|

Re: Bed leveling issue - how is this even possible? June 12, 2015 07:27PM |

Registered: 11 years ago Posts: 1,277 |

Same here and I have tried everything but after 1.5 years and thousands of hours to get this thing to work I give it up today. Just too many issues to have fun with it imo and I don't care if it is PEBKAC or there really are issues in the printer I haven't printed enough to actually have fun. All aluminum I3 Rework with mods galore and nothing fixed the 4 corner ball buster so it isn't just the Ormerod that has these issues.Quote

Sardi

It seems to me that this printer is a lot of work. Ive bought it for home fun, but must admit Ive spent more time tuning it then printing. I already have DC42s sensor, modified heat sinks, Z rod gears, extruder gears.. and now I need an aluminium bed plane and maybe aluminium X rib... Does this ever end?

I know this is a kit, but when you need to purchase and print a bunch of additional parts for it to work properly, than it just isnt worth the money or the time. Will think about daveks aluminium plate, but then I can just hope that this is the last update Ill need.

Ive literllay spent more time fixing this machine than enjoying the prints.

OT:

I have zeroed the Z in the middle (x100 y100) and it seems to do just fine. For now at least.

Edited 1 time(s). Last edit at 06/12/2015 07:39PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

Sorry, only registered users may post in this forum.