Laser cut Aluminium X-Arm & Rib kits....

Posted by Davek0974

|

Re: Laser cut Aluminium X-Arm & Rib kits.... August 25, 2016 12:34PM |

Registered: 10 years ago Posts: 776 |

Hi, its a joint effort as a clip needs printing too, have a look here.....

3d Print And Stuff

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

3d Print And Stuff

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... August 25, 2016 01:16PM |

Registered: 8 years ago Posts: 30 |

|

Re: Laser cut Aluminium X-Arm & Rib kits.... August 25, 2016 01:29PM |

Registered: 10 years ago Posts: 776 |

Hi the printed part is the bit i don't supply  I do the aluminium parts.

I do the aluminium parts.

I can only suggest contacting the guy that runs the site linked.

Dave

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

I do the aluminium parts.

I do the aluminium parts.I can only suggest contacting the guy that runs the site linked.

Dave

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... August 26, 2016 05:41AM |

Registered: 9 years ago Posts: 189 |

Quote

ayudtee

Thanks Davek0974. May I ask for a copy of the stl file for the printed part?

If you were to make replacement Y axis rod holders in aluminium for the Ormerod 2 I am interested.

Hi

Thanks for your order, Please find attached the file for holding the bearing in place. FrontBearingClip.stl

The part will need a M3 x 18mm hex screw and should line up with current nut/washer cut-out upon the metal part near the front bearing loop.

If anyone else is interested in replacing their MDF Bed Support platform for an Ormerod 2, just follow the link below

[www.3dprintandstuff.co.uk]

Thanks

Chris

Supporting 3D Printers with Parts and Build services.

Printer: Ormerod 2 (528.4) Duel extruder set-up with Aluminium X-Rib, RRPro Firmware v1.11-ch (2016-04-08)

|

Re: Laser cut Aluminium X-Arm & Rib kits.... October 12, 2016 06:46AM |

Registered: 10 years ago Posts: 776 |

Just a little bump to let newcomers know the upgrades are still available

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... October 20, 2016 09:00AM |

Registered: 9 years ago Posts: 1,699 |

Hi Dave,

I am afraid that the shim does not stick very well. At the moment I am maintaining the y-axis and the heated bed of my Ormerod 2 (The Ormerod 1 has problems with one stepper motor) and one end is nearly getting separated from the aluminium.

Best regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I am afraid that the shim does not stick very well. At the moment I am maintaining the y-axis and the heated bed of my Ormerod 2 (The Ormerod 1 has problems with one stepper motor) and one end is nearly getting separated from the aluminium.

Best regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... October 20, 2016 09:03AM |

Registered: 10 years ago Posts: 14,672 |

The shim stuck very well for me, however I cleaned the arm surface with isopropanol before sticking it on - as I always do before gluing almost anything.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Laser cut Aluminium X-Arm & Rib kits.... October 20, 2016 09:37AM |

Registered: 10 years ago Posts: 776 |

This was one of the reasons I stopped supplying the shim.

Provided your runner bearing is in good condition and turns freely, the shim is not needed on the aluminium arms.

The only failure to - date was caused by a jammed runner bearing.

As DC42 has said - the metal must be spotlessly clean before applying or it will fail.

I can send you out another length of shim if you like, UK only, PM me the details if wanted.

Dave

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Provided your runner bearing is in good condition and turns freely, the shim is not needed on the aluminium arms.

The only failure to - date was caused by a jammed runner bearing.

As DC42 has said - the metal must be spotlessly clean before applying or it will fail.

I can send you out another length of shim if you like, UK only, PM me the details if wanted.

Dave

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... October 21, 2016 02:42AM |

Registered: 9 years ago Posts: 1,699 |

Good morning.

many thanks for the replies and the offer. I cleaned the arm with brake cleaner (without Acetone) like I always do. However the shim is sticking but it is weak.

After I already got one failure I would prefer to use the metal ruler instead. On the other hand the Ormerod 2 uses another kind of bearing which seems to run better.

During the assembly I recognized that the x-carriage will soon fail of my MK2 (I could not get the screws really tight for the hotend) so I will see when I maintain the x-axis what I will do.

Dave, now I understand why you did not deliver the shim anymore.

Best regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

many thanks for the replies and the offer. I cleaned the arm with brake cleaner (without Acetone) like I always do. However the shim is sticking but it is weak.

After I already got one failure I would prefer to use the metal ruler instead. On the other hand the Ormerod 2 uses another kind of bearing which seems to run better.

During the assembly I recognized that the x-carriage will soon fail of my MK2 (I could not get the screws really tight for the hotend) so I will see when I maintain the x-axis what I will do.

Dave, now I understand why you did not deliver the shim anymore.

Best regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... January 12, 2017 01:09PM |

Registered: 10 years ago Posts: 776 |

Just a reminder that the machined aluminium parts for Mk1 and Mk2 machines are still available

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... January 12, 2017 04:53PM |

Registered: 8 years ago Posts: 164 |

|

Re: Laser cut Aluminium X-Arm & Rib kits.... January 12, 2017 05:05PM |

Registered: 9 years ago Posts: 638 |

|

Re: Laser cut Aluminium X-Arm & Rib kits.... January 12, 2017 05:10PM |

Registered: 8 years ago Posts: 164 |

|

Re: Laser cut Aluminium X-Arm & Rib kits.... January 13, 2017 02:16AM |

Registered: 10 years ago Posts: 776 |

Yep thats the one

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... January 13, 2017 04:30AM |

Registered: 10 years ago Posts: 1,230 |

Quote

0x0000

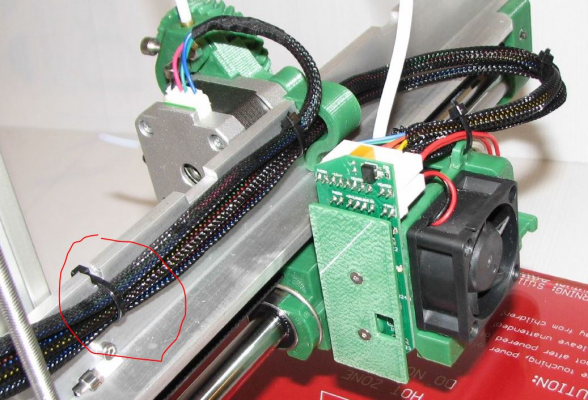

Ha, that makes total sense! It will solve a lot of my cable management problems

Erik

|

Re: Laser cut Aluminium X-Arm & Rib kits.... February 23, 2017 10:10AM |

Registered: 10 years ago Posts: 776 |

Just a little bump to let newcomers know that the Mk1 & Mk2 upgrade parts are still available

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... February 23, 2017 10:57AM |

Registered: 10 years ago Posts: 19 |

|

Re: Laser cut Aluminium X-Arm & Rib kits.... February 23, 2017 01:00PM |

Registered: 10 years ago Posts: 776 |

Excellent, thanks for the feedback.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... March 13, 2017 04:36PM |

Registered: 10 years ago Posts: 19 |

Hi Dave

Are you able to help me with some of that shim tape as I am seeing some wear starting to appear already on the arm. (my bearing is damaged and i am awaiting some replacements)

I am willing to pay for the cost of postage and materials.

Thanks

Edited 1 time(s). Last edit at 03/13/2017 04:36PM by trilby.

Are you able to help me with some of that shim tape as I am seeing some wear starting to appear already on the arm. (my bearing is damaged and i am awaiting some replacements)

I am willing to pay for the cost of postage and materials.

Thanks

Edited 1 time(s). Last edit at 03/13/2017 04:36PM by trilby.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... March 13, 2017 04:50PM |

Registered: 10 years ago Posts: 776 |

send me an address via email or pm and i'll send a bit off.

Dave

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Dave

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... March 17, 2017 04:34AM |

Registered: 10 years ago Posts: 19 |

|

Re: Laser cut Aluminium X-Arm & Rib kits.... March 17, 2017 05:12AM |

Registered: 10 years ago Posts: 776 |

Thanks for the update

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... March 17, 2017 03:15PM |

Registered: 7 years ago Posts: 28 |

|

Re: Laser cut Aluminium X-Arm & Rib kits.... June 03, 2017 02:14PM |

Registered: 10 years ago Posts: 776 |

Parts are still available

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... June 09, 2017 06:18AM |

Registered: 9 years ago Posts: 189 |

Quote

Davek0974

Parts are still available

Same here; As I still have a few Y-axis bed support platforms for the Ormerod 2 printer

[www.3dprintandstuff.co.uk]

Supporting 3D Printers with Parts and Build services.

Printer: Ormerod 2 (528.4) Duel extruder set-up with Aluminium X-Rib, RRPro Firmware v1.11-ch (2016-04-08)

|

Re: Laser cut Aluminium X-Arm & Rib kits.... July 04, 2017 01:11PM |

Registered: 6 years ago Posts: 174 |

Quote

trevmas

Quote

Davek0974

Hmm, tricky one then, is there a general consensus on the best version/design to look into?

From a quick look I think the Ormerod 1 version may be compatible for all machines with the extra slot for the ribbon cable. The position of the drive belt and end stop holes would need to be checked though. The largest holes from the different versions would be ok as strength would not be an issue. The last version was obviously an attempt to stop the acrylic splitting and provide more rigidity with the hooks into the extrusion.

However.... I'm not convinced that just replacing the plate will solve problems such as adjusting the bed and keeping everything square. You will still have the idler mount and motor mount as printed parts that hold the axis end plate in place and square. These are parts that tend to split at the countersunk holes and would in my opinion still allow some flex, with the squareness dependant upon the accuracy and strength of the printed part. I also found that the weight of the machine on the end plate foot made it very difficult to adjust. That is why I went with the idea of a frame to hold the end plates and remove the weight of the machine from them.

My mods are on Thingsverse if it's of any help.

[www.thingiverse.com]

That's a very nice design and was just what I was looking for as I have the same material in stock

|

Re: Laser cut Aluminium X-Arm & Rib kits.... July 07, 2017 05:44AM |

Registered: 8 years ago Posts: 45 |

Quote

Karoo Klong

Quote

trevmas

Quote

Davek0974

Hmm, tricky one then, is there a general consensus on the best version/design to look into?

From a quick look I think the Ormerod 1 version may be compatible for all machines with the extra slot for the ribbon cable. The position of the drive belt and end stop holes would need to be checked though. The largest holes from the different versions would be ok as strength would not be an issue. The last version was obviously an attempt to stop the acrylic splitting and provide more rigidity with the hooks into the extrusion.

However.... I'm not convinced that just replacing the plate will solve problems such as adjusting the bed and keeping everything square. You will still have the idler mount and motor mount as printed parts that hold the axis end plate in place and square. These are parts that tend to split at the countersunk holes and would in my opinion still allow some flex, with the squareness dependant upon the accuracy and strength of the printed part. I also found that the weight of the machine on the end plate foot made it very difficult to adjust. That is why I went with the idea of a frame to hold the end plates and remove the weight of the machine from them.

My mods are on Thingsverse if it's of any help.

[www.thingiverse.com]

That's a very nice design and was just what I was looking for as I have the same material in stock

Thanks, it seems to work well for me. Combined with the aluminium platform support, aluminium x-arm and a lead screw for the z-axis, my prints are much improved over the original. (Not forgetting the DC42 height sensor!) Not too much left of the original machine, but it's been a good learning exercise.

One thing to remember is that the Ormerod 1 has the Y-axis motor on the other end so you would need to mirror the parts.

I had a message from someone who used a drill rather than a reamer for the 12mm rod holes and made them fractionally too big. What I suggested was that after assembly drill a few 2mm holes in the plastic as close to the rods as possible then with some filament in his dremel on a medium speed weld the filament into the 2mm hole. As the plastic melts it will deform the 12mm hole and take up the slack. It worked well for him. It's a kludge I've used myself on other projects with both PLA and ABS and also to weld parts together..

|

Re: Laser cut Aluminium X-Arm & Rib kits.... July 07, 2017 01:27PM |

Registered: 6 years ago Posts: 174 |

Thanks for the advice.

I had an X-ARM made this week and when I went to fetch it yesterday I saw that the arm has bent from the lazer cutting heat. They will now make a new one for me from a higher grade aluminium om Tuesday. They gave me the detective part so I finished it off and bent it a little and seems like it will work fine. I cant wait for put it all together.

I also had some aluminium angle cut to the sizes in order to replace the plastic parts in the y-axis ends.

I wanted 3mm angle but they only had 2mm. But I will make it work. It will be many times stronger than the plastic parts.

Now...

I need to decide if I should replace the hotend? e3d v6 clone maybe?

Just for a start.

PS.

How do you find the machine/kit number?

I would really like to know and use it's number.

I want to make this a cool usable machine.

Edited 1 time(s). Last edit at 07/07/2017 01:34PM by Karoo Klong.

I had an X-ARM made this week and when I went to fetch it yesterday I saw that the arm has bent from the lazer cutting heat. They will now make a new one for me from a higher grade aluminium om Tuesday. They gave me the detective part so I finished it off and bent it a little and seems like it will work fine. I cant wait for put it all together.

I also had some aluminium angle cut to the sizes in order to replace the plastic parts in the y-axis ends.

I wanted 3mm angle but they only had 2mm. But I will make it work. It will be many times stronger than the plastic parts.

Now...

I need to decide if I should replace the hotend? e3d v6 clone maybe?

Just for a start.

PS.

How do you find the machine/kit number?

I would really like to know and use it's number.

I want to make this a cool usable machine.

Edited 1 time(s). Last edit at 07/07/2017 01:34PM by Karoo Klong.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... July 07, 2017 02:14PM |

Registered: 10 years ago Posts: 776 |

Quote

Karoo Klong

Thanks for the advice.

I had an X-ARM made this week and when I went to fetch it yesterday I saw that the arm has bent from the lazer cutting heat. They will now make a new one for me from a higher grade aluminium om Tuesday. They gave me the detective part so I finished it off and bent it a little and seems like it will work fine. I cant wait for put it all together.

I also had some aluminium angle cut to the sizes in order to replace the plastic parts in the y-axis ends.

I wanted 3mm angle but they only had 2mm. But I will make it work. It will be many times stronger than the plastic parts.

Now...

I need to decide if I should replace the hotend? e3d v6 clone maybe?

Just for a start.

PS.

How do you find the machine/kit number?

I would really like to know and use it's number.

I want to make this a cool usable machine.

That is the problem with heat-cutting the parts, I suffered a lot of this when I was getting going, in the end, water-jet was the only way but cost was almost what i charged so I bought a CNC mill and now machine cut the parts - no distortion and perfect finish, far better than even water-jet was.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Laser cut Aluminium X-Arm & Rib kits.... July 08, 2017 10:58AM |

Registered: 8 years ago Posts: 45 |

Quote

Karoo Klong

Thanks for the advice.

I need to decide if I should replace the hotend? e3d v6 clone maybe?

Just for a start.

PS.

How do you find the machine/kit number?

I would really like to know and use it's number.

I want to make this a cool usable machine.

I would recommend making one change before you start another then at least you have a starting point when getting the best out of the change.

I'm not sure about the older hotend, but I find the quickset hotend works really well and I don't see any point in changing it. I use the 0.3 nozzle and never seem to get any blockages. I think the secret is getting the cooling block in the right place and using reasonable retraction settings.

The version number e.g. 528.5, on an Ormerod 2 is printed on the power supply, not sure about the Ormerod 1.

Sorry, only registered users may post in this forum.