One idea for extra cooling fans

Posted by appjaws1

|

One idea for extra cooling fans August 03, 2014 05:03PM |

Registered: 10 years ago Posts: 780 |

You can have one or two extra fans as an aid to cooling the print. (Sorry no photos until end August)

The fan nozzles have flat bottoms that are lined up with the top of the bed and they rise as the x arm rises and deliver cool air from both directions, controlled by slic3r.

The procedure for the rear fan is:-

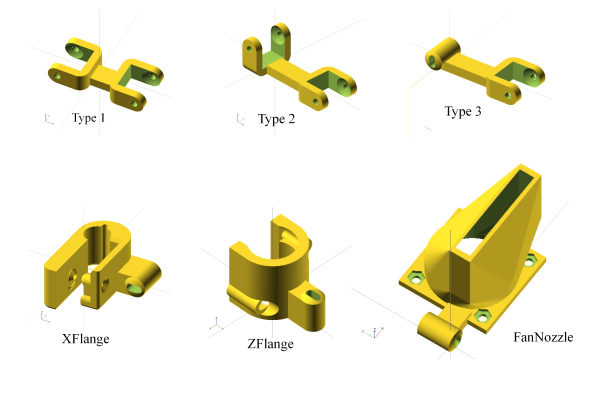

1. run OpenSCAD appjaws-Z-bearing-flange-rear-fan and produce a stl file

2. run OpenSCAD appjaws-fan-nozzle-and-mount and change the parameter "FrontFan" to false.

3. appjaws-fan-arm-connectors-v1 is parametrised for the arm connectors to attach external fans.

change "length" to set the length of the arm connector between screw hole centres

change "uc" to change the positions of the flange and/or U bracket relative to the arm

change "type" to select connector end types

For the rear fan you will need one type 1 and one type 3 arm connectors.

create stl files for each type.

For the correct arm length for the type 3 connector you will need to measure the distance from the centre of the Z-Bearing Flange to the other side of the X-motor.

For the type 1 arm length, measure the distance from the type 3 connector to the X homing plate minus the measurement from the fan nozzle output to the fan mount flange.

4. If you have a normal 40mm fan with 2 wires, you can connect them to the duet fan connector, you will need to set up the fan in the cooling section of slic3r.

NOTE The fan sits between the X-motor and the duet enclosure. You will need at least 40mm gap, preferably 50mm. To achieve this you may need to print off the modified version of the duet enclosure that has additional fixing holes provided so the duet can be mounted further along the Y extrusion. I would recommend bobtidey original, or dc42's modified version to accommodate a DueX4 board as well as the Duet.

The procedure for the front fan is:-

1. run OpenSCAD appjaws-X-idler-flange-front-fan and produce a stl file

2. run OpenSCAD appjaws-fan-nozzle-and-mount and change the parameter "FrontFan" to true.

3. run OpenSCAD appjaws-fan-arm-connectors-v1 and change the parameters.

change "length" to set the length of the arm connector between screw hole centres

change "uc" to change the positions of the flange and/or U bracket relative to the arm

change "type" to select connector end types

For the front fan you will need one type 2 and one type 3.

create stl files for each type.

The arm length requirement is very small for the type 2 and type 3 arm connectors.

Please measure from the centre of X-idler Flange to the front, allowing a small amount of clearance to the end of the X rib for the type 2 arm connector.

For the type 3 arm connector, again just enough clearance so that the fan nozzle can point straight along the X axis.

4. If you have a normal 40mm fan with 2 wires, run 2 wires from the duet fan connector, following the existing run of cables along the X-rib to the front fan.

Better control of the extra fans can be obtained by using 4-wire PMW fans.

I obtained 2 from America via ebay

ebay-fans

Manufacturer: Sanyo DenkiT

Model Number: 9GA0412P3J01

Series: SanAce40

Voltage: 12V

Current: 0.49A (As written on fan label)

RPM: 18.000

Speed / PWM Control: YES (Brown wire)

RPM/Tach/Rotor Signal/Pulse Sensor: YES (Yellow wire)

Mounting screws: No

Size: Square, 40mm

Thickness: 28mm

Mounting holes: 32mm, square pattern (See datasheet)

Life: 40,000 Hours

Operating temperature: -10 to +70 C (14 to 158 F)

Leads: (+): red (-): black Sensor(Tach): yellow Control(PWM): brown

Model No. 9GA0412P3J01

Rated Voltage 12

(V) Rated current 0.49

(A) Rated input 5.88

(W) Rated speed 18,000 (PWM Duty 100%)

(min-1) Air flow 0.67 (23.7 CFM)

(m3/min) Static pressure 535 (2.15 inchH2O)

(Pa) Noise (dB[A]) 54

Mass (g) 53

The fans will need to be connected as follows, thanks dc42.

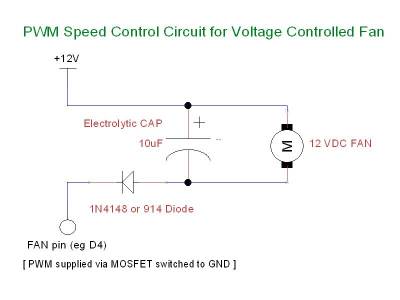

Wire the fan between +12V and ground (you can use the positive fan output on the Duet for the +12V). Then wire the fan PWM input (Brown wire) to the anode of a 1N4148 or similar diode, and the cathode of that diode (black band side) to the fan black wire to ground (like the hot end fan), not to the negative fan output terminal

The wiring instructions for the Ormerod at [reprappro.com], has a diagram showing where to connect the looms including hot end fan, then a photo with it connected to different pins and a note that "either works". So that tells you where to find an extra ground pin, and also an extra +12V pin. You can either leave the red connected to the fan +ve pin, or connect it to that +12V pin.

You'll need to select inverse PWM in the M106 command.

The fan will run at full speed if the PWM input (brown wire) is not connected. With the brown wire and the diode connected correctly, the speed should be controllable using the M106 command. M106 I1 S0 should give you minimum speed, M106 I1 S255 should give you maximum speed.

As a quick test that your fan is working properly, you can disconnect the diode and connect the brown wire to ground. That should cause the fan to run at minimum speed.

Edited 2 time(s). Last edit at 08/03/2014 05:49PM by appjaws1.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

The fan nozzles have flat bottoms that are lined up with the top of the bed and they rise as the x arm rises and deliver cool air from both directions, controlled by slic3r.

The procedure for the rear fan is:-

1. run OpenSCAD appjaws-Z-bearing-flange-rear-fan and produce a stl file

2. run OpenSCAD appjaws-fan-nozzle-and-mount and change the parameter "FrontFan" to false.

3. appjaws-fan-arm-connectors-v1 is parametrised for the arm connectors to attach external fans.

change "length" to set the length of the arm connector between screw hole centres

change "uc" to change the positions of the flange and/or U bracket relative to the arm

change "type" to select connector end types

For the rear fan you will need one type 1 and one type 3 arm connectors.

create stl files for each type.

For the correct arm length for the type 3 connector you will need to measure the distance from the centre of the Z-Bearing Flange to the other side of the X-motor.

For the type 1 arm length, measure the distance from the type 3 connector to the X homing plate minus the measurement from the fan nozzle output to the fan mount flange.

4. If you have a normal 40mm fan with 2 wires, you can connect them to the duet fan connector, you will need to set up the fan in the cooling section of slic3r.

NOTE The fan sits between the X-motor and the duet enclosure. You will need at least 40mm gap, preferably 50mm. To achieve this you may need to print off the modified version of the duet enclosure that has additional fixing holes provided so the duet can be mounted further along the Y extrusion. I would recommend bobtidey original, or dc42's modified version to accommodate a DueX4 board as well as the Duet.

The procedure for the front fan is:-

1. run OpenSCAD appjaws-X-idler-flange-front-fan and produce a stl file

2. run OpenSCAD appjaws-fan-nozzle-and-mount and change the parameter "FrontFan" to true.

3. run OpenSCAD appjaws-fan-arm-connectors-v1 and change the parameters.

change "length" to set the length of the arm connector between screw hole centres

change "uc" to change the positions of the flange and/or U bracket relative to the arm

change "type" to select connector end types

For the front fan you will need one type 2 and one type 3.

create stl files for each type.

The arm length requirement is very small for the type 2 and type 3 arm connectors.

Please measure from the centre of X-idler Flange to the front, allowing a small amount of clearance to the end of the X rib for the type 2 arm connector.

For the type 3 arm connector, again just enough clearance so that the fan nozzle can point straight along the X axis.

4. If you have a normal 40mm fan with 2 wires, run 2 wires from the duet fan connector, following the existing run of cables along the X-rib to the front fan.

Better control of the extra fans can be obtained by using 4-wire PMW fans.

I obtained 2 from America via ebay

ebay-fans

Manufacturer: Sanyo DenkiT

Model Number: 9GA0412P3J01

Series: SanAce40

Voltage: 12V

Current: 0.49A (As written on fan label)

RPM: 18.000

Speed / PWM Control: YES (Brown wire)

RPM/Tach/Rotor Signal/Pulse Sensor: YES (Yellow wire)

Mounting screws: No

Size: Square, 40mm

Thickness: 28mm

Mounting holes: 32mm, square pattern (See datasheet)

Life: 40,000 Hours

Operating temperature: -10 to +70 C (14 to 158 F)

Leads: (+): red (-): black Sensor(Tach): yellow Control(PWM): brown

Model No. 9GA0412P3J01

Rated Voltage 12

(V) Rated current 0.49

(A) Rated input 5.88

(W) Rated speed 18,000 (PWM Duty 100%)

(min-1) Air flow 0.67 (23.7 CFM)

(m3/min) Static pressure 535 (2.15 inchH2O)

(Pa) Noise (dB[A]) 54

Mass (g) 53

The fans will need to be connected as follows, thanks dc42.

Wire the fan between +12V and ground (you can use the positive fan output on the Duet for the +12V). Then wire the fan PWM input (Brown wire) to the anode of a 1N4148 or similar diode, and the cathode of that diode (black band side) to the fan black wire to ground (like the hot end fan), not to the negative fan output terminal

The wiring instructions for the Ormerod at [reprappro.com], has a diagram showing where to connect the looms including hot end fan, then a photo with it connected to different pins and a note that "either works". So that tells you where to find an extra ground pin, and also an extra +12V pin. You can either leave the red connected to the fan +ve pin, or connect it to that +12V pin.

You'll need to select inverse PWM in the M106 command.

The fan will run at full speed if the PWM input (brown wire) is not connected. With the brown wire and the diode connected correctly, the speed should be controllable using the M106 command. M106 I1 S0 should give you minimum speed, M106 I1 S255 should give you maximum speed.

As a quick test that your fan is working properly, you can disconnect the diode and connect the brown wire to ground. That should cause the fan to run at minimum speed.

Edited 2 time(s). Last edit at 08/03/2014 05:49PM by appjaws1.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: One idea for extra cooling fans August 03, 2014 05:33PM |

Registered: 10 years ago Posts: 14,672 |

Paul, thanks for the details. I would point out that it was bobtidey who designed the Duet enclosure with extra mounting points, see [forums.reprap.org]. My contribution was to adapt his design to accommodate a DueX4 board as well as the Duet.

For controlling the PWM fans, my recommendation of connecting a 1N4148 diode between the Duet fan output and the fan brown wire was made without having seen the fan specifications. Now that I have seen the specifications (in particular, the input low voltage limit of 0.4V), my recommendation is any of the following:

1. A Schottky diode such as BAT43 or BAT85 used in place of the 1N4148 (cathode to fan output -ve terminal, anode to fan brown wire); or:

2. An NPN transistor such as BC337 wired emitter to ground (i.e. fan black wire), base to fan output -ve terminal via a series resistor of about 1K to 10K, collector to fan brown wire; or:

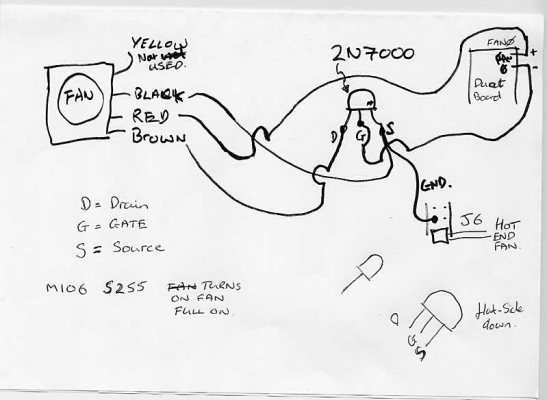

3. A 2N7000 mosfet wired source to ground (i.e. fan black wire), gate to fan output -ve terminal, drain to fan brown wire.

My preference is for the 2N7000, but note that it is static-sensitive until wired into the circuit. Using a diode requires the PWM to be inverted, but the other two solutions do not.

Edited 1 time(s). Last edit at 08/04/2014 02:39AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

For controlling the PWM fans, my recommendation of connecting a 1N4148 diode between the Duet fan output and the fan brown wire was made without having seen the fan specifications. Now that I have seen the specifications (in particular, the input low voltage limit of 0.4V), my recommendation is any of the following:

1. A Schottky diode such as BAT43 or BAT85 used in place of the 1N4148 (cathode to fan output -ve terminal, anode to fan brown wire); or:

2. An NPN transistor such as BC337 wired emitter to ground (i.e. fan black wire), base to fan output -ve terminal via a series resistor of about 1K to 10K, collector to fan brown wire; or:

3. A 2N7000 mosfet wired source to ground (i.e. fan black wire), gate to fan output -ve terminal, drain to fan brown wire.

My preference is for the 2N7000, but note that it is static-sensitive until wired into the circuit. Using a diode requires the PWM to be inverted, but the other two solutions do not.

Edited 1 time(s). Last edit at 08/04/2014 02:39AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: One idea for extra cooling fans August 03, 2014 05:33PM |

Registered: 9 years ago Posts: 119 |

|

Re: One idea for extra cooling fans August 03, 2014 06:01PM |

Registered: 10 years ago Posts: 780 |

David, thank you for your comments, I have edited and included the reference to bobtidey. Do you think that the fact that I was using a 1N4148 diode was the reason I was having problems with setting the fans up? Also do your new suggestions take into account that I will be running 2 of these fans?

Lloyd, The fans at full speed are quite noisy and I would say about the same as the fan supplied by reprap, of course when they run under the control of slic3r they are only running at full speed at certain times, not continuously.

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

Lloyd, The fans at full speed are quite noisy and I would say about the same as the fan supplied by reprap, of course when they run under the control of slic3r they are only running at full speed at certain times, not continuously.

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: One idea for extra cooling fans April 14, 2015 02:26PM |

Registered: 9 years ago Posts: 189 |

Hello,

I bought the fan mentioned in this post; the 4 wire one.

I'm using a 2N7000 method to control the fan from the PWM signal from the duet fan 0 negetive lead.

Currently the fan runs all the time and won't respond to a M106 or M107 command.

Wiring is as follows

fan's black wire goes to the source on the mosfet

fan's red wire goes to the fan 0 positive connection on the duet board

fan's brown wire goes to the drain on the mosfet

mosfet's gate goes to the negative pin on the fan 0 connection

The mosfet's source conections go to a gound pin on the duet (it's the left pin above the hot end fan connection)

The set of pins is called J6

It does mention a diode above but I haven't used one; Will that be the cause of problem?

My ormerod is running the latest firmware;

Is the fan 0 negative connection actualy giving out a PWM signal? As I would have thought it would be the red wire is the PWM one; thus meaning the fan's brown wire should be connected to the positve connection not the negative one.

Can some comfirm that to be correct way to wire a cooling fan to an ormerod 2.

Many Thanks

Chris

I bought the fan mentioned in this post; the 4 wire one.

I'm using a 2N7000 method to control the fan from the PWM signal from the duet fan 0 negetive lead.

Currently the fan runs all the time and won't respond to a M106 or M107 command.

Wiring is as follows

fan's black wire goes to the source on the mosfet

fan's red wire goes to the fan 0 positive connection on the duet board

fan's brown wire goes to the drain on the mosfet

mosfet's gate goes to the negative pin on the fan 0 connection

The mosfet's source conections go to a gound pin on the duet (it's the left pin above the hot end fan connection)

The set of pins is called J6

It does mention a diode above but I haven't used one; Will that be the cause of problem?

My ormerod is running the latest firmware;

Is the fan 0 negative connection actualy giving out a PWM signal? As I would have thought it would be the red wire is the PWM one; thus meaning the fan's brown wire should be connected to the positve connection not the negative one.

Can some comfirm that to be correct way to wire a cooling fan to an ormerod 2.

Many Thanks

Chris

|

Re: One idea for extra cooling fans April 14, 2015 04:36PM |

Registered: 10 years ago Posts: 14,672 |

That connection arrangement sounds OK to me. You may not be able to get the fan to turn off completely, because the Intel PWM fan specification only requires that the fan go down to 30% of maximum speed or lower.

Preferably, the PWM frequency should be increased to 25kHz, which my firmware fork and zombiepantslol's do.

Edited 4 time(s). Last edit at 04/14/2015 04:40PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Preferably, the PWM frequency should be increased to 25kHz, which my firmware fork and zombiepantslol's do.

Edited 4 time(s). Last edit at 04/14/2015 04:40PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: One idea for extra cooling fans April 14, 2015 04:53PM |

Registered: 9 years ago Posts: 189 |

Yes It's correct, the way I drew it out on paper and explained here was correct but had soldered the mosfet incorrectly.

I swapped the brown with the black (Source) , so that the fan's brown (PWM) wire was on the left (drain) with the mosfet flat side down.

The fan doesn't shut off completely (it might do as it's in my slicer settings it's set to disable the fan for the first layer)

It makes some noise when sent M106 S145 to 255

Edited 1 time(s). Last edit at 04/14/2015 04:56PM by orictosh.

I swapped the brown with the black (Source) , so that the fan's brown (PWM) wire was on the left (drain) with the mosfet flat side down.

The fan doesn't shut off completely (it might do as it's in my slicer settings it's set to disable the fan for the first layer)

It makes some noise when sent M106 S145 to 255

Edited 1 time(s). Last edit at 04/14/2015 04:56PM by orictosh.

|

Re: One idea for extra cooling fans April 15, 2015 10:40AM |

Registered: 12 years ago Posts: 1,611 |

Not quite sure if it's relevant; there is a bug in v1.04 of the official RepRapFirmware, where you can switch on the fan with M106 S255, but any movement of the axes will turn it off again! This has been fixed in the soon-to-be-released next version of the firmware.

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: One idea for extra cooling fans April 15, 2015 11:38AM |

Registered: 9 years ago Posts: 189 |

Hi Ian,

I can confirm the bug; I'm currently printing an item but it's hard to tell if the fan is responding from the gcode produced by slic3r as there is not many overhangs or quick layers.

Sorry if this is bit off topic for this thread;

I was using 0.78c when building my printer and upgraded (about 6hrs after it hit github) to 1.04 due to the extruder speed bug,

before the upgrade the G32 command in pronterface would should show the results of G32 in the serial window but with 1.04 it dosen't show the results.

Is this something that will be fixed in this soon-be-released firmware update?

Thanks

Chris

I can confirm the bug; I'm currently printing an item but it's hard to tell if the fan is responding from the gcode produced by slic3r as there is not many overhangs or quick layers.

Sorry if this is bit off topic for this thread;

I was using 0.78c when building my printer and upgraded (about 6hrs after it hit github) to 1.04 due to the extruder speed bug,

before the upgrade the G32 command in pronterface would should show the results of G32 in the serial window but with 1.04 it dosen't show the results.

Is this something that will be fixed in this soon-be-released firmware update?

Thanks

Chris

|

Re: One idea for extra cooling fans April 15, 2015 03:44PM |

Registered: 10 years ago Posts: 14,672 |

Quote

orictosh

I can confirm the bug; I'm currently printing an item but it's hard to tell if the fan is responding from the gcode produced by slic3r as there is not many overhangs or quick layers.

Neither my fork nor zpl's fork has that bug.

Quote

orictosh

before the upgrade the G32 command in pronterface would should show the results of G32 in the serial window but with 1.04 it dosen't show the results.

My fork had that issue a few versions ago, but I fixed it, and my current release does report the G32 results in Pronterface (I've just tested it).

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: One idea for extra cooling fans April 20, 2015 03:53PM |

Registered: 9 years ago Posts: 638 |

|

Re: One idea for extra cooling fans April 20, 2015 04:56PM |

Registered: 9 years ago Posts: 189 |

2 wire fans don't normaly respond well to PWM signals.

There is a diagram attached which I used on a RepRap Huxley to conroll a 2 wire fan via Slic3r commands correctly.

Before I put in the extra compondents the cooling fan wouldn't disable on the first layers like it was asked.

The diagram came from this post

[bukobot.com]

With the duet fan0 pin the PWM signal comes out of the postive pin (very top pin) and I would ground the fan negetive lead to another gnd pin (2nd one down on the left from the top of the J6 connecter) not the negetive on the connector.

Please check with multimeter that you have continuity to ground and you will need to reverse the cap and diode shown in the diagram as the +12v is coming out on the fan0 postive pin.

There is a diagram attached which I used on a RepRap Huxley to conroll a 2 wire fan via Slic3r commands correctly.

Before I put in the extra compondents the cooling fan wouldn't disable on the first layers like it was asked.

The diagram came from this post

[bukobot.com]

With the duet fan0 pin the PWM signal comes out of the postive pin (very top pin) and I would ground the fan negetive lead to another gnd pin (2nd one down on the left from the top of the J6 connecter) not the negetive on the connector.

Please check with multimeter that you have continuity to ground and you will need to reverse the cap and diode shown in the diagram as the +12v is coming out on the fan0 postive pin.

|

Re: One idea for extra cooling fans April 20, 2015 05:36PM |

Registered: 9 years ago Posts: 638 |

so i have to buy the diode?

Supose i buy a 4 wire fan and a 2N7000 mosfet ,

how do i wire it?

Take note that i am somewhat new to this kinda stuff , have some some soldering but ,would be nice to get a picture how its wired

nevermind ,figured it out from a datasheet for 2N7000 and dc's post ,doh!

Edited 3 time(s). Last edit at 04/20/2015 06:22PM by Darathy.

Supose i buy a 4 wire fan and a 2N7000 mosfet ,

how do i wire it?

Take note that i am somewhat new to this kinda stuff , have some some soldering but ,would be nice to get a picture how its wired

nevermind ,figured it out from a datasheet for 2N7000 and dc's post ,doh!

Edited 3 time(s). Last edit at 04/20/2015 06:22PM by Darathy.

|

Re: One idea for extra cooling fans April 20, 2015 06:14PM |

Registered: 10 years ago Posts: 14,672 |

I don't advise that circuit, the peak current flow through the diode is likely to be very high. If you just want on/off fan control, you can connect the fan directly to the FAN0 output.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: One idea for extra cooling fans April 20, 2015 06:31PM |

Registered: 9 years ago Posts: 638 |

|

Re: One idea for extra cooling fans April 20, 2015 07:22PM |

Registered: 9 years ago Posts: 189 |

Yes, using a 4 wire fan and a 2N7000 mosfet is good way to power a cooling fan so it gives variable speed and cooling when needed and requested by slic3r. The yellow wire is not used in this case.

Looking at my diagram, I would say the the PWM signal is on the negetive fan0 connection as it connected to gate pin

The +12v pin is connected to red (Postive) of the fan

The Brown wire is the PWM control wire which is connected to the Drain on the mosfet

The Black is the gnd wire for the fan and is connected to the Source pin on the mosfet

Current flows from the source to drain and the gate controls the flow with the PWM signal coming from the negetive fan0 connection.

The source pin and fan's ground is connected to a gnd pin on the J6 connecter on duet board, the pin on the left above the hot end fan connection.

Sending M106 S255 should turn the fan full on and I found that ran from S145 to S255 in a previous post.

Looking at my diagram, I would say the the PWM signal is on the negetive fan0 connection as it connected to gate pin

The +12v pin is connected to red (Postive) of the fan

The Brown wire is the PWM control wire which is connected to the Drain on the mosfet

The Black is the gnd wire for the fan and is connected to the Source pin on the mosfet

Current flows from the source to drain and the gate controls the flow with the PWM signal coming from the negetive fan0 connection.

The source pin and fan's ground is connected to a gnd pin on the J6 connecter on duet board, the pin on the left above the hot end fan connection.

Sending M106 S255 should turn the fan full on and I found that ran from S145 to S255 in a previous post.

|

Re: One idea for extra cooling fans April 21, 2015 08:20AM |

Registered: 10 years ago Posts: 2,472 |

On/off control should work fine with no additional components. Speed 0 turns off the drive current completely, and 255 should result in it being on continuously (no PWM). Brushless motors as are typical in small fans do not like PWM directly because they require a constant voltage to keep the commutation electronics powered and in any case the PWM would interfere with the commutation pulses. Some speed regulation can be achieved by changing the D.C. voltage so long as you don't go too low. I would have thought that a capacitor across the fan would work OK to effectively change the PWM to a variable voltage (low pass filter), but I would substitute a resistor (maybe 10 ohms or so) for the diode (to limit inrush current), and put a reverse biased diode across the fan if there is not one on the board (to deal with any reverse EMF generated by the fan).

Dave

Dave

|

Re: One idea for extra cooling fans April 21, 2015 08:31AM |

Registered: 9 years ago Posts: 177 |

This all makes me wonder how RepRapPro will set up their extra fan that's supposed to mount on the new acrylic fan spacer.....

Adding an extra fan is a much bigger ordeal than I'd expected (if you want variable fan control). Although orictosh's second diagram seems simple enough to do, although you're only getting about half speed on the low end (although I suppose performance may vary between fan manufacturers and models)

Makes me wonder why the duet designers didn't decide to have a 4 pin PWM fan connector for fan 0

Edited 1 time(s). Last edit at 04/21/2015 08:33AM by shadow651.

Adding an extra fan is a much bigger ordeal than I'd expected (if you want variable fan control). Although orictosh's second diagram seems simple enough to do, although you're only getting about half speed on the low end (although I suppose performance may vary between fan manufacturers and models)

Makes me wonder why the duet designers didn't decide to have a 4 pin PWM fan connector for fan 0

Edited 1 time(s). Last edit at 04/21/2015 08:33AM by shadow651.

|

Re: One idea for extra cooling fans April 21, 2015 08:40AM |

Registered: 10 years ago Posts: 2,472 |

Probably explained a while ago, but why is the FET needed for 3-wire control? It seems to act as a invertor, but If the fan's PWM control input is fed direct from the fan output of the duet (possibly with a pullup to 12V), surely a simple firmware change could supply the correct polarity pulses?

Dave

Dave

|

Re: One idea for extra cooling fans April 21, 2015 10:37AM |

Registered: 10 years ago Posts: 14,672 |

Quote

dmould

Probably explained a while ago, but why is the FET needed for 3-wire control? It seems to act as a invertor, but If the fan's PWM control input is fed direct from the fan output of the duet (possibly with a pullup to 12V), surely a simple firmware change could supply the correct polarity pulses?

Dave

One reason is that the fan PWM input has a voltage rating of 5.25V maximum, see [www.formfactors.org]. The fan output from the Duet has a LED and 4.7K series resistor pulling it up to +12V. So you should at least use a diode between the fan output and the PWM input. My fork and zpl's already include an option for inverting the PWM.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: One idea for extra cooling fans April 21, 2015 11:03AM |

Registered: 9 years ago Posts: 177 |

Quote

orictosh

Yes, using a 4 wire fan and a 2N7000 mosfet is good way to power a cooling fan so it gives variable speed and cooling when needed and requested by slic3r. The yellow wire is not used in this case.

Looking at my diagram, I would say the the PWM signal is on the negetive fan0 connection as it connected to gate pin

[attachment 53250 4_wire01.JPG]

The +12v pin is connected to red (Postive) of the fan

The Brown wire is the PWM control wire which is connected to the Drain on the mosfet

The Black is the gnd wire for the fan and is connected to the Source pin on the mosfet

Current flows from the source to drain and the gate controls the flow with the PWM signal coming from the negetive fan0 connection.

The source pin and fan's ground is connected to a gnd pin on the J6 connecter on duet board, the pin on the left above the hot end fan connection.

Sending M106 S255 should turn the fan full on and I found that ran from S145 to S255 in a previous post.

Quote

dc42

One reason is that the fan PWM input has a voltage rating of 5.25V maximum, see [www.formfactors.org]. The fan output from the Duet has a LED and 4.7K series resistor pulling it up to +12V. So you should at least use a diode between the fan output and the PWM input.

So in the above diagram, you'd add a diode between the mosfet source and the brown fan PWM input?

I really need to learn more about circuit design

I only have a basic grasp from collage physics

|

Re: One idea for extra cooling fans April 21, 2015 01:18PM |

Registered: 10 years ago Posts: 2,472 |

Quote

dc42

Quote

dmould

Probably explained a while ago, but why is the FET needed for 3-wire control? It seems to act as a invertor, but If the fan's PWM control input is fed direct from the fan output of the duet (possibly with a pullup to 12V), surely a simple firmware change could supply the correct polarity pulses?

Dave

One reason is that the fan PWM input has a voltage rating of 5.25V maximum, see [www.formfactors.org]. The fan output from the Duet has a LED and 4.7K series resistor pulling it up to +12V. So you should at least use a diode between the fan output and the PWM input. My fork and zpl's already include an option for inverting the PWM.

Surely adding single diode in series would be easier than the FET modification, and I cannot see that the FET provides any advantage other than signal inversion, which you say is configurable and so not necessary (a 5V logic level input should be perfectly happy with logic low going down to only 0.7V or so, though a schottky diode could be used for a smaller drop if necessary). Alternatively, if you want to get it working without waiting to get a diode, then removing the 4k7 LED series resistor on the Duet board would, if I understand correctly, make the Duet's fan output completely open-drain and so able to drive the fan directly with no additional components needed (although it would disable the LED indicator). I assume that the fan input has an internal pullup to 5V (otherwise your FET mod would not work as shown).

Dave

|

Re: One idea for extra cooling fans April 21, 2015 02:41PM |

Registered: 10 years ago Posts: 665 |

Quote

dmould

Alternatively, if you want to get it working without waiting to get a diode, then removing the 4k7 LED series resistor on the Duet board would, if I understand correctly, make the Duet's fan output completely open-drain and so able to drive the fan directly with no additional components needed (although it would disable the LED indicator). I assume that the fan input has an internal pullup to 5V (otherwise your FET mod would not work as shown).

I've been running my 4-pin PWM fan (SunOn 40x40x20mm) without any diodes connected for about a year now and it's working perfectly fine, though it's possible the results may look different if another fan is used (so I wouldn't recommend it, do what dc42 and dmould say and you're on the safe side). Btw this additional M106 'I' parameter was basically the first mod I did to the Duet firmware, at that time I really wouldn't have thought I'd stay in this business for so long

|

Re: One idea for extra cooling fans April 22, 2015 08:02AM |

Registered: 10 years ago Posts: 2,472 |

Quote

zombiepantslol

I've been running my 4-pin PWM fan (SunOn 40x40x20mm) without any diodes connected for about a year now and it's working perfectly fine, though it's possible the results may look different if another fan is used (so I wouldn't recommend it, do what dc42 and dmould say and you're on the safe side). Btw this additional M106 'I' parameter was basically the first mod I did to the Duet firmware, at that time I really wouldn't have thought I'd stay in this business for so long

If the fan input is a standard 5V logic input, then I suspect the input protection diode on that input is sinking the 12V. With a 4k7 series resistor and LED to 12V, the protection diode would need to sink less than 2mA to its internal 5V rail and so may survive indefinitely. The other alternative is that that particular fan's electronics run from 12V (which would seem reasonable), and the input is perfectly happy with a signal going up to 12V, but you may not be so lucky with a different fan. While the max control input voltage in the specification is 5.25V, there is nothing to prevent a device being more tolerant than the specification calls for.

I note that the specifications that DC42 referenced do not state that the fan's input must have an internal pullup or be capable of being driven from an open drain source. Therefore a pure open-drain signal as provided by DC42's circuit or a series diode may not work at all or may work sporadically with some fans. The easiest way to provide a signal from the Duet that complies 100% with the specification would be to connect the Duet fan output directly to the fan's control wire (as zombipantslol has done) but put a 4.7V zener from that signal to ground to ensure the high logic level (provided via the Duet's LED) does not exceed the maximum allowed in the specification. This will have the effect of keeping the Duet's fan LED dimly illuminated when the output is high and become brighter when the output goes low, but that is a harmless side-effect.

Dave

|

Re: One idea for extra cooling fans April 22, 2015 08:07AM |

Registered: 10 years ago Posts: 14,672 |

Quote

dmould

I note that the specifications that DC42 referenced do not state that the fan's input must have an internal pullup or be capable of being driven from an open drain source.

True, but IMO it is strongly implied by the "Absolute maximum current sourced: Imax = 5 mA (short circuit current)", "Absolute maximum voltage level: VMax = 5.25 V (open circuit voltage)" and "If no control signal is present the fan shall operate at maximum RPM" bits.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: One idea for extra cooling fans April 22, 2015 09:14AM |

Registered: 10 years ago Posts: 2,472 |

Quote

dc42

Quote

dmould

I note that the specifications that DC42 referenced do not state that the fan's input must have an internal pullup or be capable of being driven from an open drain source.

True, but IMO it is strongly implied by the "Absolute maximum current sourced: Imax = 5 mA (short circuit current)", "Absolute maximum voltage level: VMax = 5.25 V (open circuit voltage)" and "If no control signal is present the fan shall operate at maximum RPM" bits.

I respectfully disagree. Specifications are written to cover many possible implementations, and the Imax and Vmax would be specified in the event that the fan has an input arrangement that is capable of sourcing voltage & current, it in no way implies that such an arrangement is mandatory or even common. A fan with no pullup would be 100% compliant with the specification as the I and V would both be zero. I often design circuits that comply with specifications that contain limitations that I don't have to worry about as they are not relevant to my particular arrangement. As a recent example, the USB hub specification includes details for driving a port indicator LED. That does not imply that all USB hubs have LED port indicators (a very high proportion do not).

While an internal pullup would be one way of ensuring that an open control input will result in maximum RPM, it is far from the only way of achieving such a thing, and beside which a pullup that is designed to ensure that an open pin is logic high can be a very high Z (I've seen internal pullups of 150K ohm or more), and are consequently too weak to ensure reliable operation with an open drain signal. In fact, if the fan's electronics operates at 12 volts (which is not unlikely), the designer may well have used a different method of ensuring max RPM with no control signal in order to avoid the need to provide an internal 5V rail. I should think it would be trivial to include a pulse detection signal in the control logic that would achieve the same thing, for example.

Dave

|

Re: One idea for extra cooling fans April 22, 2015 10:12AM |

Registered: 10 years ago Posts: 14,672 |

I found a later version of that document here [www.formfactors.org] which specifically mentions a pullup, and driving the PWM input from an open drain or open collector device.

Edited 1 time(s). Last edit at 04/22/2015 10:13AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 04/22/2015 10:13AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: One idea for extra cooling fans April 22, 2015 10:47AM |

Registered: 10 years ago Posts: 2,472 |

Quote

dc42

I found a later version of that document here [www.formfactors.org] which specifically mentions a pullup, and driving the PWM input from an open drain or open collector device.

Yes, I agree that that later specification explicitly demands that the fan can be controlled from an open drain source, and as it was released in 2005 all new fans currently available can be expected to comply. In which case a simple series diode from the Duet's fan output and inverting the fan output using recent firmware and setting the appropriate variable should work reliably. The specification also mandates the colours of the 4 wires, but I have come across fans that are almost certainly less than 7 years old that do not comply with those colours (but they do comply with the pin numbers on the connector which is all that will normally matter).

Dave

|

Re: One idea for extra cooling fans April 22, 2015 05:18PM |

Registered: 9 years ago Posts: 638 |

i have connected my 2 pin fan to fan0 and it works after switching the wires ,even can controll fan speed with slider with Zombies web interface ,is it safe to leave the 2 pin fan like this or do i need the 4 pin PWM +2N7000 mosfet?

Edited 1 time(s). Last edit at 04/22/2015 05:20PM by Darathy.

Edited 1 time(s). Last edit at 04/22/2015 05:20PM by Darathy.

|

Re: One idea for extra cooling fans August 24, 2015 09:12PM |

Registered: 9 years ago Posts: 4 |

I too am interested in a variable speed controlled cooling fan. I connected a SunOn 40x40x20 fan directly to the fan0 terminals and was able to get on-off control. I'm guessing zombiepantslol connected his SunOn fan using the MOSFET (2N7000) for variable speed control. Is this correct? If not, are there other ways to achieve variable speed without adding the extra components (other than a fan and diode) to the printer? What other successful setups are currently being utilized to give the duet practical cooling fan control. Specially, I'm interested in tested setups and the components used.

Edited 2 time(s). Last edit at 08/24/2015 09:37PM by RedMD.

Edited 2 time(s). Last edit at 08/24/2015 09:37PM by RedMD.

Sorry, only registered users may post in this forum.