Z-axis threaded rod causes layer skipping *Please Help*

Posted by victhor

|

Z-axis threaded rod causes layer skipping *Please Help* August 14, 2014 07:27PM |

Registered: 9 years ago Posts: 18 |

Problem:

Some places on the M5 rod the nut is harder to turn, the rod also seems a little bent, the top of the rod is moving approx 5mm from side to side.

Because the nut is harder to turn at some places, the Z motor seems to skip a layer because it thinks that it has moved.

Big blobs were created when I tried to save this print, sometimes the Z axis wouldnt go up because the nut got stuck, so I paused the print and raised the nozzle 0.2 mm but it didnt help at all.

Video showing when the Z axis skips small steps:

[www.youtube.com]

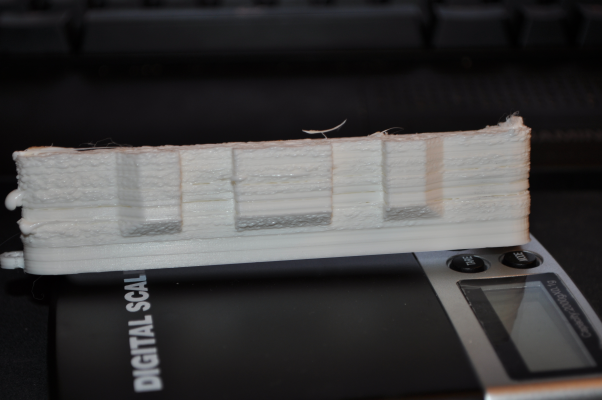

The results of layer skipping (after 3 hours print time) notice how the first layers are perfect (by my standards) and the rest turned into some goo

the rod/nut seems to wear down on the parts where the nut was hard to turn

Possible solutions:

Youtube: [www.youtube.com] 3D printing videos

3D Hub: [www.3dhubs.com] Pictures of stuff I've printed

Thingyverse: [www.thingiverse.com] More pictures

Facebook: [www.facebook.com]

Some places on the M5 rod the nut is harder to turn, the rod also seems a little bent, the top of the rod is moving approx 5mm from side to side.

Because the nut is harder to turn at some places, the Z motor seems to skip a layer because it thinks that it has moved.

Big blobs were created when I tried to save this print, sometimes the Z axis wouldnt go up because the nut got stuck, so I paused the print and raised the nozzle 0.2 mm but it didnt help at all.

Video showing when the Z axis skips small steps:

[www.youtube.com]

The results of layer skipping (after 3 hours print time) notice how the first layers are perfect (by my standards) and the rest turned into some goo

the rod/nut seems to wear down on the parts where the nut was hard to turn

Possible solutions:

Youtube: [www.youtube.com] 3D printing videos

3D Hub: [www.3dhubs.com] Pictures of stuff I've printed

Thingyverse: [www.thingiverse.com] More pictures

Facebook: [www.facebook.com]

|

Re: Z-axis threaded rod causes layer skipping *Please Help* August 15, 2014 01:48AM |

Registered: 9 years ago Posts: 88 |

I had the same problem on my Ormerod. My neighbor happen to have a tool for cutting screw threads (not sure this is the right term). We ran my rod through the tool and now the nut moves freely through the entire rod and my issue was gone. The tool removed debris stuck in the screw threads.

Not sure what the tool is called or where to buy it but I can sort that out if you want.

Edited 1 time(s). Last edit at 08/15/2014 01:50AM by bitfield.

Not sure what the tool is called or where to buy it but I can sort that out if you want.

Edited 1 time(s). Last edit at 08/15/2014 01:50AM by bitfield.

|

Re: Z-axis threaded rod causes layer skipping *Please Help* August 15, 2014 02:29AM |

Registered: 10 years ago Posts: 378 |

1, Change the nut and rod.

Probably one of them had some section of crappy thread or some dirt that caused it, or maybe it wasn't lubricated, but with that amount of metal shavings coming out both are probably badly worn by now.

Mine wasn't nearly so rough as to cause the motor to skip, but it was making a lot of noise and had some metal shavings come out of it. I replaced it with a stainless steel threaded rod and a long brass nut, which has worked perfectly (with the rod being harder and the nut being softer than the original parts). It still needs to be kept lubricated and clean though. Thin lubricating oil does work, I use PTFE spray since it attracts less dust and dirt.

As for the other two proposed things, they won't help with this specific issue. The top mount can be of use if the rod is a bit bent, and replacing the z drive gears mainly reduces the backlash in the original ones (which might matter if you do z bed levelling but not very much otherwise).

Probably one of them had some section of crappy thread or some dirt that caused it, or maybe it wasn't lubricated, but with that amount of metal shavings coming out both are probably badly worn by now.

Mine wasn't nearly so rough as to cause the motor to skip, but it was making a lot of noise and had some metal shavings come out of it. I replaced it with a stainless steel threaded rod and a long brass nut, which has worked perfectly (with the rod being harder and the nut being softer than the original parts). It still needs to be kept lubricated and clean though. Thin lubricating oil does work, I use PTFE spray since it attracts less dust and dirt.

As for the other two proposed things, they won't help with this specific issue. The top mount can be of use if the rod is a bit bent, and replacing the z drive gears mainly reduces the backlash in the original ones (which might matter if you do z bed levelling but not very much otherwise).

|

Re: Z-axis threaded rod causes layer skipping *Please Help* August 15, 2014 02:44AM |

Registered: 9 years ago Posts: 176 |

I can't see that the top mount would help with a bent rod - the rod will still be bent, but will just add an additional thing to rub against. It's fairly easy to remove the rod, then roll it on a flat surface to check it's straight. If it's bent, then it's possible if difficult to bend it straight again. Probably better to replace it with a top quality stainless steel one, and in future lubricate the rod to decrease the wear on the nut and rod.

You can increase the voltage to the stepper slightly which should stop the missing steps.

You can increase the voltage to the stepper slightly which should stop the missing steps.

|

Re: Z-axis threaded rod causes layer skipping *Please Help* August 15, 2014 02:49AM |

Registered: 9 years ago Posts: 119 |

As jstck said wobble at the top of the z-axis screw thread is not an issue, the rod on my ormerod wobbles around at the top by as much as 5mm diameter and I am getting good prints, admittedly I am only printing replacement parts for the printer, it may cause quality issues later but this is not what's causing the shavings. Also, don't be tempted to restrict this movement as other threads on this forum have suggested this restriction will then be seen in the print quality.

|

Re: Z-axis threaded rod causes layer skipping *Please Help* August 15, 2014 11:44AM |

Registered: 10 years ago Posts: 2,472 |

Adding a top support will in fact make the effect of a bent rod worse rather than better, because it forces the eccentric (sideways) forces to be exerted at the X-arm support point rather than being harmlessly expended in a free-moving rod top that is not connected to anything.

Dave

(#106)

Dave

(#106)

|

Re: Z-axis threaded rod causes layer skipping *Please Help* August 15, 2014 12:10PM |

Registered: 10 years ago Posts: 2,472 |

As a quick temporary fix you could simply turn your threaded rod up the other way so the bad spot is shifted up above common print heights. While it is off, degrease and clean the rod and then give it a light oiling with 3-in-1 or similar. A wash in petrol while scrubbing in the direction of the threads with a brass wire brush would be a good way to degrease & clean out any debris - taking precautions for the obvious fire hazard of course.

Dave

(#106)

Dave

(#106)

|

Re: Z-axis threaded rod causes layer skipping *Please Help* August 15, 2014 01:30PM |

Registered: 9 years ago Posts: 8 |

|

Re: Z-axis threaded rod causes layer skipping *Please Help* August 23, 2014 02:14PM |

Registered: 9 years ago Posts: 18 |

I fixed the problem, thanks for all your help! I will edit this post with the solution.

(I also fixed a problem where the nut on the threaded rod moved when going up and down on the z axis, I simply put a piece of paper between the nut and the printed part and the nut is no longer moving when the z axis is making small steps up and down.)

Solution:

Change the M5 threaded rod preferably rust-free steel

Change the M5 nut Preferably a long nut like this one:

Lubricate the m5 rod/nut with some lubricant for engines/bikes/hinges, it will decrease wear on the rod.

I bought "Hamron Multi Lube" its basically for everything mechanical, you can buy it (or something simular) at a gas station.

Edited 1 time(s). Last edit at 08/23/2014 02:31PM by victhor.

Youtube: [www.youtube.com] 3D printing videos

3D Hub: [www.3dhubs.com] Pictures of stuff I've printed

Thingyverse: [www.thingiverse.com] More pictures

Facebook: [www.facebook.com]

(I also fixed a problem where the nut on the threaded rod moved when going up and down on the z axis, I simply put a piece of paper between the nut and the printed part and the nut is no longer moving when the z axis is making small steps up and down.)

Solution:

Change the M5 threaded rod preferably rust-free steel

Change the M5 nut Preferably a long nut like this one:

Lubricate the m5 rod/nut with some lubricant for engines/bikes/hinges, it will decrease wear on the rod.

I bought "Hamron Multi Lube" its basically for everything mechanical, you can buy it (or something simular) at a gas station.

Edited 1 time(s). Last edit at 08/23/2014 02:31PM by victhor.

Youtube: [www.youtube.com] 3D printing videos

3D Hub: [www.3dhubs.com] Pictures of stuff I've printed

Thingyverse: [www.thingiverse.com] More pictures

Facebook: [www.facebook.com]

|

Re: Z-axis threaded rod causes layer skipping *Please Help* August 27, 2014 05:44AM |

Registered: 9 years ago Posts: 146 |

I've also had Z-axis issues.

My first simple solution was to add a flat piece of kapton tape the end of the Z threaded rod's nut and then jam the tape end into the gear hole.

Also bought a new steel threaded rod yesterday and ordering the brass nuts.

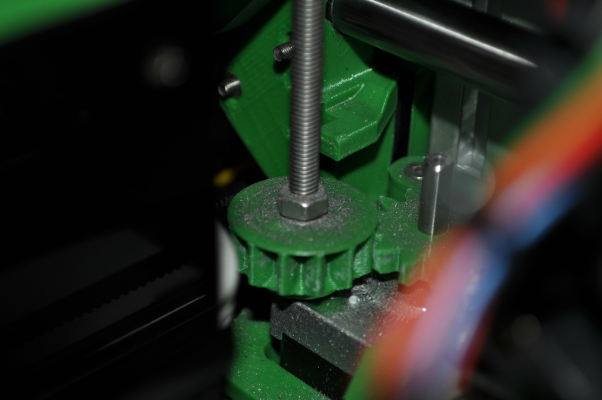

Anyone using the herringbone gears shown in #3 photo above?

[www.thingiverse.com]

They seem a better system.

My first simple solution was to add a flat piece of kapton tape the end of the Z threaded rod's nut and then jam the tape end into the gear hole.

Also bought a new steel threaded rod yesterday and ordering the brass nuts.

Anyone using the herringbone gears shown in #3 photo above?

[www.thingiverse.com]

They seem a better system.

|

Re: Z-axis threaded rod causes layer skipping *Please Help* August 27, 2014 07:21AM |

Registered: 10 years ago Posts: 378 |

Quote

Amsterdamman

Anyone using the herringbone gears shown in #3 photo above?

[www.thingiverse.com]

They seem a better system.

I do, as do many others. The original ones in my case a bit of backlash (some play when they rotate, you can basically wiggle one of them back and forth a bit without the other moving). While it was small, it could potentially have some effect when doing auto bed levelling and the Z axis moves back and forth a lot. Also they look cool.

Sorry, only registered users may post in this forum.