propper upper z mount

Posted by redblunt

|

propper upper z mount August 16, 2014 02:21PM |

Registered: 10 years ago Posts: 112 |

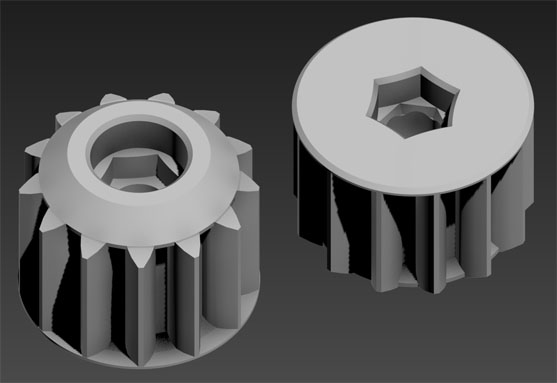

just designed and tested a new upper z mount

using a 625 2RS bearing, held by two m5 nuts

and washers. Reason of this: eliminate momentums

eversince i upgraded the tip of the x-axis does not

move anymore in y directions.

Edited 1 time(s). Last edit at 08/16/2014 02:25PM by redblunt.

Red Ormerod No. 281

Mods:

-My Bedsupport Mk2

-My upper z mount

-Davek0974s Aluminium X-Rib

-iamburnys Z Gears

-Form232-teks Cthulhu cooling ductg

-MasonStonehenges spring-loaded extruder

RepRapFirmware-0.78k-dc42,

web interface 0.99, Win7

using a 625 2RS bearing, held by two m5 nuts

and washers. Reason of this: eliminate momentums

eversince i upgraded the tip of the x-axis does not

move anymore in y directions.

Edited 1 time(s). Last edit at 08/16/2014 02:25PM by redblunt.

Red Ormerod No. 281

Mods:

-My Bedsupport Mk2

-My upper z mount

-Davek0974s Aluminium X-Rib

-iamburnys Z Gears

-Form232-teks Cthulhu cooling ductg

-MasonStonehenges spring-loaded extruder

RepRapFirmware-0.78k-dc42,

web interface 0.99, Win7

|

Re: propper upper z mount August 16, 2014 04:11PM |

Registered: 9 years ago Posts: 138 |

|

Re: propper upper z mount August 17, 2014 08:48AM |

Registered: 10 years ago Posts: 112 |

here you go

[www.thingiverse.com]

Red Ormerod No. 281

Mods:

-My Bedsupport Mk2

-My upper z mount

-Davek0974s Aluminium X-Rib

-iamburnys Z Gears

-Form232-teks Cthulhu cooling ductg

-MasonStonehenges spring-loaded extruder

RepRapFirmware-0.78k-dc42,

web interface 0.99, Win7

[www.thingiverse.com]

Red Ormerod No. 281

Mods:

-My Bedsupport Mk2

-My upper z mount

-Davek0974s Aluminium X-Rib

-iamburnys Z Gears

-Form232-teks Cthulhu cooling ductg

-MasonStonehenges spring-loaded extruder

RepRapFirmware-0.78k-dc42,

web interface 0.99, Win7

|

Re: propper upper z mount August 18, 2014 07:54AM |

Registered: 10 years ago Posts: 2,472 |

A good design, but it is really not a good idea to constrain the top of the threaded rod. Doing so means that the rod is held in 3 places rather than two, and results in any bend in the rod being translated to sideways forces on the Z nut, which will act to move the X-arm between layers and is quite likely to put steps in the print (or in extreme cases could break the nut trap or cause the Z motor to miss steps). With the top of the rod free, any bend causes the top of the rod to wave around in circles, but does not put any significant sideways forces on the Z nut and has little adverse effect. If you use this design, you should make very certain that your threaded rod is 100% straight.

Dave

(#106)

Dave

(#106)

|

Re: propper upper z mount August 18, 2014 11:20AM |

Registered: 10 years ago Posts: 112 |

äh no.

my rod wasnt straight.

the results of my prints speak for themselves.

x-axis is more stable eversince i installed the mod.

i didnt put the nuts in very tight there are alsowashers in between.

if the forces your refering to are so big that they break the nuttrap your

motor is done - exchange it :-)

PLA is a little flexible and does also compensate upmoving forces.

if im wrong id be glad to learn, tell me

Moritz

my rod wasnt straight.

the results of my prints speak for themselves.

x-axis is more stable eversince i installed the mod.

i didnt put the nuts in very tight there are alsowashers in between.

if the forces your refering to are so big that they break the nuttrap your

motor is done - exchange it :-)

PLA is a little flexible and does also compensate upmoving forces.

if im wrong id be glad to learn, tell me

Moritz

|

Re: propper upper z mount August 18, 2014 12:36PM |

Registered: 10 years ago Posts: 2,472 |

Quote

redblunt

äh no.

my rod wasnt straight.

the results of my prints speak for themselves.

x-axis is more stable eversince i installed the mod.

i didnt put the nuts in very tight there are alsowashers in between.

if the forces your refering to are so big that they break the nuttrap your

motor is done - exchange it :-)

PLA is a little flexible and does also compensate upmoving forces.

if im wrong id be glad to learn, tell me

Moritz

It is mechanics - not opinion. Imagine a Z rod that is curved so it forms part of a circle. If it is held at both top and bottom, then when the nut is at the halfway point the curve will be pulling the nut around in circles to follow the path of the mid-point of the curve. A curved rod can never fit along 3 points that are in a straight line. If however the rod is not held at the top, it can centre itself between the bottom (driven) point and the nut, and the top of the rod will move in circles instead of the nut, with the angle of the rod moving slightly as the nut moves along the rod to different points on the curve. Any curve will fit between just 2 points.

Dave

(#106)

|

Re: propper upper z mount August 18, 2014 02:02PM |

Registered: 10 years ago Posts: 14,672 |

In my experience, the problem is not that the rod is not straight, it is that the hexagonal hole or bearing hole in the Z driven gear and/or the hole in the nut that fits inside it is not quite central. When the Z motor rotates, I can see the bottom of the rod wobbling around a little. When the X axis is low, this makes the top of the rod wobble a lot. I have reprinted the Z driven gear a couple of times, but I always saw the same thing. If your Ormerod does this too, then constraining the top of the rod will cause extra wear on the Z nut and the rod, similar to how Dave has described when the rod is bent.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: propper upper z mount August 18, 2014 04:24PM |

Registered: 12 years ago Posts: 1,611 |

I think dmould (was it you, Dave?) has pointed out before, it's not necessarily the nut trap in the z-driven-gear that's off-centre, it's the slop in the thread of the nuts that are tightened together on the end of the rod that allows them to slip off-centre on the Z leadscrew! I seem to be lucky, and manage to get the lower one on central more often than not. Test by putting it in a drill and spinning it, before fitting it to the machine. I'm not sure how to get the nut to align centrally... anyone?

Ian

RepRapPro tech support

Edited 1 time(s). Last edit at 08/18/2014 04:25PM by droftarts.

Ian

RepRapPro tech support

Edited 1 time(s). Last edit at 08/18/2014 04:25PM by droftarts.

|

Re: propper upper z mount August 18, 2014 06:53PM |

Registered: 10 years ago Posts: 378 |

If the problem is the nut being off-center, then maybe the driven gear can be redesigned so the nut trap allows for that, and have the threaded rod go further down (or move the nuts up a bit) and have the rod center itself with respect to the gear. Not sure how to make such a nut trap / hole without backlash though, other than filling it up with epoxy.

|

Re: propper upper z mount August 19, 2014 10:23AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: propper upper z mount September 27, 2014 08:33PM |

Registered: 10 years ago Posts: 12 |

Hey Guys,

Ive been plagued by this problem for a while, at first i thought it was the gear part itself but then when i read this thread i found out i was on the wrong track anyway.

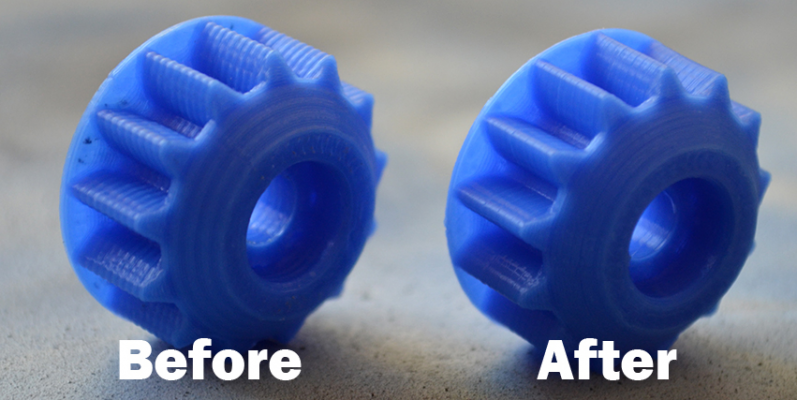

I started mucking around trying to come up with something to fix this and i think i may have had a bit of success (unless the threaded rod has randomly aligned first go

So what i did was take the original z driven gear and made it twice as tall and adding an extra nut on the other end just above where the bearing fits...

The idea was the taller gear with two nuts will result in a straighter alignment with the threaded rod.

This gear requires one extra nut to be insterted underneath, and the usual 2 nuts above. After replacement I got the result below, you can see the nasty ribbing i was getting on the left piece.

Ive attached the stl, also i had to expand the circular hole for the bearing by about 0.2mm to make it fit on my bearing, hopefully this doesnt make it too loose for you guys.

test it out and lemme know how it goes, hopefully this helps.

Ive been plagued by this problem for a while, at first i thought it was the gear part itself but then when i read this thread i found out i was on the wrong track anyway.

I started mucking around trying to come up with something to fix this and i think i may have had a bit of success (unless the threaded rod has randomly aligned first go

So what i did was take the original z driven gear and made it twice as tall and adding an extra nut on the other end just above where the bearing fits...

The idea was the taller gear with two nuts will result in a straighter alignment with the threaded rod.

This gear requires one extra nut to be insterted underneath, and the usual 2 nuts above. After replacement I got the result below, you can see the nasty ribbing i was getting on the left piece.

Ive attached the stl, also i had to expand the circular hole for the bearing by about 0.2mm to make it fit on my bearing, hopefully this doesnt make it too loose for you guys.

test it out and lemme know how it goes, hopefully this helps.

|

Re: propper upper z mount November 02, 2015 10:45AM |

Registered: 9 years ago Posts: 5 |

I tried both the Double Helix Z-Gears and the z-gear-driven_tall.stl approach.

The former I found very difficult to mash, perhaps my prints were oversized.

The latter fitted perfectly without any fettling.

I have added the brass nut from the original Ormerod 2 hot end nozzle, on top of the upper nut, just for good measure.

The result is pretty near perfect. The threaded z axle appears virtually straight, without the meandering of the top end I had before.

Many thanks to Sot.

Maurice

The former I found very difficult to mash, perhaps my prints were oversized.

The latter fitted perfectly without any fettling.

I have added the brass nut from the original Ormerod 2 hot end nozzle, on top of the upper nut, just for good measure.

The result is pretty near perfect. The threaded z axle appears virtually straight, without the meandering of the top end I had before.

Many thanks to Sot.

Maurice

Sorry, only registered users may post in this forum.