What went wrong?

Posted by Davek0974

|

What went wrong? September 14, 2014 02:41PM |

Registered: 10 years ago Posts: 776 |

Was trying to print the skull.stl that was mentioned on another thread, it's on thingyverse.

It was working perfectly for four hours or so then I heard a crunching noise from downstairs, checked the printer upstairs and find the head jumping about and the print catching on the sensor board and fan outlets, I aborted the print as it was clear it was wrecked.

You can just about see the problem in the pics, the support for I think the eye sockets was sticking way above the perimeter, about three mm higher on both sides, it was not formed correctly.

Bloody annoying as this was the best print yet, the half that was printed was 100% perfect on the outside, not happy

Any suggestions?

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

It was working perfectly for four hours or so then I heard a crunching noise from downstairs, checked the printer upstairs and find the head jumping about and the print catching on the sensor board and fan outlets, I aborted the print as it was clear it was wrecked.

You can just about see the problem in the pics, the support for I think the eye sockets was sticking way above the perimeter, about three mm higher on both sides, it was not formed correctly.

Bloody annoying as this was the best print yet, the half that was printed was 100% perfect on the outside, not happy

Any suggestions?

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: What went wrong? September 14, 2014 03:30PM |

Registered: 10 years ago Posts: 1,230 |

How fast was your print?, I have no other advice for up curling than to print slow and let the nozzle heat iron down the buggers, these were my setting for "Skull with Pointed Teeth"

[www.thingiverse.com]

; generated by Slic3r 1.0.0RC3 on 2014-05-15 at 21:21:15

; layer_height = 0.24

; perimeters = 2

; top_solid_layers = 4

; bottom_solid_layers = 3

; fill_density = 0.25

; perimeter_speed = 40

; infill_speed = 40

; travel_speed = 60

; nozzle_diameter = 0.5

; filament_diameter = 1.75

; extrusion_multiplier = 0.90

; perimeters extrusion width = 0.50mm

; infill extrusion width = 0.87mm

; solid infill extrusion width = 0.85mm

; top infill extrusion width = 0.85mm

; first layer extrusion width = 0.38mm

Pictures of Mr. Green and Mr. White in this posting and downstream

[forums.reprap.org]

Erik

[www.thingiverse.com]

; generated by Slic3r 1.0.0RC3 on 2014-05-15 at 21:21:15

; layer_height = 0.24

; perimeters = 2

; top_solid_layers = 4

; bottom_solid_layers = 3

; fill_density = 0.25

; perimeter_speed = 40

; infill_speed = 40

; travel_speed = 60

; nozzle_diameter = 0.5

; filament_diameter = 1.75

; extrusion_multiplier = 0.90

; perimeters extrusion width = 0.50mm

; infill extrusion width = 0.87mm

; solid infill extrusion width = 0.85mm

; top infill extrusion width = 0.85mm

; first layer extrusion width = 0.38mm

Pictures of Mr. Green and Mr. White in this posting and downstream

[forums.reprap.org]

Erik

|

Re: What went wrong? September 14, 2014 03:42PM |

Registered: 10 years ago Posts: 776 |

Thanks, I may be running slightly faster than that, will check.

The quality of the printed bit was fantastic, makes it more annoying.

I will have to wait until next weekend for a reprint as I don't want risk letting it run at night, if the same thing happens it might rip the sensor board off.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

The quality of the printed bit was fantastic, makes it more annoying.

I will have to wait until next weekend for a reprint as I don't want risk letting it run at night, if the same thing happens it might rip the sensor board off.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: What went wrong? September 14, 2014 03:52PM |

Registered: 10 years ago Posts: 14,672 |

I also reduce the "small perimeter" speed to 10mm/sec. But I'm not sure whether those eye sockets count as small perimeters.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: What went wrong? September 15, 2014 01:53AM |

Registered: 10 years ago Posts: 101 |

The noise is probably from the motors skipping steps because the movement is blocked by the print.

It looks like your eye is curling upwards. I have seen a similar thing happening several times when the object has a slight slope upwards - like the lower side of balls (your eyeball).

As I have no idea how to solve this problem, I'm very much looking forward to see what comes out of this thread.

Best regards,

Carsten

It looks like your eye is curling upwards. I have seen a similar thing happening several times when the object has a slight slope upwards - like the lower side of balls (your eyeball).

As I have no idea how to solve this problem, I'm very much looking forward to see what comes out of this thread.

Best regards,

Carsten

|

Re: What went wrong? September 15, 2014 03:49AM |

Registered: 10 years ago Posts: 1,230 |

Something to notice, your print: infill only where needed, my print infill 25% everywhere

Could be that the infill everywhere helps in keeping the curling down a bit - or help distributing the heat from the eye sockets

Edit: some ideas in this thread (nophead esp.)

[forums.reprap.org]

Erik

Edited 1 time(s). Last edit at 09/15/2014 03:58AM by ormerod168.

Could be that the infill everywhere helps in keeping the curling down a bit - or help distributing the heat from the eye sockets

Edit: some ideas in this thread (nophead esp.)

[forums.reprap.org]

Erik

Edited 1 time(s). Last edit at 09/15/2014 03:58AM by ormerod168.

|

Re: What went wrong? September 15, 2014 04:23AM |

Registered: 10 years ago Posts: 378 |

I think it is mostly a matter of temperature, speed and cooling. I've had this happen on overhangs where they curl upwards, but with no clear pattern to when it arises (I don't know the common factor among which prints do this and not). My best-guess theory though:

When it prints the outermost perimeter the ones inside are still soft enough that when it cools (and therefore shrinks a little bit) the whole perimeter does so. It happens on overhangs (outward slopes) because the outer perimeter has very little material underneath to stick to, which otherwise tends to keep it in place, and also less material to lead the heat away.

Since most slicers do all perimeters at once (usually from the inside and out), the other perimeter layers are just newly laid down. Layer time is not the biggest factor, but "perimeter laptime" is. Most slicers have options to slow down to do a certain minimum layer time, but in the case of this model it can spend a lot of time on the cranium part, but the eyes are still pretty fast.

A slicer option to do things in a different order, such as inner perimeters -> infill -> outer perimeters might help a little bit, in that the inner perimeters will have had some more time to cool down before the outer is laid, but since the next layer inner perimeter is then done right after it might not mean that much. Also not all models will have any significant amount of infill. Apart from just having a steady flow of cooling air, one thing to try could be to reduce perimeter speed even more. Not just external perimeters, but all of them.

When it prints the outermost perimeter the ones inside are still soft enough that when it cools (and therefore shrinks a little bit) the whole perimeter does so. It happens on overhangs (outward slopes) because the outer perimeter has very little material underneath to stick to, which otherwise tends to keep it in place, and also less material to lead the heat away.

Since most slicers do all perimeters at once (usually from the inside and out), the other perimeter layers are just newly laid down. Layer time is not the biggest factor, but "perimeter laptime" is. Most slicers have options to slow down to do a certain minimum layer time, but in the case of this model it can spend a lot of time on the cranium part, but the eyes are still pretty fast.

A slicer option to do things in a different order, such as inner perimeters -> infill -> outer perimeters might help a little bit, in that the inner perimeters will have had some more time to cool down before the outer is laid, but since the next layer inner perimeter is then done right after it might not mean that much. Also not all models will have any significant amount of infill. Apart from just having a steady flow of cooling air, one thing to try could be to reduce perimeter speed even more. Not just external perimeters, but all of them.

|

Re: What went wrong? September 15, 2014 09:17AM |

Registered: 10 years ago Posts: 2,472 |

Curl-ups can be a real challenge. I've sat babysitting prints with a flat needle file, waiting for the head to get out of the way and then pushing and grinding down the up-curls after every layer at the critical parts of the print. The only thing is that the print needs to be big enough for the head to get out of the way for long enough - or you have to put a sacrificial throwaway structure next to the part to force the head away from the main print every layer.

Apart from the thermal effects, another reason for the up-curls is if the perimeter starts and stops at the corner of an overhang. In that case the corner blobbing exacerbates the up-curl by adding material just where you don't want it. You can easily see that the up-curl on a corner where the perimeter starts & stops is worse than corners that are not used as start places even if they have similar overhangs. You could try setting "Seam position" in Slic3r (I have it under "layers & perimeters" in version 1.1.6) to "Random" which will hopefully result in the perimeter not being started at the same corner for every layer (If I recall correctly previous versions of Slic3r had "Randomise start position" as a check box instead and it did not work all that well because the start points were still not all that random, don't know about the later versions). For parts that you design yourself, try to make all corners rounded - I appreciate that you cannot do so for the part in question.

For interest, I have recently bought the slicing program "Simplify 3D" and curl-up is one thing that is improved, I think due to a "coast to end" feature that stops extruding just before reaching the end of a perimeter and so reduces blobbing at corners. It's probably not however so dramatic an improvement as to warrant the hefty price tag for that feature alone (though overall I am not disappointed with its value as it has several other good features as well).

[edit] I also notice that you have a great deal of stringing on your print. This could be a sign that your hotend is too hot - or possibly that you have not set your retraction large enough (I use 4mm).

Dave

Edited 1 time(s). Last edit at 09/15/2014 09:20AM by dmould.

Apart from the thermal effects, another reason for the up-curls is if the perimeter starts and stops at the corner of an overhang. In that case the corner blobbing exacerbates the up-curl by adding material just where you don't want it. You can easily see that the up-curl on a corner where the perimeter starts & stops is worse than corners that are not used as start places even if they have similar overhangs. You could try setting "Seam position" in Slic3r (I have it under "layers & perimeters" in version 1.1.6) to "Random" which will hopefully result in the perimeter not being started at the same corner for every layer (If I recall correctly previous versions of Slic3r had "Randomise start position" as a check box instead and it did not work all that well because the start points were still not all that random, don't know about the later versions). For parts that you design yourself, try to make all corners rounded - I appreciate that you cannot do so for the part in question.

For interest, I have recently bought the slicing program "Simplify 3D" and curl-up is one thing that is improved, I think due to a "coast to end" feature that stops extruding just before reaching the end of a perimeter and so reduces blobbing at corners. It's probably not however so dramatic an improvement as to warrant the hefty price tag for that feature alone (though overall I am not disappointed with its value as it has several other good features as well).

[edit] I also notice that you have a great deal of stringing on your print. This could be a sign that your hotend is too hot - or possibly that you have not set your retraction large enough (I use 4mm).

Dave

Edited 1 time(s). Last edit at 09/15/2014 09:20AM by dmould.

|

Re: What went wrong? September 15, 2014 01:51PM |

Registered: 10 years ago Posts: 14,672 |

On the rare occasions that I see curl-up, I have used the slider control in the web interface to slow down printing. The hot nozzle won't snag on the print if it is moving slowly enough.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: What went wrong? September 15, 2014 02:29PM |

Registered: 10 years ago Posts: 776 |

Wow, so many things to try.

I'm going to try and re slice it but only from 5mm below where the trouble started to the top, that should save a lot of time in testing.

I'll also turn on full infill at 25% and slow down a bit

Try that lot first.

I did try pulling the curl-ups off while it was paused but it didn't work and the next layer would not sit right so I aborted the print.

Could it be lack of cooling?

I fitted a quiet fan but it does not put as much through the cooling vents at the bottom of the duct due to lower pressure.

I could rig another fan maybe?

Edited 1 time(s). Last edit at 09/15/2014 02:32PM by Davek0974.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

I'm going to try and re slice it but only from 5mm below where the trouble started to the top, that should save a lot of time in testing.

I'll also turn on full infill at 25% and slow down a bit

Try that lot first.

I did try pulling the curl-ups off while it was paused but it didn't work and the next layer would not sit right so I aborted the print.

Could it be lack of cooling?

I fitted a quiet fan but it does not put as much through the cooling vents at the bottom of the duct due to lower pressure.

I could rig another fan maybe?

Edited 1 time(s). Last edit at 09/15/2014 02:32PM by Davek0974.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: What went wrong? September 15, 2014 02:36PM |

Registered: 10 years ago Posts: 1,230 |

Quote

dc42

On the rare occasions that I see curl-up..

I don't find it rare, for Me it's a general problem

Quote

dc42

I have used the slider control in the web interface to slow down printing. The hot nozzle won't snag on the print if it is moving slowly enough.

No, but it will still leave a mess (for Me it will)

Do You feel lucky? ; -)

Massive Overhang Test:

[www.thingiverse.com]

|

Re: What went wrong? September 15, 2014 06:42PM |

Registered: 10 years ago Posts: 859 |

Hi, when I modified Big Blue 360 to allow clearance for DCs I.R. Probe board, there was a corner with a Mass of Hot Plastic that did the same thing.

I didn't want to reduce the speed just because of this one small area (there is one of the Fan mounting brackets in the same spot that compounded the problem),

so I placed a pillar up from below it to anchor the corner down. It worked a treat. So I'd suggest infilling the whole area to hold the devil down.

Good Luck,

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

I didn't want to reduce the speed just because of this one small area (there is one of the Fan mounting brackets in the same spot that compounded the problem),

so I placed a pillar up from below it to anchor the corner down. It worked a treat. So I'd suggest infilling the whole area to hold the devil down.

Good Luck,

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: What went wrong? September 15, 2014 07:22PM |

Registered: 10 years ago Posts: 105 |

I'm with Erik on this one - I've found that "infill only when needed" makes curling worse, and have successfully printed this skull at 10% infill...I don't tend to go lower than that these days. I've also fitted 2 x secondary fans as per @Appjaws1 design in another thread and that has really helped reduce curling almost to the point of "no issue" from my previous position of "major pain" - hope this helps...persist with the print though...it is a real head turner

|

Re: What went wrong? September 16, 2014 02:06PM |

Registered: 10 years ago Posts: 776 |

I've set the parameters listed above m split the design in slic3r and have the top half running again now. I split about 5mm below where the trouble started before and so far it looks perfect.

Only problem if it works is, I don't know which change fixed it

My guess is the solid infill at 25% as the speed reductions were very small.

The other bits I know nothing about are the extrusion width settings, mine were all on slic3r defaults of "auto", can anyone explain what they do?

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Only problem if it works is, I don't know which change fixed it

My guess is the solid infill at 25% as the speed reductions were very small.

The other bits I know nothing about are the extrusion width settings, mine were all on slic3r defaults of "auto", can anyone explain what they do?

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: What went wrong? September 17, 2014 01:04PM |

Registered: 10 years ago Posts: 776 |

Looks good, in fact I quite like the "half-skull" effect

I've put my speeds back as there really was not much difference, I have also ticked the randomise seams option and scaled it up to 105%

G-codes all ready and will give it a go Saturday as I'm in all day and can monitor it.

The half skull took five hours to run.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

I've put my speeds back as there really was not much difference, I have also ticked the randomise seams option and scaled it up to 105%

G-codes all ready and will give it a go Saturday as I'm in all day and can monitor it.

The half skull took five hours to run.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: What went wrong? September 18, 2014 11:24AM |

Registered: 10 years ago Posts: 1,230 |

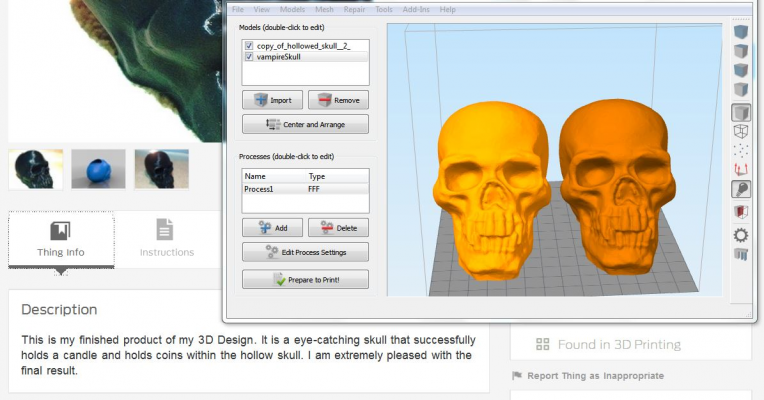

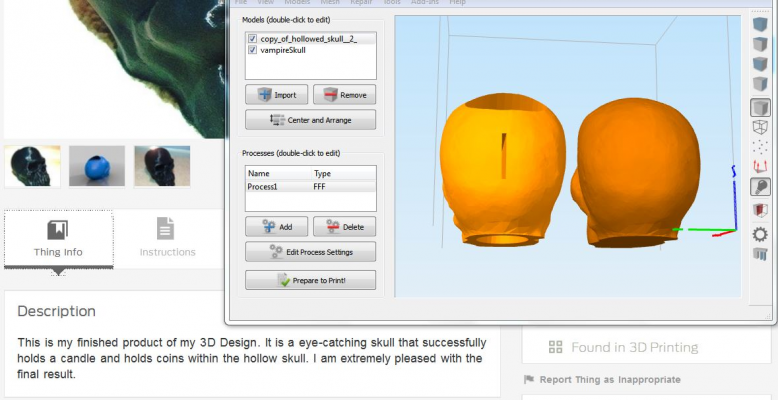

Talk about akaziuna'a Skull with Pointed Teeth, here's a new skull design on thingiverse, it looks like a mod of same but no credit payed so it can't be ahem...

[www.thingiverse.com]

Erik

Quote

kellyd

This is my finished product of my 3D Design. It is a eye-catching skull that successfully holds a candle and holds coins within the hollow skull. I am extremely pleased with the final result.

[www.thingiverse.com]

Erik

|

Re: What went wrong? September 20, 2014 06:10AM |

Registered: 10 years ago Posts: 1,230 |

|

Re: What went wrong? September 20, 2014 06:53AM |

Registered: 10 years ago Posts: 776 |

About three hours into an estimated eleven hour print and it's looking good so far

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: What went wrong? September 20, 2014 04:32PM |

Registered: 10 years ago Posts: 776 |

Alas, poor yorik.....

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: What went wrong? September 20, 2014 04:39PM |

Registered: 10 years ago Posts: 776 |

And his half-brother, Boris...

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: What went wrong? September 23, 2014 01:57AM |

Registered: 10 years ago Posts: 1,230 |

|

Re: What went wrong? September 23, 2014 04:01PM |

Registered: 10 years ago Posts: 776 |

Yes, one, ten hour print!

I think it was the infill, needs a full mesh not only where it thinks it does.

Used half a reel of filament too!

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

I think it was the infill, needs a full mesh not only where it thinks it does.

Used half a reel of filament too!

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Sorry, only registered users may post in this forum.