Dead heated bed

Posted by Pyro

|

Dead heated bed November 07, 2014 06:36PM |

Registered: 9 years ago Posts: 46 |

Ok guys I think I have killed my heated bed tonight. Which is a shame because I thought I had just gotten the z-axis nice and flat for my first test print.

I got a strange burning smell come from the printer but couldn't see smoke anywhere so I turned it all off. After running a few tests I noticed that the heated bed LED no longer came on and it was not heating.

After taking it appart I have noticed a little black around one of the power terminals where it joins the bed and the solder around the screws that hold the power cables to the bed had bubbled up and over the screwheads themselves.

I am asuming that there was a short somewhere. Would a simple continutiy test accross the terminals (after I have disconnected the power cables) confirm that the bed is indeed fried?

I got a strange burning smell come from the printer but couldn't see smoke anywhere so I turned it all off. After running a few tests I noticed that the heated bed LED no longer came on and it was not heating.

After taking it appart I have noticed a little black around one of the power terminals where it joins the bed and the solder around the screws that hold the power cables to the bed had bubbled up and over the screwheads themselves.

I am asuming that there was a short somewhere. Would a simple continutiy test accross the terminals (after I have disconnected the power cables) confirm that the bed is indeed fried?

|

Re: Dead heated bed November 08, 2014 03:06AM |

Registered: 10 years ago Posts: 14,672 |

You must have an Ormerod 2 because the heated bed on my O1 doesn't have screw terminals. Could it be that the screw was loose, giving rise to a bad contact and local overheating? Can you post a photo?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Dead heated bed November 08, 2014 12:47PM |

Registered: 9 years ago Posts: 46 |

Sorry, I have been traveling all day. I have some images here.

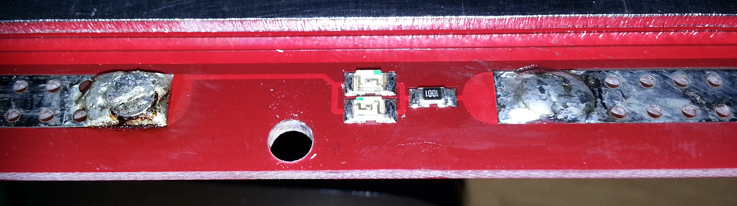

Top side shows melted solder

Bottom side has some black residue around one of the terminals.

Top side shows melted solder

Bottom side has some black residue around one of the terminals.

|

Re: Dead heated bed November 08, 2014 01:23PM |

Registered: 10 years ago Posts: 14,672 |

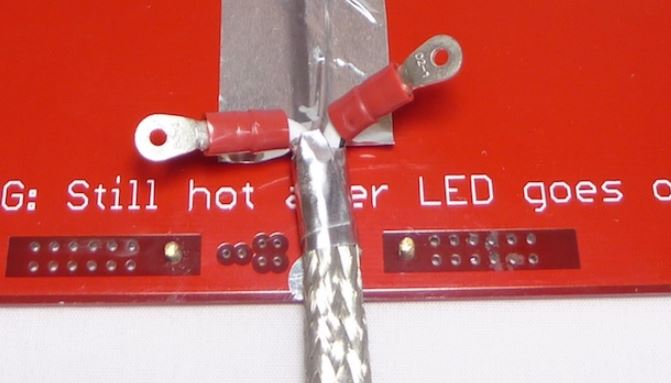

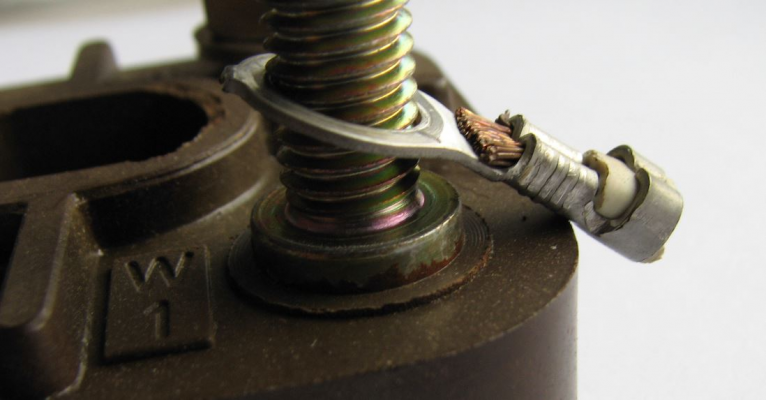

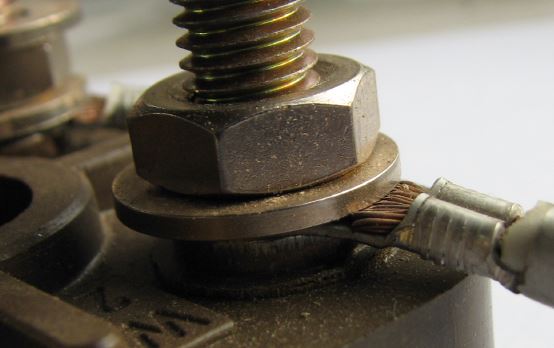

Is the nut tight?

I'm a little surprised by that method of construction. Usually when a crimp tag like that one is used, the tag would be clamped in direct contact with whatever the wire has to be connected to. But in this case, it looks to me that the current has to flow from the tag through what looks like a steel spring washer, to the nut, then to the screw thread, down the screw, and finally from the screw head to the copper trace it is soldered into. The nut is brass, but the screw looks as though it may be steel. So there is quite a lot of opportunity for bad contact, leading to overheating.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I'm a little surprised by that method of construction. Usually when a crimp tag like that one is used, the tag would be clamped in direct contact with whatever the wire has to be connected to. But in this case, it looks to me that the current has to flow from the tag through what looks like a steel spring washer, to the nut, then to the screw thread, down the screw, and finally from the screw head to the copper trace it is soldered into. The nut is brass, but the screw looks as though it may be steel. So there is quite a lot of opportunity for bad contact, leading to overheating.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Dead heated bed November 08, 2014 04:09PM |

Registered: 10 years ago Posts: 1,230 |

Quote

dc42

I'm a little surprised by that method of construction. Usually when a crimp tag like that one is used, the tag would be clamped in direct contact with whatever the wire has to be connected to. But in this case, it looks to me that the current has to flow from the tag through what looks like a steel spring washer, to the nut, then to the screw thread, down the screw, and finally from the screw head to the copper trace it is soldered into. The nut is brass, but the screw looks as though it may be steel. So there is quite a lot of opportunity for bad contact, leading to overheating.

From O2 documentation:

Agreed - this is very wrong, the connection will never be stable with that springy PCB underneath, there should at least be a brass nut on both sides of the connector, and of cause no spring washer

Erik

|

Re: Dead heated bed November 08, 2014 04:23PM |

Registered: 10 years ago Posts: 14,672 |

I'm also surprised that RRP found it necessary to change from the original ribbon cable to the 2-core screened cable. The heated bed is not normally PWM'd (although the Duet is capable of that), so EMI from the heated bed cables should not have been a big issue.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Dead heated bed November 08, 2014 05:45PM |

Registered: 9 years ago Posts: 46 |

|

Re: Dead heated bed November 08, 2014 07:13PM |

Registered: 10 years ago Posts: 14,672 |

I guess another possibility is that the solder joint between the head of that screw and the heated bed PCB trace wasn't good enough, and that's where the heat was generated. This would account for the solder melting.

I think it should be possible to save your board. You would need a high-powered soldering iron (40W or more) with a large bit. I would remove the tag and nut, then heat the head of the screw with the iron until you can push the screw out. Using a solder sucker, remove as much of the old solder as you can from the heated bed where the screw was soldered in. Get a new screw and nut. A brass screw will be much easier to solder than a steel one, but you will have to be careful not to over-tighten the nut, to avoid breaking the screw. Before fitting the screw, tin the parts of it that will be soldered to the pcb, so that you are more likely to get a good joint. Then solder the new screw in. I would fit the spring washer under the tag instead of between the tag and the nut, so that the tag is in direct contact with the brass nut.

Please note that I have no experience with the O2 variant of the heated bed, so the above is based only on what I can see in your photos. Ian (droftarts) of RepRapPro may offer some suggestions if you wait another day or two. Or you could email RepRapPro support directly.

Edited 1 time(s). Last edit at 11/08/2014 07:19PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I think it should be possible to save your board. You would need a high-powered soldering iron (40W or more) with a large bit. I would remove the tag and nut, then heat the head of the screw with the iron until you can push the screw out. Using a solder sucker, remove as much of the old solder as you can from the heated bed where the screw was soldered in. Get a new screw and nut. A brass screw will be much easier to solder than a steel one, but you will have to be careful not to over-tighten the nut, to avoid breaking the screw. Before fitting the screw, tin the parts of it that will be soldered to the pcb, so that you are more likely to get a good joint. Then solder the new screw in. I would fit the spring washer under the tag instead of between the tag and the nut, so that the tag is in direct contact with the brass nut.

Please note that I have no experience with the O2 variant of the heated bed, so the above is based only on what I can see in your photos. Ian (droftarts) of RepRapPro may offer some suggestions if you wait another day or two. Or you could email RepRapPro support directly.

Edited 1 time(s). Last edit at 11/08/2014 07:19PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Dead heated bed November 08, 2014 09:23PM |

Registered: 9 years ago Posts: 46 |

|

Re: Dead heated bed November 09, 2014 04:41AM |

Registered: 10 years ago Posts: 1,230 |

Quote

dc42

...I would fit the spring washer under the tag instead of between the tag and the nut, so that the tag is in direct contact with the brass nut...

That's good advice, would be much better, but can the PCB carry the pressure from the small surface of the spring washer or will it give over time? - I would rather lose the spring washer and solder the tag, screw and nut into a solid connection

Quote

dc42

...Please note that I have no experience with the O2 variant of the heated bed, so the above is based only on what I can see in your photos

Ditto

Erik

|

Re: Dead heated bed November 09, 2014 04:52AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Pyro

Just to double check, you are suggesting that I apply solder to the screw after a new one is fitted?

The most important bit is that there is solder between the screw and the PCB trace. After tinning the underside of the screw head, I suggest you insert the screw, add the nut and spring washer loosely done up, apply heat to the screw head, apply solder to the join between the screw head and the PCB, and tighten up the nut while the solder is molten (you may run out of hands while doing this!). Allow to cool, then add the tag and re-tighten .

Quote

ormerod168

but can the PCB carry the pressure from the small surface of the spring washer or will it give over time?

Probably better add a plain washer between the spring washer and the PCB.

Edited 1 time(s). Last edit at 11/09/2014 04:54AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Dead heated bed November 09, 2014 05:24AM |

Registered: 10 years ago Posts: 1,230 |

Like this:

Not like this:

And I prefer self locking nuts to spring washers

Erik

Not like this:

And I prefer self locking nuts to spring washers

Erik

|

Re: Dead heated bed November 09, 2014 07:18PM |

Registered: 9 years ago Posts: 4 |

I ran into the same issue with the ormerod 2 bed. It was working fine for 4 or 5 builds but then I ran into the same issue you ran into (see attached pic). I got to it too late (I had stepped away from the build for an hour), so my board is fried. I've sent a support email to reprap. Hopefully, they've got a good solution in the works. Of note, the nut was tight when I first built the printer, but I hadn't checked it prior to this most recent build. I still love the printer and have learned a ton building and using it.

Edited 1 time(s). Last edit at 11/09/2014 07:26PM by RedMD.

Edited 1 time(s). Last edit at 11/09/2014 07:26PM by RedMD.

|

Re: Dead heated bed November 10, 2014 04:45AM |

Registered: 9 years ago Posts: 92 |

|

Re: Dead heated bed November 10, 2014 05:17AM |

Registered: 12 years ago Posts: 1,611 |

Hi Pyro, RedMD

We've had a couple of reports of failure of the heated bed in this way. Unfortunately, it's not entirely obvious what causes the problem. The outcome, however, is clear; that a poor connection of the heated loom to the bed creates heat, often enough to melt the solder around the brass screw. This is not a short circuit - it's just burning out the connection, so the connection fails.

It seems there are a number of potential causes:

1. If the heated bed wiring loom is not secured to the y-carriage, the movement of the wires at the screw can fatigue and/or slacken off the connection. See 3rd step here: [reprappro.com]

2. The brass nut not being tight (or working loose), or the spring washer missing from the connection; see 7th step here: [reprappro.com]

3. The brass nut being tightened so much it breaks the solder or solder pad (It's why we used a spring washer).

4. The crimped eyelets on the end of the loom not being well crimped, or working loose.

5. Poor quality soldering not making a good connection between the screw and and the solder pad on the PCB. It's also possible that, as the brass screw cools down, it contracts, and shrinks away from the solder.

If you feel it wasn't a mounting mistake, we're sorry for the inconvenience, and we are happy to send you a new heated bed and heated bed loom. But, for the moment, it will be the same style. Email me on support@reprappro.com

If the solder pads are still okay, probably the quickest fix/alternative mounting is to solder the ends of the bed loom onto the PCB, like we do with the Mendel: [reprappro.com]

Why did we do it like this? We HAD to use a shielded cable; the ribbon cable acted like an aerial and emitted way too much EMI. We also needed a shield over the connections on the edge of the bed, for the same reason, and the IDC connectors to the board are very bulky. We also couldn't find a connector that allowed us to fit the connectors on top of the bed, without being higher than the level of the glass. We didn't have the option at the time of altering the heated bed circuit; the free version of Eagle PCB has a maximum size of PCB. So we needed to find a solution that worked with the standard and widely available heated bed PCB ( [reprap.org] ) rather than going for something bespoke, that didn't involve the customer doing any soldering, that was low profile. In retrospect, a slightly longer screw and a nut each side of the eyelet may create a better contact, but there's still the potential for it coming loose, and being poorly assembled.

We've since switched to KiCad, which allows large PCBs, and converted the bed from Eagle to KiCad, and we'll publish these soon. We've changed the bed contacts, which now has a spade connector on it, and is low-profile. We hopefully are getting the first sample today, to test.

Ian

RepRapPro tech support

We've had a couple of reports of failure of the heated bed in this way. Unfortunately, it's not entirely obvious what causes the problem. The outcome, however, is clear; that a poor connection of the heated loom to the bed creates heat, often enough to melt the solder around the brass screw. This is not a short circuit - it's just burning out the connection, so the connection fails.

It seems there are a number of potential causes:

1. If the heated bed wiring loom is not secured to the y-carriage, the movement of the wires at the screw can fatigue and/or slacken off the connection. See 3rd step here: [reprappro.com]

2. The brass nut not being tight (or working loose), or the spring washer missing from the connection; see 7th step here: [reprappro.com]

3. The brass nut being tightened so much it breaks the solder or solder pad (It's why we used a spring washer).

4. The crimped eyelets on the end of the loom not being well crimped, or working loose.

5. Poor quality soldering not making a good connection between the screw and and the solder pad on the PCB. It's also possible that, as the brass screw cools down, it contracts, and shrinks away from the solder.

If you feel it wasn't a mounting mistake, we're sorry for the inconvenience, and we are happy to send you a new heated bed and heated bed loom. But, for the moment, it will be the same style. Email me on support@reprappro.com

If the solder pads are still okay, probably the quickest fix/alternative mounting is to solder the ends of the bed loom onto the PCB, like we do with the Mendel: [reprappro.com]

Why did we do it like this? We HAD to use a shielded cable; the ribbon cable acted like an aerial and emitted way too much EMI. We also needed a shield over the connections on the edge of the bed, for the same reason, and the IDC connectors to the board are very bulky. We also couldn't find a connector that allowed us to fit the connectors on top of the bed, without being higher than the level of the glass. We didn't have the option at the time of altering the heated bed circuit; the free version of Eagle PCB has a maximum size of PCB. So we needed to find a solution that worked with the standard and widely available heated bed PCB ( [reprap.org] ) rather than going for something bespoke, that didn't involve the customer doing any soldering, that was low profile. In retrospect, a slightly longer screw and a nut each side of the eyelet may create a better contact, but there's still the potential for it coming loose, and being poorly assembled.

We've since switched to KiCad, which allows large PCBs, and converted the bed from Eagle to KiCad, and we'll publish these soon. We've changed the bed contacts, which now has a spade connector on it, and is low-profile. We hopefully are getting the first sample today, to test.

Ian

RepRapPro tech support

|

Re: Dead heated bed November 10, 2014 05:34AM |

Registered: 9 years ago Posts: 46 |

Thanks a lot for the feedback!

I have just noticed that RedMD's board has burned out on the same terminal as mine although their's seems a lot more extensive than mine. I shall have a look tonight, see if there is stll a connection accross the board and it can be salvaged. Otherwise I'll send you a mail shot about a replacement. Although it kind of sounds like it might be worth while hanging on for this new improved design.

I have just noticed that RedMD's board has burned out on the same terminal as mine although their's seems a lot more extensive than mine. I shall have a look tonight, see if there is stll a connection accross the board and it can be salvaged. Otherwise I'll send you a mail shot about a replacement. Although it kind of sounds like it might be worth while hanging on for this new improved design.

|

Re: Dead heated bed November 10, 2014 07:00AM |

Registered: 9 years ago Posts: 73 |

|

Re: Dead heated bed November 10, 2014 07:35AM |

Registered: 9 years ago Posts: 57 |

The power connector melting is due to excessive heat. This happens when you cable does not make good contact to your screw terminal. You should check your wiring connections with a multimeter. they should always read 0 Ohm resistance from one terminal to the other end. Otherwise the connection point will act as a resistor and dissipate power. this causes the terminal to heat up an melt.

|

Re: Dead heated bed November 10, 2014 08:18AM |

Registered: 9 years ago Posts: 73 |

|

Re: Dead heated bed November 10, 2014 09:08AM |

Registered: 12 years ago Posts: 1,611 |

jsv555 - I would tend to agree, that a loose connection in the screw terminal caused the terminal to melt. Generally these things are localised. We suggest checking these screw terminals as part of the maintenance procedures: [reprappro.com]

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: Dead heated bed November 10, 2014 09:58AM |

Registered: 9 years ago Posts: 73 |

Thanks Ian, the problem has sort of gone away as the the melted connector took the sleeves in the board with it when I removed it. As a result I had to solder connections to the board to make sure I was actually getting a connection. Will check all the other screwed connections though as a matter of course.

|

Re: Dead heated bed November 10, 2014 04:53PM |

Registered: 9 years ago Posts: 20 |

Ian,

as a solution to problems with finding a suitable connector...

how about using the 0.1" dual row male pins as per Ormerod 1

and making a tiny PCB with matching holes, and the 'too high' connector that you wanted.

in my best ASCII art

---------------------- glass

=!=!============= bed

+++

_!_!________ new PCB

! ! .............. X

the ! are the dual header pins, + is the insulator of the header, and the X is your connector of choice.

I'm assuming that you solder the connectors to the new carrier PCB then solder it to the bed.

DaveS

Edited 1 time(s). Last edit at 11/10/2014 04:54PM by gnarly.

as a solution to problems with finding a suitable connector...

how about using the 0.1" dual row male pins as per Ormerod 1

and making a tiny PCB with matching holes, and the 'too high' connector that you wanted.

in my best ASCII art

---------------------- glass

=!=!============= bed

+++

_!_!________ new PCB

! ! .............. X

the ! are the dual header pins, + is the insulator of the header, and the X is your connector of choice.

I'm assuming that you solder the connectors to the new carrier PCB then solder it to the bed.

DaveS

Edited 1 time(s). Last edit at 11/10/2014 04:54PM by gnarly.

|

Re: Dead heated bed November 11, 2014 05:03AM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Dead heated bed November 11, 2014 05:56AM |

Registered: 9 years ago Posts: 46 |

|

Re: Dead heated bed December 12, 2014 09:43AM |

Registered: 9 years ago Posts: 2 |

hi just stumbled upon this thread looking for a way and i have the same problem except it was on the other connector. i checked the screws and nuts and they're all tight and the pcb appears to have fallen apart where the burns are, mine isnt as bad as was printing a small project and it happened halfway through printing but luckiny it happened just as i was checking it so i was able to turn it off in time before i fried something else, could it be the same reason for the others or is the PCB officially fried? pictures are attached so you can see damages.

|

Re: Dead heated bed December 12, 2014 09:50AM |

Registered: 9 years ago Posts: 2 |

|

Re: Dead heated bed December 12, 2014 10:39AM |

Registered: 9 years ago Posts: 46 |

|

Re: Dead heated bed December 12, 2014 02:57PM |

Registered: 10 years ago Posts: 14,672 |

I'm glad I have the Ormerod 1 ribbon cable connector instead! I've not heard of it causing a problem, other than that the ribbon cable radiates EMI. Maybe RRP can sort that out by improving the board layout or adding a common mode choke in the next revision of the Duet.

Edited 1 time(s). Last edit at 12/12/2014 02:58PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 12/12/2014 02:58PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Dead heated bed December 19, 2014 05:16AM |

Registered: 9 years ago Posts: 92 |

Hi all,

After noticing a progressive darkening of the solder joint on the bed of my Ormerod 2 ( and reading this thread) I did some (rather unscientific) experimentation. Whether this is of any use to anyone I can't say, but here goes:

1) Firstly I felt the terminals during operation (one at a time!) - When turning on the bed, by the time the temp read 40 degrees C the terminals were already too hot to touch. Dont know if this is normal or not

2) as suggested by some posters here I removed the spring washer (only one terminal at first). The reasoning being that the washer is a choke point for current - current must go from the loom(crimped eyelet) to the screw terminal, and since the surface area of the eyelet in contact with the screw is very small, it must go through the washer and brass nut (the nut having the most contact with the screw). Looking at the brass nut and spring washer its clear that removing the washer doubles (at least) the area of contact between the eyelet and Brass nut. The spring washer has very little surface area.

Repeating my very unscientific finger probe of terminal temperature, there is a clear improvement - the terminal without the washer feels cooler during operation. - more in line with the actual bed temp, although my finger may lack accuracy!

I then removed the other washer - terminal also cooler.

Even after washer removal I am noticing further degradation of the solder joint

The photos attached show the state of the bed after a total of about 10 hours of printing.

I am now going to desolder the screw terminals and solder the wires directly to the bed before the bed fails completely.

It would be interesting if someone with the correct equipment could repeat my experiments with actual temperature measurements of the terminals - if this is possible - as my observations may prove to be complete hogwash :-)

I am sure though that the connections are as tight as I can safely get them, and apparently not everyone with the ormerod 2 is having this issue, so perhaps the solder joint around the screw terminal of some of the beds is just not what it should be, compounding the possible issue of the spring washer.

EDIT:

I have removed the screw terminals and soldered the wires of the loom directly to the bed. My standard finger temp probe resulted in cooler temps on the pads at a bed temp of 40 C and the pad temps seem to stay in line with the actual bed temp after that.

Cheers

James

Edited 1 time(s). Last edit at 12/19/2014 10:06AM by jamesf.

After noticing a progressive darkening of the solder joint on the bed of my Ormerod 2 ( and reading this thread) I did some (rather unscientific) experimentation. Whether this is of any use to anyone I can't say, but here goes:

1) Firstly I felt the terminals during operation (one at a time!) - When turning on the bed, by the time the temp read 40 degrees C the terminals were already too hot to touch. Dont know if this is normal or not

2) as suggested by some posters here I removed the spring washer (only one terminal at first). The reasoning being that the washer is a choke point for current - current must go from the loom(crimped eyelet) to the screw terminal, and since the surface area of the eyelet in contact with the screw is very small, it must go through the washer and brass nut (the nut having the most contact with the screw). Looking at the brass nut and spring washer its clear that removing the washer doubles (at least) the area of contact between the eyelet and Brass nut. The spring washer has very little surface area.

Repeating my very unscientific finger probe of terminal temperature, there is a clear improvement - the terminal without the washer feels cooler during operation. - more in line with the actual bed temp, although my finger may lack accuracy!

I then removed the other washer - terminal also cooler.

Even after washer removal I am noticing further degradation of the solder joint

The photos attached show the state of the bed after a total of about 10 hours of printing.

I am now going to desolder the screw terminals and solder the wires directly to the bed before the bed fails completely.

It would be interesting if someone with the correct equipment could repeat my experiments with actual temperature measurements of the terminals - if this is possible - as my observations may prove to be complete hogwash :-)

I am sure though that the connections are as tight as I can safely get them, and apparently not everyone with the ormerod 2 is having this issue, so perhaps the solder joint around the screw terminal of some of the beds is just not what it should be, compounding the possible issue of the spring washer.

EDIT:

I have removed the screw terminals and soldered the wires of the loom directly to the bed. My standard finger temp probe resulted in cooler temps on the pads at a bed temp of 40 C and the pad temps seem to stay in line with the actual bed temp after that.

Cheers

James

Edited 1 time(s). Last edit at 12/19/2014 10:06AM by jamesf.

Sorry, only registered users may post in this forum.