Help me with my doubts on buying a Omerod2

Posted by Vizual54

|

Help me with my doubts on buying a Omerod2 November 24, 2014 10:50AM |

Registered: 9 years ago Posts: 32 |

Hi!

I'm about to buy my first 3d printer but I can't really decide on what to get. Since this is my first printer and I'm not really sure how much I'll be using it, I have a few things in mind and hopefully more will come, I don't want to spend too much on it ~€600 + a few upgrades. Right now I'm choosing between the Ormerod2, Mendel and Duplicator 4.

The Omerod seems like a really nice machine and better in almost every way so the choice should be easy. It has larger build volume, a better processor with ethernet connectivity which in my opinion is a great plus, seems pretty easy to maintain and it has reasonable price. The forum seems active and at least for the Ormerod mk1 there has been quite a lot of improvements developed and made public here on the forum. DC42 seems to be doing a great job with the firmware (and other things) but are RRP pulling anything of the firmware updates to the main branch?

Though it doesn't have dual nozzle and the upgrade kit that has been promised has not been released yet.

One thing that holds me back the most is that im afraid I need to constantly tinker with the machine every time I'm about to print something. Don't get me wrong here, I love to tinker with stuff and i know that there isnt any maintenance free printers. I'm in no doubt that I will be able to assemble the printer tune it and make it work. I also looking forward to to it. What I'm worried about is that if leaving the machine turned of for a few weeks and then need to print something I have to spend a evening trying to make it work.

Also is the cartesian-xz- head construction that much of a problem as some people say? Vibrating build platform, tall objects shaking and tipping over?

Hope you can help me getting over my concerns.

Edited 1 time(s). Last edit at 11/24/2014 11:00AM by Vizual54.

I'm about to buy my first 3d printer but I can't really decide on what to get. Since this is my first printer and I'm not really sure how much I'll be using it, I have a few things in mind and hopefully more will come, I don't want to spend too much on it ~€600 + a few upgrades. Right now I'm choosing between the Ormerod2, Mendel and Duplicator 4.

The Omerod seems like a really nice machine and better in almost every way so the choice should be easy. It has larger build volume, a better processor with ethernet connectivity which in my opinion is a great plus, seems pretty easy to maintain and it has reasonable price. The forum seems active and at least for the Ormerod mk1 there has been quite a lot of improvements developed and made public here on the forum. DC42 seems to be doing a great job with the firmware (and other things) but are RRP pulling anything of the firmware updates to the main branch?

Though it doesn't have dual nozzle and the upgrade kit that has been promised has not been released yet.

One thing that holds me back the most is that im afraid I need to constantly tinker with the machine every time I'm about to print something. Don't get me wrong here, I love to tinker with stuff and i know that there isnt any maintenance free printers. I'm in no doubt that I will be able to assemble the printer tune it and make it work. I also looking forward to to it. What I'm worried about is that if leaving the machine turned of for a few weeks and then need to print something I have to spend a evening trying to make it work.

Also is the cartesian-xz- head construction that much of a problem as some people say? Vibrating build platform, tall objects shaking and tipping over?

Hope you can help me getting over my concerns.

Edited 1 time(s). Last edit at 11/24/2014 11:00AM by Vizual54.

|

Re: Help me with my doubts on buying a Omerod2 November 24, 2014 11:04AM |

Registered: 9 years ago Posts: 46 |

It does require a bit of fiddling to put together and get running. Mine is still not 100% operational but everyone on here is really helpful and friendly.

From what I have read, once you set up the configuration for your specific machine, make a note of all the settings used and put it into the SD card boot scripts so that it is set up the same way each time you turn it on. The only reconfiguring you may have to do is if you move it too much. I guess it may put the IR sensor readings out a bit.

From what I have read, once you set up the configuration for your specific machine, make a note of all the settings used and put it into the SD card boot scripts so that it is set up the same way each time you turn it on. The only reconfiguring you may have to do is if you move it too much. I guess it may put the IR sensor readings out a bit.

|

Re: Help me with my doubts on buying a Omerod2 November 24, 2014 11:21AM |

Registered: 9 years ago Posts: 19 |

i had the same doubts a couple weeks ago, i had a choice of the omerod2 or a reprap of amazon that had old technology but had a screen and the frame consist of threaded rods held on with plastic parts and tie wraps , the omerod2 looked better and despite being a little bit more expensive i went for it. i did have a couple parts missing but reprappro gave excellent service and sent them out to me first class , i ve built it and done my first print over the weekend and im more than happy with it, provided you read the instructions carefully not only will you have enjoyment building the printer but youl learn a lot of how it works and why and also learn how the programming side of things work, plus theres this forum should you get stuck

|

Re: Help me with my doubts on buying a Omerod2 November 24, 2014 11:42AM |

Registered: 10 years ago Posts: 2,472 |

The fiddly adjustments are mostly one-off - once you get the mechanics adjusted well, they don't change much over time or with use. A light oiling with something such as 3-in-1 should be carried out every couple of weeks. The Z-zero position and bed levelling are exceptions with the unmodified Ormerod kit, and these can change for a variety of reasons, but it takes less than a minute to set a new bed compensation and Z zero position by hand. Fitting an aluminium bed and DC42's differential Z probe greatly reduces those weaknesses unless you move the printer around a lot, in which case you may need to set the bed compensation or mechanically re-level the bed from time to time.

As far as tall print stability is concerned, the Y axis is implemented by moving the bed and print from side to side. Anything with a high C of G and small base area that is not securely stuck down will topple if it is accelerated sideways. The bed does not vibrate too much however, and the object needs to be very tall and thin before that becomes an issue. A greater risk for any print with a small base is that it is dislodged by the nozzle rubbing on or hitting a section that has curled up slightly.

There are several very simple solutions that can be used separately or in combination (listed in order of preference):

1) Slice the print to have a wide "brim" - this increases the base area which improves both stability and its adhesion to the bed. This is the easiest way to stop the part coming loose.

2) If applicable, orient the print with the long axis of its base in the Y direction.

3) When printing parts with a small footprint, use a bed coating that has greater adhesion.

4) Set a smaller acceleration of the Y axis.

Dave

As far as tall print stability is concerned, the Y axis is implemented by moving the bed and print from side to side. Anything with a high C of G and small base area that is not securely stuck down will topple if it is accelerated sideways. The bed does not vibrate too much however, and the object needs to be very tall and thin before that becomes an issue. A greater risk for any print with a small base is that it is dislodged by the nozzle rubbing on or hitting a section that has curled up slightly.

There are several very simple solutions that can be used separately or in combination (listed in order of preference):

1) Slice the print to have a wide "brim" - this increases the base area which improves both stability and its adhesion to the bed. This is the easiest way to stop the part coming loose.

2) If applicable, orient the print with the long axis of its base in the Y direction.

3) When printing parts with a small footprint, use a bed coating that has greater adhesion.

4) Set a smaller acceleration of the Y axis.

Dave

|

Re: Help me with my doubts on buying a Omerod2 November 24, 2014 01:57PM |

Registered: 9 years ago Posts: 102 |

According to my information yes.Quote

Vizual54

The Omerod seems like a really nice machine and better in almost every way so the choice should be easy. It has larger build volume, a better processor with ethernet connectivity which in my opinion is a great plus, seems pretty easy to maintain and it has reasonable price. The forum seems active and at least for the Ormerod mk1 there has been quite a lot of improvements developed and made public here on the forum. DC42 seems to be doing a great job with the firmware (and other things) but are RRP pulling anything of the firmware updates to the main branch?

I saw some documentation about a dual nozzle mod.Quote

Vizual54

Though it doesn't have dual nozzle and the upgrade kit that has been promised has not been released yet.

After three weeks after starting to build that thing in the evening after my dayjob i can say that it prints pretty well. I just switched it on today and printed. It goesQuote

Vizual54

One thing that holds me back the most is that im afraid I need to constantly tinker with the machine every time I'm about to print something. Don't get me wrong here, I love to tinker with stuff and i know that there isnt any maintenance free printers. I'm in no doubt that I will be able to assemble the printer tune it and make it work. I also looking forward to to it. What I'm worried about is that if leaving the machine turned of for a few weeks and then need to print something I have to spend a evening trying to make it work.

so far that one time i started a print without removing the previous. Which the printer got rid by itself...

That was my main concern also. I haven't done to tall prints right now to report. But after having seen the construction build up i was happy with what i saw.Quote

Vizual54

Also is the cartesian-xz- head construction that much of a problem as some people say? Vibrating build platform, tall objects shaking and tipping over?

Hope you can help me getting over my concerns.

While i haven't tested it, i think a Tallmerod would not be worthwhile if the construction was so flimsy.

So while i can't compare to much since this is also my first printer, i am very pleased with what i got. I am also happy with the support of RRP.

|

Re: Help me with my doubts on buying a Omerod2 November 24, 2014 02:07PM |

Registered: 10 years ago Posts: 14,672 |

Quote

tstone

I saw some documentation about a dual nozzle mod.

I wrote a blog entry on how to do it, see my signature at the bottom of this message for the link. It's not difficult. I think RepRapPro also has something in the pipeline.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Help me with my doubts on buying a Omerod2 November 24, 2014 02:35PM |

Admin Registered: 13 years ago Posts: 41 |

Quote

dc42

Quote

tstone

I saw some documentation about a dual nozzle mod.

I wrote a blog entry on how to do it, see my signature at the bottom of this message for the link. It's not difficult. I think RepRapPro also has something in the pipeline.

Yes, we do have something in the pipeline. Just waiting to do the blog post on it. We announced an upgrade to the Huxley early last week - with it we launched a new hot end, the "Quick set". Basically we wanted to start with a blank sheet with something that is setup for two colour from the start. This is ready to go in single colour configuration, the limitation on launching it for two colours at the moment is a few tweaks to the expansion PCB to make the wiring a bit neater, this isn't too far away. Of course if you want to go ahead and do your own wiring, then we'll have the nozzle on the shop fairly soon. Anyway, changes on the nozzle are as follows:

- All metal - The only PTFE is the bowden tube and this stays cold. This is to allow easier assembly, and to allow higher temperatures for (hopefully) new materials

- One Piece- The previous nozzle has a separate bowden end and nozzle. These have been combined into a single piece for easy assembly.

- Reduced melt transition length - How quickly the material transitions from solid to liquid is key to print quality and reliability. We've done a fair bit of analysis in this area to optimise the nozzle geometry. We're running the new nozzle on most of our production machines at the moment. I think we've clocked up about 1500 hours on it so far without issue.

- Easier calibration - The feedback from the Tri Colour Mendels is that the calibration of the second nozzle could be easier. We've made a lot of changes in this area. We'll do a blog post in the next few days. In essence both nozzles now fit into the same aluminum cooler block, that is the same size as the cooling blocks in the old design - so no loss of build volume. This is high precision cnc'ed so the X Y offsets are extremely well controlled. For the height adjustment between the nozzles we've done something a little more interesting. The cooler block is now basically two back-to-back C Clamps. The idea is that to set the height of the nozzle, you loosen the clamps, let both nozzles drop to the bed, and tighten the clamps up and that's it. No more fiddling for calibration, It also means the nozzles and heaters can be removed from the machines whilst leaving the fan and cooler in place - this makes maintenance much much easier.,

Edited 6 time(s). Last edit at 11/24/2014 05:16PM by rhysjones.

|

Re: Help me with my doubts on buying a Omerod2 November 24, 2014 05:06PM |

Registered: 9 years ago Posts: 395 |

This's one exciting. I am modifying my tricolous into a two noozle single hot end with good ventilation for 0.06mm. Next would be the ormerod still in the box. But if you guys plan to release a new hit end, that will save me lot of time!

I guess it might be best to just wait before mounting it?

I guess it might be best to just wait before mounting it?

|

Re: Help me with my doubts on buying a Omerod2 November 25, 2014 06:07AM |

Registered: 9 years ago Posts: 32 |

Thanks for all the reassuring answers!

Seems like I really don't have anything to worry about.

Great to hear that the dual nozzle is coming soon.

@dc42

I had read your blog about the dual nozzle conversion, though the soldering on the processor board feels a little unconfy.

By the way great work with the 3.2" lcd! I will definitely get on of those when I get the Ormerod.

Oh, there I've said it. Only question is then if I should wait until the dual nozzle support is out.

Seems like I really don't have anything to worry about.

Great to hear that the dual nozzle is coming soon.

@dc42

I had read your blog about the dual nozzle conversion, though the soldering on the processor board feels a little unconfy.

By the way great work with the 3.2" lcd! I will definitely get on of those when I get the Ormerod.

Oh, there I've said it. Only question is then if I should wait until the dual nozzle support is out.

|

Re: Help me with my doubts on buying a Omerod2 November 25, 2014 06:19AM |

Admin Registered: 13 years ago Posts: 41 |

@Vizual54

When it does launch, we'll still be shipping the current nozzle in the kit as standard. The new one will be part of a secondary upgrade kit that includes the new nozzle, electronics upgrade board, wiring and things of that nature.

Also I'd recommend you get up and running on a single nozzle before going to the dual anyway, it just keeps things simple whilst you are getting up and running.

When it does launch, we'll still be shipping the current nozzle in the kit as standard. The new one will be part of a secondary upgrade kit that includes the new nozzle, electronics upgrade board, wiring and things of that nature.

Also I'd recommend you get up and running on a single nozzle before going to the dual anyway, it just keeps things simple whilst you are getting up and running.

|

Re: Help me with my doubts on buying a Omerod2 November 25, 2014 07:48AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Vizual54

@dc42

I had read your blog about the dual nozzle conversion, though the soldering on the processor board feels a little unconfy.

The soldering isn't essential, but if you don't modify the boards then the temperature readings on the second nozzle fluctuate by several degrees, and the PID controller has some difficulty in keeping the temperature stable (I can see this by watching the heater LED on my hot end board).

I'm waiting to see what RepRapPro does about this in their dual nozzle kit, because it is a design issue with the Duet/DueX4 combo. One solution that occurred to me just now is to connect the second hot end thermistor to the heated bed thermistor pins on the Duet, and the heated bed thermistor to the DueX4 board hot end thermistor pins. Then add support in the firmware for a configuration gcode to deal with this change. The heated bed thermistor reading is less critical and less affected by noise because of its lower value. I think I'll add this configuration option in my next firmware release.

Edited 6 time(s). Last edit at 11/25/2014 07:52AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Help me with my doubts on buying a Omerod2 November 25, 2014 07:53AM |

Registered: 9 years ago Posts: 395 |

|

Re: Help me with my doubts on buying a Omerod2 November 25, 2014 06:18PM |

Registered: 9 years ago Posts: 102 |

I think its better get accustomed to a single head printer there is still a lot to learn. Get your printer with one nozzle printing and then you can think about adding another... :-)Quote

Vizual54

Oh, there I've said it. Only question is then if I should wait until the dual nozzle support is out.

|

Re: Help me with my doubts on buying a Omerod2 November 25, 2014 07:20PM |

Registered: 10 years ago Posts: 780 |

Quote

dc42

One solution that occurred to me just now is to connect the second hot end thermistor to the heated bed thermistor pins on the Duet, and the heated bed thermistor to the DueX4 board hot end thermistor pins. Then add support in the firmware for a configuration gcode to deal with this change. The heated bed thermistor reading is less critical and less affected by noise because of its lower value. I think I'll add this configuration option in my next firmware release.

This sounds really good, I don't know why I didn't think of it.

I think this will solve the problem and report accurate temperatures for the second nozzle, I won't need to modify my boards

Looking forward to your next release, will it include all of zpl's changes? especially the external fan control and the pause and resume action.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Help me with my doubts on buying a Omerod2 November 26, 2014 05:41AM |

Registered: 10 years ago Posts: 14,672 |

Quote

appjaws1

Quote

dc42

One solution that occurred to me just now is to connect the second hot end thermistor to the heated bed thermistor pins on the Duet, and the heated bed thermistor to the DueX4 board hot end thermistor pins. Then add support in the firmware for a configuration gcode to deal with this change. The heated bed thermistor reading is less critical and less affected by noise because of its lower value. I think I'll add this configuration option in my next firmware release.

This sounds really good, I don't know why I didn't think of it.

I think this will solve the problem and report accurate temperatures for the second nozzle, I won't need to modify my boards

Looking forward to your next release, will it include all of zpl's changes? especially the external fan control and the pause and resume action.

On the Ormerod 1, the wiring will be a little tricky because the thermistor uses the 2 middle wires of the ribbon cable. So you will need to cut just those 2 conductors at the Duet end of the cable, peel them back a bit, and connect them to a 2-pin header connector to plug in to the DueX4. The conductors are quite thin, so you might want to use some silicone rubber or similar as a strain relief. Make sure you use the correct 2 conductors, otherwise you will end up connecting 12V to the thermistor input via the thermistor! Alternatively, run a separate cable from the bed thermistor to the DueX4. Connecting the second hot end to the bed thermistor input can be done using the separate BED_TEMP pins provided on the Duet (you will need to solder a couple of header pins or a terminal block to those pads on the Duet).

For describing the change to the firmware, I think the M305 code could have an option to specify the thermistor channel. All the obvious parameter letters are already used in the M305 command, but X Y Z and J are free. So perhaps M305 P0 X2 would tell the Duet that heater 0 uses thermistor channel 2, and M305 P2 X0 would tell it the converse for the second hot end.

If I do you a special temporary firmware release that swaps the channels, would you like to test this out? I'd like to know whether the noise on the bed temperature is acceptable before I make the changes to M305. My firmware already has cooling fan support. What it doesn't have yet is the code queue for synchronizing fan speed change commands with movements in the queue, or the instant pause facility where moves already in the queue are paused as well as new moves. This is partly because I need to keep the Move code simple pending my next round of changes to it, and partly because the instant pause facility could result in missed steps if it isn't carefully timed. I have already included zpl's pause/resume macro files and networking changes.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Help me with my doubts on buying a Omerod2 November 26, 2014 06:17AM |

Registered: 10 years ago Posts: 780 |

Quote

dc42

Quote

appjaws1

Quote

dc42

One solution that occurred to me just now is to connect the second hot end thermistor to the heated bed thermistor pins on the Duet, and the heated bed thermistor to the DueX4 board hot end thermistor pins. Then add support in the firmware for a configuration gcode to deal with this change. The heated bed thermistor reading is less critical and less affected by noise because of its lower value. I think I'll add this configuration option in my next firmware release.

This sounds really good, I don't know why I didn't think of it.

I think this will solve the problem and report accurate temperatures for the second nozzle, I won't need to modify my boards

Looking forward to your next release, will it include all of zpl's changes? especially the external fan control and the pause and resume action.

On the Ormerod 1, the wiring will be a little tricky because the thermistor uses the 2 middle wires of the ribbon cable. So you will need to cut just those 2 conductors at the Duet end of the cable, peel them back a bit, and connect them to a 2-pin header connector to plug in to the DueX4. The conductors are quite thin, so you might want to use some silicone rubber or similar as a strain relief. Make sure you use the correct 2 conductors, otherwise you will end up connecting 12V to the thermistor input via the thermistor! Alternatively, run a separate cable from the bed thermistor to the DueX4. Connecting the second hot end to the bed thermistor input can be done using the separate BED_TEMP pins provided on the Duet (you will need to solder a couple of header pins or a terminal block to those pads on the Duet).

For describing the change to the firmware, I think the M305 code could have an option to specify the thermistor channel. All the obvious parameter letters are already used in the M305 command, but X Y Z and J are free. So perhaps M305 P0 X2 would tell the Duet that heater 0 uses thermistor channel 2, and M305 P2 X0 would tell it the converse for the second hot end.

If I do you a special temporary firmware release that swaps the channels, would you like to test this out? I'd like to know whether the noise on the bed temperature is acceptable before I make the changes to M305. My firmware already has cooling fan support. What it doesn't have yet is the code queue for synchronizing fan speed change commands with movements in the queue, or the instant pause facility where moves already in the queue are paused as well as new moves. This is partly because I need to keep the Move code simple pending my next round of changes to it, and partly because the instant pause facility could result in missed steps if it isn't carefully timed. I have already included zpl's pause/resume macro files and networking changes.

This has been transferred to a new thread Swaping thermistor channel when using DueX4

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Help me with my doubts on buying a Omerod2 November 29, 2014 03:24PM |

Registered: 10 years ago Posts: 36 |

i say dont buy it!

as a starter printer thers to much to do to get it working.

i would go for a ulltimaker or something simular.

i wouldent buy a makerbot cuz its to little to do.

ormerod is a fun machine and works realy good when ypu get it going but for a first printer i wouldent rekomend it (not even as a second printer)

as a starter printer thers to much to do to get it working.

i would go for a ulltimaker or something simular.

i wouldent buy a makerbot cuz its to little to do.

ormerod is a fun machine and works realy good when ypu get it going but for a first printer i wouldent rekomend it (not even as a second printer)

|

Re: Help me with my doubts on buying a Omerod2 November 29, 2014 05:24PM |

Registered: 10 years ago Posts: 378 |

Quote

denshine

i say dont buy it!

as a starter printer thers to much to do to get it working.

i would go for a ulltimaker or something simular.

That's not really a fair comparision, as they are very different products. An Ultimaker is a brilliant printer, and it is dead simple to get up and running (if you get a preassembled one), and generally very easy to use. The downside is it is 2-3 times more expensive than an ormerod (depending on model), spare parts are more expensive, and it is a less open or "tweakable" platform. If you get the cheapest possible Ultimaker (the kit UM1), it is comparable to the ormerod in how difficult it is to assemble and commission. In terms of printing performance (speed and precision), I'd say the UM2 is a bit better than the Ormerod, but not by much.

Comparing the Ormerod 2 to other popular repraps, it is not as "well tried", but it is a quite expandable design that in my opinion performs very well.

If you are not willing to tinker with your printer, you should not get a reprap (of any model). If you do want to modify or expand it, don't get anything but a reprap.

If you want a good, out-of-the-box printer that is simple to setup and use, get the Ultimaker 2 if you can afford it.

|

Re: Help me with my doubts on buying a Omerod2 November 29, 2014 06:14PM |

Registered: 9 years ago Posts: 395 |

The ultimaker is neither better nor simpler to use than a ormerod or a Mendel.

not even the zprinter or form are easier, the only difference is the mounting.

But at least with the mounting you get an understanding of what to do when the printer fails. Because they all do.

Or if a print goes bad, yo know what to do or how to improve.

3d printer are still far from being just like a printer. And none are actually for people not interested a bit in how they work or in people without an it expert around.

not even the zprinter or form are easier, the only difference is the mounting.

But at least with the mounting you get an understanding of what to do when the printer fails. Because they all do.

Or if a print goes bad, yo know what to do or how to improve.

3d printer are still far from being just like a printer. And none are actually for people not interested a bit in how they work or in people without an it expert around.

|

Re: Help me with my doubts on buying a Omerod2 November 29, 2014 06:15PM |

Registered: 10 years ago Posts: 36 |

Quote

jstck

Quote

denshine

i say dont buy it!

as a starter printer thers to much to do to get it working.

i would go for a ulltimaker or something simular.

That's not really a fair comparision, as they are very different products. An Ultimaker is a brilliant printer, and it is dead simple to get up and running (if you get a preassembled one), and generally very easy to use. The downside is it is 2-3 times more expensive than an ormerod (depending on model), spare parts are more expensive, and it is a less open or "tweakable" platform. If you get the cheapest possible Ultimaker (the kit UM1), it is comparable to the ormerod in how difficult it is to assemble and commission. In terms of printing performance (speed and precision), I'd say the UM2 is a bit better than the Ormerod, but not by much.

Comparing the Ormerod 2 to other popular repraps, it is not as "well tried", but it is a quite expandable design that in my opinion performs very well.

If you are not willing to tinker with your printer, you should not get a reprap (of any model). If you do want to modify or expand it, don't get anything but a reprap.

If you want a good, out-of-the-box printer that is simple to setup and use, get the Ultimaker 2 if you can afford it.

as a first printer i dont think a reprap is the go to printer thats why i rekomended a ultimaker.

i had a makerbot rep2 as a first printer and it was a good firstvstep in to 3d printing but as my skills gott better i wanted something i could tinker with more so i got the ormerod.

my ormerod makes far better prints now then the replicator2 did. (but it took almost a year of tinkering)

Edited 1 time(s). Last edit at 11/29/2014 06:19PM by denshine.

|

Re: Help me with my doubts on buying a Omerod2 November 29, 2014 07:10PM |

Registered: 9 years ago Posts: 102 |

Quote

denshine

i say dont buy it!

as a starter printer thers to much to do to get it working.

i would go for a ulltimaker or something simular.

i wouldent buy a makerbot cuz its to little to do.

ormerod is a fun machine and works realy good when ypu get it going but for a first printer i wouldent rekomend it (not even as a second printer)

Well the ormerod 2 is my first printer i really don't see why i shouldn't have bought it as a first printer so i really can't follow your arguments. Well i guess

it boils down to technical experience/background.

|

Re: Help me with my doubts on buying a Omerod2 November 29, 2014 07:27PM |

Registered: 10 years ago Posts: 14,672 |

The Ormerod 1 took quite a lot of tweaking to get good prints out of it. However, most of the issues the Ormerod 1 had have been addressed in the 2. The 2 is also easier to assemble than the 1 because all the connections are pre-crimped.

You can find a comparison of Ormerod and Mini Kossel kits on my blog.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

You can find a comparison of Ormerod and Mini Kossel kits on my blog.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Help me with my doubts on buying a Omerod2 November 29, 2014 08:45PM |

Registered: 9 years ago Posts: 21 |

Hi Vizual 54

I recently bought an Ormerod 2. I am not a computer wiz, coder, electronics buff, engineer etc. In fact I am a government health inspector and ex 4wd accessories salesman. I have no idea about what the Duet electronics do but I can follow instructions (which I found excellent) and have attention to detail and common-sense when it comes to problem solving. I can't compare the Ormerod 2 to anything else since it is my first 3d printer. But I have got it working and printing reasonably high quality (with no mods implemented whatsoever) although I have a lot to learn about optimising Slic3r settings.

In response to your concerns, I have found the following:

*Now calibrated and commissioned as per instructions, it takes me only a few minutes from switching on to starting a print from the SD card using the web interface. I pretty much home all 3 axis (I do the z manually because I don't trust the proximity sensor), move z to 2.5 do a G31 Z2.5 Pxxx (whatever the proximity sensor reading is on the web interface) then do a bed plane compensation (G32), then re check z0 and adjust if necessary then print.

*I have printed several tall items and no problems with tipping over - in fact I don't even bother turning the print bed on now mostly printing PLA because it doesn't seem to be necessary and sticks things so tight to the bed that they are sometimes hard to get off.

The only minor issue I had was with some of the wiring loom crimps which required replacement due to poor connections.

I highly recommend the Ormerod 2 based on my experiences. I hope this helps with your decision if you have not made it already.

I recently bought an Ormerod 2. I am not a computer wiz, coder, electronics buff, engineer etc. In fact I am a government health inspector and ex 4wd accessories salesman. I have no idea about what the Duet electronics do but I can follow instructions (which I found excellent) and have attention to detail and common-sense when it comes to problem solving. I can't compare the Ormerod 2 to anything else since it is my first 3d printer. But I have got it working and printing reasonably high quality (with no mods implemented whatsoever) although I have a lot to learn about optimising Slic3r settings.

In response to your concerns, I have found the following:

*Now calibrated and commissioned as per instructions, it takes me only a few minutes from switching on to starting a print from the SD card using the web interface. I pretty much home all 3 axis (I do the z manually because I don't trust the proximity sensor), move z to 2.5 do a G31 Z2.5 Pxxx (whatever the proximity sensor reading is on the web interface) then do a bed plane compensation (G32), then re check z0 and adjust if necessary then print.

*I have printed several tall items and no problems with tipping over - in fact I don't even bother turning the print bed on now mostly printing PLA because it doesn't seem to be necessary and sticks things so tight to the bed that they are sometimes hard to get off.

The only minor issue I had was with some of the wiring loom crimps which required replacement due to poor connections.

I highly recommend the Ormerod 2 based on my experiences. I hope this helps with your decision if you have not made it already.

|

Re: Help me with my doubts on buying a Omerod2 December 06, 2014 06:20PM |

Registered: 9 years ago Posts: 32 |

Hi all!

Been a while since I've read this thread and there has been some new thoughts and opinions.

First of all thank you for posting your experiences and thoughts.

I've decided to buy the Ormerod 2 and will hopefully order it some time before Christmas. I've done a lot of research and done a lot of reading about 3d printing and 3d printers the last couple of weeks and decided I want to scratch build my own machine as a fun hobby project. It will probably be a UM/Zortrax style with a frame of extruded aluminum a due card and e3d chimera extruder. We'll see if thoose plans ever come to life and there will probably be other threads discussing that topic.

Anyway, first i will order and build the Ormerod. The Omerod seems to me like a really good choice considering it price, extendibility and performance. Its also open source which is a great plus if not a necessity for me. I've been very keen on the Ultimaker 2 and the Zortrax as well as the Duplicator 4s. Though the UM2 and Zortrax are way out of my budget right now and there are some things I don't like about them.

Hopefully building and tuning the Ormerod will give me good knowledge not only on how the Ormerod works but about 3d printing in general which will come in handy for my next project.

Edited 2 time(s). Last edit at 12/06/2014 06:26PM by Vizual54.

Been a while since I've read this thread and there has been some new thoughts and opinions.

First of all thank you for posting your experiences and thoughts.

I've decided to buy the Ormerod 2 and will hopefully order it some time before Christmas. I've done a lot of research and done a lot of reading about 3d printing and 3d printers the last couple of weeks and decided I want to scratch build my own machine as a fun hobby project. It will probably be a UM/Zortrax style with a frame of extruded aluminum a due card and e3d chimera extruder. We'll see if thoose plans ever come to life and there will probably be other threads discussing that topic.

Anyway, first i will order and build the Ormerod. The Omerod seems to me like a really good choice considering it price, extendibility and performance. Its also open source which is a great plus if not a necessity for me. I've been very keen on the Ultimaker 2 and the Zortrax as well as the Duplicator 4s. Though the UM2 and Zortrax are way out of my budget right now and there are some things I don't like about them.

Hopefully building and tuning the Ormerod will give me good knowledge not only on how the Ormerod works but about 3d printing in general which will come in handy for my next project.

Edited 2 time(s). Last edit at 12/06/2014 06:26PM by Vizual54.

|

Re: Help me with my doubts on buying a Omerod2 December 07, 2014 05:08AM |

Registered: 10 years ago Posts: 51 |

I can't comment on the Ormerod 2, as I have a model 1.

I am a Software Engineer by trade, and very much like Magoo, I don't have a background in mechanics or electronics - I dabble a little in electronics for fun, but at an extremely basic level, and I can do the basic handyman stuff around the house. I am by no means a hobbyist machinist or anything of that sort however. What I AM good at though, is problem solving, and logical thinking.

With that in mind, I built my Ormerod 1 over a weekend (about 5 hours the Friday night, about 8 hours the Saturday and 8 hours the Sunday). The instructions were pretty clear (one or 2 places I needed to closely study the photographs to understand what the instruction said, but one can figure it out).

The first few nights of printing were painful, I really struggled UNTIL I realised that the stock z-probe simply does not work. I gave up, followed the advice here and leveled the bed by hand.That solved probably 80% of my printing issues. Essentially the only things you need to get right on the printer to have good prints are a level bed, correct tension on the belts, and the rate of extrusion. The final issue I occasionally experienced was the PLA not sticking to the glass (I didn't bother with Kaftan). I've solved that by a) getting the z-axis zeroed correctly using the paper method below and b) setting my bed temperature to 65 degrees.

I disagree that an Ormerod is a bad choice for a first 3rd printer to build - I am extremely happy with mine. If you want something out of the box that doesn't require assembly, then be prepared to spend a significant amount of more money. As as been remarked above, even "out of the box" 3D printers still require significant effort to maintain and operate, compared to a normal desktop laser or jet printer.

I also don't feel one needs to do THAT much tweaking to get it running smoothly. The biggest problem I found, is that one has to hunt through the forum to find the really necessary upgrades in order to make the Ormerod print easily. If someone had given me the list of things below to do, I would have been printing flawlessly after the first night. With that in mind here are the actions or upgrades I feel one should do immediately (frankly I think RRP should have incorporated all of these into the standard Ormerod by now - most of them are printed parts anyway)

1. Fit the extra bed adjustments screws (No idea why RRP didn't just make this the standard build, but anyway) Extra Adjustment Screws

2. iamburny's https://github.com/iamburny/OrmerodUpgrades/blob/master/y-belt-clamp-v7.stl]Y-belt clamp[/url]

3. Y-idler tensioner (works great with iamburny's belt clamp) - I think I got them from here

4. Load DC42's excellent firmware immediately

5. Zeroing the z-axis - The best technique I have found is the paper method suggested by many on this forum: I use a piece of A4 paper, and drop the printer head by 0.1 at a time until the nozzle touches the piece of paper and I can feel the friction when moving the piece of paper. I usually also hear the vibration of the hot-end fan onto the bed. Some people recommend lifting the head by 0.1 after this, and using that as zero. However for my printer I find using the place where there is friction between the paper and the nozzle to be zero - YMMV.

6. MrBurns' extruder upgrade - a number of Ormerods on the forum (mine included) are showing signs of wear on the extruders.

Later today I am planning to look at improving the bed adjustment screw setup in 1 by adding small springs over the screws- it should remove the biggest finickiness of the process, which is when you tighten the screws you inevitably adjust the bed height slightly too.

Once you've made the above free (except for the cost of filament) upgrades, here are the paid upgrades I have made, or am planning to make.

6. DC42's z-sensor/lighting/fan control board comes highly recommded . I ordered one several months ago and DC's service was superb, sadly due to an ongoing South African Post Office strike I have not received it yet

7. Aluminium Bed Upgrade. I know someone with a waterjet cutter - if they can cut one for me I am going to go that route, otherwise I am planning to order one from Davek - it really is not that expensive for what you get.

If you do upgrade 1-5 above, you will have pain free printing as long as you don't bump or move the print bed too much. If you bump the bed, reset your bed as per step 1. Otherwise I just zero my Z-axis manually before every print - takes me around a minute (I am hoping DC's upgrade board will also make this a thing of the past )

)

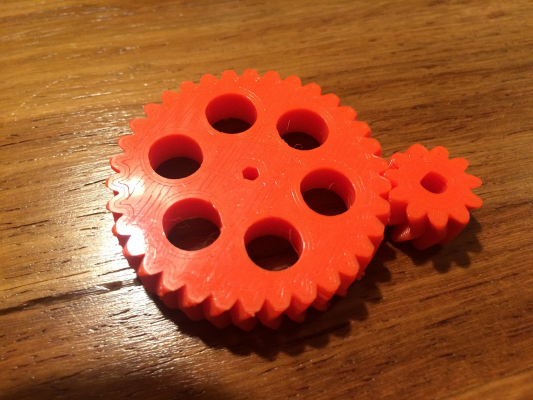

As for print quality, I'm attaching some photos of parts I've printed and am planning to fit in the holidays (They are burny's Double Helix gears and they look uber-cool even it makes no difference to my printing )

)

I am a Software Engineer by trade, and very much like Magoo, I don't have a background in mechanics or electronics - I dabble a little in electronics for fun, but at an extremely basic level, and I can do the basic handyman stuff around the house. I am by no means a hobbyist machinist or anything of that sort however. What I AM good at though, is problem solving, and logical thinking.

With that in mind, I built my Ormerod 1 over a weekend (about 5 hours the Friday night, about 8 hours the Saturday and 8 hours the Sunday). The instructions were pretty clear (one or 2 places I needed to closely study the photographs to understand what the instruction said, but one can figure it out).

The first few nights of printing were painful, I really struggled UNTIL I realised that the stock z-probe simply does not work. I gave up, followed the advice here and leveled the bed by hand.That solved probably 80% of my printing issues. Essentially the only things you need to get right on the printer to have good prints are a level bed, correct tension on the belts, and the rate of extrusion. The final issue I occasionally experienced was the PLA not sticking to the glass (I didn't bother with Kaftan). I've solved that by a) getting the z-axis zeroed correctly using the paper method below and b) setting my bed temperature to 65 degrees.

I disagree that an Ormerod is a bad choice for a first 3rd printer to build - I am extremely happy with mine. If you want something out of the box that doesn't require assembly, then be prepared to spend a significant amount of more money. As as been remarked above, even "out of the box" 3D printers still require significant effort to maintain and operate, compared to a normal desktop laser or jet printer.

I also don't feel one needs to do THAT much tweaking to get it running smoothly. The biggest problem I found, is that one has to hunt through the forum to find the really necessary upgrades in order to make the Ormerod print easily. If someone had given me the list of things below to do, I would have been printing flawlessly after the first night. With that in mind here are the actions or upgrades I feel one should do immediately (frankly I think RRP should have incorporated all of these into the standard Ormerod by now - most of them are printed parts anyway)

1. Fit the extra bed adjustments screws (No idea why RRP didn't just make this the standard build, but anyway) Extra Adjustment Screws

2. iamburny's https://github.com/iamburny/OrmerodUpgrades/blob/master/y-belt-clamp-v7.stl]Y-belt clamp[/url]

3. Y-idler tensioner (works great with iamburny's belt clamp) - I think I got them from here

4. Load DC42's excellent firmware immediately

5. Zeroing the z-axis - The best technique I have found is the paper method suggested by many on this forum: I use a piece of A4 paper, and drop the printer head by 0.1 at a time until the nozzle touches the piece of paper and I can feel the friction when moving the piece of paper. I usually also hear the vibration of the hot-end fan onto the bed. Some people recommend lifting the head by 0.1 after this, and using that as zero. However for my printer I find using the place where there is friction between the paper and the nozzle to be zero - YMMV.

6. MrBurns' extruder upgrade - a number of Ormerods on the forum (mine included) are showing signs of wear on the extruders.

Later today I am planning to look at improving the bed adjustment screw setup in 1 by adding small springs over the screws- it should remove the biggest finickiness of the process, which is when you tighten the screws you inevitably adjust the bed height slightly too.

Once you've made the above free (except for the cost of filament) upgrades, here are the paid upgrades I have made, or am planning to make.

6. DC42's z-sensor/lighting/fan control board comes highly recommded . I ordered one several months ago and DC's service was superb, sadly due to an ongoing South African Post Office strike I have not received it yet

7. Aluminium Bed Upgrade. I know someone with a waterjet cutter - if they can cut one for me I am going to go that route, otherwise I am planning to order one from Davek - it really is not that expensive for what you get.

If you do upgrade 1-5 above, you will have pain free printing as long as you don't bump or move the print bed too much. If you bump the bed, reset your bed as per step 1. Otherwise I just zero my Z-axis manually before every print - takes me around a minute (I am hoping DC's upgrade board will also make this a thing of the past

)

)As for print quality, I'm attaching some photos of parts I've printed and am planning to fit in the holidays (They are burny's Double Helix gears and they look uber-cool even it makes no difference to my printing

)

)

|

Re: Help me with my doubts on buying a Omerod2 December 07, 2014 05:42AM |

Registered: 10 years ago Posts: 1,230 |

Hope you don't mind but your prints look so nice I had to..

(Attach file/Choose/Attach/Create link in message)

Erik

(Attach file/Choose/Attach/Create link in message)

Erik

|

Re: Help me with my doubts on buying a Omerod2 December 07, 2014 03:22PM |

Registered: 10 years ago Posts: 51 |

|

Re: Help me with my doubts on buying a Omerod2 December 12, 2014 05:56PM |

Registered: 9 years ago Posts: 32 |

Finally there is a Ormerod2 heading my way. Really looking forward to start the build.

That's some really nice prints there Pandionx! Those images you posed made me feel like I had made the right decision in buying the O2.

Thanks for the tips, will come in handy in a short while.

Is there any place where modifications and upgrades for the Ormerod are gathered? Maybe a wiki page would be nice or rather two, one for O1 and one for O2.

Maybe I should live as i learn and google first and ask questions later

[reprap.org]

Edited 2 time(s). Last edit at 12/12/2014 06:09PM by Vizual54.

That's some really nice prints there Pandionx! Those images you posed made me feel like I had made the right decision in buying the O2.

Thanks for the tips, will come in handy in a short while.

Is there any place where modifications and upgrades for the Ormerod are gathered? Maybe a wiki page would be nice or rather two, one for O1 and one for O2.

Maybe I should live as i learn and google first and ask questions later

[reprap.org]

Edited 2 time(s). Last edit at 12/12/2014 06:09PM by Vizual54.

|

Re: Help me with my doubts on buying a Omerod2 December 18, 2014 07:37PM |

Registered: 9 years ago Posts: 32 |

Got the O2 yesterday and started assembling it in the evening. Was oh so careful with the acrylic y-axis endplates since reading about people cracking them when putting the rods in. No worries though got the y and z axis assembled and started on the x axis yesterday.

Though when I was about to get going today I ran the y carriage back and fourth and suddenly heard a crack. Left endplate had shattered!!

Managed to glue it together to at least be able to continue building. At a closer inspection it seems like the hole for the rod in the y-idler-bracket and the acrylic part didn't line up and that probably put too much stress on the acrylic. Actually the y-idler-bracket was a really bad print compared with the other printed parts. Going to contact RRP tomorrow and see if they can send a new part.

Though when I was about to get going today I ran the y carriage back and fourth and suddenly heard a crack. Left endplate had shattered!!

Managed to glue it together to at least be able to continue building. At a closer inspection it seems like the hole for the rod in the y-idler-bracket and the acrylic part didn't line up and that probably put too much stress on the acrylic. Actually the y-idler-bracket was a really bad print compared with the other printed parts. Going to contact RRP tomorrow and see if they can send a new part.

|

Re: Help me with my doubts on buying a Omerod2 December 19, 2014 05:52AM |

Registered: 9 years ago Posts: 92 |

After I broke mine I had new ones laser cut. The fit is looser than the original and my x-y axes are at exactly 90 degrees, so I wonder if the extremely tight fit of the original parts isn't a disadvantage - leading to slightly off center insertion which twists the axis and stresses the part when the other end of the rod is inserted into the opposite acrylic piece.

James

Edited 1 time(s). Last edit at 12/19/2014 07:50AM by jamesf.

James

Edited 1 time(s). Last edit at 12/19/2014 07:50AM by jamesf.

Sorry, only registered users may post in this forum.