Printing ABS

Posted by Fpex

|

Re: Printing ABS December 10, 2014 04:47AM |

Registered: 9 years ago Posts: 37 |

|

Re: Printing ABS December 15, 2014 07:08AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Jon Steward

..I must be really lucky as I've now managed to print off 3 ABS x carriages directly to glass...

Can't be done, airwolfman said so (LOL)

[airwolf3d.com]

Yes must be sheer luck - happy printing Sherlock! :-)

..allow me to totally off-topic quote one of my favorite LOL movies:

Quote

The Adventure of Sherlock Holmes' Smarter Brother

Orville: Are you Mister S., for Sigerson, Holmes?

Sigerson Holmes: Perhaps.

Orville: Do you have a brother whose first name is Sherlock?

Sigerson Holmes: I do not.

Orville: You do have a brother?

Sigerson Holmes: I do.

Orville: Might I inquire as to his first name?

Sigerson Holmes: "Sheer luck."

Erik

|

Re: Printing ABS December 15, 2014 12:56PM |

Registered: 10 years ago Posts: 100 |

|

Re: Printing ABS December 16, 2014 02:31PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Jon Steward

Erik. You do need to get out more!

I'll take your advice and go out and buy more filament :-)

Quote

I'm really motoring now with ABS on glass.

Thought I might try a 2mm brim on the latest ABS on glass print.

I have to give it a rest for now, two failed prints (Paul's appjaws-HotEnd-3Vents-3) vinegar/110/240

A huge skirt may have made a difference and BTW I do wonder why the solidified ABS slurry sticks to the glass but ABS filament don't as ABS slurry is solidified ABS made from failed prints - maybe the cure could be to print with solidified ABS slurry instead of ABS filament ;-)

I'm glad it works for you though, now we know it can be done!

Erik

|

Re: Printing ABS December 16, 2014 02:42PM |

Registered: 10 years ago Posts: 665 |

Wow, I can't believe you can print ordinary ABS on plain glass - are you sure it's real ABS or rather a special mix? One of my suppliers offers "Smart ABS" which is said to shrink a lot less, but I haven't tried that one yet. Depending on the shape and size of my own prints, I even had problems getting the first layer to stick to a thin layer of glue stick, so I'm really surprised you apparently manage to do it...

|

Re: Printing ABS December 20, 2014 03:03AM |

Registered: 10 years ago Posts: 100 |

Now you've got me checking!

Purchased from ebay a few months ago, No exact detail on my ebay history, just says ABS/PLA. No info on the reel either.

So test time..

Extruded filament at 240, measure .47mm diameter

At 185 measures .63mm

Photo shows nice extrusion at 240 (left in photo) and poor quality at 185 (right in photo)

So I reckon I have been printing ABS on glass.

I've ordered another reel of ABS, so we'll see how I get on with that.

Cheers

Jon

Purchased from ebay a few months ago, No exact detail on my ebay history, just says ABS/PLA. No info on the reel either.

So test time..

Extruded filament at 240, measure .47mm diameter

At 185 measures .63mm

Photo shows nice extrusion at 240 (left in photo) and poor quality at 185 (right in photo)

So I reckon I have been printing ABS on glass.

I've ordered another reel of ABS, so we'll see how I get on with that.

Cheers

Jon

|

Re: Printing ABS December 20, 2014 05:21AM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Printing ABS December 21, 2014 09:48AM |

Registered: 9 years ago Posts: 395 |

|

Re: Printing ABS December 21, 2014 10:31AM |

Registered: 10 years ago Posts: 665 |

Hmm, hairspray has never worked for me. I've been using this alu plate instead, it doesn't need any primer at all. I also talked to that reseller a few days ago and they told me to use only water to clean it, acetone will actually dissolve its coating. I didn't know that before either, but someone (Erik I believe?) tried it and it didn't go out too well. I actually managed to destroy the coating of my first plate by trying to print Nylon on it, so I can't recommend that either. Now I have a spare one without coating (well, except for UHU stick), so I can use that one to print Nylon again.

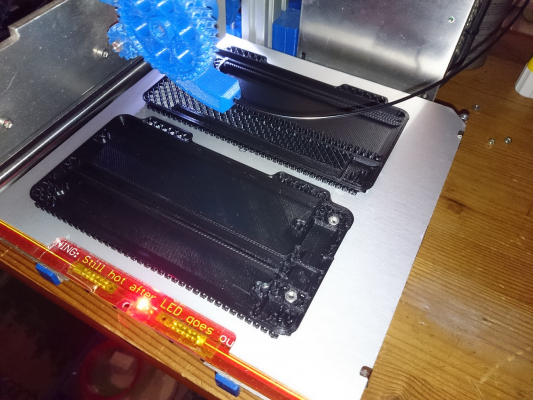

Right now I'm printing ABS at 250C at a bed temperature of 90C (first layer 120C). That configuration hasn't disappointed me for months. Here I paused my print once to insert some nuts primed with UHU glue stick - that's really a nice technique for ABS as far as I can tell:

Right now I'm printing ABS at 250C at a bed temperature of 90C (first layer 120C). That configuration hasn't disappointed me for months. Here I paused my print once to insert some nuts primed with UHU glue stick - that's really a nice technique for ABS as far as I can tell:

|

Re: Printing ABS December 21, 2014 11:10AM |

Registered: 9 years ago Posts: 395 |

|

Re: Printing ABS December 21, 2014 01:25PM |

Registered: 10 years ago Posts: 1,230 |

Quote

zombiepantslol

Hmm, hairspray has never worked for me. I've been using this alu plate instead..

Is it perfectly flat/will it stay flat while hot?, aka do it live up to the name "Thermostabile-Dauerdruckplatte"

Quote

..acetone will actually dissolve its coating. I didn't know that before either, but someone (Erik I believe?) tried it and it didn't go out too well..

Was dmould/Dave AFAIR - I use kapton for PLA...and ABS slurry for ABS and that works perfect for me, but sometime a smoother surface would be preferable

There is also this glue-on "BuildTak 3D Print Plade" - have anyone tried that? - will buy one with next filament order and do a test

Quote

http://3deksperten.dk/buildtak-3d-print-plade-vaelg-storrelse.html

BuildTak is a thin, durable plastic sheet that adheres to the print bed of FDM (fused deposition modeling) 3D printers to provide an ideal surface for 3D printing. It replaces the need for blue masking tape and/or polyimide films such as Kapton. Composed of high quality, heat-resistant raw materials, BuildTak provides a stable build platform for 3D printed objects to adhere to while allowing for a clean, easy removal of completed builds.

[3deksperten.dk]

Erik

|

Re: Printing ABS December 21, 2014 03:15PM |

Registered: 10 years ago Posts: 665 |

Quote

Fpex

Tell me more about the nylon. I also have but not used the alu plate because I found the carbon works great for pla and abs, even with lower temps. And the air spray is very effective above 50C.

But now. I Get worried for nylon ruining my plates.

Heh, but your carbon plate isn't coated, is it? I doubt you'd experience problems if you decide to print Nylon on it. That material has an awful high tendency to shrink (and thus warping is very likely to happen unless you use a large brim) and you need a really high bed temperature (120C throughout the entire print) and an extrusion temperature of 245C. I also get a lot of strings during travelling moves, so it's a good idea to print parts individually. But the resulting parts are very strong (if they were printed slowly at ~20mm/sec), which is why I actually use Nylon parts as support pieces for my heated bed. I believe they're also less affected by heat than PLA and even ABS.

|

Re: Printing ABS December 21, 2014 05:15PM |

Registered: 9 years ago Posts: 395 |

does the ormerod do above 100 as bed temp? I thought it was still 100 and really slow!!

I print abs at 80 and it is perfectly fine.

Carbon plate is coated on both sides, but without the spray it does not work, and not with all types of spray. The worst the spray is for hair, the better for abs :-)

I print abs at 80 and it is perfectly fine.

Carbon plate is coated on both sides, but without the spray it does not work, and not with all types of spray. The worst the spray is for hair, the better for abs :-)

|

Re: Printing ABS December 21, 2014 05:20PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Fpex

does the ormerod do above 100 as bed temp? I thought it was still 100 and really slow!!

On the O1, to reach high bed temperatures it helps if you use a better power supply that the ATX PSU supplied with the kit, preferably the sort that has a voltage adjustment and can be turned up to about 14V. I believe the O2 is supplied with such a PSU.

Edited 1 time(s). Last edit at 12/21/2014 05:20PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Printing ABS December 21, 2014 06:05PM |

Registered: 9 years ago Posts: 395 |

|

Re: Printing ABS December 21, 2014 06:19PM |

Registered: 10 years ago Posts: 14,672 |

btw you can see details of my O1 PSU conversion here [www.thingiverse.com]. See the Instructions tab for the parts list. Only attempt this if you are comfortable with doing mains wiring.

Edited 1 time(s). Last edit at 12/21/2014 06:20PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 12/21/2014 06:20PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Printing ABS December 22, 2014 03:20AM |

Registered: 10 years ago Posts: 100 |

The PSU is a really good upgrade.

I use DC42's PSU cover but found it slightly too tight to push all the way back.

I would try a rescale by 5% larger.

The switch at the front and indicator light are nice touches and I've directly connected the 12V wires via a 20mm stuffing gland, (no connectors)

Is 14VOK?. I read in the instructions the 13.5V was the highest. Don't want to damage anything.

Is that 14V measured at the PSU with no load?

I use DC42's PSU cover but found it slightly too tight to push all the way back.

I would try a rescale by 5% larger.

The switch at the front and indicator light are nice touches and I've directly connected the 12V wires via a 20mm stuffing gland, (no connectors)

Is 14VOK?. I read in the instructions the 13.5V was the highest. Don't want to damage anything.

Is that 14V measured at the PSU with no load?

|

Re: Printing ABS December 22, 2014 03:34AM |

Registered: 9 years ago Posts: 395 |

|

Re: Printing ABS December 22, 2014 05:34AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Jon Steward

Is 14VOK?. I read in the instructions the 13.5V was the highest. Don't want to damage anything.

Is that 14V measured at the PSU with no load?

The Duet is rated at up to 35V maximum input, so no problem there. It should also have no problem passing the extra heated bed current and hot end heater current you will get at 14V. The component that you would be running above its rating is the hot end fan. You could add a couple of 1N4004 diodes in series with it to bring the voltage down a little.

However, on an O2 the heated bed connections can be problematic, and increasing the voltage would make them more prone to overheating.

Edited 2 time(s). Last edit at 12/23/2014 06:41AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Printing ABS December 23, 2014 06:22AM |

Registered: 10 years ago Posts: 2,472 |

Sorry, only registered users may post in this forum.