2 printing issues

Posted by Sardi

|

2 printing issues January 15, 2015 11:59AM |

Registered: 10 years ago Posts: 466 |

Got some new filament colors, so Im coloring my Ormerod

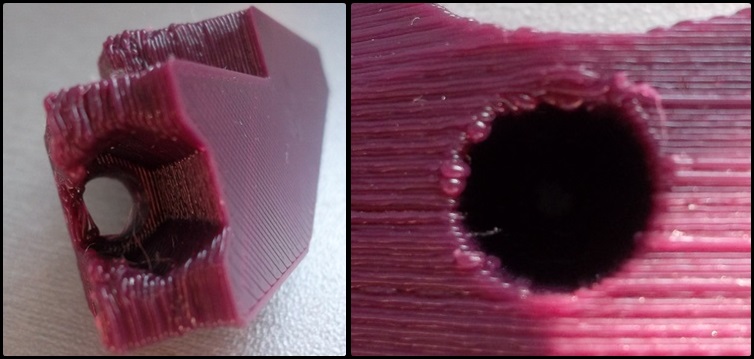

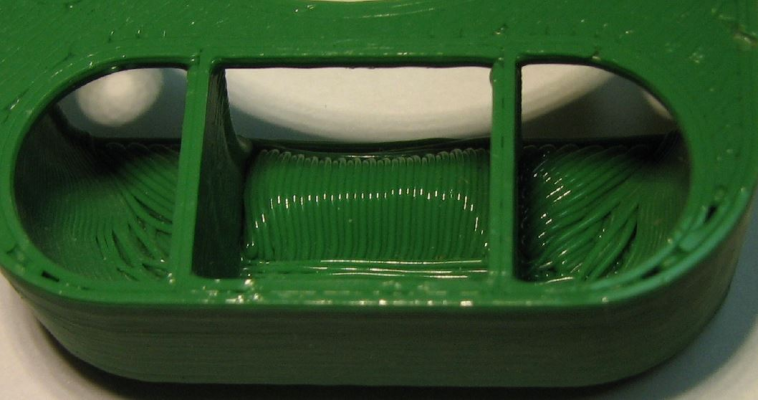

1) Z-Nut trap, the model is fine except for this parts:

On the left picture the problem happens because the nozzle visits the same place twice in a very short period of time. My guess is the part does not have enough time to cool off before the next hot filament arrives on the same place.

The file is sliced in Cura 14.03, temps 185/175, 75/60. Also, Cura does not have the option to randomize the starting points of each layer, maybe I should try Slic3r?

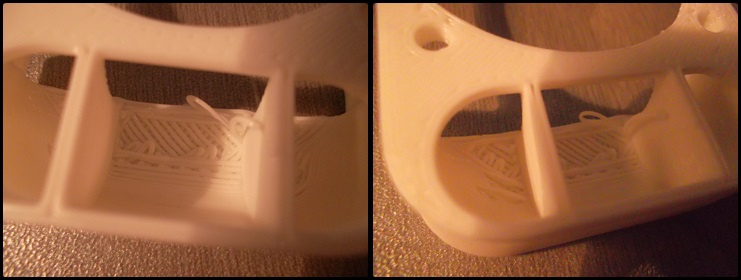

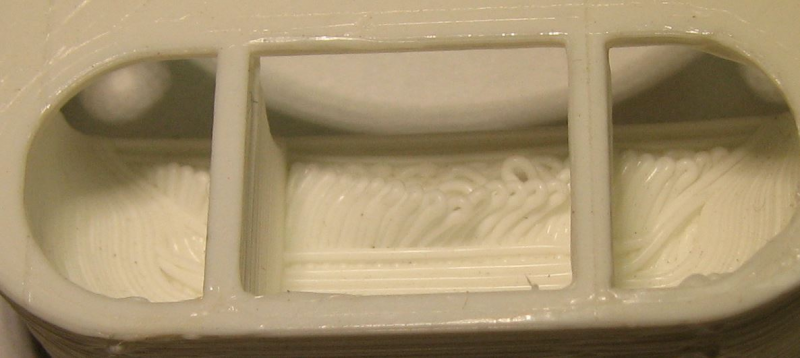

2) Fanduct

This part was printed a long time ago, since it failed, I used the original (green) fanduct but now that I have other colors I would like to print it again, however, I dont want this to happen again.

My guess is that I do not have any guess what to change for this part to print out correctly.

Any help and advice is welcome.

Regards,

Antonio

Edited 1 time(s). Last edit at 01/15/2015 12:01PM by Sardi.

1) Z-Nut trap, the model is fine except for this parts:

On the left picture the problem happens because the nozzle visits the same place twice in a very short period of time. My guess is the part does not have enough time to cool off before the next hot filament arrives on the same place.

The file is sliced in Cura 14.03, temps 185/175, 75/60. Also, Cura does not have the option to randomize the starting points of each layer, maybe I should try Slic3r?

2) Fanduct

This part was printed a long time ago, since it failed, I used the original (green) fanduct but now that I have other colors I would like to print it again, however, I dont want this to happen again.

My guess is that I do not have any guess what to change for this part to print out correctly.

Any help and advice is welcome.

Regards,

Antonio

Edited 1 time(s). Last edit at 01/15/2015 12:01PM by Sardi.

|

Re: 2 printing issues January 15, 2015 01:10PM |

Registered: 10 years ago Posts: 2,472 |

The meltdown issue when printing several layers that only have one or two small perimeters is well known. One solution is to print 2 or more parts at the same time so the head has to alternate between parts and gives each one time to cool, the other is to make an STL of a thin sacrificial column the same height as the part and position this far enough away from the print to achieve the same thing.

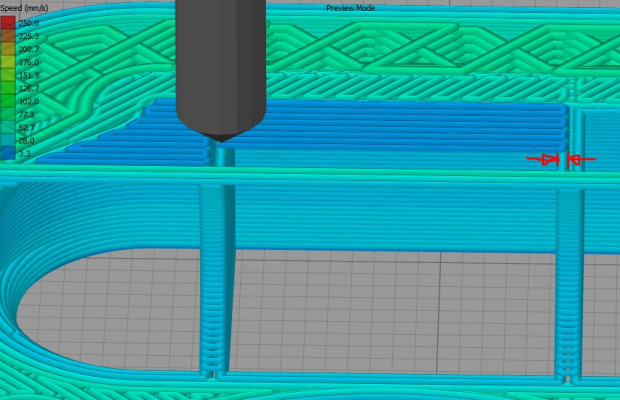

Your second issue seems to be failed bridging. You should be able to bridge successfully if you slow down the bridging - Slic3r has a separate speed setting for bridges which I set to15mm/s (very slow). You must also check the box "Detect bridging parameters" in Slic3r's menu.

Sometimes an an infill line or perimeter has a break, curl-up or corner blob (overhangs are particularly prone to curling up). At typical normal printing speeds this may well amplify over a few layers by causing bigger breaks and curl-ups in each successive layer until the print is ruined. If you use DC42's firmware and web interface you can use the speed slider of the web interface to slow the print speed at any point. That allows you to slow down to 50% or less as soon as you see that such a defect has begun to occur, which often allows the printer to bridge the defect more successfully until the defect is "healed" (at which point you can resume 100% print speed). Of course, to do so you have to monitor the print constantly, which is not always what you want to do. I usually sit at my desk next to the printer and do other work while keeping an eye on the print unless it is a very long print job. If I leave my desk I usually slow the print speed while I am away to lower the chance of such defects (and I use lower print speeds in general for unmonitored print jobs). Speed changes are buffered along with the moves and so are delayed, so on a large print that you only want to slow down over the defective region, you have to make the change 35 or so moves before the defect is reached.

The first top solid layer must effectively bridge over the lines of infill, and with very sparse infill (<30% or so) you can get breaks because the bridges are quite long. Like any other bridge this is best done at a lower speed, but unfortunately Slic3r has no setting to slow down the first solid top layer automatically and so it can result in a very similar effect as in your second photo. Again, good use of the speed slider can prevent that.

Dave

Your second issue seems to be failed bridging. You should be able to bridge successfully if you slow down the bridging - Slic3r has a separate speed setting for bridges which I set to15mm/s (very slow). You must also check the box "Detect bridging parameters" in Slic3r's menu.

Sometimes an an infill line or perimeter has a break, curl-up or corner blob (overhangs are particularly prone to curling up). At typical normal printing speeds this may well amplify over a few layers by causing bigger breaks and curl-ups in each successive layer until the print is ruined. If you use DC42's firmware and web interface you can use the speed slider of the web interface to slow the print speed at any point. That allows you to slow down to 50% or less as soon as you see that such a defect has begun to occur, which often allows the printer to bridge the defect more successfully until the defect is "healed" (at which point you can resume 100% print speed). Of course, to do so you have to monitor the print constantly, which is not always what you want to do. I usually sit at my desk next to the printer and do other work while keeping an eye on the print unless it is a very long print job. If I leave my desk I usually slow the print speed while I am away to lower the chance of such defects (and I use lower print speeds in general for unmonitored print jobs). Speed changes are buffered along with the moves and so are delayed, so on a large print that you only want to slow down over the defective region, you have to make the change 35 or so moves before the defect is reached.

The first top solid layer must effectively bridge over the lines of infill, and with very sparse infill (<30% or so) you can get breaks because the bridges are quite long. Like any other bridge this is best done at a lower speed, but unfortunately Slic3r has no setting to slow down the first solid top layer automatically and so it can result in a very similar effect as in your second photo. Again, good use of the speed slider can prevent that.

Dave

|

Re: 2 printing issues January 15, 2015 01:27PM |

Registered: 9 years ago Posts: 92 |

From my very limited slicing experience I have found one thing to help a lot with small pieces

Slic3r has cooling control settings which can be activated. This has two effects on layers that are going to take less than 30 seconds to print

1. Increases fan speed ( not applicable to ormerod)

2. Slows the printing in proportion to the time the layer will take

I found this to help a lot, even with lack of fan speed control

James

Slic3r has cooling control settings which can be activated. This has two effects on layers that are going to take less than 30 seconds to print

1. Increases fan speed ( not applicable to ormerod)

2. Slows the printing in proportion to the time the layer will take

I found this to help a lot, even with lack of fan speed control

James

|

Re: 2 printing issues January 15, 2015 01:29PM |

Registered: 9 years ago Posts: 92 |

Hi

From my very limited slicing experience I have found one thing to help a lot with small pieces

Slic3r has cooling control settings which can be activated. This has two effects on layers that are going to take less than 30 seconds to print

1. Increases fan speed ( not applicable to ormerod)

2. Slows the printing in proportion to the time the layer will take

I found this to help a lot, even with lack of fan speed control

James

sorry about double post - had bot error and went south from there

Edited 1 time(s). Last edit at 01/15/2015 01:32PM by jamesf.

From my very limited slicing experience I have found one thing to help a lot with small pieces

Slic3r has cooling control settings which can be activated. This has two effects on layers that are going to take less than 30 seconds to print

1. Increases fan speed ( not applicable to ormerod)

2. Slows the printing in proportion to the time the layer will take

I found this to help a lot, even with lack of fan speed control

James

sorry about double post - had bot error and went south from there

Edited 1 time(s). Last edit at 01/15/2015 01:32PM by jamesf.

|

Re: 2 printing issues January 16, 2015 04:38AM |

Registered: 10 years ago Posts: 466 |

dmould, thank you very much for explaining, you were very helpful.

Regarding the meltdown, sacrificial column seems to me the easiest way to go (if I dont need two same parts of course) but would maybe an additional fan help? Or lower printining temperature? Currently I am at 185/175 but as I see I could lower that even more by 10C and get colder filament to be extruded. So colder filament + additional fan, maybe?

Regarding the bridges, I have just set this speeds in Slic3r: Perimeters 25, External Perimeters 35, Infill 100 - so it gets to the bridges faster as the model is not complex, and then Bridges 10mms, so I think this could solve the problem.

James, yes, I can not control the fan speed, but the sacrificial column seems like a good way to go to let the model cool + I can set the travel speed low (arr 50mms) so it takes time for the nozzle to get to and from the column

Regards,

Antonio

Regarding the meltdown, sacrificial column seems to me the easiest way to go (if I dont need two same parts of course) but would maybe an additional fan help? Or lower printining temperature? Currently I am at 185/175 but as I see I could lower that even more by 10C and get colder filament to be extruded. So colder filament + additional fan, maybe?

Regarding the bridges, I have just set this speeds in Slic3r: Perimeters 25, External Perimeters 35, Infill 100 - so it gets to the bridges faster as the model is not complex, and then Bridges 10mms, so I think this could solve the problem.

James, yes, I can not control the fan speed, but the sacrificial column seems like a good way to go to let the model cool + I can set the travel speed low (arr 50mms) so it takes time for the nozzle to get to and from the column

Regards,

Antonio

|

Re: 2 printing issues January 16, 2015 05:20AM |

Registered: 10 years ago Posts: 859 |

Hi Sardi, I had something similar a while back, where the item didn't have time to cool, and I placed two columns (one either side of the item) about 3 or 4cm away from it

and that cured the problem. If you use one column, then the item to be printed get added time to cool when printing in one direction, but no extra time when printing in the other.

I'd also use a slightly lower temp for the Extruder.... Try lowering by 5' and that will help.

Good Luck,

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

and that cured the problem. If you use one column, then the item to be printed get added time to cool when printing in one direction, but no extra time when printing in the other.

I'd also use a slightly lower temp for the Extruder.... Try lowering by 5' and that will help.

Good Luck,

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: 2 printing issues January 16, 2015 06:38AM |

Registered: 10 years ago Posts: 466 |

|

Re: 2 printing issues January 16, 2015 07:38AM |

Registered: 10 years ago Posts: 2,472 |

I have not tried a fan, which would probably help, but I have tried lowering the hotend temperature, and that did not help a lot. James, I have also used the minimum layer time setting, but that just slows down the print speed so each layer takes longer to print. It helps with medium-sizes areas, but with small areas the print head does not move enough, and the nozzle stays in proximity to one place all the time, keeping the small area molten from its radiated heat. If anything the slowdown makes matters worse. Kim, while one sacrificial column means that two layers are printed in succession between each move to and from the column, I found that the print could handle getting two layers between cooling periods, but certainly having a column on each side would result in only one layer being printed between cooling cycles so should be used if a single column still results in problems.

One other solution that I did not mention as it is more complex than the others is to edit the G-code file so as to insert a move away from the part and back to it between layer changes, and maybe a delay in between the moves (either with the G4 delay code if it is implemented or by making a slow move). A few lines of G-code could be written by hand and then pasted after each Z move in a text editor. One advantage of this method is that only the layers that have a small area need be modified, so you are not wasting time printing a column on larger lower layers that do not require cooling time. Hand editing is not too onerous because you can do a search for the letter "Z" to quickly find each layer change - and if the editor has a macro feature the process of searching for the layer change and inserting the extra code could be made into a macro to make the editing very quick & easy. It would not be difficult to write a simple program to modify any print file automatically from a given layer height, and I may do so somewhen. It surprises me that none of the slicing software has such a feature as this is such a common issue.

Dave

One other solution that I did not mention as it is more complex than the others is to edit the G-code file so as to insert a move away from the part and back to it between layer changes, and maybe a delay in between the moves (either with the G4 delay code if it is implemented or by making a slow move). A few lines of G-code could be written by hand and then pasted after each Z move in a text editor. One advantage of this method is that only the layers that have a small area need be modified, so you are not wasting time printing a column on larger lower layers that do not require cooling time. Hand editing is not too onerous because you can do a search for the letter "Z" to quickly find each layer change - and if the editor has a macro feature the process of searching for the layer change and inserting the extra code could be made into a macro to make the editing very quick & easy. It would not be difficult to write a simple program to modify any print file automatically from a given layer height, and I may do so somewhen. It surprises me that none of the slicing software has such a feature as this is such a common issue.

Dave

|

Re: 2 printing issues January 18, 2015 04:37PM |

Registered: 10 years ago Posts: 466 |

Regarding bridges - in my limited experience printing bridges Ive come to the conclusion that the speed of bridging should be very very slow.

I have done a print with Slic3rs 0.5 default settings where the bridge speed was 20mms - the first moves for the bridges werent good, altough what saved the situation was lowering the speed to 50% via web interface, so the next layers closed the remaining gaps and nothing bad is visible from the outside of the model. For every next time I am going to set the bridge speed to 5mms, I think that could bring good results and keep other speeds like outer perimeters high.

Edited 1 time(s). Last edit at 01/18/2015 04:56PM by Sardi.

I have done a print with Slic3rs 0.5 default settings where the bridge speed was 20mms - the first moves for the bridges werent good, altough what saved the situation was lowering the speed to 50% via web interface, so the next layers closed the remaining gaps and nothing bad is visible from the outside of the model. For every next time I am going to set the bridge speed to 5mms, I think that could bring good results and keep other speeds like outer perimeters high.

Edited 1 time(s). Last edit at 01/18/2015 04:56PM by Sardi.

|

Re: 2 printing issues January 20, 2015 04:55AM |

Registered: 10 years ago Posts: 466 |

After more playing with bridge speeds,

- 3mms was somewhat too slow, it didnt give the chance for the filament to grab on to the other side.

- 5mms was ok, sometimes the filament would bend a bit downwards but top layer wouldnt suffer

- 7mms was my latest try, ant so far the best, bridge almost perfect.

Next one I will try 10mms.

My first every try was with 20mms and that is was not good at all.

- 3mms was somewhat too slow, it didnt give the chance for the filament to grab on to the other side.

- 5mms was ok, sometimes the filament would bend a bit downwards but top layer wouldnt suffer

- 7mms was my latest try, ant so far the best, bridge almost perfect.

Next one I will try 10mms.

My first every try was with 20mms and that is was not good at all.

|

Re: 2 printing issues January 20, 2015 07:01AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: 2 printing issues January 20, 2015 08:25AM |

Registered: 10 years ago Posts: 466 |

|

Re: 2 printing issues January 20, 2015 01:21PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Sardi

Regarding bridges - in my limited experience printing bridges Ive come to the conclusion that the speed of bridging should be very very slow.

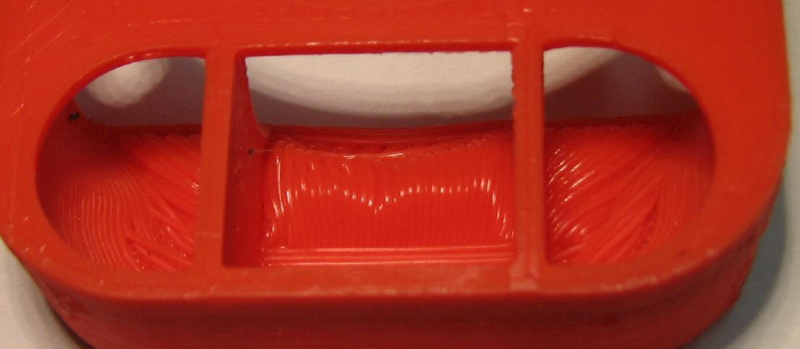

Good work Sardi, you choose one of the worst models to bridge me think, the filament only got one single perimeter to attach to, Wile E Coyote would drop like a rock with such short run-in - not bridge 3 feet of air and wave bye-bye

..but your print is not bad, here compared with RepRapPro printed parts:

..and here's my print:

..and here with long run-in (if thats the word), much much easier to bridge (4,5mm airgun pellet for scale):

Erik

|

Re: 2 printing issues January 20, 2015 01:24PM |

Registered: 10 years ago Posts: 1,230 |

Sorry, only registered users may post in this forum.