Nozzle offset, helps with excess material accumulation

Posted by BenBB

|

Nozzle offset, helps with excess material accumulation April 11, 2015 08:07AM |

Registered: 9 years ago Posts: 78 |

Hi All

I found that something simple helped my prints very much, that is by adjusting the nozzle protrusion from being near flush to the HEX but to protruding about 3mm from then Hex nut, previously I found that allot of "dead" material accumulated as the hot end move and print, sometimes the hex nut grabs the pieces of dead PLA and then later accumulate so much that they interfere with the prints

Now by extending the nozzle 2mm past the nut the dead material is MUCH less and if the hex nut grabs it, it is now higher above the bed and does not stick to the print

The ORMEROD setup says the nozzle must almost from an "extension" of the hex nut, like a V, but the nut also get hot and material accumulate around the big surface

one needs to compensate with the Z-cal, mine came down from 2.0 to 2.2mm @ G31 count of 500/515 to 0.8 to 1.0 for the same setting all depends on the bed

Sometimes simple changes make a big difference

Tx Ben

I found that something simple helped my prints very much, that is by adjusting the nozzle protrusion from being near flush to the HEX but to protruding about 3mm from then Hex nut, previously I found that allot of "dead" material accumulated as the hot end move and print, sometimes the hex nut grabs the pieces of dead PLA and then later accumulate so much that they interfere with the prints

Now by extending the nozzle 2mm past the nut the dead material is MUCH less and if the hex nut grabs it, it is now higher above the bed and does not stick to the print

The ORMEROD setup says the nozzle must almost from an "extension" of the hex nut, like a V, but the nut also get hot and material accumulate around the big surface

one needs to compensate with the Z-cal, mine came down from 2.0 to 2.2mm @ G31 count of 500/515 to 0.8 to 1.0 for the same setting all depends on the bed

Sometimes simple changes make a big difference

Tx Ben

|

Re: Nozzle offset, helps with excess material accumulation April 13, 2015 09:06AM |

Registered: 10 years ago Posts: 2,472 |

It sounds like you are curing the symptom of a different issue. The only time I have seen my nozzle collect bits of plastic is right at the start of the print when the initial ooze can result in a bit of loose filament which can get dragged around. One way I have heard to prevent that is to lower the nozzle to the bed (zero Z height) while the nozzle is heating. However I find it pretty easy to grab and remove any loose plastic bits while it is printing the skirt, so have not taken any additional measures. I pick off any oozed plastic on the nozzle before starting a print (while the nozzle is cold).

If your nozzle is picking up plastic it may mean that your nozzle tip is scratched. I had that issue after I had used a needle file to remove plastic "nibs" a few times, and I had to replace the nozzle because a scratched tip does indeed tend to pull up and collect plastic. I find the cold plastic can be picked off with a fingernail very easily, so no longer use any metal tools on the nozzle.

Dave

If your nozzle is picking up plastic it may mean that your nozzle tip is scratched. I had that issue after I had used a needle file to remove plastic "nibs" a few times, and I had to replace the nozzle because a scratched tip does indeed tend to pull up and collect plastic. I find the cold plastic can be picked off with a fingernail very easily, so no longer use any metal tools on the nozzle.

Dave

|

Re: Nozzle offset, helps with excess material accumulation April 14, 2015 04:59AM |

Registered: 12 years ago Posts: 1,611 |

If you have plastic stuck to the hot end, heat the hot end to around 90 to 100C. I tend to use some long nose pliers, or tweezers, to grab any plastic. At this temperature, the plastic sticks to itself but is soft enough to detach from the hot end, so it usually comes off in one piece, very satisfyingly! Like picking a scab...

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: Nozzle offset, helps with excess material accumulation April 14, 2015 09:46AM |

Registered: 9 years ago Posts: 57 |

|

Re: Nozzle offset, helps with excess material accumulation April 15, 2015 06:07AM |

Registered: 9 years ago Posts: 78 |

Hi All

Valid comments, however...

Yes I agree, there are other symptoms at play here, the PLA seems to be a BIG culprit ! I got a roll with the printer, it printed VERY well, then I bought 2 rolls from RS electronics, the brand is from a UK manufacturer, it is rubbish ! I will not buy it again, I bought white and Orange

It is VERY stringy, and oozes allot, I tried from 185 all the way to 210degC

So in order not to waist the $60 rolls I had to use them, so they produce allot of fine strings, and initial oozing, even when printing I find that the printer would ooze ever so slightly. Playing with M221 helps

These bits accumulated on the Hex nut, however by doing the mentioned in the previous above, I find that it eliminates 90% of the accumulated material at least now they drop off and can be picked off and not get caught in the Hex nut

Yes as with all things new one must get the hang of it, one month down the line and only now I`m getting to know the nitty gritty stuff

*AHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH.................... now only do I see this !!!!!!!!!!!!!!!!!!!!!!!

I went on RS website and checked the fine print of RS brand, this UK company sells both PLA and ABS HOWVER they do not indicate ABS or PLA

on the rolls, just manufacturer and WEB address. The deception of ASSUMPTION !!

I actually thought I bought 2 rolls of PLA, but was supplied ABS instead, so all the while I was using the PLA setting, deforming and stringyness, battling like mad, as we say in South Africa EISH....being a newby, but you sometimes have to learn the hard way, I don`t think I `m alone and others have made this mistake as well ))

))

Tx Ben

Edited 4 time(s). Last edit at 04/15/2015 06:24AM by BenBB.

Valid comments, however...

It is VERY stringy, and oozes allot, I tried from 185 all the way to 210degC

So in order not to waist the $60 rolls I had to use them, so they produce allot of fine strings, and initial oozing, even when printing I find that the printer would ooze ever so slightly. Playing with M221 helps

These bits accumulated on the Hex nut, however by doing the mentioned in the previous above, I find that it eliminates 90% of the accumulated material at least now they drop off and can be picked off and not get caught in the Hex nut

Yes as with all things new one must get the hang of it, one month down the line and only now I`m getting to know the nitty gritty stuff

*AHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH.................... now only do I see this !!!!!!!!!!!!!!!!!!!!!!!

I went on RS website and checked the fine print of RS brand, this UK company sells both PLA and ABS HOWVER they do not indicate ABS or PLA

on the rolls, just manufacturer and WEB address. The deception of ASSUMPTION !!

I actually thought I bought 2 rolls of PLA, but was supplied ABS instead, so all the while I was using the PLA setting, deforming and stringyness, battling like mad, as we say in South Africa EISH....being a newby, but you sometimes have to learn the hard way, I don`t think I `m alone and others have made this mistake as well

))

))Tx Ben

Edited 4 time(s). Last edit at 04/15/2015 06:24AM by BenBB.

|

Re: Nozzle offset, helps with excess material accumulation April 15, 2015 07:37AM |

Registered: 10 years ago Posts: 2,472 |

Quote

BenBB

I actually thought I bought 2 rolls of PLA, but was supplied ABS instead, so all the while I was using the PLA setting, deforming and stringyness, battling like mad, as we say in South Africa EISH....being a newby, but you sometimes have to learn the hard way, I don`t think I `m alone and others have made this mistake as well))

Tx Ben

You can tell by the distinctive smell of ABS while it is printing (though obviously you would not recognise the smell if you had never used it before!) ABS will also dissolve in acetone but PLA will not. Just dip the filament in acetone and then wipe your finger along it. (Borrow your wife's nail polish remover to test!)

Dave

|

Re: Nozzle offset, helps with excess material accumulation April 15, 2015 11:08AM |

Registered: 9 years ago Posts: 78 |

HAHAHA Dave you hit the nail on the HEAD !!

(I do have 5litres of ACETONE on hand, I use it to clean the bed....)

No smell from my ABS material though BUT I printed the CURA robot and then did the "boiling frog" trick, just out of curiosity 2 days ago,

BEFORE I knew it was ABS, I thought but the this PLA comes out very nice with acetone what gives, I though PLA is acetone resistant

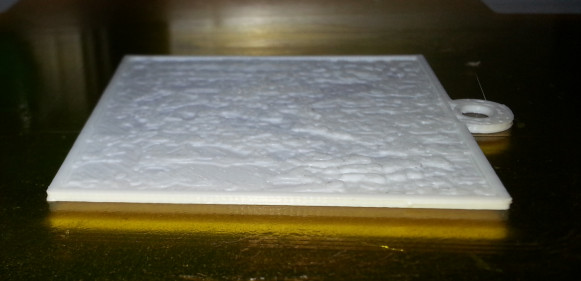

So yes this PLA has now become ABS... I reprinted a Lithophane at 240 hot end and 90dC bed, 110 is a bit steep for the bed temp it seems

and it came out flat and not curling up on the edges as before, so the results are already better, phew...

Tx Ben

Edited 1 time(s). Last edit at 04/15/2015 11:17AM by BenBB.

|

Re: Nozzle offset, helps with excess material accumulation April 15, 2015 02:08PM |

Registered: 10 years ago Posts: 1,230 |

Quote

BenBB

BEFORE I knew it was ABS, I thought but the this PLA comes out very nice with acetone what gives, I though PLA is acetone resistant..

LOL! - It sure is - found that out when I made the mistake of adding PLA bits to ABS slurry, patiently waiting weeks for the bits to dissolve - and furthermore in the department of facepalms, no, Kapton tape will not help making the print stick if placed on the underside of the glass (doh!)

Erik

|

Re: Nozzle offset, helps with excess material accumulation April 17, 2015 12:29PM |

Registered: 9 years ago Posts: 176 |

|

Re: Nozzle offset, helps with excess material accumulation April 18, 2015 03:56AM |

Registered: 9 years ago Posts: 78 |

|

Re: Nozzle offset, helps with excess material accumulation April 18, 2015 04:13PM |

Registered: 9 years ago Posts: 176 |

|

Re: Nozzle offset, helps with excess material accumulation April 20, 2015 08:25AM |

Registered: 10 years ago Posts: 2,472 |

It is a lithophane (see [en.wikipedia.org]). What looks like bubbles is thus how it is designed. I've been wanting to print a lithophane for some time but not so far got around to it, there are applications available to convert photographs to lithophane STLs. A few lithophane panels put together to form a lampshade might look good.Quote

VortyZA

I'm trying to work out what that 'bubble' effect is..

Dave

Sorry, only registered users may post in this forum.