The Boiling Frog

Posted by ormerod168

|

The Boiling Frog April 11, 2015 12:39PM |

Registered: 10 years ago Posts: 1,230 |

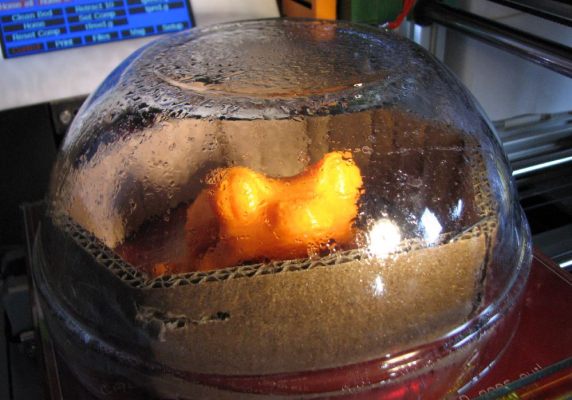

Was printed layer hight 0,25 - Acetone vapor at 50 degrees C, 120 minutes

MorenaP's beautiful Treefrog (scaled1,5 2,25):

[www.thingiverse.com]

If want to print, notice this:

PLA frogs with and without cooling fan (experiment)

[www.thingiverse.com]

Erik

Edited 1 time(s). Last edit at 04/12/2015 10:36AM by ormerod168.

MorenaP's beautiful Treefrog (scaled

[www.thingiverse.com]

If want to print, notice this:

PLA frogs with and without cooling fan (experiment)

[www.thingiverse.com]

Erik

Edited 1 time(s). Last edit at 04/12/2015 10:36AM by ormerod168.

|

Re: The Boiling Frog April 11, 2015 02:26PM |

Registered: 9 years ago Posts: 191 |

|

Re: The Boiling Frog April 11, 2015 02:43PM |

Registered: 9 years ago Posts: 62 |

|

Re: The Boiling Frog April 11, 2015 03:00PM |

Registered: 10 years ago Posts: 1,230 |

Quote

fotomas

It is my understanding that acetone do not work on PLA. Is that PLA?

You are right, was printed in ABS, should have said that sorry, a bonus picture for your eyes only ;-)

Smooooth...

Erik :-)

|

Re: The Boiling Frog April 11, 2015 03:09PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Yella3D

That's really nice Erik.

I don't print as much ABS as I should, I can't stand the fumes!

Thank You - I got used to the fumes and don't notice them anymore - its like smoking, you don't notice the smell until you stop smoking yourself

...or like living with a goat, the goat will adapt to the smell :-)

Erik

|

Re: The Boiling Frog April 11, 2015 04:40PM |

Registered: 10 years ago Posts: 100 |

|

Re: The Boiling Frog April 12, 2015 06:43AM |

Registered: 9 years ago Posts: 78 |

Hi Erik

Nice finish

Can you maybe publish the settings for this frog;

Lots of Q`s

Did you use Pronterface or the WEB interface, did you print from SD

Did you use slic3r or some other app. to generate the G-Code...

What base did you use to print on, on glass direct, kapton etc..

Is this a stock standard Ormerod or is it modified in any way ?

If you used pronterface can you publish the setting, not the frog G file settings, as I find that the comments are quite confusing and sometimes one cannot relate them to the actual pronterface entries

VERY IMPORTANT what temperatures did you run the bed ?

I see the frog experiment on ThingeVerse, but I would like first hand to get it from the actual "result maker"

Then did you pour the acetone on the printer bed, cover it and left it or soaked the cardboard and then set the heat up to 50degC

Tx Ben

Edited 1 time(s). Last edit at 04/12/2015 06:44AM by BenBB.

Nice finish

Can you maybe publish the settings for this frog;

Lots of Q`s

Did you use Pronterface or the WEB interface, did you print from SD

Did you use slic3r or some other app. to generate the G-Code...

What base did you use to print on, on glass direct, kapton etc..

Is this a stock standard Ormerod or is it modified in any way ?

If you used pronterface can you publish the setting, not the frog G file settings, as I find that the comments are quite confusing and sometimes one cannot relate them to the actual pronterface entries

VERY IMPORTANT what temperatures did you run the bed ?

I see the frog experiment on ThingeVerse, but I would like first hand to get it from the actual "result maker"

Then did you pour the acetone on the printer bed, cover it and left it or soaked the cardboard and then set the heat up to 50degC

Tx Ben

Edited 1 time(s). Last edit at 04/12/2015 06:44AM by BenBB.

|

Re: The Boiling Frog April 12, 2015 08:16AM |

Registered: 10 years ago Posts: 1,230 |

Hi Jon

Yes the cardboard carry the acetone and act as a wick, could be anything else, preferable something with a big surface to vapor the fumes

I ad acetone to the material but only as much as it will carry, if you ad too much it will float the floor glass plate and mess up the model

Can be a bit tricky to get an even surface, without heat the fumes will hang out at the bottom but adding heat (e.g. using the ormerod bed) will move them to the top

Acetone is highly flame able so do take care! - fire is not always you friend, I once nearly cremated my ormerod with a flame thrower, forgot I had it in my left hand, the shame tsk. tsk...

Maybe safer not to ad heat or just place outside in the sun

I think its best to use a "wick" higher than the object to ad more vapor top down, here I used a few pages from a newspaper fixed in the jar with a string of metal packing band, BTW the little guy sweating in the jar is Master Cylinder Card holder from thingiverse, amazingly you _can_ print this model with out support if you use a lot of cooling (and ad a large brim so it wont tip over)

[www.thingiverse.com]

And of cause, the finer the print, the faster the smoothing and the more details will survive

Erik

Yes the cardboard carry the acetone and act as a wick, could be anything else, preferable something with a big surface to vapor the fumes

I ad acetone to the material but only as much as it will carry, if you ad too much it will float the floor glass plate and mess up the model

Can be a bit tricky to get an even surface, without heat the fumes will hang out at the bottom but adding heat (e.g. using the ormerod bed) will move them to the top

Acetone is highly flame able so do take care! - fire is not always you friend, I once nearly cremated my ormerod with a flame thrower, forgot I had it in my left hand, the shame tsk. tsk...

Maybe safer not to ad heat or just place outside in the sun

I think its best to use a "wick" higher than the object to ad more vapor top down, here I used a few pages from a newspaper fixed in the jar with a string of metal packing band, BTW the little guy sweating in the jar is Master Cylinder Card holder from thingiverse, amazingly you _can_ print this model with out support if you use a lot of cooling (and ad a large brim so it wont tip over)

[www.thingiverse.com]

And of cause, the finer the print, the faster the smoothing and the more details will survive

Erik

|

Re: The Boiling Frog April 12, 2015 10:33AM |

Registered: 10 years ago Posts: 1,230 |

Quote

BenBB

Can you maybe publish the settings for this frog;

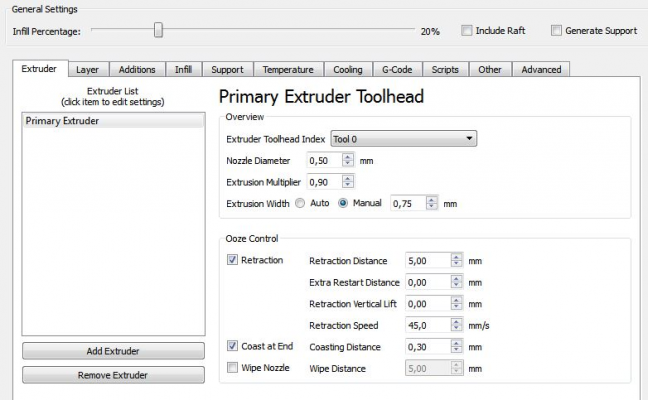

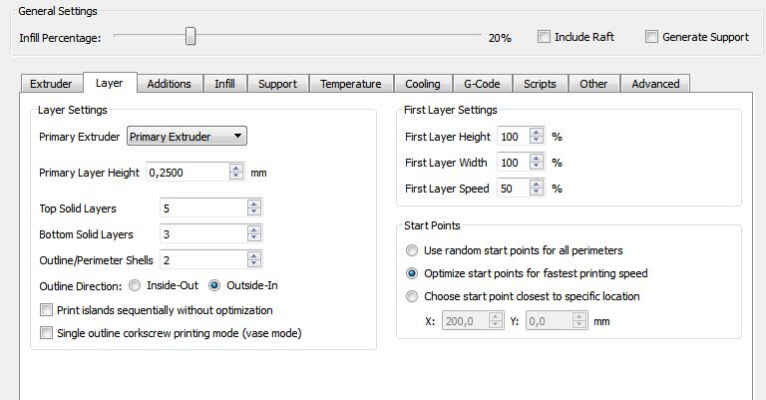

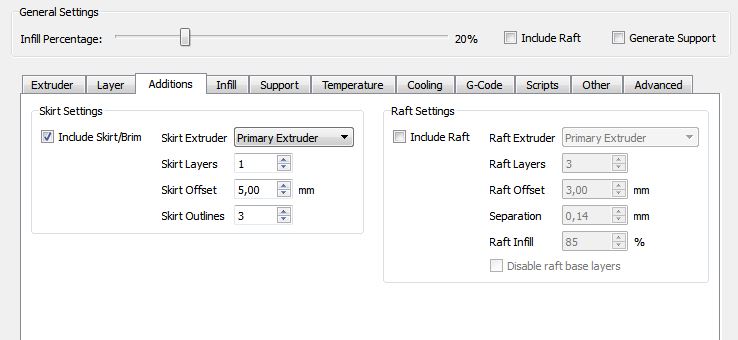

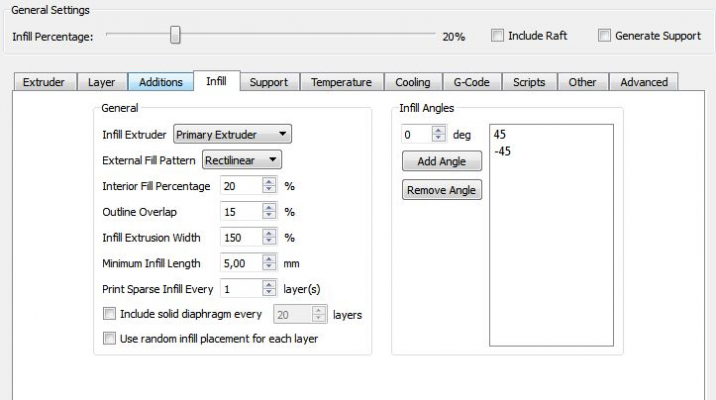

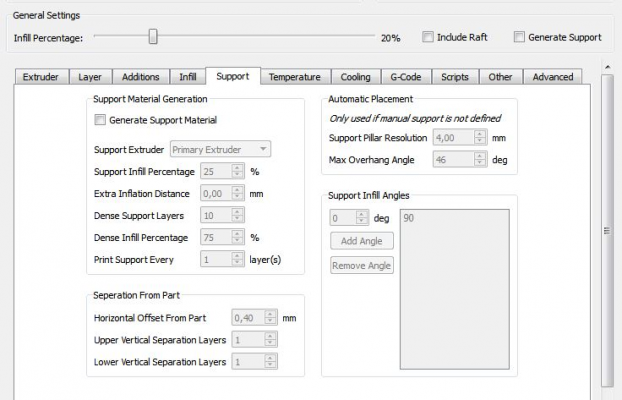

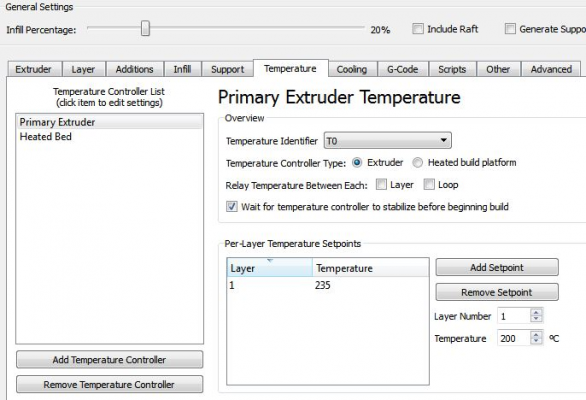

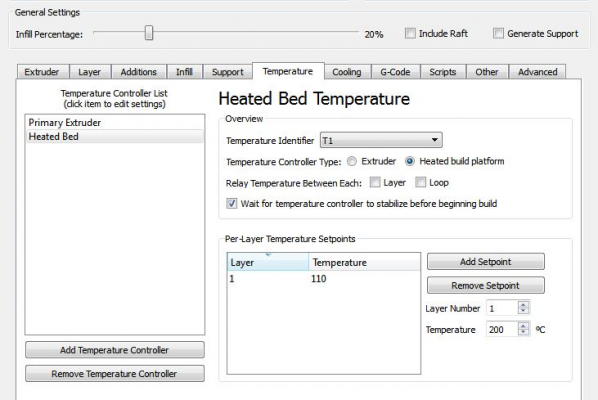

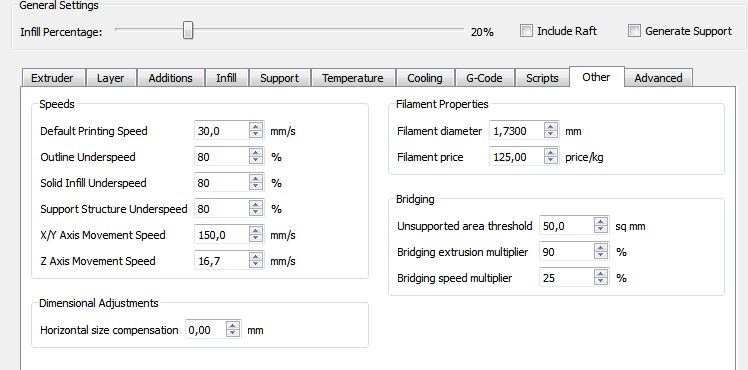

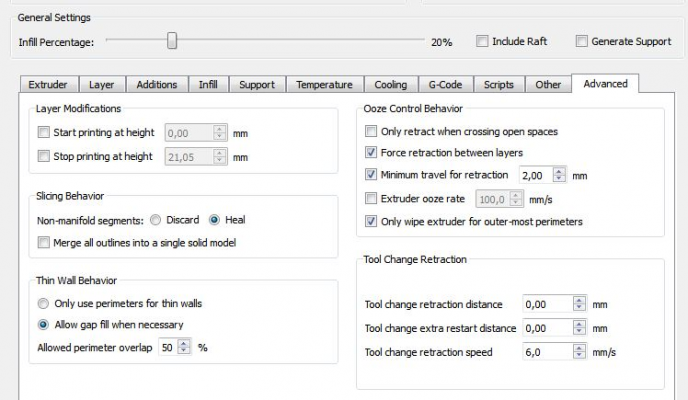

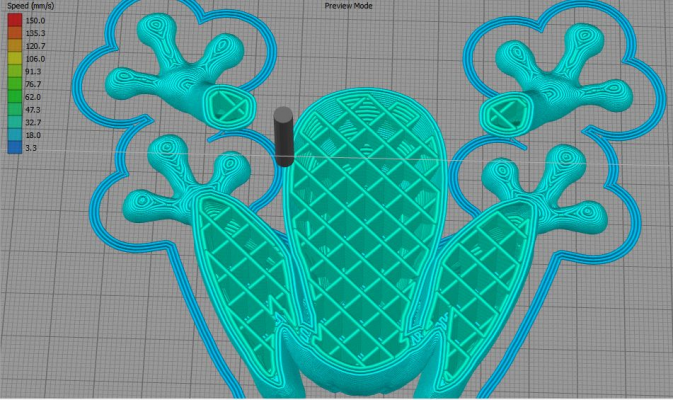

Hi Ben, will be happy to, firstly the posted orange one was printed in scale 2,25, not as I wrote 1,50, but they were sliced with nearly the same settings (little one in layer 0,2), here's both

Quote

Lots of Q`s

Did you use Pronterface or the WEB interface, did you print from SD

I always print from SD-card now using dc42 (David's) brilliant PanelDue, its really is a pleasure to have the printer as a stand alone item, not have to worry about net access or any PC trouble or communication messing up the print, best ormerod mod ever IMHO, can't thank David enough!, will do everything Pronterface did but command lines but you can make macros for that

Quote

Did you use slic3r or some other app. to generate the G-Code...

Was sliced with Simplify3D but I don't think there will be much difference sliced with Slic3r or Cura - I just got tired of Slic3r because of slow slicing/new bugs in every version but afaik, more work is done on the program now and it seems to get better and more stable - I still use Slic3r for cutting models in half, thats something SF3D cant do

Quote

What base did you use to print on, on glass direct, kapton etc..

Was printed on Kapton, this model is very easy to make stick to bed

Quote

Is this a stock standard Ormerod or is it modified in any way ?

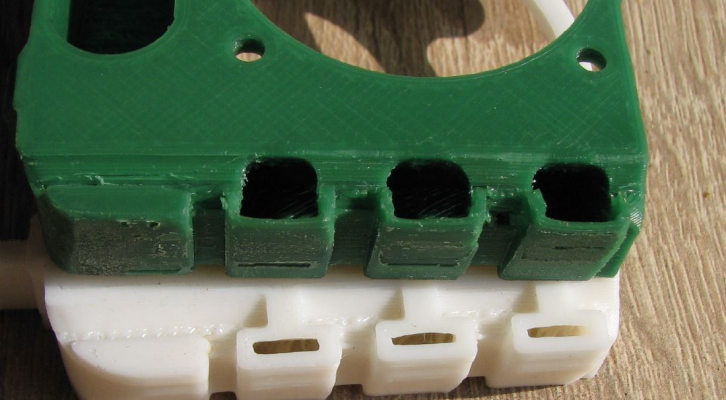

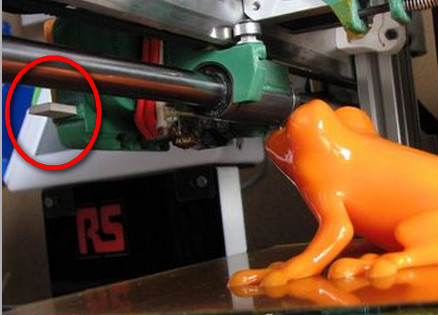

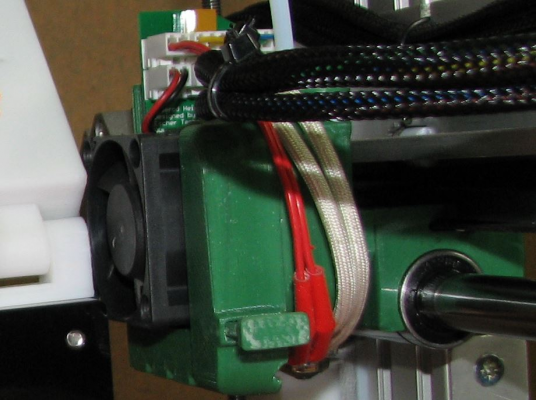

I have changed a lot but mostly to make the bed flat and stable, the only thing changed that influence the print is I opened the cooling slot on the fan duct a lot, I'm using johneato's control to the nozzle mod, but basically the air flow is the same as the stock Ormerod1 one:

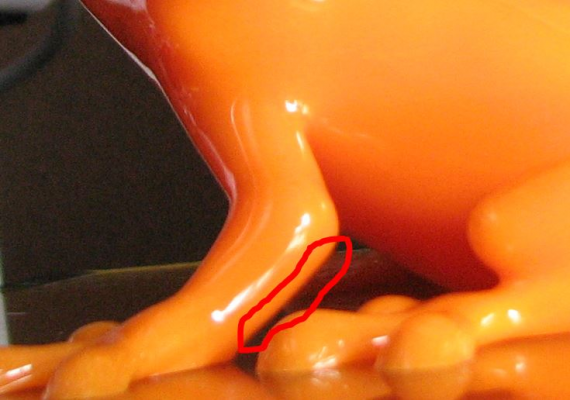

as the cooling is one-sided only position of the print can be of importance:

Could use more cooling from the other side for this part:

Quote

If you used pronterface can you publish the setting, not the frog G file settings, as I find that the comments are quite confusing and sometimes one cannot relate them to the actual pronterface entries

VERY IMPORTANT what temperatures did you run the bed ?

Will post screen shots of all the settings so you can use them in Slic3r

Quote

Then did you pour the acetone on the printer bed, cover it and left it or soaked the cardboard and then set the heat up to 50degC

See my reply upstreams

Erik

|

Re: The Boiling Frog April 12, 2015 10:47AM |

Registered: 10 years ago Posts: 1,230 |

Erik

|

Re: The Boiling Frog April 12, 2015 12:45PM |

Registered: 9 years ago Posts: 78 |

Hi Erik

Thank a mill ! Your post is most valuable for me as a new be to 3d printing. Mnnn it seems Simplify3D is worth the money, I will buy it as soon as I get the OR2 properly set-up, the OR2 still has a long way to go before it prints like this, at least I know that it is capable...

YES I also found just today that the airflow is VERY limited and with the DC42 backwash plate even less air, I removed it for PLA and will open up the holes, my PLA print are already looking better

I will try the frog in ABS and compare notes

Tx Ben

Thank a mill ! Your post is most valuable for me as a new be to 3d printing. Mnnn it seems Simplify3D is worth the money, I will buy it as soon as I get the OR2 properly set-up, the OR2 still has a long way to go before it prints like this, at least I know that it is capable...

YES I also found just today that the airflow is VERY limited and with the DC42 backwash plate even less air, I removed it for PLA and will open up the holes, my PLA print are already looking better

I will try the frog in ABS and compare notes

Tx Ben

|

Re: The Boiling Frog April 12, 2015 12:58PM |

Registered: 9 years ago Posts: 78 |

Hi Erik

Please see the pic, what else have you done to the OR hotend ? what is that white piece protruding there

Tx Ben

Please see the pic, what else have you done to the OR hotend ? what is that white piece protruding there

Tx Ben

|

Re: The Boiling Frog April 12, 2015 02:19PM |

Registered: 10 years ago Posts: 1,230 |

Quote

BenBB

Please see the pic, what else have you done to the OR hotend ? what is that white piece protruding there

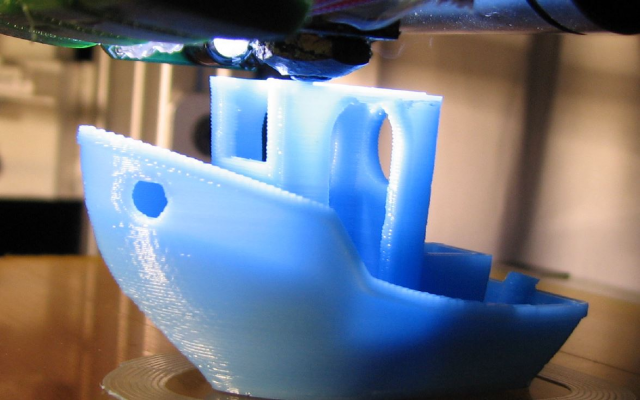

The white piece is just a slice of white rubber that I use instead of the printed plate part from johneato's Control To The Nozzle mod, that part would sometime fall of while printing when adjusted for max airflow - besides adjusting the amount of air, johneato's mod and the stock O1 version is the same - but as said, I did drill out the air slot to make way for more airflow and I think the printer could use a lot more cooling and preferable all around the nozzle, especially when printing small parts like this:

3DBenchy - The jolly 3D printing torture-test

[www.3dbenchy.com]

but here's a picture with the original part in place:

Johneato's Control air to the nozzles:

[forums.reprap.org]

Erik

|

Re: The Boiling Frog April 13, 2015 12:19AM |

Registered: 10 years ago Posts: 41 |

Good job!

Is it sliced by skeinforge?

Everything of 3D printer. www.3dminions.com

[www.facebook.com]

Is it sliced by skeinforge?

Everything of 3D printer. www.3dminions.com

[www.facebook.com]

|

Re: The Boiling Frog April 13, 2015 01:10PM |

Registered: 10 years ago Posts: 1,230 |

Quote

BenBB

... and with the DC42 backwash plate even less air...

Yes have noticed that, I use this one posted by dmould for over a year ago

[forums.reprap.org]

|

Re: The Boiling Frog April 13, 2015 01:19PM |

Registered: 10 years ago Posts: 1,230 |

|

Re: The Boiling Frog April 28, 2015 04:03PM |

Registered: 10 years ago Posts: 100 |

|

Re: The Boiling Frog April 29, 2015 10:54AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Jon Steward

I've tried dipping an ABS print directly into acetone.

Only needs a few seconds.

The gopro holder didn't really work as the walls are quite thin.

A printed part acts a bit like a sponge and soaks up quite a bit of acetone between the layers if you submerge it. I soak a paper towel in acetone and just rub it over the surface of the part, which smooths it and helps bond the layers without soaking in and making the ABS go rubbery.

Dave

|

Re: The Boiling Frog April 29, 2015 01:22PM |

Registered: 10 years ago Posts: 1,230 |

Quote

dmould

.. I soak a paper towel in acetone and just rub it over the surface of the part, which smooths it and helps bond the layers without soaking in and making the ABS go rubbery.

Dave

will have to try that, would think it would be safer to use a brush, don't you risk getting small bits of paper in the surface that way?

Erik

|

Re: The Boiling Frog April 29, 2015 02:34PM |

Registered: 10 years ago Posts: 2,472 |

Quote

ormerod168

Quote

dmould

.. I soak a paper towel in acetone and just rub it over the surface of the part, which smooths it and helps bond the layers without soaking in and making the ABS go rubbery.

Dave

will have to try that, would think it would be safer to use a brush, don't you risk getting small bits of paper in the surface that way?

Erik

None of the kitchen towels I have used (all cheap supermarket brands) have had any tendency to shed fibres or other bits when used for that purpose, so I have never experienced that problem. I do not re-use the towel though - I use a new sheet each time, so a large printed item may need 4 sheets by the time it has been completely covered. Most parts are covered by 2 sheets - first rub down one half while holding the other end, wait for it to dry and then hold the part by the completed end do the remainder with a fresh sheet. I have not tried a brush, it may well work just as well.

Dave

|

Re: The Boiling Frog April 29, 2015 03:06PM |

Registered: 9 years ago Posts: 34 |

Sorry, only registered users may post in this forum.