It's been a while - sigh

Posted by Radian

|

It's been a while - sigh April 18, 2015 09:30AM |

Registered: 10 years ago Posts: 300 |

I haven't been keeping up with Ormerod developments for a year or so now and it looks like plenty has happened. I want to dust of my printer and get it printing again but I'm a bit nervous about jumping in with firmware upgrades and the like, The last firmware I loaded was David's 057s-dc42.bin used with Matt's OrmerodWebControl V0.65

My own capacitive Z-probe is still fitted and works well with the firmware so I'm a bit wary of changing it on account of the big leaps that are bound to have taken place since. I didn't even realise that Ormerod 2 was a thing! Do you guys here think there's anything I should know about?

RS Components Reprap Ormerod No. 481

My own capacitive Z-probe is still fitted and works well with the firmware so I'm a bit wary of changing it on account of the big leaps that are bound to have taken place since. I didn't even realise that Ormerod 2 was a thing! Do you guys here think there's anything I should know about?

RS Components Reprap Ormerod No. 481

|

Re: It's been a while - sigh April 18, 2015 11:18AM |

Registered: 10 years ago Posts: 14,672 |

Hi Radian, welcome back!

Assuming your capacitive probe produces an analog output like the regulator Z probe, then the newer firmware should handle it just fine, with the probe type set at 1 in the M558 command. You will need to move the Z probe signal wire to a different pin on the Duet expansion connector.

Lastest firmware is RRP 1.04, or my 1.04e, or zombiepantlol's 1.08e. Mine and zpl's share a lot of extra features, the biggest difference is that mine uses completely rewritten movement code to generate step pulses more precisely, support extruder elasticity compensation (which doesn't help as much as I hoped), and support Delta and CoreXY printers. [edit: also simultaneous XY homing.] Best web interface for either my or zpl's firmware is zpl's DuetWerbControl 1.06.

The main development has been dual extrusion. I developed a dual extrusion mod which I described here [miscsolutions.wordpress.com], and now RepRapPro sells a dual extrusion upgrade kit, which uses a new Quick Set nozzle design.

I now manufacture a controller board to add a touch screen control panel to the ormerod, details here [miscsolutions.wordpress.com].

Edited 2 time(s). Last edit at 04/18/2015 11:20AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Assuming your capacitive probe produces an analog output like the regulator Z probe, then the newer firmware should handle it just fine, with the probe type set at 1 in the M558 command. You will need to move the Z probe signal wire to a different pin on the Duet expansion connector.

Lastest firmware is RRP 1.04, or my 1.04e, or zombiepantlol's 1.08e. Mine and zpl's share a lot of extra features, the biggest difference is that mine uses completely rewritten movement code to generate step pulses more precisely, support extruder elasticity compensation (which doesn't help as much as I hoped), and support Delta and CoreXY printers. [edit: also simultaneous XY homing.] Best web interface for either my or zpl's firmware is zpl's DuetWerbControl 1.06.

The main development has been dual extrusion. I developed a dual extrusion mod which I described here [miscsolutions.wordpress.com], and now RepRapPro sells a dual extrusion upgrade kit, which uses a new Quick Set nozzle design.

I now manufacture a controller board to add a touch screen control panel to the ormerod, details here [miscsolutions.wordpress.com].

Edited 2 time(s). Last edit at 04/18/2015 11:20AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: It's been a while - sigh April 18, 2015 02:06PM |

Registered: 10 years ago Posts: 300 |

Good to be back, thanks. I'm very puzzled though... before upgrading to your latest firmware, I successfully printed an object using Matt's we control panel and all went well.

Next I updated the firmware to your 1.04e and also installed zpl's web control. This looked very promising but I seemed to have to reverse the X axis motor connector to get it going in the right direction.Then when I attempt to home the Z axis, I just get slow movement of both the x & Y axis until I hit emergency stop.

I checked and already had M558 P1 in the config file. My Z probe is analog and connects to A7. It gives a reading of around 600 when on the bed and 400 when 10mm above. I'm feeling a bit rusty after not playing with the printer for a year or so but I can't think of why homing Z (G28 Z) would do this?

RS Components Reprap Ormerod No. 481

Next I updated the firmware to your 1.04e and also installed zpl's web control. This looked very promising but I seemed to have to reverse the X axis motor connector to get it going in the right direction.Then when I attempt to home the Z axis, I just get slow movement of both the x & Y axis until I hit emergency stop.

I checked and already had M558 P1 in the config file. My Z probe is analog and connects to A7. It gives a reading of around 600 when on the bed and 400 when 10mm above. I'm feeling a bit rusty after not playing with the printer for a year or so but I can't think of why homing Z (G28 Z) would do this?

RS Components Reprap Ormerod No. 481

|

Re: It's been a while - sigh April 18, 2015 02:10PM |

Registered: 10 years ago Posts: 665 |

Presuming you've upgraded to dc42's new firmware, it's a good idea to replace the homing files from his SD image. That should solve the first few problems. Apart from that I think you need to add an M574 line to your config file to get the Y axis endstop working, see his config template to get an idea how it's done.

|

Re: It's been a while - sigh April 18, 2015 02:41PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Radian

Next I updated the firmware to your 1.04e and also installed zpl's web control. This looked very promising but I seemed to have to reverse the X axis motor connector to get it going in the right direction.

Sorry, I should have mentioned that. The default motor direction in my firmware is now set up for the Ormerod 2, which has the X motor wired the same way round as all the others, unlike the way the Ormerod 1 was wired. There is a gcode you can put in config.g to reverse the direction, but reversing the connector is fine too.

Quote

Radian

Then when I attempt to home the Z axis, I just get slow movement of both the x & Y axis until I hit emergency stop.

Strange, someone recently reported that, but when using my homing files with RRP's 1.04 release. I thought that RRP's 1.04 homing files worked OK on my build. But maybe you are using older homing files? Try the homing files from my repository.

I'm guessing you have already added the M574 command (see zombiepantslol's reply above) if Y homing is working.

Edited 1 time(s). Last edit at 04/18/2015 02:45PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: It's been a while - sigh April 18, 2015 06:33PM |

Registered: 10 years ago Posts: 300 |

Cheers guys. Using the SD image from dc42's branch resolved the problems for me. Previously the G31 settings were held in non-volatile store so I had the G31 line commented out - I take it from seeing it back in the config file once more, that NV parameter store has been depreciated? I'm also curious about finding the MAC address in the config now - why's this here now?

Great work though, loving the new web controls :-)

RS Components Reprap Ormerod No. 481

Great work though, loving the new web controls :-)

RS Components Reprap Ormerod No. 481

|

Re: It's been a while - sigh April 19, 2015 03:49AM |

Registered: 10 years ago Posts: 14,672 |

RepRapPro doesn't like using a nonvolatile parameter store because they think it makes support more difficult, so it is turned off by default. You can use M500 to store parameters in nvram manually, M501 to load them, and M500 S1 to store them automatically when you change anything. So M501 at the start of config.g and M500 S1 at the end of config.g should restore something like the old behaviour.

The MAC address is there because otherwise, all Duets use the same MAC address, so you need to change it if you want to put more than one Duet on the same network.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The MAC address is there because otherwise, all Duets use the same MAC address, so you need to change it if you want to put more than one Duet on the same network.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: It's been a while - sigh April 19, 2015 05:50PM |

Registered: 10 years ago Posts: 300 |

OK, it's beginning to come back to me. Amazing how unfamiliar this stuff looks after a year away from it all.

Unfortunately I think my bed has warped as I'm getting lots of curling. I've tried bed leveling compensation and it's helped a bit but still not enough to prevent lifting. Bother. Let me just check I'm doing it right...

In config I specify four corners using M557 and then issue G32 before I run a print. That's all there is to it? It does then go to each corner and starting up at 5mm drops down to around 1 ro 2mm. I can then see Z turning as it prints a layer so it's compensating for something! I just don't know quite what.

What I do notice though is quite a lot of jitter in the Z probe reading - around 10% at worst. The output from my probe is steady enough although I recall the Duet used digital ground as the reference for the Z probe. I think I asked before if it was feasible to create a digital (SPI or UART) channel to read probe height. It would seem to be the best way to get round noise in this critical reading.

RS Components Reprap Ormerod No. 481

Unfortunately I think my bed has warped as I'm getting lots of curling. I've tried bed leveling compensation and it's helped a bit but still not enough to prevent lifting. Bother. Let me just check I'm doing it right...

In config I specify four corners using M557 and then issue G32 before I run a print. That's all there is to it? It does then go to each corner and starting up at 5mm drops down to around 1 ro 2mm. I can then see Z turning as it prints a layer so it's compensating for something! I just don't know quite what.

What I do notice though is quite a lot of jitter in the Z probe reading - around 10% at worst. The output from my probe is steady enough although I recall the Duet used digital ground as the reference for the Z probe. I think I asked before if it was feasible to create a digital (SPI or UART) channel to read probe height. It would seem to be the best way to get round noise in this critical reading.

RS Components Reprap Ormerod No. 481

|

Re: It's been a while - sigh April 19, 2015 06:12PM |

Registered: 10 years ago Posts: 300 |

As soon as I wrote that I remembered I have a LED on my probe that fires at Z=0 threshold. After compensation and stepping X I can see that deviation in Z from my bed is less than +/-0.1mm across the axis (I've been trying all day to print a long thin object in that axis). The curling must be another adhesion issue.

Looking at the base of the failed prints it looks rather open so there's less contact area than there might be. I'm using the same Slic3r settings I always used to but I see no separate infill density for the top/bottom. I'm assuming it defaults to solid.? My old prints looked much "shinier" and dense on the base.

RS Components Reprap Ormerod No. 481

Looking at the base of the failed prints it looks rather open so there's less contact area than there might be. I'm using the same Slic3r settings I always used to but I see no separate infill density for the top/bottom. I'm assuming it defaults to solid.? My old prints looked much "shinier" and dense on the base.

RS Components Reprap Ormerod No. 481

|

Re: It's been a while - sigh April 19, 2015 06:20PM |

Registered: 10 years ago Posts: 14,672 |

Using the standard IR probe, the noise corresponds to less than 0.05mm change in height, so it's not a serious problem. You might want to change the firmware in your capacitive probe to make the output change more rapidly with height. Or do what I do in my differential IR probe: provide an output that jumps between 3 voltages, corresponding to sensor nowhere near the bed, sensor approaching trigger height, and sensor at/below trigger height.

Most of the noise is picked up from the switching regulator by the Z probe wiring to the expansion connector. I halved it on my Duet board by adding a Z probe pin header at the bottom, and routing wires to it from the expansion header carefully on the back of the board.

Edited 1 time(s). Last edit at 04/20/2015 10:10AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Most of the noise is picked up from the switching regulator by the Z probe wiring to the expansion connector. I halved it on my Duet board by adding a Z probe pin header at the bottom, and routing wires to it from the expansion header carefully on the back of the board.

Edited 1 time(s). Last edit at 04/20/2015 10:10AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: It's been a while - sigh April 20, 2015 08:12AM |

Registered: 10 years ago Posts: 300 |

OK, I will have a go at increasing the "gain" to increase the SNR. I keep looking at that unshielded inductor and plotting its removal....

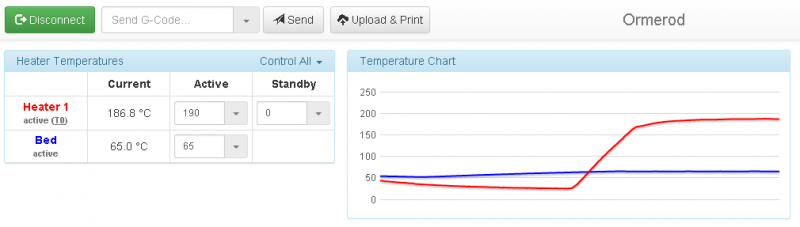

But now I'm getting the error: "Heating fault on heater 1, T = 187.3 C; still not at temperature 190.0 after 150.356766 seconds" as an example - the temperature is still slowly climbing, and it happens again and again at around this point. I assume this is your firmware being cautious? It's only just started doing this today, and I'm pretty sure the temperature was OK for printing yesterday so I've no reason to suspect the thermistor etc. Is 150s really long enough to reach a couple of hundred degrees?

RS Components Reprap Ormerod No. 481

But now I'm getting the error: "Heating fault on heater 1, T = 187.3 C; still not at temperature 190.0 after 150.356766 seconds" as an example - the temperature is still slowly climbing, and it happens again and again at around this point. I assume this is your firmware being cautious? It's only just started doing this today, and I'm pretty sure the temperature was OK for printing yesterday so I've no reason to suspect the thermistor etc. Is 150s really long enough to reach a couple of hundred degrees?

RS Components Reprap Ormerod No. 481

|

Re: It's been a while - sigh April 20, 2015 09:11AM |

Registered: 10 years ago Posts: 2,472 |

To compensate for a bed that is not quite level (or adequately compensated), try setting your first layer height quite thick (you can go up to 0.5mm), and then set the Z zero height to be correct at the lowest point of the bed (or just try setting it about 0.15mm too low at the normal homing place). Thicker layers are far more tolerant of a nozzle that is too low.

With DC42's firmware you can adjust the PID values of the heater to get to temperature a bit more rapidly. IMO a bit of overshoot on the initial heating from cold does no harm so you can set the PID quite aggressively, though my hotend reaches 230 deg C with no overshoot in under a minute (but I am using a 14V PSU, which helps), so 150 seconds seems a tad too long. As you have not used the printer for a while, check that the 12V connections are still tight. A few people have had a lot of damage caused by these connectors getting loose and causing the connector to overheat (it can easily catch fire), and a hotend that takes a long time to heat could be a symptom of a poor (high-resistance) 12V connection.

Dave

With DC42's firmware you can adjust the PID values of the heater to get to temperature a bit more rapidly. IMO a bit of overshoot on the initial heating from cold does no harm so you can set the PID quite aggressively, though my hotend reaches 230 deg C with no overshoot in under a minute (but I am using a 14V PSU, which helps), so 150 seconds seems a tad too long. As you have not used the printer for a while, check that the 12V connections are still tight. A few people have had a lot of damage caused by these connectors getting loose and causing the connector to overheat (it can easily catch fire), and a hotend that takes a long time to heat could be a symptom of a poor (high-resistance) 12V connection.

Dave

|

Re: It's been a while - sigh April 20, 2015 09:16AM |

Registered: 10 years ago Posts: 300 |

|

Re: It's been a while - sigh April 20, 2015 09:19AM |

Registered: 10 years ago Posts: 300 |

Ah, Dave, thanks for your tips - I didn't read them until I submitted my last post. I will have a look at changing the PID settings.

Edit:: I'm getting 11.2V with both heaters on so not clever but not much different than last time I measured things.

Edited 1 time(s). Last edit at 04/20/2015 09:22AM by Radian.

RS Components Reprap Ormerod No. 481

Edit:: I'm getting 11.2V with both heaters on so not clever but not much different than last time I measured things.

Edited 1 time(s). Last edit at 04/20/2015 09:22AM by Radian.

RS Components Reprap Ormerod No. 481

|

Re: It's been a while - sigh April 20, 2015 09:26AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Radian

David, it seems to me as though the PID parameters are holding back the hot-end temperature such that it takes ages to reach the set point. Aiming for 190, It gets to 185 in 90 secs. but doesn't reach 190 until well after 3 mins.

Yes, it sounds like your PID values need tweaking, though 90 seconds to reach 185 degrees still seems very excessive to me, mine probably takes 15 seconds to reach that point - if you are sure your 12V connections are tight perhaps your heater or PSU is under-powered, and I would suggest you measure the voltage at the heater terminals and work backwards if necessary to find the real reason for the lack of oomph. I am not all that familiar with tweaking the PIDs for the Ormerod, so maybe wait for DC42 to see these posts and give a better suggestion of how to adjust them than I could.

If PSU supply voltage is an issue you could also ensure the bed heater is off at the time you initially heat the hotend. Maybe temporarily lower the bed temperature when you initially heat the nozzle, then set it again after the hotend is up to temperature.

Dave

|

Re: It's been a while - sigh April 20, 2015 10:16AM |

Registered: 10 years ago Posts: 14,672 |

Hi Radian,

1. You can increase the heaster timeout using the M570 command, e.g. M570 S180 will set it to 3 minutes.

2. If the temperature is undershooting, try increasing the S parameter in the M301 command for that heater. This scales up the PID output to account for a weaker than average heater or a lower than average supply voltage. The default is 1.0 and I suggest you try 1.1. So send M301 H1 S1.1.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. You can increase the heaster timeout using the M570 command, e.g. M570 S180 will set it to 3 minutes.

2. If the temperature is undershooting, try increasing the S parameter in the M301 command for that heater. This scales up the PID output to account for a weaker than average heater or a lower than average supply voltage. The default is 1.0 and I suggest you try 1.1. So send M301 H1 S1.1.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: It's been a while - sigh April 20, 2015 10:24AM |

Registered: 10 years ago Posts: 300 |

11V at the heater wires - which is about as good as can be expected given the 11.2V on the main PCB. The issue is clearly marginal, as I just managed to get a print started without changing anything. The starting temperature may be making all the difference.

This is how it looks - once it turns the corner it takes too long to reach the target. When I took the screenshot it had just started to print.

Edit: Thanks David. Will try when print finished.

Edited 1 time(s). Last edit at 04/20/2015 10:25AM by Radian.

RS Components Reprap Ormerod No. 481

This is how it looks - once it turns the corner it takes too long to reach the target. When I took the screenshot it had just started to print.

Edit: Thanks David. Will try when print finished.

Edited 1 time(s). Last edit at 04/20/2015 10:25AM by Radian.

RS Components Reprap Ormerod No. 481

|

Re: It's been a while - sigh April 20, 2015 06:05PM |

Registered: 10 years ago Posts: 300 |

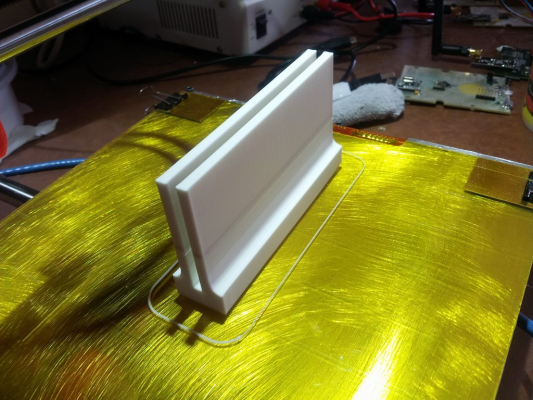

PID scale 1.1 didn't make any noticeable difference. 2 did though!

I think there's just not enough juice coming out the ATX supply so I'm swapping over to a 13.8V 25A PSU next. Anyway, I finally got my print done thanks to everyone's help here..

It's for a repair job on the broken salad drawer in our fridge

RS Components Reprap Ormerod No. 481

I think there's just not enough juice coming out the ATX supply so I'm swapping over to a 13.8V 25A PSU next. Anyway, I finally got my print done thanks to everyone's help here..

It's for a repair job on the broken salad drawer in our fridge

RS Components Reprap Ormerod No. 481

Sorry, only registered users may post in this forum.