Can't stop warping on certain prints

Posted by Radian

|

Can't stop warping on certain prints May 02, 2015 09:02AM |

Registered: 10 years ago Posts: 300 |

I know this is a topic that comes up frequently with beginners but I felt that I'd got on top of this sort of problem ages ago. Not so it seems.

I'm trying to print a rectangular enclosure (in PLA, direct on glass) for a PCB that's 110mm x 70mm x 25mm tall.

The first layer goes down nicely and builds up perfectly flat for the first 10 layers or so, sticking well to the bed. This tells me that the curling about to take place isn't because the bed is not level - if, for example, I just wanted to print a 110 x 70 x 2.4mm plate then all would be fine.

But the base thickness for my enclosure is 3mm and as the layers go on above 10 or so, all four corners very slowly start to curl upwards. I don't understand why it only starts doing this so late in the print? The bed temp. is set to 65C initial then 50C for the duration. Does warping set in when the temperatures of the top and bottom diverge too far?

RS Components Reprap Ormerod No. 481

I'm trying to print a rectangular enclosure (in PLA, direct on glass) for a PCB that's 110mm x 70mm x 25mm tall.

The first layer goes down nicely and builds up perfectly flat for the first 10 layers or so, sticking well to the bed. This tells me that the curling about to take place isn't because the bed is not level - if, for example, I just wanted to print a 110 x 70 x 2.4mm plate then all would be fine.

But the base thickness for my enclosure is 3mm and as the layers go on above 10 or so, all four corners very slowly start to curl upwards. I don't understand why it only starts doing this so late in the print? The bed temp. is set to 65C initial then 50C for the duration. Does warping set in when the temperatures of the top and bottom diverge too far?

RS Components Reprap Ormerod No. 481

|

Re: Can't stop warping on certain prints May 02, 2015 09:41AM |

Registered: 10 years ago Posts: 14,672 |

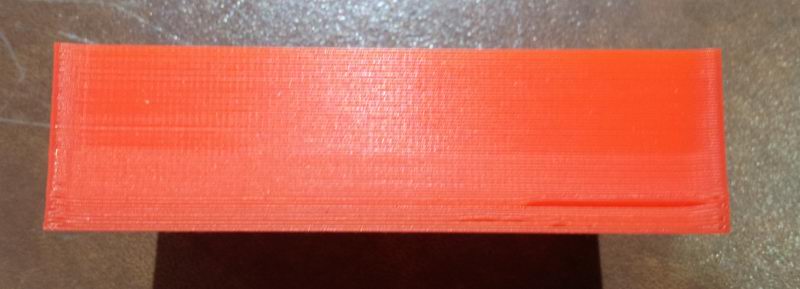

I keep the bed at a constant 65C when printing direct on glass. I occasionally get slight warping at the corners of a print like that, but not as bad as in your photo.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Can't stop warping on certain prints May 02, 2015 10:02AM |

Registered: 10 years ago Posts: 300 |

OK, thanks David, I'll give it a try - but I can't help thinking that the bottom of the printed part is too hot compared to the top - hence a greater thermal expansion factor. I thought the usual setting for a higher bed temperature for the first layer was so the freshly deposited plastic didn't cool too far and contract/come unstuck before the print got going. That was just my assumption at any rate.

RS Components Reprap Ormerod No. 481

RS Components Reprap Ormerod No. 481

|

Re: Can't stop warping on certain prints May 02, 2015 10:14AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Radian

OK, thanks David, I'll give it a try - but I can't help thinking that the bottom of the printed part is too hot compared to the top - hence a greater thermal expansion factor. I thought the usual setting for a higher bed temperature for the first layer was so the freshly deposited plastic didn't cool too far and contract/come unstuck before the print got going. That was just my assumption at any rate.

There may be some truth in that, but the counter argument is that reducing the bed temperature reduces the adhesion between the print and the glass.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Can't stop warping on certain prints May 02, 2015 10:37AM |

Registered: 9 years ago Posts: 1,699 |

|

Re: Can't stop warping on certain prints May 03, 2015 11:30AM |

Registered: 10 years ago Posts: 36 |

|

Re: Can't stop warping on certain prints May 04, 2015 02:35PM |

Registered: 10 years ago Posts: 2,472 |

A hollow box is one of the worst shapes for warping. The walls contract and exert a bending force on the base. At the worst case getting the adhesion to the bed doesn't help - the base sticks to the bed and stays flat, bur the walls split (delaminate) and bend up. Round corners help a lot - the bigger the radius the better.

Dave

Dave

|

Re: Can't stop warping on certain prints May 07, 2015 09:43AM |

Registered: 10 years ago Posts: 300 |

Thanks all for the tips. I tried a few "surface treatments" on the bed but in the end got the best adhesion by wiping the glass with some sugary concentrate (Bottle Green lemongrass & ginger). I'd noticed before when making drinks how sticky the stuff was! I especially like the fact that it's quick and easy to wipe on and off.

RS Components Reprap Ormerod No. 481

RS Components Reprap Ormerod No. 481

|

Re: Can't stop warping on certain prints May 07, 2015 04:12PM |

Registered: 9 years ago Posts: 49 |

|

Re: Can't stop warping on certain prints May 07, 2015 05:43PM |

Registered: 10 years ago Posts: 300 |

|

Re: Can't stop warping on certain prints May 07, 2015 07:22PM |

Registered: 9 years ago Posts: 30 |

|

Re: Can't stop warping on certain prints May 09, 2015 07:59AM |

Registered: 10 years ago Posts: 300 |

Quote

dc42

Quote

Radian

OK, thanks David, I'll give it a try - but I can't help thinking that the bottom of the printed part is too hot compared to the top - hence a greater thermal expansion factor. I thought the usual setting for a higher bed temperature for the first layer was so the freshly deposited plastic didn't cool too far and contract/come unstuck before the print got going. That was just my assumption at any rate.

There may be some truth in that, but the counter argument is that reducing the bed temperature reduces the adhesion between the print and the glass.

I'm not convinced. Sure, after printing parts come off easier only when the bed cools down - but I think that's due too the contraction of the plastic, not that the heat was making the plastic sticky.

The curl upwards still tells me that the lower layers are hotter than the layers above and if I measure the average temperature of the top layer while printing is in progress with the bed unheated I see it's only around 10C above ambient. This is just for one piece I'm trying to print though, I don't know how other shaped parts would compare but I don't think there's much heat transfer going from the nozzle to the object being printed.

So on this basis, I tried seting the bed temperature to just 30C (10C above ambient room temp 20C) in an attempt to maintain the same overall temperature throughout the material.

By doing this I finaly managed to print of a part that I never could print before without it warping... [www.thingiverse.com] ...It came out dead flat first time!

This was direct on glass that had previously had a thin wipe of sticky sugar water - my simple cleaning/adhesion promoting all-in-one solution.

RS Components Reprap Ormerod No. 481

|

Re: Can't stop warping on certain prints May 09, 2015 04:05PM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Can't stop warping on certain prints May 09, 2015 06:45PM |

Registered: 10 years ago Posts: 300 |

I can confirm this - and before needing a full re-coat just a wipe with a damp cloth works for print after print. Any sticky left on the part wipes off soooo easily (or you can just lick it offQuote

dmould

I've read elsewhere that a coat of sugar water makes a great bed preparation - and what's more does not adhere to the print when the print is removed so does not need a re-coat after every print. I will try it out somewhen.

Dave

)

)RS Components Reprap Ormerod No. 481

|

Re: Can't stop warping on certain prints May 10, 2015 11:35AM |

Registered: 10 years ago Posts: 300 |

OK, I don't want to lead anyone astray so I will confess that today I tried printing with a 30C bed and had all kinds of warping. Seems I haven't nailed the true cause and effect yet.

Taking a heat gun to one side of a room-temperature 80mm square by 3mm thick printed plate, contrary to my intuition, the hot side becomes concave such that the edges would be forced down if on a heated surface. I really don't understand the physics governing this. The implication is that either the PLA material or the resulting structure made from it has a negative expansion coefficient. Such things do exist but data I've seen for PLA indicates that it, in common with most materials, has a positive expansion coefficient. I wish someone could explain why the considerable distortion takes place - all discussions appear to focus only on how to remedy the problem without saying why this or that has a beneficial effect.

RS Components Reprap Ormerod No. 481

Taking a heat gun to one side of a room-temperature 80mm square by 3mm thick printed plate, contrary to my intuition, the hot side becomes concave such that the edges would be forced down if on a heated surface. I really don't understand the physics governing this. The implication is that either the PLA material or the resulting structure made from it has a negative expansion coefficient. Such things do exist but data I've seen for PLA indicates that it, in common with most materials, has a positive expansion coefficient. I wish someone could explain why the considerable distortion takes place - all discussions appear to focus only on how to remedy the problem without saying why this or that has a beneficial effect.

RS Components Reprap Ormerod No. 481

|

Re: Can't stop warping on certain prints May 10, 2015 11:43AM |

Registered: 10 years ago Posts: 14,672 |

Have you tried reducing the amount of cooling air flowing over the nozzle from the fan duct? The later Ormerod hot ends do not direct any of the air from the hot end fan over the nozzle.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Can't stop warping on certain prints May 10, 2015 02:53PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Radian

..Taking a heat gun to one side of a room-temperature 80mm square by 3mm thick printed plate, contrary to my intuition, the hot side becomes concave such that the edges would be forced down if on a heated surface. I really don't understand the physics governing this..

Neither do I but keep thinking :-) - until shrink-less filament is invented I see no other cure than to make sure the print sticks to the bed and ad a lot of cooling to the printed part as well as directly to the newly laid down filament

Erik

|

Re: Can't stop warping on certain prints May 10, 2015 05:37PM |

Registered: 10 years ago Posts: 300 |

Quote

dc42

Have you tried reducing the amount of cooling air flowing over the nozzle from the fan duct? The later Ormerod hot ends do not direct any of the air from the hot end fan over the nozzle.

Well that's very interesting - has there been any explanation of why this was done?

Quote

ormerod168

... until shrink-less filament is invented I see no other cure than to make sure the print sticks to the bed and ad a lot of cooling to the printed part as well as directly to the newly laid down filament

Hi Erik, that's a fabulous looking thing - what is it?

Logically speaking, any printed object that's in thermal equilibrium with itself and its surroundings is obviously stable - i.e a part I pick up that was printed a day ago isn't actively curling up at the edges!

So if the extruded filament is rapidly brought down to ambient temperature as printing progresses then the emerging object should remain stable. I guess the problem is that while it would be possible to rapid-cool the extruded filament, it might adversely affect the fusion of the plastic?

It would be interesting to test this theory though... perhaps a cylindrical co-axial duct surrounding the nozzle blowing thermoelectrically chilled air under closed-loop temperature control to cancel the thermal input from the hot-end ?

I'd be more than happy to go to such lengths if it guaranteed consistent results.

RS Components Reprap Ormerod No. 481

|

Re: Can't stop warping on certain prints May 10, 2015 05:51PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Radian

I guess the problem is that while it would be possible to rapid-cool the extruded filament, it might adversely affect the fusion of the plastic?

That's certainly the case when printing ABS, and I would expect to be true to a lesser extent when printing PLA. When I was printing ABS on my Mini Kossel, I had huge problems with warping and delamination. I mostly solved them by putting 2 plastic bags over the printer to create a warmer environment. However, I subsequently discovered that the hot end fan was blowing a gale around the nozzle. As soon as I sorted that out, I found I could print some of the same ABS parts without the plastic bags over the printer - and I got much better bonding between layers.

Edited 1 time(s). Last edit at 05/10/2015 05:52PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Can't stop warping on certain prints May 11, 2015 07:54AM |

Registered: 10 years ago Posts: 2,472 |

Not quite true. While it may not be moving, it may well have internal stresses that are pulling on the layers and making the part weaker. I suppose ideally all printed parts should be put into a very well regulated oven and left at the glass transition temperature until heated all the way through to relieve any internal stress, and then the oven should cool down very slowly so it cools down without creating any temperature differentials between the inside and outside of the part..Quote

Radian

Logically speaking, any printed object that's in thermal equilibrium with itself and its surroundings is obviously stable - i.e a part I pick up that was printed a day ago isn't actively curling up at the edges!

The only way that the layers are going to fuse together is if the extruded plastic is molten when it touches the previous layer. You then have a thin thread of very hot plastic that is fused with much cooler plastic, and so when that top thread cools it is going to try to pull up the ends of the cooler layer. My thinking is that if it cools down slowly the thermal shrinking will take place while the plastic is still pliable enough to stretch, so the shrinking is compensated for by the stretching. This is why cooling air increases warping - but decreases curl-up on overhangs by stopping the lower layers becoming molten, and also reduces sag on bridges. This is why a controllable nozzle fan is useful - you need to cool the layer slowly in most cases, but there are times when it needs to be cooled faster. The hotter the lower layer, the less the temperature difference and hence less differential shrinkage (warping), which is why printing in a hot cabinet reduces warping. Again though, large parts should be allowed to cool down inside the enclosure so they cool slowly, otherwise there will be created a large temperature difference between the inside and outside of the print which could potentially cause internal delamination that is not easily detectable.Quote

Radian

So if the extruded filament is rapidly brought down to ambient temperature as printing progresses then the emerging object should remain stable. I guess the problem is that while it would be possible to rapid-cool the extruded filament, it might adversely affect the fusion of the plastic?

Dave

|

Re: Can't stop warping on certain prints May 11, 2015 08:18AM |

Registered: 10 years ago Posts: 300 |

That all seems to make perfect sense Dave. I hadn't been considering the curl-up that happens on overhangs. But going back to warping on the base, while the first few layers start off well-stuck, I find it often only begins to lift (at any sharp corners) when the nozzle is several mm further up. This made me think that by then the body of the part had cooled to a lower temperature than the base. Are you suggesting that the contraction is always "top down"?

RS Components Reprap Ormerod No. 481

RS Components Reprap Ormerod No. 481

|

Re: Can't stop warping on certain prints May 11, 2015 08:55AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Radian

That all seems to make perfect sense Dave. I hadn't been considering the curl-up that happens on overhangs. But going back to warping on the base, while the first few layers start off well-stuck, I find it often only begins to lift (at any sharp corners) when the nozzle is several mm further up. This made me think that by then the body of the part had cooled to a lower temperature than the base. Are you suggesting that the contraction is always "top down"?

The exact mechanism is something that I have to guess at, but I think what is happening is that each layer creates a small force on the previous layer as the molten plastic cools, and these forces all add together as the height increases, so the base layer is getting the total force from all layers. On many of my earlier prints I thought that the solution was to increase the adhesion to the bed - until I found that the prints would still warp when they got high enough by ripping apart at a layer.

I find it easiest to accommodate for shrinkage in the design - if you think about the ways used to take up expansion in long runs of central heating pipes, then similar techniques can be used by creating "expansion joints" in straight wall sections. Using round corners is one such method for short walls, the corner acting as a quarter-turn spring to take up the thermal contraction. Better is to make the entire wall curved, e.g. make the box semi-oval instead of rectangular, or give it a "waist" of concave sides. The curve does not have to be all that much to make a big improvement in warping. Often it will improve the appearance as well. You can break up a long straight wall by putting open slots, a few U-shaped indents or making the entire wall corrugated, which will appear to be mere decoration but is in reality creating thermal expansion (contraction) nodes. Obviously the method depends very much on the design.

Dave

Edited 1 time(s). Last edit at 05/11/2015 08:57AM by dmould.

|

Re: Can't stop warping on certain prints May 11, 2015 09:09AM |

Registered: 9 years ago Posts: 177 |

I think lifting at corners at the base is from a somewhat different mechanic. I think it's the result of shrinkage in the 'in line' direction of perimeters

As each of the perimeters shrink, there's some tension that develops. On shallow corners or rounded corners this never accumulates to enough force to overcome the adhesion to the bed, in fact rounded corners will cancel out some of the forces in question. But when you get into sharper corners (<= 90 Degrees) both sides of each corner are pulling away from the corner. The sharper the angle, the higher the resulting combined force acting on the corner. This is why printing a triangle with an angle of 10 or 20 degrees is almost impossible to do without the corners lifting up. Also, the part is typically quite thin when this happens and it therefore still quite flexible, so the corners lift up.

There are basically two ways to fix corner lifting.

The first is to lower the force acting on the corners. This means to optimise the print by not have sharp corners, and to have them rounded whenever possible. However, this isn't always possible depending on what you're printing.

The second is to increase the bed adhesion force which can be done in a number of ways. You could change the print surface (i.e. ABS slurry, PVAC, Buildtak, etc...), or try adding a brim to the print. Having the first layer width higher, and printed slower can also help.

Something that fits into both categories would be changing the filament. A different filament might contract less lowering the forces (and help with overhang curling), and/or increase the amount of bed adhesion.

I've heard of a brand of filament called 'EasyFil' which claims to have significantly reduced the shrinkage. However, I haven't tried it myself, and I think I remember reading somewhere that it's made the plastic somewhat 'softer' and more flexible. I've also read in reviews that it's increased oozing.

As each of the perimeters shrink, there's some tension that develops. On shallow corners or rounded corners this never accumulates to enough force to overcome the adhesion to the bed, in fact rounded corners will cancel out some of the forces in question. But when you get into sharper corners (<= 90 Degrees) both sides of each corner are pulling away from the corner. The sharper the angle, the higher the resulting combined force acting on the corner. This is why printing a triangle with an angle of 10 or 20 degrees is almost impossible to do without the corners lifting up. Also, the part is typically quite thin when this happens and it therefore still quite flexible, so the corners lift up.

There are basically two ways to fix corner lifting.

The first is to lower the force acting on the corners. This means to optimise the print by not have sharp corners, and to have them rounded whenever possible. However, this isn't always possible depending on what you're printing.

The second is to increase the bed adhesion force which can be done in a number of ways. You could change the print surface (i.e. ABS slurry, PVAC, Buildtak, etc...), or try adding a brim to the print. Having the first layer width higher, and printed slower can also help.

Something that fits into both categories would be changing the filament. A different filament might contract less lowering the forces (and help with overhang curling), and/or increase the amount of bed adhesion.

I've heard of a brand of filament called 'EasyFil' which claims to have significantly reduced the shrinkage. However, I haven't tried it myself, and I think I remember reading somewhere that it's made the plastic somewhat 'softer' and more flexible. I've also read in reviews that it's increased oozing.

|

Re: Can't stop warping on certain prints May 11, 2015 09:18AM |

Registered: 10 years ago Posts: 300 |

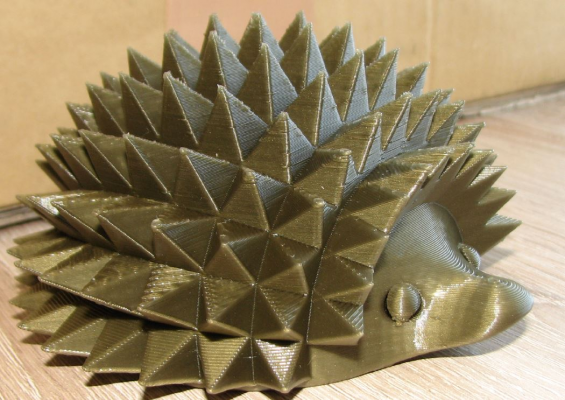

I hadn't realised that the layers would pull apart if the base remained stuck on the bed but that explains the mystery delamnation I had with this part:

So in this case which direction would corrugations go to relieve the stress? From what you say I'm guessing vertical (90deg from the bed plane)

RS Components Reprap Ormerod No. 481

So in this case which direction would corrugations go to relieve the stress? From what you say I'm guessing vertical (90deg from the bed plane)

RS Components Reprap Ormerod No. 481

|

Re: Can't stop warping on certain prints May 11, 2015 09:27AM |

Registered: 10 years ago Posts: 300 |

|

Re: Can't stop warping on certain prints May 11, 2015 10:27AM |

Registered: 10 years ago Posts: 2,472 |

Yes, that's correct - IOW they would create vertical lines.Quote

Radian

So in this case which direction would corrugations go to relieve the stress? From what you say I'm guessing vertical (90deg from the bed plane)

Quote

Radian

I wish OpenSCAD had a simple "rounding" or "Fillet" parameter for cube edges. That would help with my cubist tendencies!

The big advantage with Openscad is that if it hasn't got a particular function, you can simply create one by writing a module. I have two "rounded cube" and a "fillet" module that I just paste into a new design. They are all pretty simple.

Use the cubes as you would normally, with the added radius parameter. e.g.

$fn=100;

RoundedCube(15,20,25,5);

The fillet can be used additively (to fill inside corners) or subtractively (to round off outside corners). e.g.

$fn=100;

Wall=3;

Rad=3;

difference()

{

union()

{

cube([30,Wall,10]); // This makes a simple 2-wall corner

cube([Wall,30,10]); // ...

translate([Wall,Wall,0]) // Fillet the inside of the corner

Fillet(Rad,10); // ...

}

translate([0,0,-0.1]) // Fillet the outside of the corner

Fillet(Rad+Wall,10+0.2); // ...

}

Use the rotate function to fillet the other 3 corner orientations.

These are the modules

module Fillet(Rad,Height)

{

difference()

{

translate([-.1,-.1,0])

cube([Rad+.1,Rad+.1,Height]);

translate([Rad,Rad,-.1])

cylinder(r=Rad,h=Height+.2,$fn=50);

}

}

module RoundCube(X,Y,Z,Rad)

{

hull()

{

translate([Rad,Rad,0])

cylinder(r=Rad,h=Z);

translate([X-Rad,Rad,0])

cylinder(r=Rad,h=Z);

translate([X-Rad,Y-Rad,0])

cylinder(r=Rad,h=Z);

translate([Rad,Y-Rad,0])

cylinder(r=Rad,h=Z);

}

}

module RoundedCube(X,Y,Z,Rad)

{

hull()

{

translate([Rad,Rad,Rad])

sphere(r=Rad);

translate([X-Rad,Rad,Rad])

sphere(r=Rad);

translate([X-Rad,Y-Rad,Rad])

sphere(r=Rad);

translate([Rad,Y-Rad,Rad])

sphere(r=Rad);

translate([Rad,Rad,Z-Rad])

sphere(r=Rad);

translate([X-Rad,Rad,Z-Rad])

sphere(r=Rad);

translate([X-Rad,Y-Rad,Z-Rad])

sphere(r=Rad);

translate([Rad,Y-Rad,Z-Rad])

sphere(r=Rad);

}

}

Dave

|

Re: Can't stop warping on certain prints May 11, 2015 01:40PM |

Registered: 10 years ago Posts: 1,230 |

Quote

shadow651

I think lifting at corners at the base is from a somewhat different mechanic. I think it's the result of shrinkage in the 'in line' direction of perimeters

As each of the perimeters shrink, there's some tension that develops. On shallow corners or rounded corners this never accumulates to enough force to overcome the adhesion to the bed, in fact rounded corners will cancel out some of the forces in question. But when you get into sharper corners (<= 90 Degrees) both sides of each corner are pulling away from the corner. The sharper the angle, the higher the resulting combined force acting on the corner.....

I agree with the cure (round corners print better) but I'm not convinced about the cause - in line forces even out in round corners bit - yes if we e.g. see the perimeters as free floating rubber bands on top of each other around a cardboard box, surely adding more and more rubber band up the sides will ad greater and greater pulling force to the walls and lift the corners as much as the sides will compress (as long as the stay flat, not collapse)

If the corners of same cardboard box was rounded a bit the sides would already be in the direction of cylinder mode (did not sound right, hope you get my drift), and fail with less force, the lift should be worse

I cannot picture how the force of perimeters fused together would be canceled out in the corners, I would think its more about greater heat accumulation in sharp corners than rounded, would be interesting to see a time shift thermo graph picture of a print

Erik

|

Re: Can't stop warping on certain prints May 11, 2015 02:14PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Radian

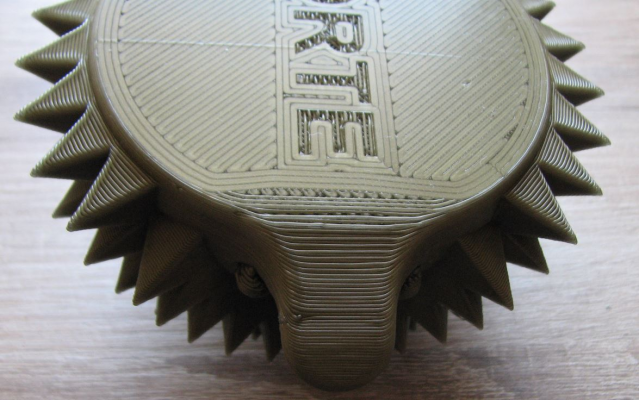

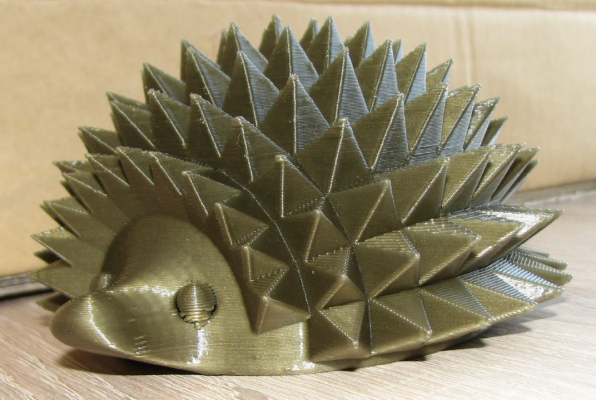

Hi Erik, that's a fabulous looking thing - what is it?

Hedgehog Forte from thingiverse, great overhang/cooling/retraction test piece, notice how close the overhangs is to the heatbed, you got to start the cooling as soon as the print get a grip, but amazingly it prints very well, only have tried with PLA

- layerHeight,0.25

extruderWidth,0.75

topSolidLayers,4

bottomSolidLayers,3

perimeterOutlines,3

printPerimetersInsideOut,1

infillPercentage,20

outlineOverlapPercentage,15

infillExtrusionWidthPercentage,150

generateSupport,0

temperatureSetpointTemperatures,185,57

defaultSpeed,2400

outlineUnderspeed,0.5

rapidXYspeed,9000

retraction distance,5.0

[www.thingiverse.com]

Quote

.. perhaps a cylindrical co-axial duct surrounding the nozzle blowing thermoelectrically chilled air under closed-loop temperature control to cancel the thermal input from the hot-end ?

Yes I have been thinking about that but there is too little space available under the original ormerod hotend, even a higher pressure (aquarium pump) one so I'm thinking about changing that part and mount something like this:

Erik

|

Re: Can't stop warping on certain prints May 11, 2015 02:40PM |

Registered: 9 years ago Posts: 177 |

Quote

ormerod168

Quote

shadow651

I think lifting at corners at the base is from a somewhat different mechanic. I think it's the result of shrinkage in the 'in line' direction of perimeters

As each of the perimeters shrink, there's some tension that develops. On shallow corners or rounded corners this never accumulates to enough force to overcome the adhesion to the bed, in fact rounded corners will cancel out some of the forces in question. But when you get into sharper corners (<= 90 Degrees) both sides of each corner are pulling away from the corner. The sharper the angle, the higher the resulting combined force acting on the corner.....

I agree with the cure (round corners print better) but I'm not convinced about the cause - in line forces even out in round corners bit - yes if we e.g. see the perimeters as free floating rubber bands on top of each other around a cardboard box, surely adding more and more rubber band up the sides will ad greater and greater pulling force to the walls and lift the corners as much as the sides will compress (as long as the stay flat, not collapse)

If the corners of same cardboard box was rounded a bit the sides would already be in the direction of cylinder mode (did not sound right, hope you get my drift), and fail with less force, the lift should be worse

I cannot picture how the force of perimeters fused together would be canceled out in the corners, I would think its more about greater heat accumulation in sharp corners than rounded, would be interesting to see a time shift thermo graph picture of a print

Erik

Well, I guess I've been thinking about this as a force vector problem.... with a 90 degree corner and assuming the two sides forces are the same, you'll get a resultant force 45 degrees pointing inwards, with a magnitude equivalent to that of one of the sides. As you make the corner tighter, the magnitude of the vector increases, and of course if you make it smaller it decreases. If it pops off the bed, the only way it can move is up, the bed prevents bending down, and the infill prevents it from crumpling in (unless it's a thin wall test or something), and the layers aren't yet thick enough to be fully rigid.

Of course in a finished print, you have all of the stuff above it to hold it in place.

Well, with the rounded corners, they kind of act like an arch (except sorta in reverse). As it takes the resultant force vector from both sides, it starts to undergo tension. Of course it will resist this (plus the plastic in the corners has also shrunk some as well) and the result is that the corners cause force vectors that cancel out some of the forces from the sides. Also I would think some (or maybe most) of the forces get dissipated against the infill as well, because the rounded corners have much more area in contact with the infill vs a sharp corner.

I could try and draw some diagrams or something.... but I think we might be going down the rabbit hole here

Admittedly it's all my guess as to what's going on, but I think it explains why the sharper a corner gets, the harder it is to keep adhered to the bed.

Quote

ormerod168

Quote

Radian

Hi Erik, that's a fabulous looking thing - what is it?

Hedgehog Forte from thingiverse, great overhang/cooling/retraction test piece, notice how close the overhangs is to the heatbed, you got to start the cooling as soon as the print get a grip, but amazingly it prints very well, only have tried with PLA

Quote

.. perhaps a cylindrical co-axial duct surrounding the nozzle blowing thermoelectrically chilled air under closed-loop temperature control to cancel the thermal input from the hot-end ?

Yes I have been thinking about that but there is too little space available under the original ormerod hotend, even a higher pressure (aquarium pump) one so I'm thinking about changing that part and mount something like this:

Erik

That's a nice test piece there, I might have to give it a try when I get AUX cooling set up. Still trying to figure out the best way to deal with the PWM signal....

I've been thinking about something like that cooling ring, would give nice even cooling. But I hadn't really checked clearance..... I wonder if the O2 has more room for such a duct.

And what is this high pressure aquarium pump thing you speak of? Is this some sort of water cooled hot end mod?

|

Re: Can't stop warping on certain prints May 11, 2015 04:30PM |

Registered: 10 years ago Posts: 300 |

Thanks for sharing Dave. It's a new way of modelling for me but I'm getting to like it the more I use it.Quote

dmould

The big advantage with Openscad is that if it hasn't got a particular function, you can simply create one by writing a module. I have two "rounded cube" and a "fillet" module that I just paste into a new design. They are all pretty simple.

RS Components Reprap Ormerod No. 481

Sorry, only registered users may post in this forum.