Can't stop warping on certain prints

Posted by Radian

|

Re: Can't stop warping on certain prints May 11, 2015 04:35PM |

Registered: 10 years ago Posts: 300 |

That's it! Yes, there's insufficient space for the usual ducting so a high pressure supply would be the way to go.Quote

ormerod168

Quote

.. perhaps a cylindrical co-axial duct surrounding the nozzle blowing thermoelectrically chilled air under closed-loop temperature control to cancel the thermal input from the hot-end ?

Yes I have been thinking about that but there is too little space available under the original ormerod hotend, even a higher pressure (aquarium pump) one so I'm thinking about changing that part and mount something like this:

[attachment 54494 nozzle_cooling_ring.JPG]

Erik

RS Components Reprap Ormerod No. 481

|

Re: Can't stop warping on certain prints May 11, 2015 04:39PM |

Registered: 10 years ago Posts: 300 |

|

Re: Can't stop warping on certain prints May 11, 2015 10:31PM |

Registered: 9 years ago Posts: 177 |

well, most 2 wire DC fans aren't set up to handle PWM because 4 wire fans are the default for accepting PWM variable speed in the PC world. So you have to rig up a (relatively simple) circuit to either make a 4 wire fan work with the 2 wire PWM or get a 2 wire fan working with something like a low pass filter (turning the PWM into a variable voltage signal).

Or if you're lucky you might find a 2 wire fan that is ok with PWM.

There's a thread floating around here somewhere about it. Honestly not sure why the Duet isn't wired for a 4 wire aux fan.......

Or if you're lucky you might find a 2 wire fan that is ok with PWM.

There's a thread floating around here somewhere about it. Honestly not sure why the Duet isn't wired for a 4 wire aux fan.......

|

Re: Can't stop warping on certain prints May 12, 2015 02:56PM |

Registered: 9 years ago Posts: 638 |

The Thread is here:[forums.reprap.org]

I used the 2N7000 mosfet as DC42 suggested and orictosh discribed how to wire it few posts down ,it works great but i will have to put a switch next to it so i can switch it off becouse it never stops blowing(PWM fans go down to 30% when there is no signal acroding to dc42) so i can print abs with no problems

I also bought the fan mentioned in the post and damn its powerfull ,i have it set to 25% max in slicer otherwise it blows like crazy xD

Edited 2 time(s). Last edit at 05/12/2015 03:24PM by Darathy.

I used the 2N7000 mosfet as DC42 suggested and orictosh discribed how to wire it few posts down ,it works great but i will have to put a switch next to it so i can switch it off becouse it never stops blowing(PWM fans go down to 30% when there is no signal acroding to dc42) so i can print abs with no problems

I also bought the fan mentioned in the post and damn its powerfull ,i have it set to 25% max in slicer otherwise it blows like crazy xD

Edited 2 time(s). Last edit at 05/12/2015 03:24PM by Darathy.

|

Re: Can't stop warping on certain prints May 12, 2015 03:17PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Darathy

I used the 2N7000 mosfet as DC42 suggested and orictosh discribed how to wire it few posts down ,it works great but i will have to put a switch next to it so i can switch it off becouse it never stops blowing(PWM fans go down to 30% when there is no signal acroding to dc42) so i can print abs with no problems

Yes, this is a problem. If there is enough interest, I guess I could do an adapter board that generates the PWM signal and also turns the fan off completely when the PWM goes below e.g. 20%.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Can't stop warping on certain prints May 12, 2015 03:19PM |

Registered: 10 years ago Posts: 1,230 |

Quote

shadow651

...Or if you're lucky you might find a 2 wire fan that is ok with PWM...

I use this one, runs just fine on PWM directly

NMB TECHNOLOGIES BM4515-04W-B30-L00 FAN, BLOWER, 45X44X15MM, 12VDC

[uk.farnell.com]

Erik

|

Re: Can't stop warping on certain prints May 12, 2015 03:40PM |

Registered: 10 years ago Posts: 14,672 |

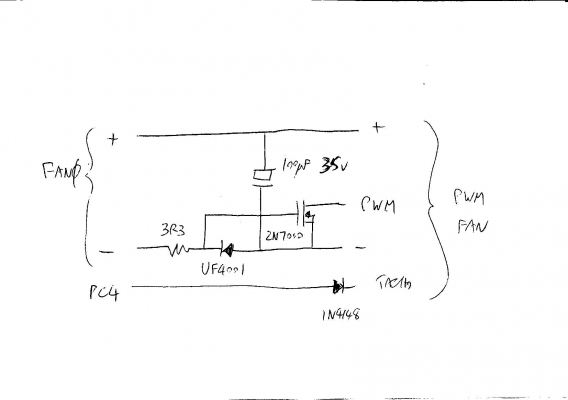

I've given this some more thought, and I think this (as yet untested) circuit should do the job of shutting the fan off when the PWM is set to zero:

I'm assuming the fan PWM frequency is set to 25kHz (the recommended frequency according to the Intel PWM fan specification), which my firmware fork does and I think zpl's does too - I haven't checked RepRapPro 1.09.

Note that the diode needs to be a fast recovery one to cope with the 25kHz switching frequency, hence UF4001 and not 1N4001.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I'm assuming the fan PWM frequency is set to 25kHz (the recommended frequency according to the Intel PWM fan specification), which my firmware fork does and I think zpl's does too - I haven't checked RepRapPro 1.09.

Note that the diode needs to be a fast recovery one to cope with the 25kHz switching frequency, hence UF4001 and not 1N4001.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Can't stop warping on certain prints May 12, 2015 03:41PM |

Registered: 10 years ago Posts: 1,230 |

Quote

shadow651

..And what is this high pressure aquarium pump thing you speak of? Is this some sort of water cooled hot end mod?

Should have said aquarium air pump, something like this:

[www.ebay.de]

These pump is supposed to be low noise, long lasting and energy efficient, another upside is that feeding a cooling ring through soft tubes will not add much weight to the hotend

Erik

|

Re: Can't stop warping on certain prints May 12, 2015 05:23PM |

Registered: 9 years ago Posts: 177 |

Quote

dc42

I've given this some more thought, and I think this (as yet untested) circuit should do the job of shutting the fan off when the PWM is set to zero:

[attachment 54569 Scan244.JPG]

I'm assuming the fan PWM frequency is set to 25kHz (the recommended frequency according to the Intel PWM fan specification), which my firmware fork does and I think zpl's does too - I haven't checked RepRapPro 1.09.

Note that the diode needs to be a fast recovery one to cope with the 25kHz switching frequency, hence UF4001 and not 1N4001.

Is that bottom wire hooking up to the tachometer wire? Would the firmware then know how fast the fan is actually going? and what would the benefit of that be?

I have to admit I'd probably be interested in some sort of simple PCB that would just plug into the duet and have a PC 4 wire PWM plug in port on it.

I might just have a go at having one made for myself though (was thinking about doing it before you mentioned that you might do one), It'd be easy enough to have everything be PTH (I think) and small enough to be made $5-$10 USD/3 boards though oshpark or 123dCircuits (although I'm a bit dubious about PCB's through autodesk though).

I had a lot of trouble with customs/UPS etc... getting my duet replacement.

I suppose it depends how much your hypothetical board cost, and how lazy I'm feeling; and if any surface mount stuff was involved

|

Re: Can't stop warping on certain prints May 12, 2015 05:48PM |

Registered: 10 years ago Posts: 14,672 |

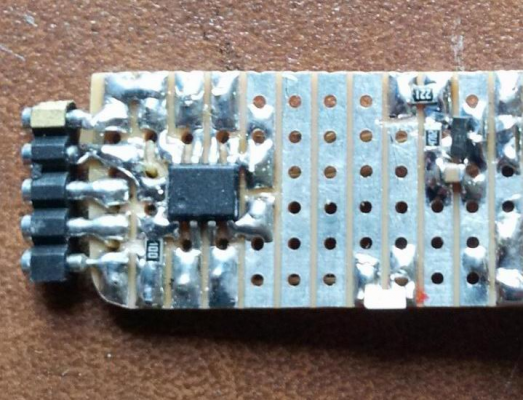

I always use SMD components if I am making a PCB, however for a one-off, you could use through-hole components and assemble it on stripboard.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Can't stop warping on certain prints May 12, 2015 06:09PM |

Registered: 10 years ago Posts: 300 |

Quote

dc42

I always use SMD components if I am making a PCB, however for a one-off, you could use through-hole components and assemble it on stripboard.

Or solder SM parts to the underside of stripboard ;-)

0805 parts fit nicely between tracks, SOT23 parts straddle two tracks if you cut through the track between the two legs on the same track, SO8 chips with 0.05" pitch sit nicely on split tracks - a nice sharp XACTO knife and some 3.5 reading glasses make it easier.

RS Components Reprap Ormerod No. 481

|

Re: Can't stop warping on certain prints May 18, 2015 09:35AM |

Registered: 9 years ago Posts: 177 |

Well, for the moment looks like I might have found a 2 wire fan that is ok with PWM.

[www.amazon.com]

But I might try prototyping the 4 wire circuit at some point in the future just because.

Thanks for the tips on strip boards.

Just wondering, does anyone have a ballpark number for how many CFM (Cubic feet per minute) we'd want in an ideal cooling fan? And what is the CFM for the hot end fan?

I think the one I have is ~8.5, which I'm hoping is enough. I know the 4 wire fans have some high power ones that are like 18CFM, but I think that's overkill.

on another note:

I'm still a bit confused as to why the proposed 4-wire circuit connects the tach wire to the Duets PC4 pin. I thought that the tach wire was an output of the fans speed, and as far as I can tell PC4 is a low PWM output from the processor.

Maybe I'm miss reading that as tach, or I'm misunderstanding how the tach wire works.

Edited 1 time(s). Last edit at 05/18/2015 09:37AM by shadow651.

[www.amazon.com]

But I might try prototyping the 4 wire circuit at some point in the future just because.

Thanks for the tips on strip boards.

Just wondering, does anyone have a ballpark number for how many CFM (Cubic feet per minute) we'd want in an ideal cooling fan? And what is the CFM for the hot end fan?

I think the one I have is ~8.5, which I'm hoping is enough. I know the 4 wire fans have some high power ones that are like 18CFM, but I think that's overkill.

on another note:

I'm still a bit confused as to why the proposed 4-wire circuit connects the tach wire to the Duets PC4 pin. I thought that the tach wire was an output of the fans speed, and as far as I can tell PC4 is a low PWM output from the processor.

Maybe I'm miss reading that as tach, or I'm misunderstanding how the tach wire works.

Edited 1 time(s). Last edit at 05/18/2015 09:37AM by shadow651.

|

Re: Can't stop warping on certain prints May 18, 2015 10:53AM |

Registered: 10 years ago Posts: 665 |

Quote

shadow651

on another note:

I'm still a bit confused as to why the proposed 4-wire circuit connects the tach wire to the Duets PC4 pin. I thought that the tach wire was an output of the fans speed, and as far as I can tell PC4 is a low PWM output from the processor.

Maybe I'm miss reading that as tach, or I'm misunderstanding how the tach wire works.

No, it's a digital input on the Duet and may be used for 4-pin PWM fans, such as this one: [webshop.schneider-consulting.it]

I installed one of these on my Ormerod 1 a few months ago and it's been working great, but I think RRP are planning a different solution for the Ormerod 2.

|

Re: Can't stop warping on certain prints May 18, 2015 01:14PM |

Registered: 9 years ago Posts: 177 |

Quote

zombiepantslol

Quote

shadow651

on another note:

I'm still a bit confused as to why the proposed 4-wire circuit connects the tach wire to the Duets PC4 pin. I thought that the tach wire was an output of the fans speed, and as far as I can tell PC4 is a low PWM output from the processor.

Maybe I'm miss reading that as tach, or I'm misunderstanding how the tach wire works.

No, it's a digital input on the Duet and may be used for 4-pin PWM fans, such as this one: [webshop.schneider-consulting.it]

I installed one of these on my Ormerod 1 a few months ago and it's been working great, but I think RRP are planning a different solution for the Ormerod 2.

Ok, so looking at the diode the fan must trigger an internal ground connection for the tach signal... I see.

I also see that the fan you got is much more powerful (~25CFM) than the one I got, would you say this fan is ok, or too strong?

I'm not at all sure how RRP intends to solve the cooling fan issue..... The newest version has the acrylic spacer, with a mount for some sort of vent/fan. But I've gotten tired of waiting for their cooling solution and I'm just going to use this comunity made vent for starters [forums.reprap.org] But I think a 'donut' style vent is the best way to go, otherwise cooling is uneven, but not sure how much of a problem that is... but uneven cooling is better than no cooling, at least sometimes.

I may switch to RRP cooling solution when it comes out, but we'll see.

The biggest issue with the acrylic spacer is it's incompatible with DC42's hot end board. But I haven't had too much trouble with the RRP modulated IR probe yet.

|

Re: Can't stop warping on certain prints May 18, 2015 02:06PM |

Registered: 10 years ago Posts: 2,472 |

The 4 wire fans have 2 wires for power (12V), 1 wire is a digital input to the fan that sets the fan speed, and 1 wire is a digital output from the fan to report the fan's actual RPM. That latter signal is not required to control the fan's speed. Just connect the fan's power leads directly to + and - 12V, connect its digital input to the Duet's fan PWM output via a diode (cathode to Duet) and leave the 4th fan wire disconnected. Unless you particularly want to know what the fan's actual RPM is (if it is implemented in firmware), I don't see any point in connecting the 4th wire.

Dave

Dave

|

Re: Can't stop warping on certain prints May 18, 2015 02:07PM |

Registered: 9 years ago Posts: 638 |

i have (23.7 CFM) (http://www.ebay.co.uk/itm/181308769874?_trksid=p2059210.m2749.l2649&ssPageName=STRK:MEBIDX:IT) and i must say its way overkill ,i have it set to 20% for normal and 30% for bridging ,at 100% it would probably blow my print right off the bed!!!...i will have to look into getting a less powerfullone or a better fan duct xD

|

Re: Can't stop warping on certain prints May 18, 2015 02:21PM |

Registered: 10 years ago Posts: 665 |

Quote

dmould

Unless you particularly want to know what the fan's actual RPM is (if it is implemented in firmware), I don't see any point in connecting the 4th wire.

It is implemented in the firmware and I find it quite nice to see the actual fan RPM on the web interface, you just need to enable the fan controls to unhide the appropriate sensor field. My fan goes from 4.000RPM to ~16.000RPM which is absolutely sufficient, in fact I never set it to 100% either. My maximum cooling values in S3D are 57% for short layer times and 65% for bridges, but overall I'm quite satisfied with this solution. It's not nearly as loud as the original Ormerod 1 fan used to be, unless I set it to 100% of course.

|

Re: Can't stop warping on certain prints May 18, 2015 02:24PM |

Registered: 9 years ago Posts: 638 |

this fan i have gets louder at 20% then the hot end fan ,but i guess its a lot more powerful then the hotend fan. ,where would the signal wire go on the duet?Quote

zombiepantslol

Quote

dmould

Unless you particularly want to know what the fan's actual RPM is (if it is implemented in firmware), I don't see any point in connecting the 4th wire.

It is implemented in the firmware and I find it quite nice to see the actual fan RPM on the web interface, you just need to enable the fan controls to unhide the appropriate sensor field. My fan goes from 4.000RPM to ~16.000RPM which is absolutely sufficient, in fact I never set it to 100% either. My maximum cooling values in S3D are 57% for short layer times and 65% for bridges, but overall I'm quite satisfied with this solution. It's not nearly as loud as the original Ormerod 1 fan used to be, unless I set it to 100% of course.

Edited 1 time(s). Last edit at 05/18/2015 02:26PM by Darathy.

|

Re: Can't stop warping on certain prints May 18, 2015 02:28PM |

Registered: 9 years ago Posts: 638 |

Quote

shadow651

Quote

zombiepantslol

Quote

shadow651

on another note:

I'm still a bit confused as to why the proposed 4-wire circuit connects the tach wire to the Duets PC4 pin. I thought that the tach wire was an output of the fans speed, and as far as I can tell PC4 is a low PWM output from the processor.

Maybe I'm miss reading that as tach, or I'm misunderstanding how the tach wire works.

No, it's a digital input on the Duet and may be used for 4-pin PWM fans, such as this one: [webshop.schneider-consulting.it]

I installed one of these on my Ormerod 1 a few months ago and it's been working great, but I think RRP are planning a different solution for the Ormerod 2.

Ok, so looking at the diode the fan must trigger an internal ground connection for the tach signal... I see.

I also see that the fan you got is much more powerful (~25CFM) than the one I got, would you say this fan is ok, or too strong?

I'm not at all sure how RRP intends to solve the cooling fan issue..... The newest version has the acrylic spacer, with a mount for some sort of vent/fan. But I've gotten tired of waiting for their cooling solution and I'm just going to use this comunity made vent for starters [forums.reprap.org] But I think a 'donut' style vent is the best way to go, otherwise cooling is uneven, but not sure how much of a problem that is... but uneven cooling is better than no cooling, at least sometimes.

I may switch to RRP cooling solution when it comes out, but we'll see.

The biggest issue with the acrylic spacer is it's incompatible with DC42's hot end board. But I haven't had too much trouble with the RRP modulated IR probe yet.

The fan duct is actualy RepRapPros fan duct ,i noticed it other day when i was looking at solidworks assembly of the hot end ,that fan duct is in there. Also found solidworks file for it in Ormerod Master files i got with the printer,.

I can Testify that the fan duct is good ,but does not cool on all areas well only in direction its facing and thats that side of the print. other side still suffers a bit but less then withought it.

Edited 3 time(s). Last edit at 05/18/2015 02:32PM by Darathy.

|

Re: Can't stop warping on certain prints May 18, 2015 03:49PM |

Registered: 10 years ago Posts: 1,230 |

not community but a reprappro prototype

Quote

But I think a 'donut' style vent is the best way to go, otherwise cooling is uneven...

I agree, a donut style cooling ring with the right diameter to permit the perimeter to hot glue to the print

about how much air is needed, the easiest way to get an idea of the numbers would be to adjust the output from a air hose so the air stream feels just right, then use a plastic bag of known volume and tape it around the air nozzle, fill the bag with air while taking note of the time - did that, wrote it down, lost the note :-)

Erik

|

Re: Can't stop warping on certain prints May 18, 2015 05:15PM |

Registered: 9 years ago Posts: 177 |

Quote

dmould

The 4 wire fans have 2 wires for power (12V), 1 wire is a digital input to the fan that sets the fan speed, and 1 wire is a digital output from the fan to report the fan's actual RPM. That latter signal is not required to control the fan's speed. Just connect the fan's power leads directly to + and - 12V, connect its digital input to the Duet's fan PWM output via a diode (cathode to Duet) and leave the 4th fan wire disconnected. Unless you particularly want to know what the fan's actual RPM is (if it is implemented in firmware), I don't see any point in connecting the 4th wire.

Dave

Well, knowing the RPM could be useful, and it's just an extra wire to the expansion header. I guess it depends if you want to know it or not.

I know there was some debate on the other thread about feeding a 12V PWM into the sense (PWM) wire of the fan. The standard lists a 5.25V max, so not all fans will necessarily take that voltage on that wire, unless the manufacturer decides to engineer in excess of the standard. Of course with a 12V fan they might just make this 12V too, but you don't know till you try and possibly break the fan. So there was the drawing orictosh had about using a 2N7000 Mosfet, which fixed that issue.

But, the standard doesn't require that fans turn off when the PWM duty is 0%, the manufacturer can choose to keep the fan at 30% if the PWM duty is <30% (Type A) Or stay at 30% when PWM is 5% - 29% and then off at 0% (Type B ) or they can support speeds lower then 30% and then turn off (Type C). Sadly these are only suggestions about how to handle low PWM values, the only requirement is that the fan speed not go over 30% when PWM is lower then 30%. [www.formfactors.org] (This is all covered in section 3.4).

And it seems that most manufactures just go for Type A, probably because it's cheaper.

That's where DC42's proposed circuit comes in.

I also stand corrected on the Duct being a RRP prototype. The thread I found it on was kinda vague about where it came from, so I assumed it wasn't made by RRP.

At some point I might have a go at designing a donut style duct that connects to the acrylic spacer, anyone have an Idea about what diameter hole would be best?

Edited 3 time(s). Last edit at 05/18/2015 05:23PM by shadow651.

|

Re: Can't stop warping on certain prints May 19, 2015 12:11PM |

Registered: 10 years ago Posts: 2,472 |

Quote

shadow651

I know there was some debate on the other thread about feeding a 12V PWM into the sense (PWM) wire of the fan. The standard lists a 5.25V max, so not all fans will necessarily take that voltage on that wire, unless the manufacturer decides to engineer in excess of the standard. Of course with a 12V fan they might just make this 12V too, but you don't know till you try and possibly break the fan. So there was the drawing orictosh had about using a 2N7000 Mosfet, which fixed that issue.

I can see that an "off" control for low PWM is desirable, but a diode is sufficient to feed the fan's input (and easier to wire in) - no need for a mosfet. The only reason for using a mosfet rather than a diode is that it has a low voltage drop while a normal silicon diode (e.g. 1N4148) will have a 0.6 volt drop. But the fan will work just the same with much more that 0.6V as its logic low threshold, so such a consideration is unnecessary. You could also wire it direct if you remove the LED and/or its associated resistor on the Duet.

Dave

Sorry, only registered users may post in this forum.