A circle should be a circle, shouldn't it?

Posted by Treito

|

A circle should be a circle, shouldn't it? May 15, 2015 04:24PM |

Registered: 9 years ago Posts: 1,699 |

Hello,

sorry that I have to ask again. I have no idea anymore. I managed it by now that the layer perfectly fits on the last layer, but for example I have problems with circles. The diameter is not constant. So it means I have something like an ellipse. It is not much roughly 0.5mm in the diameter, but it ends in problems for example with Iamburny's Extruder Gears. The diameter is in one direction to small. I did not figure out by now in which direction, but I gues it is the y-axis - again. Because the layers fits good on the last layer I do not think, that it good be a loose belt. What else can it be? Reprinting the ormaxis.g could not help, am I right? Or is there any possibility to calibrate the motor steps like the extruder?

Regards,

Sven

sorry that I have to ask again. I have no idea anymore. I managed it by now that the layer perfectly fits on the last layer, but for example I have problems with circles. The diameter is not constant. So it means I have something like an ellipse. It is not much roughly 0.5mm in the diameter, but it ends in problems for example with Iamburny's Extruder Gears. The diameter is in one direction to small. I did not figure out by now in which direction, but I gues it is the y-axis - again. Because the layers fits good on the last layer I do not think, that it good be a loose belt. What else can it be? Reprinting the ormaxis.g could not help, am I right? Or is there any possibility to calibrate the motor steps like the extruder?

Regards,

Sven

|

Re: A circle should be a circle, shouldn't it? May 15, 2015 05:07PM |

Registered: 9 years ago Posts: 638 |

|

Re: A circle should be a circle, shouldn't it? May 15, 2015 06:55PM |

Registered: 10 years ago Posts: 2,472 |

It is unnecessary to calibrate X & Y because the steps per mm is fixed by the size of the drive cogs and will not change (unless you fit different pulleys). Z is also fixed by the gear ratio (1:1) and the pitch of the thread on the Z lead screw, so also requires no calibration.

The most common causes of elliptical circles is a slipping pulley or a loose belt. Make sure that the grub screws on the motor pulleys are oriented with the flat on the shafts and are tight. A loose belt is another possibility - they should be banjo-string tight - perhaps one of the belts has slipped a tooth since you originally tightened them?

Unlike a skipping motor or slipping belt teeth, a loose belt or pulley will not always result in steps between layers. You will only get steps if the start & end positions of the perimeter are approached from different directions on different layers. If for example you print three columns in a row, the middle column will probably have stepped layers because it is approached from opposite directions on alternate layers, but the end two columns probably will not have steps, they will just be elliptical. An object with a single or concentrically nested perimeters (such as a gear wheel) is unlikely to have steps in the layers, it will just be too short in the direction of the loose axis.

Dave

The most common causes of elliptical circles is a slipping pulley or a loose belt. Make sure that the grub screws on the motor pulleys are oriented with the flat on the shafts and are tight. A loose belt is another possibility - they should be banjo-string tight - perhaps one of the belts has slipped a tooth since you originally tightened them?

Unlike a skipping motor or slipping belt teeth, a loose belt or pulley will not always result in steps between layers. You will only get steps if the start & end positions of the perimeter are approached from different directions on different layers. If for example you print three columns in a row, the middle column will probably have stepped layers because it is approached from opposite directions on alternate layers, but the end two columns probably will not have steps, they will just be elliptical. An object with a single or concentrically nested perimeters (such as a gear wheel) is unlikely to have steps in the layers, it will just be too short in the direction of the loose axis.

Dave

|

Re: A circle should be a circle, shouldn't it? May 16, 2015 03:24AM |

Registered: 9 years ago Posts: 1,699 |

Hi Dave,

many many thanks for this reply, but there is maybe a misunderstanding. The gears were only an example. I am formerly coming from the electrical part and I normally would say: A tolerance of 0.5mm that is not bad especially when printed. I printed that 3D benchmark boat and so I know that the dimensions could be hit exactly.

Nevermind. I printed parts of this thing:

[www.thingiverse.com]

At first the tripod base in ABS (bad idea because of warping). The other parts in PLA of different colors: 6x the bearing wheel (I had a rest of a PLA example of a failed print), the spool spindle and the short guide holder using one print (!) and the centering cone at last.

Coming back to the tripod base: Slic3r did not an intelligent job, so the outer line ended in an outer corner. If you see at the bottom of the print, there are some small holes at each end. So slic3r moved from the outer corner first to the middle feet, then to the other outer feet and then back to the first feet before it got to the center circle.

Nevertheless I got a perfect layer match and during printing I sometimes checked the infill. Not long ago I got a problem with the layer match, but this is gone.

So regarding the object sizes I should have got any problems with the layers if there is a loose belt or something?

I am not sure, but I think I had reduced this problem by increasing the current of the y motor (before I printed this huge thing), but the cone is not a cone, if you understand.

I would like to maintenance the printer today or tommorrow, adding for example the y belt clamps from Iamburny, checking the x belt and so on. But what is the reason of my circle problem? If I print the spring loaded extruder with such kind of problem the filament may not get transported correctly.

Sven

many many thanks for this reply, but there is maybe a misunderstanding. The gears were only an example. I am formerly coming from the electrical part and I normally would say: A tolerance of 0.5mm that is not bad especially when printed. I printed that 3D benchmark boat and so I know that the dimensions could be hit exactly.

Nevermind. I printed parts of this thing:

[www.thingiverse.com]

At first the tripod base in ABS (bad idea because of warping). The other parts in PLA of different colors: 6x the bearing wheel (I had a rest of a PLA example of a failed print), the spool spindle and the short guide holder using one print (!) and the centering cone at last.

Coming back to the tripod base: Slic3r did not an intelligent job, so the outer line ended in an outer corner. If you see at the bottom of the print, there are some small holes at each end. So slic3r moved from the outer corner first to the middle feet, then to the other outer feet and then back to the first feet before it got to the center circle.

Nevertheless I got a perfect layer match and during printing I sometimes checked the infill. Not long ago I got a problem with the layer match, but this is gone.

So regarding the object sizes I should have got any problems with the layers if there is a loose belt or something?

I am not sure, but I think I had reduced this problem by increasing the current of the y motor (before I printed this huge thing), but the cone is not a cone, if you understand.

I would like to maintenance the printer today or tommorrow, adding for example the y belt clamps from Iamburny, checking the x belt and so on. But what is the reason of my circle problem? If I print the spring loaded extruder with such kind of problem the filament may not get transported correctly.

Sven

|

Re: A circle should be a circle, shouldn't it? May 16, 2015 06:08AM |

Registered: 10 years ago Posts: 2,472 |

Sven,think of just the bed moving back and forth over 100mm. Now imagine that the belt is very loose - it has 10mm of slack. When the motor reverses direction at the end of the 100mm move, the bed will not move until that 10mm of slack is taken up. Then it will move only 90mm, and again will stay there until the slack is taken up after the motor changes direction. So the bed will move back and forth over 90mm instead of 100mm. But it will stop at exactly the same place at each end. There will be no layer steps, only a line that is too short. The same effect will happen if the grub screw on the motor is loose. Here the shaft will have a few degrees of free movement before the loose screw hits the edge of the flat after it changes direction.

You say that the difference is 0.5mm - the belt does not need to be too slack or the grub screw too loose to have 0.5mm of play. But it is quite possible to get them tight enough so that there is not even that amount.

It will become worse if the bed cannot move freely, so make sure that the bed runs smoothly along the ground rod.

P.S. - I was not able to get my Y belt tight enough before I printed and fitted a different Y clamp, so that may be your problem.

Dave

Edited 1 time(s). Last edit at 05/16/2015 06:13AM by dmould.

You say that the difference is 0.5mm - the belt does not need to be too slack or the grub screw too loose to have 0.5mm of play. But it is quite possible to get them tight enough so that there is not even that amount.

It will become worse if the bed cannot move freely, so make sure that the bed runs smoothly along the ground rod.

P.S. - I was not able to get my Y belt tight enough before I printed and fitted a different Y clamp, so that may be your problem.

Dave

Edited 1 time(s). Last edit at 05/16/2015 06:13AM by dmould.

|

Re: A circle should be a circle, shouldn't it? May 16, 2015 06:30AM |

Registered: 9 years ago Posts: 1,699 |

Thanks Dave,

the Y belt was loose not long ago, but I was unable to print anything because the layer did not fit the layer before. The bed and the rods can move smoothly. I used silicone spray to lubrify all and I tested the free movement. So I have to use the Y belt clamps, but I still cannot imagine that there is no layer problem especially for this huge objects like the spindle with an object height of 116mm.

the Y belt was loose not long ago, but I was unable to print anything because the layer did not fit the layer before. The bed and the rods can move smoothly. I used silicone spray to lubrify all and I tested the free movement. So I have to use the Y belt clamps, but I still cannot imagine that there is no layer problem especially for this huge objects like the spindle with an object height of 116mm.

|

Re: A circle should be a circle, shouldn't it? May 16, 2015 02:10PM |

Registered: 9 years ago Posts: 1,699 |

|

Re: A circle should be a circle, shouldn't it? May 17, 2015 05:46AM |

Registered: 9 years ago Posts: 1,699 |

Nobody an idea? Maybe it is Slic3r 1.2.6. I am testing this at the moment. Printinting the 3DBenchy with generated G-Code from Slic3r 1.2.6 fails in the dimensions. With Cura the dimensions are okay but at one place it does not look as good as Slic3r. So Slic3r 1.1.7? But this is extremely slow and I did not test the accuracy yet.

|

Re: A circle should be a circle, shouldn't it? May 17, 2015 07:33AM |

Registered: 10 years ago Posts: 2,472 |

Circles print smaller than the STL model, so the STL must have larger circular sections to compensate. The smaller the circle the worse the error. The main reason is that Slic3r assumes that the nozzle will move along the center of the extruded line, but the line deposited on a circular path has a larger outside circumference than inside circumference, which displaces the plastic to the inside of the circle making it small than intended. However the error should be consistent all around the circle. To be honest I have never looked to see whether large circles are accurate to within 0.5mm The start & end "seam" is usually bigger than that, and so I always need to finish off exact mating parts with a file. All the gears I have printed have a tolerance of more than 0.5mm so it would not notice there either.

My guess is that it is to do with the print speed. I have noticed that when using DC42's later firmware, the print speed around the circumference of a circle is not constant (and can become extremely jerky if the circle is not a fine resolution). I think that is due to his more accurate acceleration algorithms and is not necessarily wrong, but could cause print artefacts due to Bowden lag (which causes under-extrusion during acceleration and over-extrusion during deceleration). If you are using that firmware, you could try reverting to older firmware that has less accurate acceleration but will give a more steady speed around the circumference of a circle. Or just try printing much more slowly so that the acceleration limit does not affect the speed so much.

Dave

My guess is that it is to do with the print speed. I have noticed that when using DC42's later firmware, the print speed around the circumference of a circle is not constant (and can become extremely jerky if the circle is not a fine resolution). I think that is due to his more accurate acceleration algorithms and is not necessarily wrong, but could cause print artefacts due to Bowden lag (which causes under-extrusion during acceleration and over-extrusion during deceleration). If you are using that firmware, you could try reverting to older firmware that has less accurate acceleration but will give a more steady speed around the circumference of a circle. Or just try printing much more slowly so that the acceleration limit does not affect the speed so much.

Dave

|

Re: A circle should be a circle, shouldn't it? May 17, 2015 07:41AM |

Registered: 9 years ago Posts: 1,699 |

What about the firmware 1.09?

Cura did not help. Some details are much better, some not, but my circles are still not circles. But cura hits the dimensions a little bit better.

Strange is that my circles most differ roughly 0.5mm independently from the diameter. I tested last an object with a diameter of 45mm.

I am using the firmware from DC42. but in the meantime the firmware from ZPL seems to be official.

I am currently running ormaxis.g. I changed/ fixed some parts, for example adding the Z belt clamps from Iamburny. Maybe this has an effect on it. I do not believe in this, but I am totally desperate.

Slic3r settings where only 30mm/s main speed. Travel time I cannot imagine that would not affect the roundness of the circle.

So I should test printing speed of 15mm/s for example?

Cura did not help. Some details are much better, some not, but my circles are still not circles. But cura hits the dimensions a little bit better.

Strange is that my circles most differ roughly 0.5mm independently from the diameter. I tested last an object with a diameter of 45mm.

I am using the firmware from DC42. but in the meantime the firmware from ZPL seems to be official.

I am currently running ormaxis.g. I changed/ fixed some parts, for example adding the Z belt clamps from Iamburny. Maybe this has an effect on it. I do not believe in this, but I am totally desperate.

Slic3r settings where only 30mm/s main speed. Travel time I cannot imagine that would not affect the roundness of the circle.

So I should test printing speed of 15mm/s for example?

|

Re: A circle should be a circle, shouldn't it? May 17, 2015 07:45AM |

Registered: 9 years ago Posts: 638 |

|

Re: A circle should be a circle, shouldn't it? May 17, 2015 07:53AM |

Registered: 9 years ago Posts: 1,699 |

Quote

Darathy

Strange ,i am using Slic3r 1.2.6 and when i printed benchy some sizes were as described but some were off by 0.3 ,i still think its a calibration issue tho ,i havent tested with Cura yet but will soon.

The strange think is that using Slic3r 1.1.7 also hits the dimensions, but Slic3r 1.2.6 seems to differ roughly 0.3-0.5mm.

Be careful testing Cura as it only supports absolute Extruder length. If you try to pause the print the filament will be unloaded if you do not modify your commands.

|

Re: A circle should be a circle, shouldn't it? May 17, 2015 09:29AM |

Registered: 9 years ago Posts: 638 |

Quote

Treito

Quote

Darathy

Strange ,i am using Slic3r 1.2.6 and when i printed benchy some sizes were as described but some were off by 0.3 ,i still think its a calibration issue tho ,i havent tested with Cura yet but will soon.

The strange think is that using Slic3r 1.1.7 also hits the dimensions, but Slic3r 1.2.6 seems to differ roughly 0.3-0.5mm.

Be careful testing Cura as it only supports absolute Extruder length. If you try to pause the print the filament will be unloaded if you do not modify your commands.

I have removed some of the Start and End gcode in Cura and put M83 for relative extruder moves ,also used this plugin :[forums.reprap.org]

Slic3r is still giving me better results ,but support is not as good as Cura ,i like with Cura that i can set the distance between object and support as i like(0.1 which makes the print look a lot better) while i have only 0.2 and 0 option in slic3r, Cura also does crazy jerky moves compared to slic3r ,the outside perimiters look way better on slic3r then on Cura.

Would like to try Simplify3D but i'm a bit short on budget atm , 150$ is a bit much for it.

Edited 1 time(s). Last edit at 05/17/2015 09:31AM by Darathy.

|

Re: A circle should be a circle, shouldn't it? May 17, 2015 11:06AM |

Registered: 13 years ago Posts: 1,611 |

Hi Sven

As dmould already said: check the pulley (I think the Y axis belt pulley) is tight on the motor shaft. The grub screw may not be tight, and it's allowing a small amount of 'backlash'. Alternatively, look at this troubleshooting guide: [reprappro.com]

The section before, and section after, can also be useful.

I very much doubt it's a slicing problem (check your gcode by opening it in a gcode visualiser, eg Repetier Host or [gcode.ws] ), and unless you are setting a different value for the steps per mm on X and Y (as dmould says, don't! See [reprappro.com] ), it's not a firmware issue.

If the above doesn't help, post a picture of the printing problem, so we can see the issue.

Ian

RepRapPro tech support

As dmould already said: check the pulley (I think the Y axis belt pulley) is tight on the motor shaft. The grub screw may not be tight, and it's allowing a small amount of 'backlash'. Alternatively, look at this troubleshooting guide: [reprappro.com]

The section before, and section after, can also be useful.

I very much doubt it's a slicing problem (check your gcode by opening it in a gcode visualiser, eg Repetier Host or [gcode.ws] ), and unless you are setting a different value for the steps per mm on X and Y (as dmould says, don't! See [reprappro.com] ), it's not a firmware issue.

If the above doesn't help, post a picture of the printing problem, so we can see the issue.

Ian

RepRapPro tech support

|

Re: A circle should be a circle, shouldn't it? May 17, 2015 11:28AM |

Registered: 9 years ago Posts: 1,699 |

Hello Ian,

it is indeed not a problem with the slicing software. I do not think that you can see the problem on a picture.

Let me try to explain: If I print a circle and measure the diameter according to the X axis or the Y axis everything is alright. If i measure diagonal the diameter is missing roughly 0.5 mm.

Maybe I have an idea how to take some photos, but it will not be easy.

it is indeed not a problem with the slicing software. I do not think that you can see the problem on a picture.

Let me try to explain: If I print a circle and measure the diameter according to the X axis or the Y axis everything is alright. If i measure diagonal the diameter is missing roughly 0.5 mm.

Maybe I have an idea how to take some photos, but it will not be easy.

|

Re: A circle should be a circle, shouldn't it? May 17, 2015 11:51AM |

Registered: 13 years ago Posts: 1,611 |

|

Re: A circle should be a circle, shouldn't it? May 17, 2015 11:53AM |

Registered: 9 years ago Posts: 1,699 |

|

Re: A circle should be a circle, shouldn't it? May 17, 2015 03:56PM |

Registered: 9 years ago Posts: 1,699 |

I have an idea for this problem.

I redrawed an object new and I sliced it new (changed from Cura to Slic3r). The first time I got some errors using Slic3r but this time everything was alright. But then I could watch a strange phenomena: My problems rotated by 45°. Now the length of the X axis and Y axis did not fit but the diagonals.

And also the inner circle seemed to nearly fit (320mm - max. 0.1mm)

I think that the reason is the small bearing of the X runner mount. I can not manage it to get close enough to the acrylic arm. So my nozzle is not straight 90° to the bed. At first this does not matter but if the nozzle slides over the printing the angle can change. According to where the layer starts this could explain my problem, maybe. But it will take some time to test this.

I redrawed an object new and I sliced it new (changed from Cura to Slic3r). The first time I got some errors using Slic3r but this time everything was alright. But then I could watch a strange phenomena: My problems rotated by 45°. Now the length of the X axis and Y axis did not fit but the diagonals.

And also the inner circle seemed to nearly fit (320mm - max. 0.1mm)

I think that the reason is the small bearing of the X runner mount. I can not manage it to get close enough to the acrylic arm. So my nozzle is not straight 90° to the bed. At first this does not matter but if the nozzle slides over the printing the angle can change. According to where the layer starts this could explain my problem, maybe. But it will take some time to test this.

|

Re: A circle should be a circle, shouldn't it? May 17, 2015 03:59PM |

Registered: 9 years ago Posts: 638 |

Quote

Treito

I have an idea for this problem.

I redrawed an object new and I sliced it new (changed from Cura to Slic3r). The first time I got some errors using Slic3r but this time everything was alright. But then I could watch a strange phenomena: My problems rotated by 45°. Now the length of the X axis and Y axis did not fit but the diagonals.

And also the inner circle seemed to nearly fit (320mm - max. 0.1mm)

I think that the reason is the small bearing of the X runner mount. I can not manage it to get close enough to the acrylic arm. So my nozzle is not straight 90° to the bed. At first this does not matter but if the nozzle slides over the printing the angle can change. According to where the layer starts this could explain my problem, maybe. But it will take some time to test this.

The weight of the HotEnd should push the bearing against the acrylic ,check that the cable is not pulling it up.

|

Re: A circle should be a circle, shouldn't it? May 17, 2015 04:12PM |

Registered: 9 years ago Posts: 1,699 |

Quote

Darathy

The weight of the HotEnd should push the bearing against the acrylic ,check that the cable is not pulling it up.

Yes of course, but there is much movement, so as soon as the extruder is over the printed part it is moved up and if not it is standing diagonal. I think that is the problem. Some movement should be but I think my movement is too much. I have no other explantion for my problem especially as it rotates now by 45° and the inner circle is nearly perfectly. The inner diameter is roughly 320mm and the outer should be 450mm but is 449.4-450.1mm.

|

Re: A circle should be a circle, shouldn't it? May 26, 2015 04:16AM |

Registered: 9 years ago Posts: 1,699 |

Hello,

I need further help with this issue. I also had found a problem regarding the x-carriage. The small rod is a little bit too small, so I fixed this temporarly until I am ablte to print a new one (ABS won't stick, but that is another problem). Now I have still a strange problem. If I try to print a circle alone in the middle of the bed it is not round, but if I print a round part (like the extruder gear from iamburny) it is perfectly round. Why is this so?

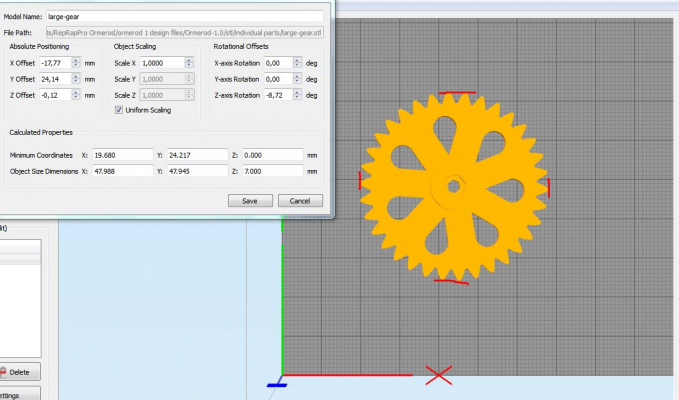

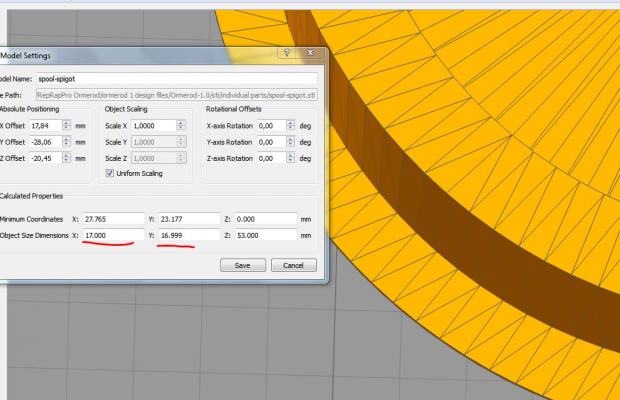

Something is also strange. If I open the original parts from the Ormerod 1 for example the extruder gear, Slic3r tells me that the X and Y dimensions are different.

Regards,

Sven

I need further help with this issue. I also had found a problem regarding the x-carriage. The small rod is a little bit too small, so I fixed this temporarly until I am ablte to print a new one (ABS won't stick, but that is another problem). Now I have still a strange problem. If I try to print a circle alone in the middle of the bed it is not round, but if I print a round part (like the extruder gear from iamburny) it is perfectly round. Why is this so?

Something is also strange. If I open the original parts from the Ormerod 1 for example the extruder gear, Slic3r tells me that the X and Y dimensions are different.

Regards,

Sven

|

Re: A circle should be a circle, shouldn't it? May 26, 2015 04:42AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Treito

...Something is also strange. If I open the original parts from the Ormerod 1 for example the extruder gear, Slic3r tells me that the X and Y dimensions are different....

notice the dimensions depends of the position of the teeth

Erik

|

Re: A circle should be a circle, shouldn't it? May 26, 2015 05:02AM |

Registered: 9 years ago Posts: 1,699 |

|

Re: A circle should be a circle, shouldn't it? May 26, 2015 05:32AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Treito

...Slic3r tells me that the dimensions are 17.00x16.96x53.00. And there are no teeth...

a circle is made of lines so the flat lines and corners so will have the same effect

Erik

|

Re: A circle should be a circle, shouldn't it? May 26, 2015 06:02AM |

Registered: 9 years ago Posts: 1,699 |

|

Re: A circle should be a circle, shouldn't it? May 26, 2015 06:52AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Treito

What software do you use?

BTT: But why my circles are not circles in the center of the bed but they are circles at the edges of the bed you cannot answer, right? Anybody else? Where I have to look for this error?

Can you publish a photo of an example print, with circles both at the centre and away from it, along with the gcode?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: A circle should be a circle, shouldn't it? May 26, 2015 07:06AM |

Registered: 9 years ago Posts: 1,699 |

Hello,

thanks for the reply. We are talking about roughly 0.5mm difference and 0.5mm to small. For example the extruder gears should be 47.96mm x 47.96mm and the printed one have 47.00 x 47.5mm. That would be hard to see at pictures. The round one was printed with many many other parts (round about 25 meters of filament). There was a problem with one or two layers during this print but the dimensions are perfect. My full example differs from material (the good one was ABS, the bad one was PLA), but I also tried to print HIPS/ ABS and the same problem occurs. So the material is not the cause.

So, I can provide everything. I see I have also a failed fully print in HIPS with the same dimension errors like the part of PLA.

thanks for the reply. We are talking about roughly 0.5mm difference and 0.5mm to small. For example the extruder gears should be 47.96mm x 47.96mm and the printed one have 47.00 x 47.5mm. That would be hard to see at pictures. The round one was printed with many many other parts (round about 25 meters of filament). There was a problem with one or two layers during this print but the dimensions are perfect. My full example differs from material (the good one was ABS, the bad one was PLA), but I also tried to print HIPS/ ABS and the same problem occurs. So the material is not the cause.

So, I can provide everything. I see I have also a failed fully print in HIPS with the same dimension errors like the part of PLA.

|

Re: A circle should be a circle, shouldn't it? May 26, 2015 07:25AM |

Registered: 10 years ago Posts: 14,672 |

For reasons already described, you will never get gears with an odd number of teeth to measure the same in both directions to within 0.5mm. Try printing circular parts instead, and make sure that you generate them with a number of facets that is divisible by 4.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: A circle should be a circle, shouldn't it? May 26, 2015 07:28AM |

Registered: 9 years ago Posts: 1,699 |

|

Re: A circle should be a circle, shouldn't it? May 26, 2015 08:15AM |

Registered: 10 years ago Posts: 2,472 |

Use OpenScad and you can control the number of segments (using the $fn variable). Having said that, a thread on the Slic3r forum indicated that for some reason Slic3r does not always generate the same number of segments as the STL contains.

Attached are STL's containing a 50mm diameter cylinder (3mm high) with various numbers of segments (divisable by 4)

Dave

Attached are STL's containing a 50mm diameter cylinder (3mm high) with various numbers of segments (divisable by 4)

Dave

Attachments:

open | download - Circle_004.stl (1.9 KB)

open | download - Circle_008.stl (4.4 KB)

open | download - Circle_016.stl (9.4 KB)

open | download - Circle_032.stl (19.5 KB)

open | download - Circle_064.stl (39.6 KB)

open | download - Circle_128.stl (79.9 KB)

open | download - Circle_256.stl (160.8 KB)

open | download - Circle_512.stl (322.5 KB)

open | download - Circle_004.stl (1.9 KB)

open | download - Circle_008.stl (4.4 KB)

open | download - Circle_016.stl (9.4 KB)

open | download - Circle_032.stl (19.5 KB)

open | download - Circle_064.stl (39.6 KB)

open | download - Circle_128.stl (79.9 KB)

open | download - Circle_256.stl (160.8 KB)

open | download - Circle_512.stl (322.5 KB)

Sorry, only registered users may post in this forum.