|

Extruder gear keeps slipping on infill May 17, 2015 08:17AM |

Registered: 9 years ago Posts: 78 |

Hi All

I`ve been through all the settings:

1- Calibrate the extruder steps so that it extrudes exactly 100mm (got to M92 E441) then it is spot on

2- Measured the filament 1.78mm or so

But when I print the infills 100% ovelap 5% causes the gears to slip ie. trying to extrude to much material

I then issue M221 S80 even sometimes I set it down to S50..... before it stops slipping...

I must add this is mainly on "long" infills 100mm in length..

What gives here

Layer height is 0.2 and nozzle 0.5mm

What more can be done to avoid this... the bed is 99% level... but why the huge M221 factor

Thx Ben

Edited 1 time(s). Last edit at 05/17/2015 08:18AM by BenBB.

I`ve been through all the settings:

1- Calibrate the extruder steps so that it extrudes exactly 100mm (got to M92 E441) then it is spot on

2- Measured the filament 1.78mm or so

But when I print the infills 100% ovelap 5% causes the gears to slip ie. trying to extrude to much material

I then issue M221 S80 even sometimes I set it down to S50..... before it stops slipping...

I must add this is mainly on "long" infills 100mm in length..

What gives here

Layer height is 0.2 and nozzle 0.5mm

What more can be done to avoid this... the bed is 99% level... but why the huge M221 factor

Thx Ben

Edited 1 time(s). Last edit at 05/17/2015 08:18AM by BenBB.

|

Re: Extruder gear keeps slipping on infill May 17, 2015 09:54AM |

Registered: 10 years ago Posts: 665 |

What's your infilll speed and which temperatures are you using? Also, can you easily rotate the extruder gears while the machine is turned off and no filament is loaded (or rather, not stuck in the nozzle)?

Increasing the E motor current to 1000 might help, I've done this on both of my machines.

Increasing the E motor current to 1000 might help, I've done this on both of my machines.

|

Re: Extruder gear keeps slipping on infill May 17, 2015 12:28PM |

Registered: 10 years ago Posts: 2,472 |

What is your infill extrusion width and what speed are you printing at? The extruder is the limiting factor regarding speed. With long infill and an extrusion width of 0.5mm and 0.2mm layer height, my Ormerod's extruder starts skipping steps at around 70mm/s.

First, I assume that the motor is stalling (The gears stop and skip backwards when it stalls). If the gears turn OK but the filament stops feeding, it will probably be a clogged hobbed bolt - just take it out and clean it. If the motor is stalling it means that it cannot push plastic fast enough.

You say you have set 100% infill (i.e. solid) Does it still skip if you set 50% infill? If not it would indicate that you are over-extruding a bit and the excess is causing the plastic to mount up higher than your layer height, which gets progressively worse until the extruder starts skipping because there is not enough room to push material. Setting 100% infill is seldom necessary, and it often causes problems. For a very dense part try 80% instead (it does not result in a significantly weaker part).

I assume that you have set the extruder motor current to 1000mA in the config file. If not, do so. The extruder motor needs the greatest torque of all the 4 motors - pushing plastic rapidly through a small nozzle is hard work!

If it is none of the above, it is quite likely that your nozzle is partially blocked. Try the nozzle cleaning procedure, but if that fails it may be easiest to buy another nozzle. It's happened to me twice, and so now I keep a spare nozzle handy. The first symptom of a partially blocked nozzle is the extruder skipping at much lower speeds than usual.

Dave

First, I assume that the motor is stalling (The gears stop and skip backwards when it stalls). If the gears turn OK but the filament stops feeding, it will probably be a clogged hobbed bolt - just take it out and clean it. If the motor is stalling it means that it cannot push plastic fast enough.

You say you have set 100% infill (i.e. solid) Does it still skip if you set 50% infill? If not it would indicate that you are over-extruding a bit and the excess is causing the plastic to mount up higher than your layer height, which gets progressively worse until the extruder starts skipping because there is not enough room to push material. Setting 100% infill is seldom necessary, and it often causes problems. For a very dense part try 80% instead (it does not result in a significantly weaker part).

I assume that you have set the extruder motor current to 1000mA in the config file. If not, do so. The extruder motor needs the greatest torque of all the 4 motors - pushing plastic rapidly through a small nozzle is hard work!

If it is none of the above, it is quite likely that your nozzle is partially blocked. Try the nozzle cleaning procedure, but if that fails it may be easiest to buy another nozzle. It's happened to me twice, and so now I keep a spare nozzle handy. The first symptom of a partially blocked nozzle is the extruder skipping at much lower speeds than usual.

Dave

|

Re: Extruder gear keeps slipping on infill May 17, 2015 12:43PM |

Registered: 9 years ago Posts: 78 |

Hi Dave

Tx for the post, you ask the right Q`s !! I can see you have been around the "bug finding block"

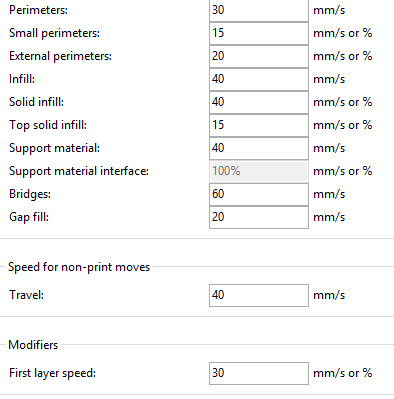

Extrusion speed is very slow

I did not set the current to 1000, Will try that and see...

Tx Ben

Tx for the post, you ask the right Q`s !! I can see you have been around the "bug finding block"

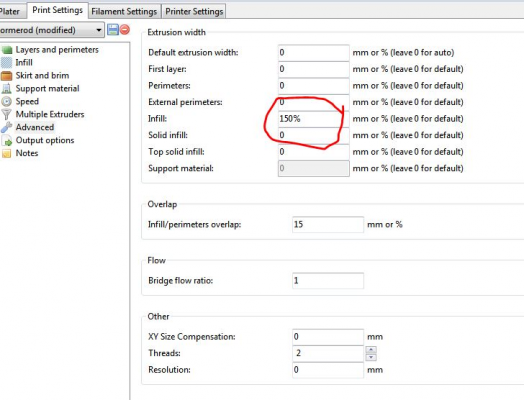

I`m not with you on this one, Slic3r does not have infill extrusion width ?Quote

What is your infill extrusion width and what speed are you printing at?

Extrusion speed is very slow

I did not set the current to 1000, Will try that and see...

Tx Ben

|

Re: Extruder gear keeps slipping on infill May 17, 2015 02:20PM |

Registered: 10 years ago Posts: 1,230 |

As dmould asked, what is your infill extrusion width, look under advanced settings, maybe you canged something there and forgot about it, something like this could do it:

Erik

Erik

|

Re: Extruder gear keeps slipping on infill May 18, 2015 07:44AM |

Registered: 10 years ago Posts: 2,472 |

Your print speed is very slow (40mm/s for infill), so unless you have accidentally set a silly value for the extrusion width (see Erik's post), the extruder should easily cope. Max speed before the extruder starts slipping on long infill on my printer for a 0.2mm layer height and default extrusion width (0.5mm) is around 70mm/s or more, and I now usually use 60mm/s print speeds. As said, try setting 80% infill in case it is building the 100% infill too high due to slight over-extrusion, and also change the motor current. If it is neither of those things, or if it has suddenly started happening when it was OK before, then you probably have a partial nozzle blockage. You should however first check that there is no restriction in the Bowden tube or elsewhere. Extract all the filament and switch off the printer. Now feed in filament by hand using the extruder gear. It should be easy to turn the wheel and the filament should feed completely smoothly all the way until it hits the nozzle. Use a dark filament and you will easily see its progress though the Bowden tube. If you feel any resistance or unevenness you need to investigate what is causing it. If the gear is stiff to turn with no filament it indicates an incorrectly assembled extruder (missing washers or gear touching the body are the usual causes).

One last thing that is usually obvious is that the filament is able to feed smoothly off the reel. I have had slipping due to the filament being a bit tangled on the reel.

Dave

One last thing that is usually obvious is that the filament is able to feed smoothly off the reel. I have had slipping due to the filament being a bit tangled on the reel.

Dave

|

Re: Extruder gear keeps slipping on infill May 18, 2015 09:29AM |

Registered: 9 years ago Posts: 176 |

|

Re: Extruder gear keeps slipping on infill May 18, 2015 11:53AM |

Registered: 10 years ago Posts: 2,472 |

Quote

VortyZA

Didn't see if anyone mentioned this, but extruding at too low a temperature for the material can also cause skipping. I find that some materials require quite different temperatures.

Skipping on the first layer can be due to the nozzle being too close to the bed.

Good point - I had forgotten about that reason. Remember it is possible that your thermistor is not sending the correct temperature, so even if the temperature is set correctly it may be printing too cold. At least one person found that he was printing with ABS filament when he thought it was PLA, which will also mean that your temperature is too low!

I had also assumed that the OP was reporting something that happened above the first layer, but see that this is not stated, so if it only happens on the first layer it is probable that the Z zero height is too low.

Dave

Sorry, only registered users may post in this forum.