|

Sweet bed treatment May 20, 2015 05:53PM |

Registered: 10 years ago Posts: 300 |

I love sugar.

I'm printing PLA on glass with a wipe over of sugar dissolved in water. Lots of sugar, not so much water. Just enough to make a syrup.

The neat thing is that once set with a little heat, it's not sticky but gives the glass a matt glaze that seems to hold onto the plastic like crazy.

To refresh between prints it's enough just to wipe over with more syrup. Cleanup with water. Couldn't be simpler. Anyone tried it with ABS?

I don't use that stuff

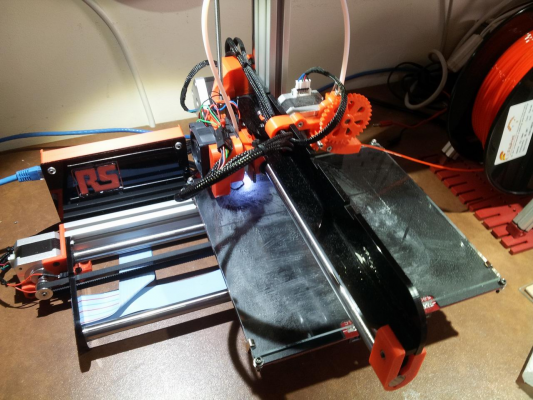

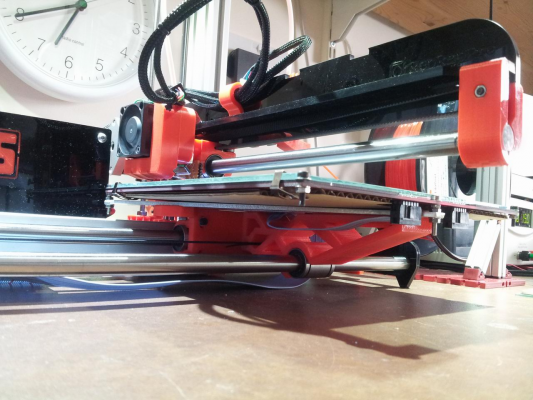

I've also given Ormerod a make-over today - fitted a one-piece printed bed support topped off with Davek0974's aluminium bed and painted the heat spreader black.

RS Components Reprap Ormerod No. 481

I'm printing PLA on glass with a wipe over of sugar dissolved in water. Lots of sugar, not so much water. Just enough to make a syrup.

The neat thing is that once set with a little heat, it's not sticky but gives the glass a matt glaze that seems to hold onto the plastic like crazy.

To refresh between prints it's enough just to wipe over with more syrup. Cleanup with water. Couldn't be simpler. Anyone tried it with ABS?

I don't use that stuff

I've also given Ormerod a make-over today - fitted a one-piece printed bed support topped off with Davek0974's aluminium bed and painted the heat spreader black.

RS Components Reprap Ormerod No. 481

|

Re: Sweet bed treatment May 21, 2015 03:59AM |

Registered: 10 years ago Posts: 665 |

I tried to print ABS on sugar coating many months ago, but I found it wasn't sticky enough for larger objects. Then I bought two alu plates, but unfortuantely ruined both of of them (first one by printing Nylon on it and the second one when I did some experiments with SoftPLA). I guess they have some kind of PEI coating which is excellent, but it only works with pure PLA and ABS AFAICT. If affordable PEI sheets were available anywhere near, I'd probably replace the coating, but now I print ABS on self-adhesive laminating foil at 110°C instead. So far it appears to be working quite nicely, too, but larger objects still need a brim to prevent warping.

|

Re: Sweet bed treatment May 21, 2015 04:57AM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Sweet bed treatment May 21, 2015 05:48AM |

Registered: 10 years ago Posts: 300 |

I'm just too clumsy to have any kind of delicate surface (even kapton LOL) that's why I wanted a way to print on glass which can take a fair amount of abuse.

I started out with a wipe of Bottle Green ginger and lemongrass concentrate that I'd been swigging (diluted of course) and noticed how sticky it was around the bottle top. This worked really well but remained sticky to the touch so collected dust and dirt like a magnet. It's expensive too.

Plain white sugar solution on the other hand dries solid - like sugar crystals are to the touch. Being water based makes cleanup nice and easy to. I like to avoid the use of solvents whenever possible.

RS Components Reprap Ormerod No. 481

I started out with a wipe of Bottle Green ginger and lemongrass concentrate that I'd been swigging (diluted of course) and noticed how sticky it was around the bottle top. This worked really well but remained sticky to the touch so collected dust and dirt like a magnet. It's expensive too.

Plain white sugar solution on the other hand dries solid - like sugar crystals are to the touch. Being water based makes cleanup nice and easy to. I like to avoid the use of solvents whenever possible.

RS Components Reprap Ormerod No. 481

|

Re: Sweet bed treatment May 21, 2015 02:29PM |

Registered: 9 years ago Posts: 638 |

i just usualy clean the glass with Alcohol and print directly on it with PLA. But i always preheat the bed to 65 and clean while its heating from 40 to 65C ,i noticed it always stuck better when i cleaned the warm/hot glass ,but only with the fillament from [3dfilaments.ie].

Sticks so strong i cant get it loose untill it coolsdown(i usualy just take the glass off and put it under water) and it just falls off xD

Edited 1 time(s). Last edit at 05/21/2015 02:31PM by Darathy.

Sticks so strong i cant get it loose untill it coolsdown(i usualy just take the glass off and put it under water) and it just falls off xD

Edited 1 time(s). Last edit at 05/21/2015 02:31PM by Darathy.

|

Re: Sweet bed treatment May 21, 2015 02:37PM |

Registered: 9 years ago Posts: 1,699 |

|

Re: Sweet bed treatment May 22, 2015 07:37AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Treito

Quote

Darathy

Sticks so strong i cant get it loose untill it coolsdown(i usualy just take the glass off and put it under water) and it just falls off xD

Be careful, because of the high temperature difference the glass could break.

By the time you get the glass to the sink it will be no hotter than 60 degrees, and the water will be 10 degrees minimum, which I doubt is a large enough temperature differential to crack the glass. You can after all get similar temperature differentials when cleaning outside windows in Winter. Using a steam cleaner on windows has often resulted in cracking, but not AFAIAA a bucket of hot water. More care is needed at ABS bed temperatures though.

Dave

|

Re: Sweet bed treatment May 22, 2015 11:15AM |

Registered: 9 years ago Posts: 1,699 |

Sorry, only registered users may post in this forum.