E3D V6

Posted by Darathy

|

Re: E3D V6 June 18, 2015 05:35PM |

Registered: 9 years ago Posts: 606 |

|

Re: E3D V6 June 18, 2015 05:47PM |

Registered: 9 years ago Posts: 638 |

|

Re: E3D V6 June 18, 2015 07:30PM |

Registered: 10 years ago Posts: 14,672 |

I have just installed an E3Dv6 in my Duet-powered Kossel, so I can tell you that you need to set the B parameter in the M305 P1 command in config.g to 4267. Despite the heater being only 25W power, it heats up very quickly and the temperature overshoots (I guess that shows how good the thermal break is). So I will be reducing the S factor in that M305 command too.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D V6 June 19, 2015 08:25AM |

Registered: 9 years ago Posts: 638 |

Quote

dc42

I have just installed an E3Dv6 in my Duet-powered Kossel, so I can tell you that you need to set the B parameter in the M305 P1 command in config.g to 4267. Despite the heater being only 25W power, it heats up very quickly and the temperature overshoots (I guess that shows how good the thermal break is). So I will be reducing the S factor in that M305 command too.

Thank you, it will work on your probe with no modifications?

|

Re: E3D V6 June 19, 2015 10:40AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Darathy

Quote

dc42

I have just installed an E3Dv6 in my Duet-powered Kossel, so I can tell you that you need to set the B parameter in the M305 P1 command in config.g to 4267. Despite the heater being only 25W power, it heats up very quickly and the temperature overshoots (I guess that shows how good the thermal break is). So I will be reducing the S factor in that M305 command too.

Thank you, it will work on your probe with no modifications?

The E3D is mechanically very different from the standard Ormerod hot end, so you would need to design a different mounting for my hot end board. For my delta, I adapted an existing design for a hot end fan duct to accommodate the E3D and one of my mini IR sensor boards. It's at [www.thingiverse.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D V6 June 19, 2015 11:01AM |

Registered: 9 years ago Posts: 1,699 |

What about this design? That should fit, I hope so.

thingiverse.com

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

thingiverse.com

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: E3D V6 June 19, 2015 11:07AM |

Registered: 9 years ago Posts: 119 |

I noticed that the cooling section with the fins of the E3D clone that I bought from China via ebay is longer, and didnt allow it to be assembled to the mounts published on thingiverse and the forums.

So I advise verify the dimensions of your E3D against the design before wasting plastic printing a part that will not fit.

So I advise verify the dimensions of your E3D against the design before wasting plastic printing a part that will not fit.

|

Re: E3D V6 June 19, 2015 11:14AM |

Registered: 9 years ago Posts: 1,159 |

Quote

ezwul

I noticed that the cooling section with the fins of the E3D clone that I bought from China via ebay is longer, and didnt allow it to be assembled to the mounts published on thingiverse and the forums.

So I advise verify the dimensions of your E3D against the design before wasting plastic printing a part that will not fit.

Would suggest that the clone is of a V5 which is longer than a V6 and I believe that the groove might be slightly narrower as well but can't confirm that without checking the drawing's on E3D's web page

Doug

|

Re: E3D V6 June 19, 2015 12:18PM |

Registered: 9 years ago Posts: 119 |

Without checking (at work at the moment) that sounds very plausable, not very experienced in the different versions of the E3D, and I dont think the chinese site was very descriptve either.

Pay peanuts get monkeys. Quite happy to design my own mount, just worried that others mught get caught as well.

Quite happy to design my own mount, just worried that others mught get caught as well.

Pay peanuts get monkeys.

Quite happy to design my own mount, just worried that others mught get caught as well.

Quite happy to design my own mount, just worried that others mught get caught as well.

|

Re: E3D V6 June 19, 2015 12:24PM |

Registered: 9 years ago Posts: 1,699 |

So I am excited what I will get. How can I seperate the two versions?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: E3D V6 June 19, 2015 01:31PM |

Registered: 9 years ago Posts: 1,159 |

Quote

Treito

So I am excited what I will get. How can I seperate the two versions?

Where have you got it from?

check these drawing's and you can soon tell the difference RAWING-V5-SINK.jpg" target="_blank" rel="nofollow">V5 Heatsink and RAWING-V6-175-SINK.png" target="_blank" rel="nofollow">V6 Heatsink

The V5 has I believe the same size groove as a J-Head the V6 is slightly wider 6 mm against 5.6 mm wide mounting groove also the centre part of the heatsink on the V5 is stepped and parallel and the V6 is tapered

To the best of my knowledge E3D themselves only do the V6 now and if you might want to go multi extruder anytime then the E3D Chimera is probably the way to go it is tiny.

Doug

|

Re: E3D V6 June 19, 2015 01:42PM |

Registered: 9 years ago Posts: 1,699 |

Quote

dougal1957

To the best of my knowledge E3D themselves only do the V6 now and if you might want to go multi extruder anytime then the E3D Chimera is probably the way to go it is tiny.

Doug

I knew I forgot something

. The parts are not here yet. I bought it at a website where the risk of false part is pretty high.

. The parts are not here yet. I bought it at a website where the risk of false part is pretty high.Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: E3D V6 June 19, 2015 02:22PM |

Registered: 9 years ago Posts: 638 |

Fortinetly i have found someone who was using Dc's probe and E3D V6 :[forums.reprap.org]

He posted a mount and fan duct stls.

I have bought the Original from their website. Nearly 100€ with postage tho...

I am guessing Ormerod would not support this kind of thermistor: [e3d-online.com]

Edited 2 time(s). Last edit at 06/19/2015 02:32PM by Darathy.

He posted a mount and fan duct stls.

I have bought the Original from their website. Nearly 100€ with postage tho...

I am guessing Ormerod would not support this kind of thermistor: [e3d-online.com]

Edited 2 time(s). Last edit at 06/19/2015 02:32PM by Darathy.

|

Re: E3D V6 June 19, 2015 02:56PM |

Registered: 9 years ago Posts: 1,699 |

I have definitely did not buy an original one or to be more precise two.

Maybe you can get the Thermistor to work with dc42's firmware only and a lot of maths.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Maybe you can get the Thermistor to work with dc42's firmware only and a lot of maths.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: E3D V6 June 19, 2015 03:15PM |

Registered: 10 years ago Posts: 14,672 |

Platinum resistance thermometers need rather specialised circuitry to drive them. IMO a thermocouple would be a better bet if you want to exceed 295C. I have a thermocouple adaptor in front of me, but I haven't done anything about getting it to work with the Duet yet.

Edited 1 time(s). Last edit at 06/19/2015 03:16PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D V6 June 20, 2015 07:45AM |

Registered: 10 years ago Posts: 14,672 |

Has anyone using the E3D on the Ormerod got high-quality prints with it yet? Since I changed over to it on my delta, I've been getting a lot of very small blobs on the print. The same test print on the Ormerod, and on the delta while it still had the Jhead, is much better. I've tried lower temperature, higher temperature, 6mm retraction (as used on the Jhead), and 2mm retraction (maximum recommended by E3D), all to no avail.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D V6 June 20, 2015 08:30AM |

Registered: 9 years ago Posts: 638 |

Quote

dc42

Has anyone using the E3D on the Ormerod got high-quality prints with it yet? Since I changed over to it on my delta, I've been getting a lot of very small blobs on the print. The same test print on the Ormerod, and on the delta while it still had the Jhead, is much better. I've tried lower temperature, higher temperature, 6mm retraction (as used on the Jhead), and 2mm retraction (maximum recommended by E3D), all to no avail.

I will probably be fitting the E3D today ,still have to print the mountings and commision your probe. I was printing the mountings yesterday in ABS but unfortinetly the heat deformed my X carridge

Warning to those who bought from 3Dfilaments.ie PLA atleast: its deforming Temperature is a lot lower then standard PLA(atleast i notice it can be printed at lower temeprature then most aswell) ,I would not use it for anything that is exposed to temps araund 50C , I like the fillament couse it is quite strong and good for Printing objects that are not exposed to too much heat.

My X-carridge was printed with this fillament and could not withstand the heat from the hot bed and deformed so my bearing sliped out.

Anyway i'm gona print mountings temporary in Esuns fillament and hope it can withstand heat till i print them in ABS.

|

Re: E3D V6 June 20, 2015 09:25AM |

Registered: 9 years ago Posts: 638 |

Quote

dc42

I have just installed an E3Dv6 in my Duet-powered Kossel, so I can tell you that you need to set the B parameter in the M305 P1 command in config.g to 4267. Despite the heater being only 25W power, it heats up very quickly and the temperature overshoots (I guess that shows how good the thermal break is). So I will be reducing the S factor in that M305 command too.

M305 P1 R4700 H0 L0 ; Put your own H and/or L values here to set the first nozzle thermistor ADC correction ,you mean this? or should i add another M305 line?

|

Re: E3D V6 June 20, 2015 09:27AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Darathy

Quote

dc42

I have just installed an E3Dv6 in my Duet-powered Kossel, so I can tell you that you need to set the B parameter in the M305 P1 command in config.g to 4267. Despite the heater being only 25W power, it heats up very quickly and the temperature overshoots (I guess that shows how good the thermal break is). So I will be reducing the S factor in that M305 command too.

M305 P1 R4700 H0 L0 ; Put your own H and/or L values here to set the first nozzle thermistor ADC correction ,you mean this? or should i add another M305 line?

Yes, add the B4267 parameter to that one.

Edited 1 time(s). Last edit at 06/20/2015 09:27AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D V6 June 20, 2015 09:41AM |

Registered: 9 years ago Posts: 638 |

|

Re: E3D V6 June 20, 2015 02:39PM |

Registered: 9 years ago Posts: 1,159 |

Quote

dc42

Has anyone using the E3D on the Ormerod got high-quality prints with it yet? Since I changed over to it on my delta, I've been getting a lot of very small blobs on the print. The same test print on the Ormerod, and on the delta while it still had the Jhead, is much better. I've tried lower temperature, higher temperature, 6mm retraction (as used on the Jhead), and 2mm retraction (maximum recommended by E3D), all to no avail.

Dave

I have used it on my Prusa I3 with no issues and as you know am having the same probs as you on my delta my changes to external perims first didn't work so back to the drawing board!!

Doug

|

Re: E3D V6 June 21, 2015 03:21PM |

Registered: 9 years ago Posts: 638 |

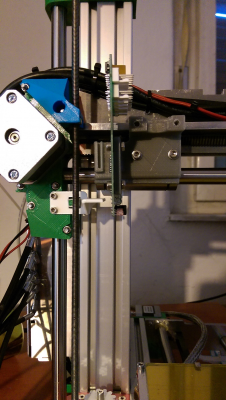

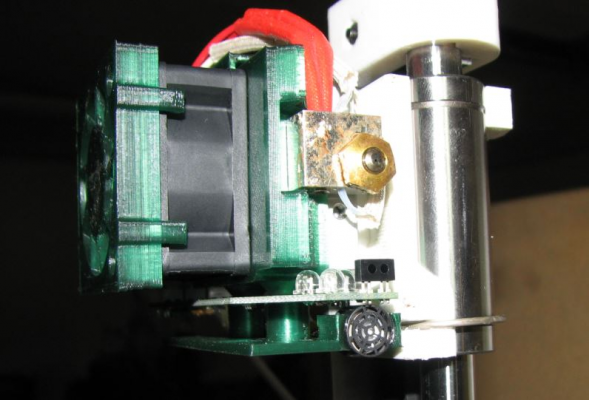

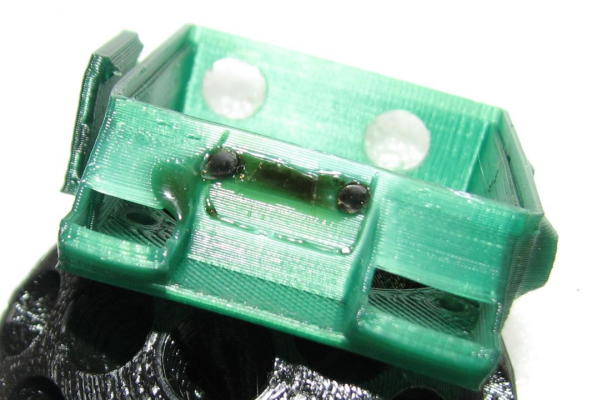

Well i have made a huge mistake.... the person who designed the mounts designed his own X.home pad which he failed to include in the Stl's. Silly me printed Dc's sensor pad and only after asembeling i notice the sensor is lower then the pad...

Now my question is for DC42: Do i turn the Original Hot end away from the new air duct or keep it like it is? It is verry close to the fan duct and it will most probably melt it like you see in the picture:

Should i turn the aluminum part to other side?

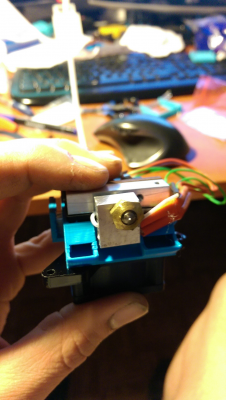

Also i have recived a part i dont know if it is soposed to be used in my E3D:

Looks like pneumatic fiting type for bowden but it is much too big for my hot end.

Excuse the messy table! xD

Edited 2 time(s). Last edit at 06/21/2015 04:13PM by Darathy.

Now my question is for DC42: Do i turn the Original Hot end away from the new air duct or keep it like it is? It is verry close to the fan duct and it will most probably melt it like you see in the picture:

Should i turn the aluminum part to other side?

Also i have recived a part i dont know if it is soposed to be used in my E3D:

Looks like pneumatic fiting type for bowden but it is much too big for my hot end.

Excuse the messy table! xD

Edited 2 time(s). Last edit at 06/21/2015 04:13PM by Darathy.

|

Re: E3D V6 June 21, 2015 04:23PM |

Registered: 9 years ago Posts: 1,159 |

Quote

Darathy

Well i have made a huge mistake.... the person who designed the mounts designed his own X.home pad which he failed to include in the Stl's. Silly me printed Dc's sensor pad and only after asembeling i notice the sensor is lower then the pad...

[attachment 56966 IMAG0256.jpg]

Now my question is for DC42: Do i turn the Original Hot end away from the new air duct or keep it like it is? It is verry close to the fan duct and it will most probably melt it like you see in the picture:

[attachment 56967 IMAG0257.jpg]

Should i turn the aluminum part to other side?

Also i have recived a part i dont know if it is soposed to be used in my E3D:

[attachment 56974 IMAG0258.jpg]

Looks like pneumatic fiting type for bowden but it is much too big for my hot end.

Excuse the messy table! xD

That other part has a 1/8 BSPP thread on it and it is meant for the extruder to form a BOWDEN Setup don't think you will need it I think that is the extra part they supply with there Bowden Hotend (But the hotend itself has the bowden clamp with it It isn't very clear when you order them).

They will self tap into a 9.5 mm hole (If your Careful)

Doug

|

Re: E3D V6 June 21, 2015 04:33PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Darathy

Well i have made a huge mistake.... the person who designed the mounts designed his own X.home pad which he failed to include in the Stl's. Silly me printed Dc's sensor pad and only after asembeling i notice the sensor is lower then the pad...

You can probably make up a temporary sensor pad from cardboard until you can print another one. Or you can home the X axis manually for now, by putting the head at the right position along the X axis and sending G92 X0, and making sure you don't have a G28 command in your slic3r start gcode.

Quote

Darathy

Now my question is for DC42: Do i turn the Original Hot end away from the new air duct or keep it like it is? It is verry close to the fan duct and it will most probably melt it like you see in the picture:

That's the way round I used when I was using that one-piece duct. The clearance should be about 5mm clearance, which is enough.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D V6 June 21, 2015 04:50PM |

Registered: 9 years ago Posts: 638 |

clearance is less then 1mm for me if i have it turned like in the picture, if i turn it araund it does not come anywhere near the spacer thats why i asked ,but i can not get the heater cartridge out ,seems its stuck. so wires gona have to go on the oposite side. My idea was to fit the dual nozzle board to my Original Ormerod hot end and use it to print the new homing pad for the E3D.

Edited 1 time(s). Last edit at 06/21/2015 04:55PM by Darathy.

Edited 1 time(s). Last edit at 06/21/2015 04:55PM by Darathy.

|

Re: E3D V6 June 21, 2015 05:17PM |

Registered: 10 years ago Posts: 14,672 |

I remember now, the clearance is rather tight at the sides; but that's still the way I had it round.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D V6 June 21, 2015 09:12PM |

Registered: 9 years ago Posts: 119 |

|

Re: E3D V6 June 22, 2015 01:55AM |

Registered: 9 years ago Posts: 638 |

|

Re: E3D V6 June 22, 2015 02:46AM |

Registered: 10 years ago Posts: 1,230 |

Quote

dc42

I remember now, the clearance is rather tight at the sides; but that's still the way I had it round.

Ditto, yes it do get a little hot (printed in PLA), the picture was taken after a ABS print

Erik

Sorry, only registered users may post in this forum.