E3D V6

Posted by Darathy

|

Re: E3D V6 June 25, 2015 03:53PM |

Registered: 9 years ago Posts: 638 |

|

Re: E3D V6 June 25, 2015 06:45PM |

Registered: 10 years ago Posts: 14,672 |

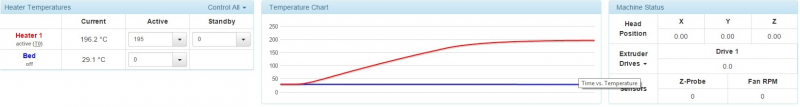

Can you post a graph of your hot end temperature?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D V6 June 26, 2015 04:32PM |

Registered: 9 years ago Posts: 638 |

I find it ok if it overshots it by 1C but i feel like it heats up a lot slower then the original Ormerod hot end. Anyway to increase the speed?

Also if anyone will be printing that E3D mount here is a Sensor pad i designed for DC's sensor

Edited 4 time(s). Last edit at 06/26/2015 04:38PM by Darathy.

Also if anyone will be printing that E3D mount here is a Sensor pad i designed for DC's sensor

Edited 4 time(s). Last edit at 06/26/2015 04:38PM by Darathy.

|

Re: E3D V6 June 26, 2015 05:04PM |

Registered: 10 years ago Posts: 14,672 |

Looks to me like it's flattening off a little too early. If you are using the default PID parameters, try increasing the S term to 1.1 or 1.2, or the I term to 0.1 or 0.2 in the M301 H1 command (add that command if you don't already have it in config.g).

The heater in the E3D is only 25W, so it may be a little slower heating than the Ormerod hot end.

Edited 1 time(s). Last edit at 06/26/2015 05:05PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The heater in the E3D is only 25W, so it may be a little slower heating than the Ormerod hot end.

Edited 1 time(s). Last edit at 06/26/2015 05:05PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D V6 June 27, 2015 05:49AM |

Registered: 10 years ago Posts: 14,672 |

I've just done some investigation, and it looks to me that although E3D say you should use a B value of 4267 in RepRapFirmware for the thermistor they supply, a value of 4388 will give more accurate temperature readings. I will shortly start a new thread on thermistor B values.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D V6 June 28, 2015 06:46AM |

Registered: 9 years ago Posts: 638 |

Thank you for looking into it. Now it seems i get a diferent problem seems like at start of the print when the hot end is heating i get a temp error showing at random.I havent had it do it during printing but during Heating up i had it a few times now. Any ideas what might be cousing it?

|

Re: E3D V6 June 28, 2015 07:16AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Darathy

Thank you for looking into it. Now it seems i get a diferent problem seems like at start of the print when the hot end is heating i get a temp error showing at random.I havent had it do it during printing but during Heating up i had it a few times now. Any ideas what might be cousing it?

Probably a loose thermistor connection. Perhaps you didn't squeeze the crimps tight enough. Or possibly an intermittent short between one of the thermistor wires and the heater block.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D V6 July 03, 2015 04:42PM |

Registered: 9 years ago Posts: 638 |

Quote

dc42

Quote

Darathy

Thank you for looking into it. Now it seems i get a diferent problem seems like at start of the print when the hot end is heating i get a temp error showing at random.I havent had it do it during printing but during Heating up i had it a few times now. Any ideas what might be cousing it?

Probably a loose thermistor connection. Perhaps you didn't squeeze the crimps tight enough. Or possibly an intermittent short between one of the thermistor wires and the heater block.

I redid the Crimps i squized them as tight as i could. Checked the hermistor wires in the heater block they looked covered to tip with the fiberglass. I still get error when print is heating up to temperature and only then, i have had several hour long prints with no errors during those prints. Any more ideas what to check? i am also using on of your Dual nozzle Sensor boards which i installed at the same time as the E3D

Edited 1 time(s). Last edit at 07/03/2015 04:44PM by Darathy.

|

Re: E3D V6 July 04, 2015 07:42AM |

Registered: 10 years ago Posts: 14,672 |

It could be caused by a bad crimp connection on one of the wires connected to the hot end board. Have you tried waggling them, to see if you can induce the fault?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D V6 July 04, 2015 07:56AM |

Registered: 9 years ago Posts: 638 |

|

Re: E3D V6 July 04, 2015 10:41AM |

Registered: 9 years ago Posts: 638 |

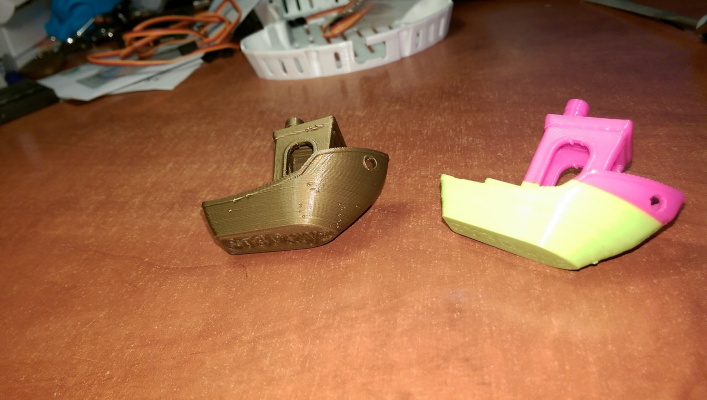

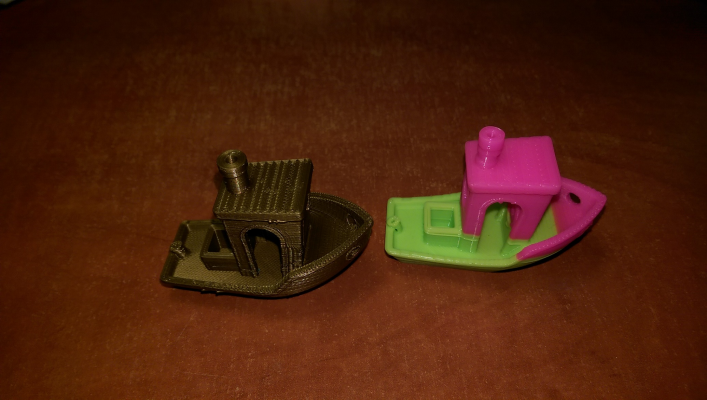

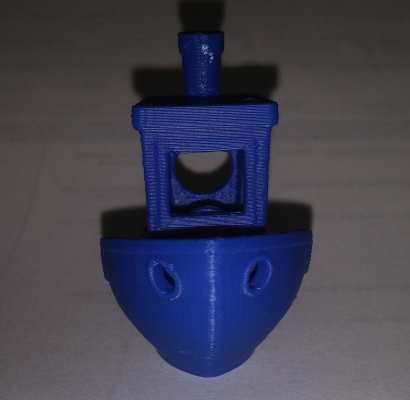

on the other note i have printed 3D Benchy with E3D V6 and i can confirm dc42s problem ,it does seem to make blobs at the layer starting positions retraction didnt seem to help:

I also have ringing issues araund the holes and on 1 side of door.

The green/pink one is printed with Ormerod stock nozzle with no obvius blobs or layer starting positions.

Edited 1 time(s). Last edit at 07/04/2015 10:43AM by Darathy.

I also have ringing issues araund the holes and on 1 side of door.

The green/pink one is printed with Ormerod stock nozzle with no obvius blobs or layer starting positions.

Edited 1 time(s). Last edit at 07/04/2015 10:43AM by Darathy.

|

Re: E3D V6 July 09, 2015 02:45PM |

Registered: 9 years ago Posts: 638 |

I must say i am a little disapointed in Quality i'm getting with E3D ,i expected something a lot better ,i think my Original Ormerod hotend was printing better or its just the diference in 0.5 and 0.4 nozzles , the 0.4 nozzle just doent seem to be able to do overhangs as well as 0.5 and i'm getting blobs on my prints aswell.

|

Re: E3D V6 July 09, 2015 03:12PM |

Registered: 9 years ago Posts: 1,699 |

Or maybe it is just only some wrong slicing settings?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: E3D V6 July 09, 2015 04:45PM |

Registered: 10 years ago Posts: 51 |

|

Re: E3D V6 July 09, 2015 05:27PM |

Registered: 10 years ago Posts: 14,672 |

I am coming to the opinion that the E3Dv6 is less suited to Bowden extruders that the RepRapPro hot ends on my Ormerod 1 or the J head that I had on my delta originally. I am considering using either an E3D lite or a RepRapPro hot end on my delta.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D V6 July 09, 2015 06:36PM |

Registered: 9 years ago Posts: 44 |

|

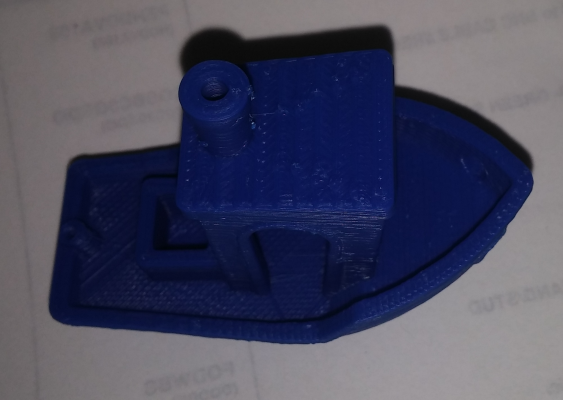

Re: E3D V6 July 13, 2015 07:38PM |

Registered: 9 years ago Posts: 44 |

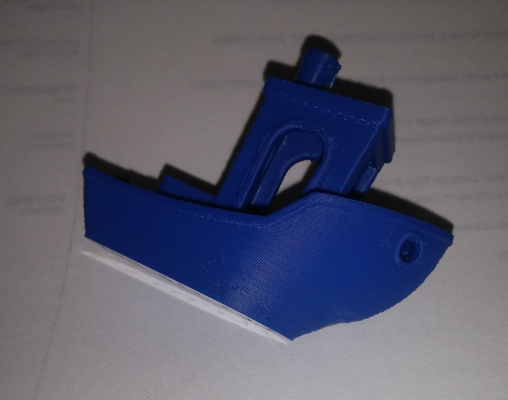

ABS, 0.2mm layers @235C

0.8mm perimeters (likely the cause of deformation area in the bow, an earlier print with 1.2mm walls did not suffer this)

1.6mm retraction

Sliced with Cura.

Edited 1 time(s). Last edit at 07/14/2015 12:20PM by achaz.

0.8mm perimeters (likely the cause of deformation area in the bow, an earlier print with 1.2mm walls did not suffer this)

1.6mm retraction

Sliced with Cura.

Edited 1 time(s). Last edit at 07/14/2015 12:20PM by achaz.

|

Re: E3D V6 July 14, 2015 12:49AM |

Registered: 9 years ago Posts: 1,699 |

What do you use as bed surface?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: E3D V6 July 14, 2015 09:00AM |

Registered: 9 years ago Posts: 44 |

|

Re: E3D V6 July 15, 2015 03:16PM |

Registered: 9 years ago Posts: 638 |

i do see a lot of blobs on your prints too ,altho overall print quality is very nice. I have found the main problem with most of my prints which was Slic3r 1.2.0 onwards to 1.2.9 ,i'm trying with 1.1.7 and it makes much better look quaility but does not completely fill gaps and has a much less efficient moves. I hope they fix the problem with slic3r soon.

Edited 1 time(s). Last edit at 07/15/2015 03:18PM by Darathy.

Edited 1 time(s). Last edit at 07/15/2015 03:18PM by Darathy.

|

Re: E3D V6 July 15, 2015 03:35PM |

Registered: 9 years ago Posts: 44 |

a little blobbing yes, extrusion and retraction fine tuning isn't really my thing, and most of what I print will either have some additional fitting work done anyways (so no problem to clean up a little nubbin on a vertical seam), or will be parts for model combat warships (see rcwarshipcombat.com ) and a little blob isn't a big deal there.

Overall I feel my quality and consistency of print and precision is much better with the e3d. For me a little blobbing (and it isn't as bad as the photos make it look) is no problem. I do think that everyone has to decide what is best for their own needs though, and if blobs are a problem, the e3dv6 may not be a good pickup.

This was the first thing I printed that wasn't a calibration angle or cube after installing the e3d:

I had a few extruder feed problems but overall the result was great compared to what I had been getting off the printer previously which i felt tended to turn everything a bit melty from the nozzles radiant heat.

I've been reasonably happy with Cura (at least until their latest beta release), my biggest gripe has been the support structure and trying to get it to generate support for thin items. You might try Cura 15.x and see if it gets you better results than slic3r.

Edited 2 time(s). Last edit at 07/15/2015 03:41PM by achaz.

Overall I feel my quality and consistency of print and precision is much better with the e3d. For me a little blobbing (and it isn't as bad as the photos make it look) is no problem. I do think that everyone has to decide what is best for their own needs though, and if blobs are a problem, the e3dv6 may not be a good pickup.

This was the first thing I printed that wasn't a calibration angle or cube after installing the e3d:

I had a few extruder feed problems but overall the result was great compared to what I had been getting off the printer previously which i felt tended to turn everything a bit melty from the nozzles radiant heat.

I've been reasonably happy with Cura (at least until their latest beta release), my biggest gripe has been the support structure and trying to get it to generate support for thin items. You might try Cura 15.x and see if it gets you better results than slic3r.

Edited 2 time(s). Last edit at 07/15/2015 03:41PM by achaz.

|

Re: E3D V6 July 15, 2015 03:46PM |

Registered: 9 years ago Posts: 638 |

What i dont like abaut cura is it hard to calibrate anything ,most holes are way too small .while with slic3r i can change almost evrything and get really good hole sizes. I was printing this [www.thingiverse.com] and nothing fitted together ,while with slic3r it did. But cura makes a better support structure and fails to save settings and plugins(not to mention it cant replace existing cura version and i have to remove it by hand) with new releses . I am seriusly thinking of buying Simplify3D ,i've been hearing lots of good things abaut it but the cost is damn expensive....

Edited 1 time(s). Last edit at 07/15/2015 03:47PM by Darathy.

Edited 1 time(s). Last edit at 07/15/2015 03:47PM by Darathy.

|

Re: E3D V6 July 15, 2015 04:28PM |

Registered: 9 years ago Posts: 44 |

Yeah, I can't bring myself to buy S3d either.

The too small-hole thing got better for me after I switched to the e3d, not sure why, but I'm guessing since the Ultimaker ships with a 0.4mm nozzle maybe it internally does some things better for that size than the 0.5? The new beta release of Cura exposes a lot of the underlying settings for adjustment, but I really don't like the UI so haven't played with it much yet.

That ballista is pretty slick, going to have to queue that up

The too small-hole thing got better for me after I switched to the e3d, not sure why, but I'm guessing since the Ultimaker ships with a 0.4mm nozzle maybe it internally does some things better for that size than the 0.5? The new beta release of Cura exposes a lot of the underlying settings for adjustment, but I really don't like the UI so haven't played with it much yet.

That ballista is pretty slick, going to have to queue that up

|

Re: E3D V6 July 15, 2015 06:04PM |

Registered: 9 years ago Posts: 638 |

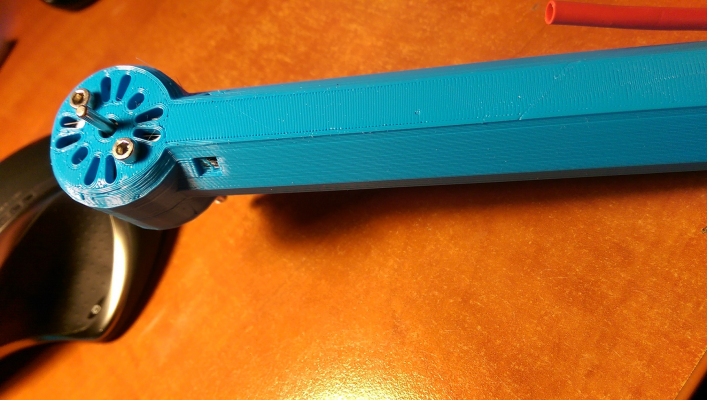

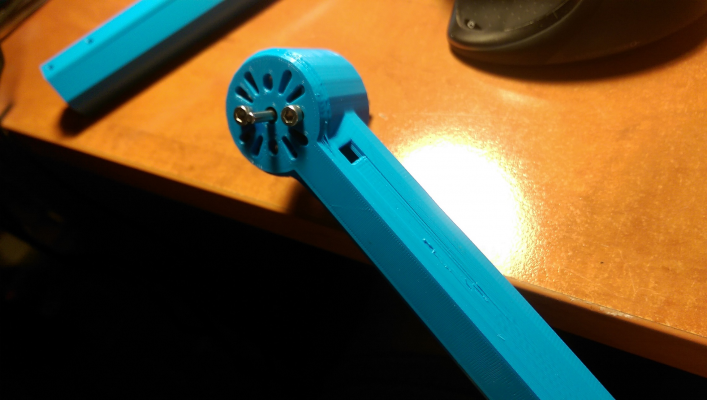

So heres the diference between slic3r 1.2.9 and 1.1.7:

Printed an Arm for [www.thingiverse.com] with same settings for both.

1.2.9:

Sorry i did not disasemble the quad to show you how it looks on the inside.

1.1.7:

(with 1.2.9 the middle part was really messy with overextrusion eventho i have it set to underextrude by a lot)

(it did not fill the small holes where as 1.2.9 does fill them)

Something strange happaned with slic3r after 1.1.7 which couses overextrusion and i hope it gets fixed.

Edited 2 time(s). Last edit at 07/15/2015 06:07PM by Darathy.

Printed an Arm for [www.thingiverse.com] with same settings for both.

1.2.9:

Sorry i did not disasemble the quad to show you how it looks on the inside.

1.1.7:

(with 1.2.9 the middle part was really messy with overextrusion eventho i have it set to underextrude by a lot)

(it did not fill the small holes where as 1.2.9 does fill them)

Something strange happaned with slic3r after 1.1.7 which couses overextrusion and i hope it gets fixed.

Edited 2 time(s). Last edit at 07/15/2015 06:07PM by Darathy.

|

Re: E3D V6 July 15, 2015 07:16PM |

Registered: 9 years ago Posts: 1,699 |

Hey you have the same mice.

Slic3r 1.2.x got some new settings. As I did not experince problems like this and for me the quality is much better I still think that some of the new settings are causing this and it is only a problem with your configuration. Maybe you can post a g-code file or at least the parts showing your set up.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slic3r 1.2.x got some new settings. As I did not experince problems like this and for me the quality is much better I still think that some of the new settings are causing this and it is only a problem with your configuration. Maybe you can post a g-code file or at least the parts showing your set up.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: E3D V6 July 16, 2015 12:35PM |

Registered: 9 years ago Posts: 638 |

|

Re: E3D V6 August 29, 2015 08:43AM |

Registered: 9 years ago Posts: 638 |

I have reverted back to Original Nozzle finding it providing a much better print quality then the E3D  ,now have a spare E3D laying araund. Mybe i will make a delta will see

,now have a spare E3D laying araund. Mybe i will make a delta will see

My personal experiance i dont recomend anyone to upgrade to E3D, but thats just my experiance

Edited 1 time(s). Last edit at 08/29/2015 08:43AM by Darathy.

,now have a spare E3D laying araund. Mybe i will make a delta will see

,now have a spare E3D laying araund. Mybe i will make a delta will see

My personal experiance i dont recomend anyone to upgrade to E3D, but thats just my experiance

Edited 1 time(s). Last edit at 08/29/2015 08:43AM by Darathy.

|

Re: E3D V6 August 29, 2015 10:57AM |

Registered: 9 years ago Posts: 1,699 |

But you had the original one, hadn't you?

I cannot imagine, why your print was not getting better. It would have been nice if you could show us pictures where we can compare your problem. Probably it is only a setting. Or maybe it is the heating cartridge so the Duet is not able to compensate temperature drops during the print. One of thousand possibilities.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I cannot imagine, why your print was not getting better. It would have been nice if you could show us pictures where we can compare your problem. Probably it is only a setting. Or maybe it is the heating cartridge so the Duet is not able to compensate temperature drops during the print. One of thousand possibilities.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: E3D V6 August 29, 2015 01:37PM |

Registered: 9 years ago Posts: 638 |

|

Re: E3D V6 August 29, 2015 02:39PM |

Registered: 10 years ago Posts: 25 |

Someone else having the same problem with S3D. Go here to find their forum suggestions to solve the problem: Blobby problems with ormerod and Simply3D

Sorry, only registered users may post in this forum.