Got problem about the slic3r setting

Posted by jhlee1994

|

Got problem about the slic3r setting June 19, 2015 09:53AM |

Registered: 8 years ago Posts: 76 |

|

Re: Got problem about the slic3r setting June 19, 2015 10:12AM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Got problem about the slic3r setting June 20, 2015 01:14AM |

Registered: 8 years ago Posts: 76 |

|

Re: Got problem about the slic3r setting June 20, 2015 06:34AM |

Registered: 9 years ago Posts: 1,699 |

Two problems with you G-Code:

1. You use absolute Extruder distances. It is recommended to use relative extrusion.

But the main problem is the 2. one:

2. Your filament diameter is indeed set to 3.0 mm. You should try to restart Slic3r and load the settings again.

If you use a good Text-Editor you can check this by yourself. At the end of the file there are the parameters listed.

Find this one and check it. You cannot change here anything this is only for information:

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

1. You use absolute Extruder distances. It is recommended to use relative extrusion.

But the main problem is the 2. one:

2. Your filament diameter is indeed set to 3.0 mm. You should try to restart Slic3r and load the settings again.

If you use a good Text-Editor you can check this by yourself. At the end of the file there are the parameters listed.

Find this one and check it. You cannot change here anything this is only for information:

; filament_diameter = 3

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Got problem about the slic3r setting June 20, 2015 08:51AM |

Registered: 9 years ago Posts: 638 |

|

Re: Got problem about the slic3r setting June 22, 2015 07:47AM |

Registered: 8 years ago Posts: 76 |

|

Re: Got problem about the slic3r setting June 22, 2015 08:17AM |

Registered: 8 years ago Posts: 76 |

|

Re: Got problem about the slic3r setting June 22, 2015 08:51AM |

Registered: 10 years ago Posts: 2,472 |

Quote

jhlee1994

Hi sir, about the raft and support material what is the correct setting if it? And what does the skirt for?

The skirt is the outer circle that is printed around the part. Its main use is just to get the plastic flowing well before starting the print. Usual settings are two or 3 loops and 1 layer high. A raft or a brim is used for objects that have a small footprint to keep them stuck to the bed. Support material is enabled for prints that have big overhangs or unsupported areas that would otherwise be printing in thin air - it automatically adds columns that act as a scaffold to support hanging bits. Rafts, brims and support must be cut off the print after completion. Most objects do not not need raft, brim or support. I suggest that once you get reasonable prints, try printing something 3 times, once without raft or brim, once with a raft and once with a brim, and you will see what they do.

Dave

|

Printing problem June 23, 2015 11:32AM |

Registered: 8 years ago Posts: 76 |

|

Re: Printing problem June 23, 2015 12:36PM |

Registered: 10 years ago Posts: 2,472 |

Quote

jhlee1994

Hi sir, I'd print 2 object the top view is ok but the below surface which is contact with raft and support material wasn't very good quality and have very rough first layer. How can I solve this problem?

A raft and support material will leave marks when removed, so don't use them unless you need to. Cura makes better support than Slic3r.

Dave

|

Re: Printing problem June 24, 2015 12:20AM |

Registered: 8 years ago Posts: 76 |

|

Re: Printing problem June 24, 2015 08:26AM |

Registered: 10 years ago Posts: 2,472 |

Quote

jhlee1994

Hi sir, so in what situation raft and support material are need and in what situation they are no need?

Raft or brim is needed when the part has a very small footprint area or large height to base ratio, support is needed if the part has overhangs greater than about 45 degrees which are not bridges.

Dave

|

Re: Printing problem June 24, 2015 11:04AM |

Registered: 8 years ago Posts: 76 |

|

Re: Printing problem June 24, 2015 11:04AM |

Registered: 8 years ago Posts: 76 |

Hi sir, how to set the cura for the bed setting. I'd convert the stl to gcode and upload it to my printer but from my printer interface the printing object was printed at the corner of the bed.. How can I set it to the center point of my heat bed?

Edited 1 time(s). Last edit at 06/24/2015 11:05AM by jhlee1994.

Edited 1 time(s). Last edit at 06/24/2015 11:05AM by jhlee1994.

|

Re: Printing problem June 25, 2015 08:06AM |

Registered: 10 years ago Posts: 2,472 |

Quote

jhlee1994

Hi sir, how to set the cura for the bed setting. I'd convert the stl to gcode and upload it to my printer but from my printer interface the printing object was printed at the corner of the bed.. How can I set it to the center point of my heat bed?

"Machine" > "Machine Settings" > "RepRap" Set maximum width 200, maximum depth 200, maximum height 200, GCode Flavor=RepRap (Marlin/Sprinter) check heated bed, uncheck "Machine center 0,0"

Dave

|

Re: Printing problem June 25, 2015 11:26AM |

Registered: 8 years ago Posts: 76 |

|

Re: Printing problem June 25, 2015 12:24PM |

Registered: 10 years ago Posts: 2,472 |

Quote

jhlee1994

Why i got this word appear when I was printing :"Setting bed temperature to 56.000000 degrees Celsius.

Setting hotend temperature to 200.000000 degrees Celsius.

Error: invalid M Code: M117 Printing..." After that the printer will stop.

Where did the G-code come from? M117 is the command to display a message which is not supported by the Ormerod, so it seems that you have put that command into the start code in Cura or Slic3r. You cannot use settings that are recommended for other printers - follow the Ormerod instructions and settings.

Dave

|

Re: Printing problem June 26, 2015 03:55AM |

Registered: 8 years ago Posts: 76 |

So you mean my temperature setting wasn't match with the setting on the gcode, so the M117 massages was come out isn't it? All I know is I'd set 210 degree Celsius for tool. 60 for heat bed on the cura. But I was setting 200 for tool and 56 for heatbed in the printer interface. So was it this causing the problem?

|

Re: Printing problem June 26, 2015 07:30AM |

Registered: 10 years ago Posts: 2,472 |

Quote

jhlee1994

So you mean my temperature setting wasn't match with the setting on the gcode, so the M117 massages was come out isn't it? All I know is I'd set 210 degree Celsius for tool. 60 for heat bed on the cura. But I was setting 200 for tool and 56 for heatbed in the printer interface. So was it this causing the problem?

No, that is not what I meant. You should not have any M117 command in your start or end G code. That code is used on another printer to display a message. It is not used with the Ormerod. Your problem has nothing to do with temperature setting.

Dave

|

Re: Printing problem June 26, 2015 11:34AM |

Registered: 8 years ago Posts: 76 |

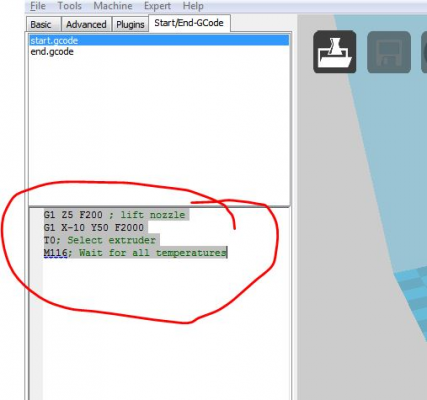

If you mention this... I'd notice something at the cura setting's start.gcode

This is what I got :

";Sliced at: {day} {date} {time}

;Basic settings: Layer height: {layer_height} Walls: {wall_thickness} Fill: {fill_density}

;Print time: {print_time}

;Filament used: {filament_amount}m {filament_weight}g

;Filament cost: {filament_cost}

;M190 S{print_bed_temperature} ;Uncomment to add your own bed temperature line

;M109 S{print_temperature} ;Uncomment to add your own temperature line

G21 ;metric values

G90 ;absolute positioning

M82 ;set extruder to absolute mode

M107 ;start with the fan off

G28 X0 Y0 ;move X/Y to min endstops

G28 Z0 ;move Z to min endstops

G1 Z15.0 F{travel_speed} ;move the platform down 15mm

G92 E0 ;zero the extruded length

G1 F200 E3 ;extrude 3mm of feed stock

G92 E0 ;zero the extruded length again

G1 F{travel_speed}

;Put printing message on LCD screen

M117 Printing..."

So what should I do to it

This is what I got :

";Sliced at: {day} {date} {time}

;Basic settings: Layer height: {layer_height} Walls: {wall_thickness} Fill: {fill_density}

;Print time: {print_time}

;Filament used: {filament_amount}m {filament_weight}g

;Filament cost: {filament_cost}

;M190 S{print_bed_temperature} ;Uncomment to add your own bed temperature line

;M109 S{print_temperature} ;Uncomment to add your own temperature line

G21 ;metric values

G90 ;absolute positioning

M82 ;set extruder to absolute mode

M107 ;start with the fan off

G28 X0 Y0 ;move X/Y to min endstops

G28 Z0 ;move Z to min endstops

G1 Z15.0 F{travel_speed} ;move the platform down 15mm

G92 E0 ;zero the extruded length

G1 F200 E3 ;extrude 3mm of feed stock

G92 E0 ;zero the extruded length again

G1 F{travel_speed}

;Put printing message on LCD screen

M117 Printing..."

So what should I do to it

|

Re: Printing problem June 26, 2015 11:35AM |

Registered: 8 years ago Posts: 76 |

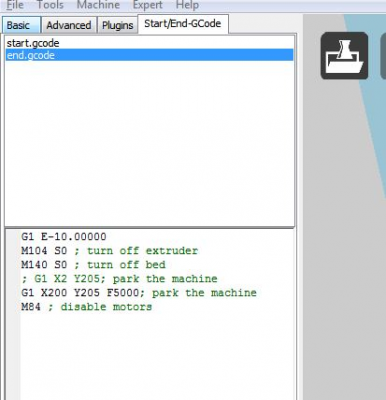

And the End g.code is as above:

";End GCode

M104 S0 ;extruder heater off

M140 S0 ;heated bed heater off (if you have it)

G91 ;relative positioning

G1 E-1 F300 ;retract the filament a bit before lifting the nozzle, to release some of the pressure

G1 Z+0.5 E-5 X-20 Y-20 F{travel_speed} ;move Z up a bit and retract filament even more

G28 X0 Y0 ;move X/Y to min endstops, so the head is out of the way

M84 ;steppers off

G90 ;absolute positioning

;{profile_string}"

";End GCode

M104 S0 ;extruder heater off

M140 S0 ;heated bed heater off (if you have it)

G91 ;relative positioning

G1 E-1 F300 ;retract the filament a bit before lifting the nozzle, to release some of the pressure

G1 Z+0.5 E-5 X-20 Y-20 F{travel_speed} ;move Z up a bit and retract filament even more

G28 X0 Y0 ;move X/Y to min endstops, so the head is out of the way

M84 ;steppers off

G90 ;absolute positioning

;{profile_string}"

|

Re: Printing problem June 26, 2015 12:11PM |

Registered: 8 years ago Posts: 76 |

|

Re: Got problem about the slic3r setting June 26, 2015 01:05PM |

Registered: 10 years ago Posts: 2,472 |

I do not know where you got those settings. They are not for the Ormerod. I no longer have the Cura settings I used to use, perhaps someone can post suitable ones. Meanwhile if you do not understand what the settings mean, you should use Slic3r with the settings suggested by RRP - except increase filament retraction to 4mm (I think the recommended setting is 1mm which is too small).

Dave

Dave

|

Re: Printing problem June 27, 2015 11:38PM |

Registered: 8 years ago Posts: 76 |

|

Re: Got problem about the slic3r setting June 28, 2015 05:31AM |

Registered: 9 years ago Posts: 638 |

|

Re: Printing problem June 28, 2015 07:47AM |

Registered: 8 years ago Posts: 76 |

|

Re: Printing problem June 28, 2015 08:24AM |

Registered: 9 years ago Posts: 638 |

|

Re: Printing problem June 29, 2015 01:22AM |

Registered: 8 years ago Posts: 76 |

|

Re: Printing problem June 29, 2015 02:06AM |

Registered: 9 years ago Posts: 1,699 |

Quote

Darathy

i think so, i think it mainly enables Relative extruder moves and retraction per layer change. but you will have to apply it evrytime you update cura(since it can not upgrade its previus version -.-, atleast slicer keeps configs after you update...)

That is nearly perfect. It also adds the possibility to change the temperatures after the first layer. But I would not use it anymore as you can get other problems especially at the end or if you pause. In roughly 12 hours I could provide my settings for absolute extrusion if demanded. BTW recent versions of Cura supports retraction on layer change as well. Maybe not so good as the plug-in but it does the job.

There should be no difference between Ormerod 1+2 in this case. The changes between them does not effect the Cura slicing settings.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Printing problem June 29, 2015 02:49AM |

Registered: 10 years ago Posts: 1,230 |

Quote

jhlee1994

How can I apply the setting to my cura? i'd try a lot of time but still don't get it.

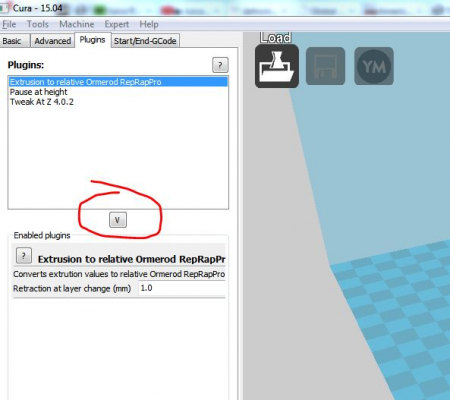

Copy the EAtoR.py to your (e.g. on my system) C:\Program Files (x86)\Cura_15.04\plugins, start the program, go to plugins, highlight the "extrustion to relative Ormerod RepRapPro" plugin and press the ad button

open the cura start/end-Gcode menu, chose the start code, copy over the text from your slic3r settings start code

ditto end Gcode

Erik

Sorry, only registered users may post in this forum.