Got problem about the slic3r setting

Posted by jhlee1994

|

Re: Printing problem June 29, 2015 03:05AM |

Registered: 8 years ago Posts: 76 |

|

Re: Printing problem June 29, 2015 03:16AM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Printing problem June 29, 2015 05:01AM |

Registered: 8 years ago Posts: 76 |

|

Re: Printing problem June 29, 2015 06:16AM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Printing problem June 29, 2015 06:45AM |

Registered: 8 years ago Posts: 76 |

|

Re: Printing problem June 29, 2015 07:39AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Printing problem June 29, 2015 07:40AM |

Registered: 9 years ago Posts: 638 |

thank you I forgot to write how to instal itQuote

ormerod168

Quote

jhlee1994

How can I apply the setting to my cura? i'd try a lot of time but still don't get it.

Copy the EAtoR.py to your (e.g. on my system) C:\Program Files (x86)\Cura_15.04\plugins, start the program, go to plugins, highlight the "extrustion to relative Ormerod RepRapPro" plugin and press the ad button

[attachment 57262 curaadplugin.JPG]

open the cura start/end-Gcode menu, chose the start code, copy over the text from your slic3r settings start code

[attachment 57263 curastartcode.JPG]

ditto end Gcode

[attachment 57264 curaendcode.JPG]

Erik

|

Re: Printing problem June 29, 2015 08:27AM |

Registered: 8 years ago Posts: 76 |

|

Re: Printing problem June 29, 2015 09:34AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Printing problem June 29, 2015 11:41AM |

Registered: 8 years ago Posts: 76 |

Sir, I still got problem. I'd use the start gcode and end g.code which is eric give me. Same thing happen with T0, the hot extruder never extrude filament out. In another case, with T1 it work but just a while and the extruder stop extrude filament and it's still continue printing.

Edited 1 time(s). Last edit at 06/29/2015 11:42AM by jhlee1994.

Edited 1 time(s). Last edit at 06/29/2015 11:42AM by jhlee1994.

|

Re: Got problem about the slic3r setting June 29, 2015 11:58AM |

Registered: 10 years ago Posts: 1,230 |

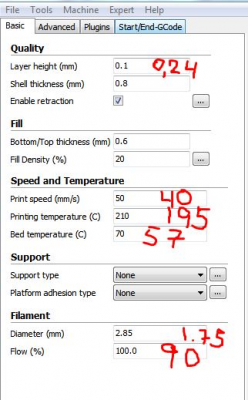

As Dave said, the default setting will get you printing, just make sure to change the filament diameter (2.85) to 1.75 and nozzle size (0.4) to 0.5, this is what I would change for starters (Cura filament flow same as Slic3r's extrusion multiplier)

Erik

Erik

|

Re: Printing problem June 30, 2015 04:53AM |

Registered: 8 years ago Posts: 76 |

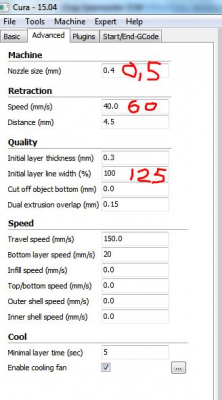

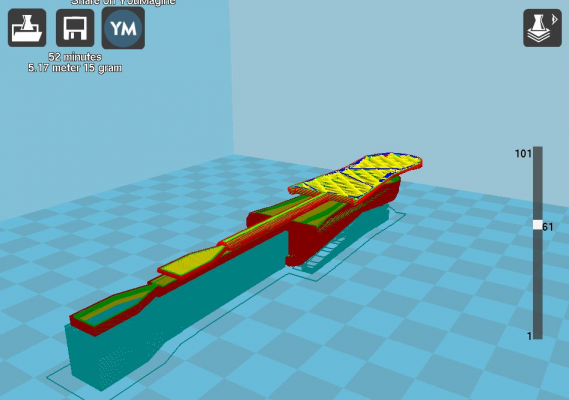

I'd follow the setting that Erik show me. But it seem's come out like this. I'd sent the setting over at here. Please help me see where go wrong.

|

Re: Printing problem June 30, 2015 04:59AM |

Registered: 8 years ago Posts: 76 |

|

Re: Got problem about the slic3r setting June 30, 2015 07:28AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Got problem about the slic3r setting June 30, 2015 12:06PM |

Registered: 10 years ago Posts: 1,230 |

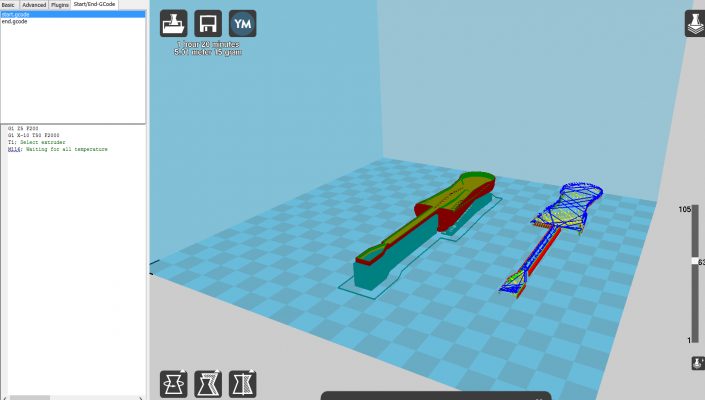

Yes that do look strange, has hardly anything to do with your Cura settings - please post the STL, make a multi volume zip file if over the file size limit - or post a link if you got it from another site

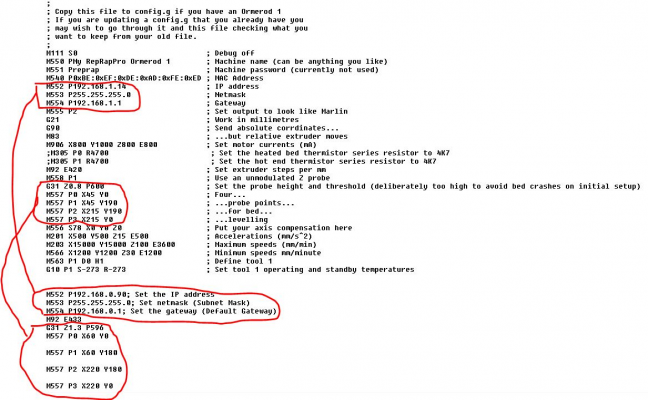

..and post your config.g and printer firmware version as well - I see your start gcode list the extruder as T1, the numbering of tools was change in later firmware, first extruder used to be T1, is now T0

Erik

..and post your config.g and printer firmware version as well - I see your start gcode list the extruder as T1, the numbering of tools was change in later firmware, first extruder used to be T1, is now T0

Erik

|

Re: Got problem about the slic3r setting July 02, 2015 06:14AM |

Registered: 8 years ago Posts: 76 |

|

Re: Got problem about the cura slic3r setting July 02, 2015 06:18AM |

Registered: 8 years ago Posts: 76 |

|

Re: Got problem about the slic3r setting July 02, 2015 08:49AM |

Registered: 10 years ago Posts: 2,472 |

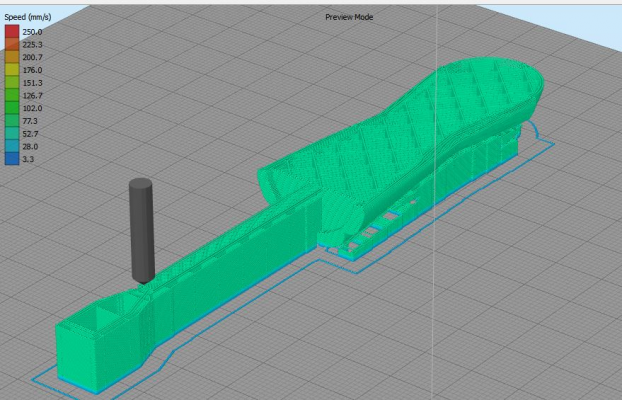

That design is very difficult to print as shown, because there are huge overhangs and very little bed contact. The lower half would need to be encased in support material, and even then is unlikely to print well, and the support will be difficult to remove. It is therefore not surprising that you are having problems. If I were making such an object, I would print it in two halves and glue the halves together. I have attached a modified STL showing what I mean. Print this object twice, and glue together. It will not need a raft, but support will be required for the bottom flutes. I print with ABS and use acetone to glue, but I believe superglue works well for PLA.

3D printing is a great way to make things, but like all tools it has limitations and so you must adapt your designs so that they are suitable for that type of manufacturing. In most cases it will be possible to print the part in sections and glue or bolt together afterwards.

Dave

3D printing is a great way to make things, but like all tools it has limitations and so you must adapt your designs so that they are suitable for that type of manufacturing. In most cases it will be possible to print the part in sections and glue or bolt together afterwards.

Dave

|

Temperature problem while printing using ABS July 02, 2015 09:19AM |

Registered: 8 years ago Posts: 76 |

|

Re: Got problem about the slic3r setting July 02, 2015 09:23AM |

Registered: 8 years ago Posts: 76 |

|

Re: Got problem about the slic3r setting July 02, 2015 09:30AM |

Registered: 8 years ago Posts: 76 |

|

Re: Got problem about the slic3r setting July 02, 2015 09:33AM |

Registered: 8 years ago Posts: 76 |

|

Re: Got problem about the slic3r setting July 02, 2015 09:48AM |

Registered: 8 years ago Posts: 76 |

|

Re: Got problem about the slic3r setting July 02, 2015 01:43PM |

Registered: 10 years ago Posts: 2,472 |

Quote

jhlee1994

Sir, I think the problem is pretty obvious at my cura setting. I put other stl file at it, it still the same. infill still at outside.

You must have a different version of Cura to mine. My version does not display the G-paths. If there is infill on the base and top, it means you have the shell thickness set to 0. Why not use Slic3r?

I use an LED PSU turned up to 14 volts, and the bed heats to 110 degrees in a few minutes. I print with bed at 110 deg first layer, then 95 deg for the rest. Acetone is available from shops that sell fibreglass materials. I do not recommend nail polish remover as it usually contains added oil. If you cannot get acetone, you can use solvent cement (used to join plastic water pipes) - available from most hardware and DIY stores. Plastic model cement will probably also work (I have not tried).

But I suggest you try with PLA first. ABS brings its own set of problems.

If your bed is not heating enough, put a sheet of cardboard or foam over it while it is heating, and remove just before printing.

Dave

|

Re: Got problem about the cura slic3r setting July 02, 2015 02:30PM |

Registered: 10 years ago Posts: 1,230 |

Quote

jhlee1994

And here is the firmware. the config.g also inside this folder

Your config.g look a bit messy with double commands but (without knowing) I guess the later overrules the first ones

You said the snowman.g printed OK and you have M563 P1 D0 H1 in you config.g so T1 should be right

Yes the screwdriver looks weird in Cura 14.09:

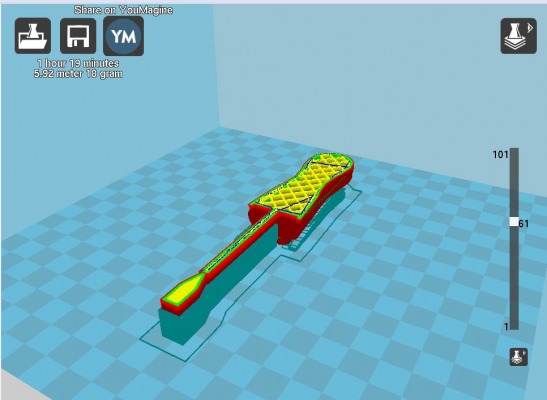

but ok in Cura 15.04:

and with Simplify3D's viewer the Cura 14.09 sliced file looks fine so its only a fault in Cura's viewer, the file should print ok

BTW, forgot to say that the shell thickness should be a multiple of the nozzle size, so change that from the 0.8 to 1 or 1.5

Erik

|

Printing problem with ABS July 03, 2015 11:31AM |

Registered: 8 years ago Posts: 76 |

So you mean I should put a piece of cardboard or foam at the top of the glass printing surface until the temperature reach 110 degree Celsius. I think my heat bed max is 100+ but need quite long time. At the printing the temperature keep dropping, this is the big problem. I always need to pause and heat up the heat bed. then I can continue. This was delay my finishing time

|

Re: Printing problem with ABS July 03, 2015 11:58AM |

Registered: 10 years ago Posts: 2,472 |

Quote

jhlee1994

So you mean I should put a piece of cardboard or foam at the top of the glass printing surface until the temperature reach 110 degree Celsius. I think my heat bed max is 100+ but need quite long time. At the printing the temperature keep dropping, this is the big problem. I always need to pause and heat up the heat bed. then I can continue. This was delay my finishing time

With ABS the high temperature is only needed for the first layer to get good adhesion - 100 degrees should be OK. After the first layer it can drop quite a bit and still print OK - though don't go below 80 degrees. It will be easier to get a higher temperature in the hot weather.

Dave

|

Re: Printing problem with ABS July 04, 2015 04:26AM |

Registered: 8 years ago Posts: 76 |

I'd tried to put a cardboard while heat up the heat bed. Well it's come effectively. But at printing the first layer it keep dropping greatly and I gonna keep pause and heat the heat bed up again with cover with cardboard. It's dropping till 98 degree just the raft first layer only. I think the heat escape from the heatbed was faster than it's generate. I think maybe it's the environment issue or something else

|

Re: Printing problem with ABS July 04, 2015 04:30AM |

Registered: 8 years ago Posts: 76 |

|

Re: Printing problem with ABS July 04, 2015 05:58AM |

Registered: 9 years ago Posts: 1,699 |

Two days ago I found the optimal print solution for me. Using Simplify3D my printing speed is set up to 70mm/s. Perimeters at 80%, solid infill at 90%. Most important: First layer at 25%. Bed temperature: I am starting at 100° and after the first layer I set it up to 120° even though I know that I am not able to reach this temperature, but my bed is keeping heating without pause. During the printing 105° is the maximum that I can reach. If I pause I can reach up to 115°.

As you can see that my settings totally differs from the settings you normally should do except for the first layer speed. So nobody can really tell you what you should do. By the way my settings even work with Kapton tape as I crashed my BuildTak (RIP) yesterday. I have still one but as long as Kapton tape works...

Edited 2 time(s). Last edit at 07/04/2015 05:59AM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

As you can see that my settings totally differs from the settings you normally should do except for the first layer speed. So nobody can really tell you what you should do. By the way my settings even work with Kapton tape as I crashed my BuildTak (RIP) yesterday. I have still one but as long as Kapton tape works...

Edited 2 time(s). Last edit at 07/04/2015 05:59AM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.