Got problem about the slic3r setting

Posted by jhlee1994

|

Re: Got problem about the slic3r setting July 05, 2015 09:18AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Printing problem with ABS July 11, 2015 04:31AM |

Registered: 8 years ago Posts: 76 |

|

Re: Printing problem with ABS July 11, 2015 06:42AM |

Registered: 10 years ago Posts: 1,230 |

Quote

jhlee1994

Was it the ormerod 1 got feature to insulate the heat? I think this heatbed got design some feature for it. And now I'd observe that my bed supporter which is made by wood was sinking. Was it that got do with the bed insulate heat?

I don't think the heat has much to do with it but it won't harm to reduce the heat loss,

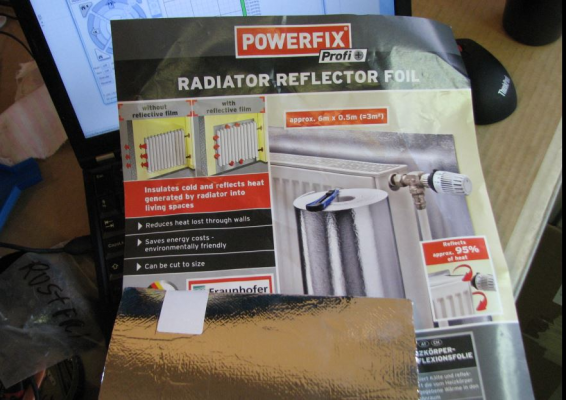

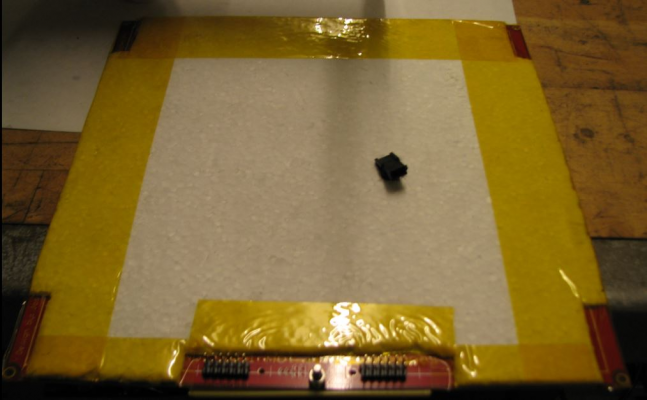

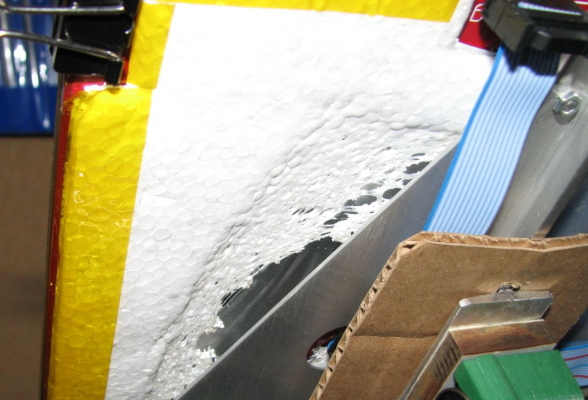

I use radiator foil under the bed as isolator..

...reflective side up and sealed around the heatbed with kapton tape

with 11V (measured at heatbed in) and a slice of cardboard on top of the bed it reach 110 degrees in 10 minutes

..and 150 degrees in 20 minutes but not going to do that again :-)

Erik

|

Re: Printing problem with ABS July 12, 2015 02:56AM |

Registered: 8 years ago Posts: 76 |

|

Re: Printing problem with ABS July 12, 2015 03:01AM |

Registered: 8 years ago Posts: 76 |

|

Re: Printing problem with ABS July 13, 2015 03:14PM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Printing problem with ABS July 14, 2015 11:26AM |

Registered: 8 years ago Posts: 76 |

|

Re: Printing problem with ABS July 14, 2015 12:10PM |

Registered: 10 years ago Posts: 1,230 |

Quote

jhlee1994

I'd apply a layer of aluminium foil it's performance better already maximum can reach 90 degree. I think the aluminium foil wasn't heavy duty...

used as a reflector it doesn't matter, and I was wrong, the foil on the product I use is actually only 0,03-4mm thick

Quote

..or can I just change my power supply into 13V? But I'm afraid the arduino got burn off

As far as I know the Duet can handle a lot more than that, I think dc42 d wrote that the fan is the weak link and you can reduce the voltage to that with a diode or two in series

Erik

|

Re: Printing problem with ABS July 15, 2015 11:36PM |

Registered: 8 years ago Posts: 76 |

|

Slic3r setting problem July 17, 2015 08:04AM |

Registered: 8 years ago Posts: 76 |

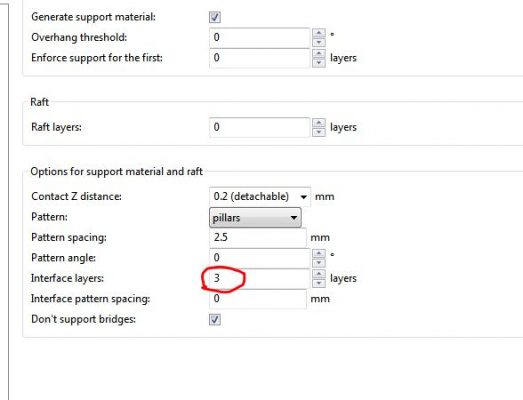

For the slic3r 1-2-9 version there is contact z distance in the print setting, what should I put for this? 0.2 the support material will be detachable to the object. Now I'm facing the problem is I'm printing a tube so inside the tube hole got the support material, but it's attached to the inner surface. I can't remove it

Edited 1 time(s). Last edit at 07/17/2015 08:05AM by jhlee1994.

Edited 1 time(s). Last edit at 07/17/2015 08:05AM by jhlee1994.

|

Re: Slic3r setting problem July 17, 2015 10:40AM |

Registered: 10 years ago Posts: 1,230 |

Quote

jhlee1994

For the slic3r 1-2-9 version there is contact z distance in the print setting, what should I put for this? 0.2 the support material will be detachable to the object..

I have this setting at 0.4 In SF3D but thats just the default setting

Quote

Now I'm facing the problem is I'm printing a tube so inside the tube hole got the support material, but it's attached to the inner surface. I can't remove it

if you mean "attached to the inner vertical surface" is guess this is the setting you should adjust but 3 layers should be plenty if not sagging be cause of excessive heat that is:

Erik

|

Cura setting problem July 18, 2015 10:40AM |

Registered: 8 years ago Posts: 76 |

I'd do the setting according to your instruction, but the extruder wasn't working. after homing the extruder retract the filament 5mm while printing start the extruder got extrude back 5mm after that it wasn't work but the printing process still on.

Edited 1 time(s). Last edit at 07/18/2015 10:40AM by jhlee1994.

Edited 1 time(s). Last edit at 07/18/2015 10:40AM by jhlee1994.

|

Re: Cura setting problem July 19, 2015 10:28AM |

Registered: 8 years ago Posts: 76 |

|

Re: Cura setting problem July 19, 2015 02:16PM |

Registered: 10 years ago Posts: 1,230 |

Quote

jhlee1994

Was it my setting in the machine setting went wrong? would you check and guide me.

the easiest way for you to get printing would be to share a profile you could import but its long time since I sliced and printed anything with Cura and not sure my setup is up to date

Anyone got a known working Cura profile to share?....pretty please?

Erik

|

Re: Got problem about the slic3r setting July 20, 2015 03:22PM |

Registered: 10 years ago Posts: 1,230 |

Ok, could not get the latest Cura version going so installed ver. 15.04 instead, sliced a test file and everything worked from start to finish, activated hotend, waited for bed and hotend temperatures, the print, to parking the machine

I use David's PanelDue to control the printer so had to test this first to be sure that it work

I have attached the Cura 15.04 ini file, you can load in the files menu/open profile

also attached EAtoR.py, copy the files to your plugin folder (e.g. on my system the path is:C:\Program Files (x86)\Cura_15.04\plugins)

firmware installed is David's RepRapFirmware-1.09a-dc42.bin

..and my config.g, use it for reference only

hope you get it going, fingers crossed :-)

Erik

I use David's PanelDue to control the printer so had to test this first to be sure that it work

I have attached the Cura 15.04 ini file, you can load in the files menu/open profile

also attached EAtoR.py, copy the files to your plugin folder (e.g. on my system the path is:C:\Program Files (x86)\Cura_15.04\plugins)

firmware installed is David's RepRapFirmware-1.09a-dc42.bin

..and my config.g, use it for reference only

M111 S0; Debug off M550 POrmerod168 ; Machine name (can be anything you like) M551 Preprap ; Machine password M552 P192.168.1.14 ; IP address M553 P255.255.255.0 ; Netmask M554 P192.168.1.1 ; Gateway M555 P2 ; Set output to look like Marlin G21 ; Work in millimetres G90 ; Send absolute coordinates M83 ; relative extruder moves M906 X1000 Y1200 Z800 E1200 ; Set motor currents (mA) M563 P0 D0 H1 ; Define tool 1 G10 P1 S0 R0 ; Set tool 1 operating and standby temperatures M92 E420 ; Set extruder steps per mm M558 P1 ; Use an unmodulated Z probe or an intelligent Z probe G31 Z0.75 P500 ; Set the probe height and threshold (put your own values here) M201 X800 Y800 Z15 E3600 ; Accelerations (mm/s^2) M556 S78 X0 Y0 Z0 ; axis compensation M203 E3600 ; Maximum speeds (mm/min) M566 X1800 Y1800 Z30 E20 ; maximum jerk speed mm/minute(i.e. maximum instantaneous change in speed) M208 X210 Y205 ; set axis travel M208 X 0 S1 ; set axis minimum M574 X0 Y2 Z0 S1 T0

hope you get it going, fingers crossed :-)

Erik

|

Re: Slic3r setting problem July 26, 2015 04:53AM |

Registered: 8 years ago Posts: 76 |

|

Re: Slic3r setting problem July 27, 2015 09:36AM |

Registered: 10 years ago Posts: 2,472 |

Quote

jhlee1994

I got some trouble at printing using slic3r. Sometimes the filament can't come out and extruder just keep extruding

Could you describe the issue in more detail. Under what circumstances? What print speed and other settings were you using?

Could be caused by several things. (1) print speed too fast. (2) hotend too cold. (3) Partially blocked nozzle (4) Bad filament size (5) clogged Hobbed part and a few other things.

Dave

|

Re: Slic3r setting problem July 27, 2015 11:55PM |

Registered: 8 years ago Posts: 76 |

|

Re: Slic3r setting problem July 28, 2015 03:41AM |

Registered: 9 years ago Posts: 1,699 |

You should change the temperature of the other layers otherwise your heater are turned off after the first layer according to your settings right now.

Edit: And please also try only half or even quarter of your print speed. Youi are way to fast. Over 50mm/s you will get artifacts.

Edited 1 time(s). Last edit at 07/28/2015 03:43AM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Edit: And please also try only half or even quarter of your print speed. Youi are way to fast. Over 50mm/s you will get artifacts.

Edited 1 time(s). Last edit at 07/28/2015 03:43AM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Got problem about the slic3r setting July 28, 2015 10:10AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Slic3r setting problem July 30, 2015 04:37AM |

Registered: 8 years ago Posts: 76 |

|

Re: Slic3r setting problem July 30, 2015 06:39AM |

Registered: 9 years ago Posts: 1,699 |

All speeds. Any speed (except for travel speed) above 50mm/s causes artifacts and above 60mm/s it may skip the extruder (even though i reached 70mm/s for perimeters).

At the beginning it is a good idea to print small objects witn 30mm/s as long as you find the right settings like temperature, bed leveling and so on. Only if you have good results here you can increase the speed. Otherwise it will be hard to define errors.

At Simplify3D the perimter speed is the maximum and all other speeds are lower than this. Simplify3D gives better print results than Slic3r, in my eyes.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

At the beginning it is a good idea to print small objects witn 30mm/s as long as you find the right settings like temperature, bed leveling and so on. Only if you have good results here you can increase the speed. Otherwise it will be hard to define errors.

At Simplify3D the perimter speed is the maximum and all other speeds are lower than this. Simplify3D gives better print results than Slic3r, in my eyes.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Got problem about the slic3r setting July 30, 2015 11:49AM |

Registered: 10 years ago Posts: 2,472 |

Skipping is caused when the printer tries to push plastic too fast. There are three settings that affect how fast the plastic must be extruded. The first is print speed (which is easiest to adjust as it can be changed on the fly), the second is extrusion width (which needs to be kept reasonably close to the nozzle diameter), and the third is layer height. The greater the layer height or extrusion width, the slower you are able to print. Infill is usually printed with a slightly thicker extrusion width than perimeters, which is why the max speed is higher for perimeters, though faster speed reduces surface quality so it is usually best to limit that speed as well. If you want to print with a very fine layer height you will be able to increase the print speed before the extruder skips (though the print will still take considerably longer than when printed with thicker layers)

Dave

Dave

|

Re: Slic3r setting problem July 31, 2015 01:37AM |

Registered: 8 years ago Posts: 76 |

But I can't set the bed temperature at the slic3r setting or it'll take a long time to heat plus the temperature can't stable at 110 degree it'll drop after a while. this keep bothering me while I need to print big part. Now the small part wasn't a issue. But the bigger one. I post the file to you better for you to understand. This is the file I want to print but due to the heat problem, it can't print the first layer finish before the temp drop till below 100 degree

|

Re: Slic3r setting problem July 31, 2015 04:31AM |

Registered: 9 years ago Posts: 1,699 |

As I said I would first start with similar prints as you get more problems with bigger parts. Do you have a source where you get this file?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Slic3r setting problem July 31, 2015 07:08AM |

Registered: 10 years ago Posts: 2,472 |

Quote

jhlee1994

But I can't set the bed temperature at the slic3r setting or it'll take a long time to heat plus the temperature can't stable at 110 degree it'll drop after a while. this keep bothering me while I need to print big part. Now the small part wasn't a issue. But the bigger one. I post the file to you better for you to understand. This is the file I want to print but due to the heat problem, it can't print the first layer finish before the temp drop till below 100 degree

Then set the highest bed temperature that you can achieve and see if it prints OK. If that's not enough, you can try putting a tent partially over the printer (e.g. plastic bin bag) to retain some heat, or do as many of us have done who print ABS and replace the power supply with one that can be adjusted to 14 volts or so. There are 12V LED power supplies that can be adjusted that are not too expensive. The maximum bed temperature will follow the room temperature - e.g. a bed that can only reach 100 degrees in a room temperature of 15 degrees will be able to reach 110 degrees in a room that is 25 degrees. A hot room will also decrease warping. Another very important thing is to prevent any draft over the bed. I once opened the door of the room while printing and the draft it made caused the print to almost instantly warp.

Dave

|

Re: Slic3r setting problem July 31, 2015 09:30AM |

Registered: 8 years ago Posts: 76 |

Treito, here is the link where I download this file :[www.thingiverse.com]

I want to print this cause the original design of filament spool was not very good.

After I put the filament at the spool which is install at the duet enclose base, the whole thing was fall down, also my wiring also disconnected from the duet because of this. The filament was too heavy to sit on it

Edited 3 time(s). Last edit at 07/31/2015 09:36AM by jhlee1994.

I want to print this cause the original design of filament spool was not very good.

After I put the filament at the spool which is install at the duet enclose base, the whole thing was fall down, also my wiring also disconnected from the duet because of this. The filament was too heavy to sit on it

Edited 3 time(s). Last edit at 07/31/2015 09:36AM by jhlee1994.

|

Re: Slic3r setting problem July 31, 2015 09:42AM |

Registered: 8 years ago Posts: 76 |

dmould, what about a room temperature of 30+-? Cause my country wasn't has 4 season but just summer whole year. Can the duet can stand 14V? last time the instruction tell not to go more than 13.5V. I also afraid it got burn off. I'd experience once, It's quite messy but I'd manage to repair it up.

|

Re: Slic3r setting problem July 31, 2015 10:10AM |

Registered: 10 years ago Posts: 14,672 |

Quote

jhlee1994

... Can the duet can stand 14V? last time the instruction tell not to go more than 13.5V. I also afraid it got burn off. I'd experience once, It's quite messy but I'd manage to repair it up.

The Duet can easily take 14V, in fact the Huxley Duo and the Fisher run it at 19V. Preferably, you should put a couple of silicon rectifier diodes in series with the hot end fan to reduce the voltage it gets back to 12V.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Slic3r setting problem July 31, 2015 12:46PM |

Registered: 9 years ago Posts: 1,699 |

Thanks, but this is too complicated for me as i am looking for a simplified thing. For that reason I want to use this: [www.thingiverse.com]

For the moment I use this [www.thingiverse.com] but if the spool is full it is loosing the coils and they are tightened below the spool. First I did not understand why everybody uses a standing holder, know I now it.

And also no hot summer at the moment? That can indeed makes trouble. Maybe you should turn on your heating.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.