Keep little fingers safe!

Posted by droftarts

|

Keep little fingers safe! July 07, 2015 11:09AM |

Registered: 12 years ago Posts: 1,611 |

A customer, Marco, sent me these two designs for shrouds around the Y motor pulley and extruder, to keep inquisitive little fingers out of harms way, and so avoid ruining prints! His comments:

what do you think about these my two designs?

[www.thingiverse.com]

[www.thingiverse.com]

they are very usefull to avoid baby fingers damage

Ian

RepRapPro tech support

what do you think about these my two designs?

[www.thingiverse.com]

[www.thingiverse.com]

they are very usefull to avoid baby fingers damage

Ian

RepRapPro tech support

|

Re: Keep little fingers safe! July 07, 2015 11:35AM |

Registered: 9 years ago Posts: 1,699 |

Hello,

in my opinion it is indeed a good idea to add these if you have little child, but that is far away from being enough. There are fans, the x-carriage, the hot-end itself and so on. First of all I have to say that I have no children but in my eyes it is most important that you keep the printer out of reach of children. I think especially the hot-end can be very interesting. So you may add these covers but it is more important to keep the child away from the printer (seperate room for example) or otherwise do not use it.

Regards,

Sven

Edited 1 time(s). Last edit at 07/07/2015 11:35AM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

in my opinion it is indeed a good idea to add these if you have little child, but that is far away from being enough. There are fans, the x-carriage, the hot-end itself and so on. First of all I have to say that I have no children but in my eyes it is most important that you keep the printer out of reach of children. I think especially the hot-end can be very interesting. So you may add these covers but it is more important to keep the child away from the printer (seperate room for example) or otherwise do not use it.

Regards,

Sven

Edited 1 time(s). Last edit at 07/07/2015 11:35AM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Keep little fingers safe! July 08, 2015 03:17AM |

Registered: 10 years ago Posts: 275 |

[www.dropbox.com]

[www.dropbox.com]

for children is a wonderful toy..... a simple kitchen has more dangers... the sidewalk of a street tremendously more

I like them.... Thanks

Dario

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

[www.dropbox.com]

for children is a wonderful toy..... a simple kitchen has more dangers... the sidewalk of a street tremendously more

I like them.... Thanks

Dario

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

|

Re: Keep little fingers safe! July 08, 2015 03:38AM |

Registered: 9 years ago Posts: 1,699 |

Hi Dario,

sorry for being OT but what is this red rod on the left side? A bumper or a linear bearing?

Regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Keep little fingers safe! July 08, 2015 03:54AM |

Registered: 10 years ago Posts: 275 |

Quote

Treito

Hi Dario,

sorry for being OT but what is this red rod on the left side? A bumper or a linear bearing?

Regards,

Sven

OT ok ....is a linear bearing too small to slide... used to strengthen the corner on the Ormerod187 (I changed as little as possible to keep the original)

I'm using printed linear bearing (Y front only) on the 2 color.... and Bamboo

Dario

Edited 1 time(s). Last edit at 07/08/2015 04:06AM by Ormerod187.

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

|

Re: Keep little fingers safe! July 08, 2015 06:37AM |

Registered: 9 years ago Posts: 1,699 |

Okay thanks for the answer. I also use printed bearings for the x-axis. Can you please tell me which model you use? You can also answer here: Topic printed linear bearings

BTT

As I said before you should add some kind of grid for the fans and the nozzle could be also of interest. Okay if you have small buildings that is no problem but with bigger and especially higher ones? What do you think?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

BTT

As I said before you should add some kind of grid for the fans and the nozzle could be also of interest. Okay if you have small buildings that is no problem but with bigger and especially higher ones? What do you think?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Keep little fingers safe! July 08, 2015 07:42AM |

Registered: 10 years ago Posts: 2,472 |

I agree that children who are too young to understand should not be given unsupervised access to the Ormerod (or any other tool). However, I can't see that anything on the Ormerod is likely to cause serious injury, apart from the possibility of pulling the printer off a table and having it fall on the child's head, or falling on the printer and getting an eye impaled on the Z screw (which is arguably the most dangerous part that requires guarding). The moving parts could cause slight pinch and crush injuries, and the bed and hotend could cause burns, but IMO the motors are not powerful enough to cause injuries that will not completely heal within a reasonable time, and the child's natural reflexes will cause a hand to be pulled away before the hot parts cause a serious burn - contact must be maintained for several seconds before 250 degrees will cause significant tissue damage.

Not that I am for a moment advocating that it is OK to expose young children to the possibility of painful injuries (though a few painful lessons are beneficial as they teach a child to exercise caution) - I'm just making an observation that it is far from being the most dangerous item in the house, and a bigger concern might be the damage that the child could do to the printer rather than the other way around!

Dave

Not that I am for a moment advocating that it is OK to expose young children to the possibility of painful injuries (though a few painful lessons are beneficial as they teach a child to exercise caution) - I'm just making an observation that it is far from being the most dangerous item in the house, and a bigger concern might be the damage that the child could do to the printer rather than the other way around!

Dave

|

Re: Keep little fingers safe! July 08, 2015 12:16PM |

Registered: 9 years ago Posts: 1,699 |

Quote

dmould

...and getting an eye impaled on the Z screw (which is arguably the most dangerous part that requires guarding).

Dave

You are right that is indeed the most dangerous part. I did not think of it because I replaced my z-upper-mount with a part providing a bearing and now the Z threaded bar is not long enough anymore to hurt something. Maybe this thing is the most important. I used the bearing only without any nuts and I exchanged the bar with a new not wobbling one.

thingiverse

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Keep little fingers safe! July 08, 2015 02:12PM |

Registered: 10 years ago Posts: 1,230 |

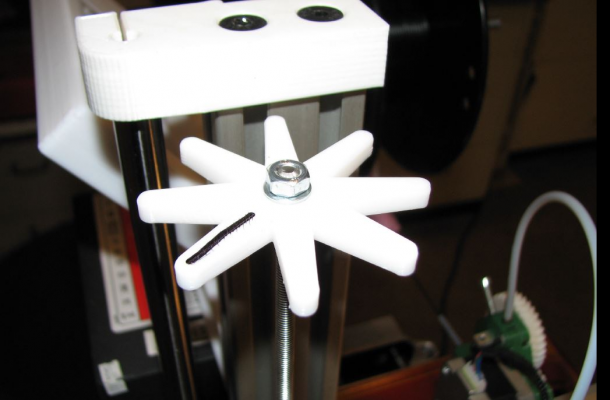

I added this on top of the treaded rod, keeps me from poking my eyes out and is great for fine tuning the nozzle hight on the fly

Erik

Erik

|

Re: Keep little fingers safe! July 09, 2015 08:08AM |

Registered: 10 years ago Posts: 2,472 |

A guard over the Z screw is indeed a good thing, but I advise against a bearing or similar that constrains the top of the screw, which should remain free to wave about. The reason is that if the screw is constrained at both top and bottom, any slight misalignment or bend in the screw will be translated to significant horizontal forces on the X-arm, which can result in lateral movement of the head when Z changes and create banding in the printed part.

Dave

Dave

Sorry, only registered users may post in this forum.